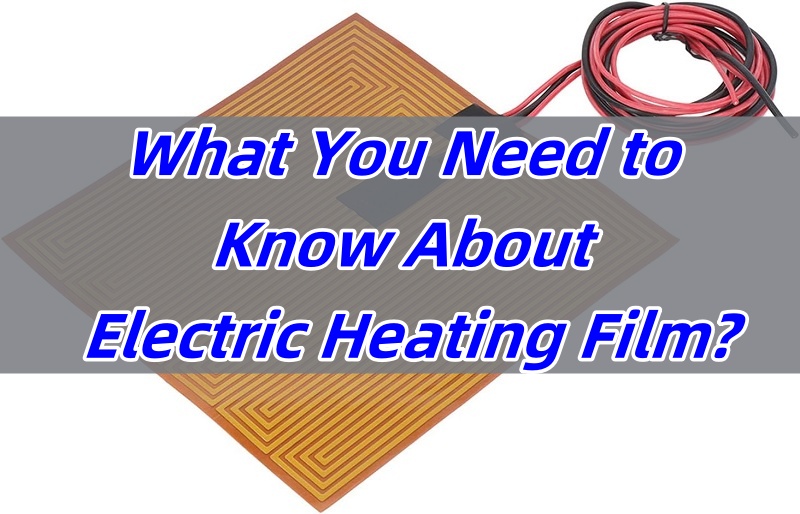

Electric heating film is becoming a popular choice for various heating applications. This advanced technology is known for its efficiency and versatility. It’s used in everything from underfloor heating to heated windows and even glass surfaces. If you’re considering electric heating films, you’ll want to understand how they work, where they are used, and the benefits they provide. This article explores the details of electric heating film, including its applications, benