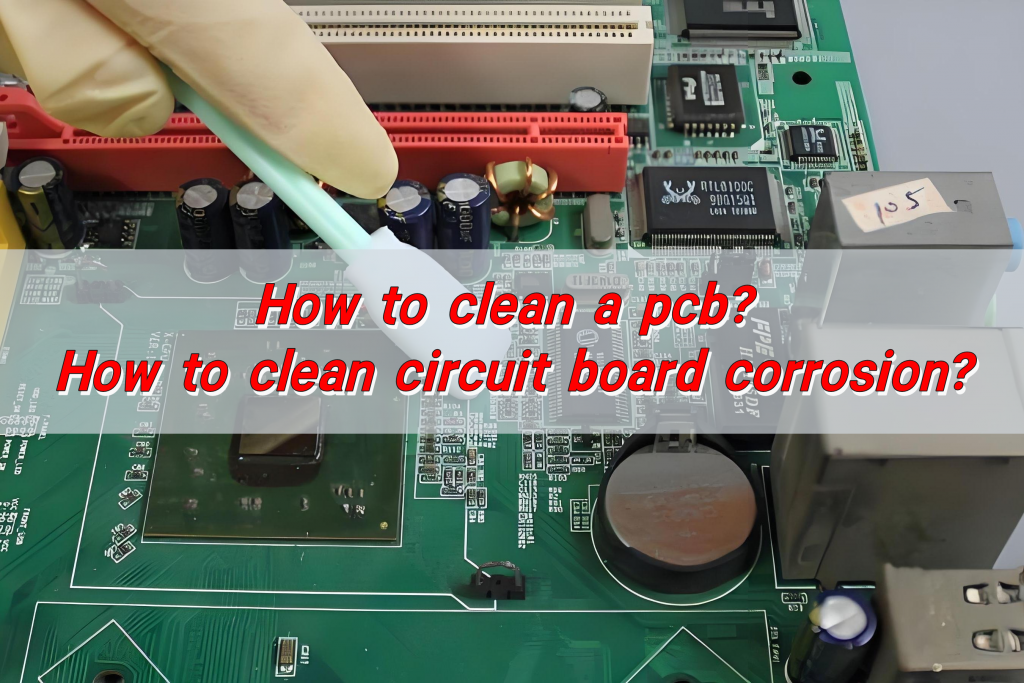

How to clean a pcb?First, prepare a soft brush, high-concentration isopropyl alcohol or special cleaning agent, and tweezers, and take power-off and anti-static measures. Then use a soft brush dipped in cleaning agent to brush, soak the stains in the cleaning agent first and then brush, use a cotton swab to clean the gaps and blow them clean again. After cleaning, use a low-temperature hot air blower to blow dry from a distance, and finally check whether the appearance is damaged and perform functional tests.

How do you clean up PCBs?

PCB is a key component of electronic equipment. Cleaning PCB helps ensure its normal operation and extend its service life. Here are some common cleaning methods and precautions:

1. Eraser cleaning method:

- Tools: Choose a soft eraser.

- Operation: Gently press the eraser on the part that needs to be cleaned, such as the gold finger, and wipe back and forth along its arrangement direction until the surface is restored to brightness. This method is simple and effective, and will not damage the gold-plated layer on the surface of the gold finger.

2. Alcohol wiping method:

- Tools: medical alcohol (or anhydrous ethanol), soft cloth or cotton wool.

- Operation: Pour an appropriate amount of alcohol on a soft cloth or cotton wool, and then gently wipe the surface of the PCB to ensure that the alcohol is evenly covered. After wiping, wait for the alcohol to evaporate naturally.

3. Special detergent method:

- Tools: Goldfinger special detergent, board washing water, hydrogen peroxide, etc., as well as cleaning cloth, cotton swabs or soft brushes.

- Operation: Dilute the detergent to an appropriate concentration according to the instructions for use, then dip the detergent with a soft cloth, cotton swab or soft brush, and gently wipe the surface of the PCB. After wiping, rinse thoroughly with clean water, then wipe dry with a clean cloth or dry naturally.

4. Ultrasonic cleaning method:

- Equipment: Ultrasonic cleaning machine.

- Operation: First calculate and configure the dilution ratio of the cleaning solution, add water to the cleaning machine tank, and then add the cleaning solution. Preheat the solution to the appropriate temperature according to the detergent recommendation. Then put in the PCB and set the cleaning time, usually a few minutes. After cleaning, remove the PCB, rinse and dry thoroughly.

5. High-pressure spray cleaning and brushing:

- Equipment: High-pressure spray cleaning machine or soft brush.

- Operation: High-pressure spray cleaning is to spray the cleaning liquid onto the PCB surface at a high pressure through a high-pressure pump, and use the impact of the water flow to wash away the contaminants. Brushing is to use a soft brush to dip the cleaning liquid and manually or automatically brush the PCB surface.

When cleaning the PCB, you should choose the appropriate cleaning method and tools according to the actual situation, and pay attention to the safety and effectiveness during the operation. At the same time, the cleanliness of the PCB should be carefully checked after cleaning to ensure that there are no residues and stains that affect the performance and stability of the circuit board.

Can you use WD-40 to clean a circuit board?

You can use WD-40 to clean the circuit board, but you need to be careful. WD-40 can effectively remove oil, dust, oxides and some minor corrosion on the circuit board, and can form a thin protective film on the surface of the circuit board to prevent the circuit board from getting wet.

In addition, WD-40 precision electrical cleaner is suitable for various electronic instrument circuit boards. It has the characteristics of fast cleaning and no residue. It is suitable for plastic, rubber and metal materials, safe and non-corrosive.

Advantages and disadvantages of using WD-40 to clean circuit boards

Advantages:

- Good cleaning effect: WD-40 can effectively remove various dirt on circuit boards, especially dirt in narrow gaps and between components.

- Moisture-proof effect: Form a protective film on the surface of the circuit board to prevent moisture, suitable for circuit boards in humid environments or long-term storage.

- Quick drying and no residue: WD-40 precision electrical cleaner evaporates quickly without leaving any residue.

Disadvantages:

- Need to dry thoroughly: After cleaning, you must ensure that the circuit board is completely dry, otherwise it may cause problems such as short circuits.

- Avoid sensitive components: Avoid WD-40 directly spraying on sensitive components during cleaning, such as high-precision sensors, chip pins, etc.

What is the best solvent to clean PCB?

The best solvent for cleaning PCBs depends on the specific cleaning needs and environmental requirements.

Common solvents and their advantages and disadvantages

- Organic solvents: such as acetone, ethanol or isopropyl alcohol. These solvents have strong dissolving power and can effectively remove dirt and grease on the surface of PCB. The advantages are simple operation, easy to obtain solvents, and suitable for most conventional cleaning needs.

- Chlorinated solvents: For example, the washing water made by mixing chlorinated solvents with other solvents can dissolve rosin and remove flux quickly, and is easy to volatilize after cleaning, but it is often easy to turn white and sticky, and it is a flammable solvent. Environmental regulations are becoming increasingly stringent, and its use has been reduced.

- Hydrocarbon solvents: composed of two elements, carbon and hydrogen, are mainly used to clean various oils, greases, and soldering resins. Hydrocarbon cleaning agents can be used in various ways, but they are flammable and explosive, so safety should be paid attention to when using them.

- Water-based washing water: With water as the solute carrier, it is environmentally friendly, safe, non-toxic, and has no irritating gas volatilization. It is suitable for SMT steel mesh, fixtures, wave soldering equipment, etc., with good cleaning effect and environmental protection.

What is a good substitute for PCB cleaner?

Substitutes for PCB cleaners include alcohol, detergent, white vinegar and lemon juice. These alternatives perform well in cleaning electronic components and have less impact on the human body and the environment.

- Alcohol: Alcohol is a relatively environmentally friendly cleaning agent that can effectively remove oil and dirt from the surface of PCBs and electronic components. Alcohol is not only affordable and easily available, but also evaporates quickly and does not leave water stains after use.

- Dishwashing liquid: Dishwashing liquid does not contain any harmful substances and is harmless to the human body and the environment. It is also suitable for cleaning oil and dirt on the surface of PCB boards and electronic components, and is inexpensive.

- White vinegar: White vinegar is an environmentally friendly and non-toxic natural cleaning agent that can effectively remove stains and sediments from the surface of electronic components. White vinegar is readily available in the home and is easy to use.

- Lemon juice: Lemon juice contains acidic ingredients that can remove stains and sediments from the surface of electronic components. It is a natural cleaning agent that is non-toxic, environmentally friendly and has a natural aroma.

What breaks down PCBs?

When cleaning PCBs, the following situations may cause them to break down:

- Chemical corrosion: Using a cleaning agent containing highly corrosive substances (such as concentrated acids, strong alkalis, and halogenated solvents) will react with the PCB substrate material and destroy its structure; the moisture or chemical components in the cleaning agent residue may also cause oxidation corrosion of the metal circuit, accelerating the aging and decomposition of the PCB.

- Physical damage: Brushes with hard bristles, sharp tools, or excessive force can scratch the circuit, damage the protective layer, or even cut the circuit, and may also cause components to loosen and fall off; high temperatures during drying can soften and deform the substrate material, affecting the quality of the solder joints and further damaging the PCB.

- Electrostatic discharge: If anti-static measures are not taken during cleaning, static electricity will accumulate and then discharge, which may damage static-sensitive components, cause damage to the internal circuit structure, affect the PCB function, and even cause further damage such as short circuits.

Is 70% isopropyl alcohol safe for electronics?

70% isopropyl alcohol is generally safe for electronic products. It has good cleaning properties, can dissolve common stains such as oil, and has moderate volatility, which means it can evaporate quickly after cleaning. But there are risks. The 30% water it contains may harm components that are sensitive to humidity, causing short circuits, corrosion, or performance degradation.

Of course, as long as you operate carefully, avoid liquid from entering the components, and ensure complete drying, it is generally safe, but higher purity isopropyl alcohol or special cleaning agents may be required for precision or humidity-sensitive electronic products.

How to clean circuit board corrosion?

There are several ways to clean circuit board corrosion:

- Use compressed air: Compressed air is a common tool for electronic cleaning. It can remove dust and impurities by releasing short pulses into the vents.

- Use baking soda: Baking soda (sodium bicarbonate) is an alkaline substance that can effectively neutralize the acid in the corrosive solution and help remove corrosion on the surface of the PCB.

- Use distilled water: Distilled water has high purity and can be used to clean circuit boards, but you need to be careful to avoid using ordinary tap water because the impurities in it may aggravate corrosion.

- Use special cleaning agents: such as board washing water, alcohol, etc. These cleaning agents can effectively remove stains and flux residues on the circuit board.

- Ultrasonic cleaning technology: Use ultrasonic vibration to improve the cleaning effect, suitable for the cleaning needs of high-end precision products.

- Dry ice cleaning method: This is an environmentally friendly cleaning technology that removes stains by spraying dry ice particles, suitable for precision products that are sensitive to shaking.

Methods to prevent circuit board corrosion include:

- Keep it dry: Avoid circuit boards in a humid environment for a long time. Keeping the circuit board dry is the key to preventing corrosion.

- Clean flux residues in time: Clean flux residues in time after welding to prevent them from reacting with PCBs and causing corrosion.

In short, cleaning PCBs is an indispensable part of electronic equipment maintenance. By choosing appropriate cleaning methods and tools, pollutants on the PCB surface can be effectively removed, and the stability and service life of the equipment can be improved. At the same time, precautions and effect inspections during the cleaning process are also very important.

Tags: clean pcb, how to clean a pcb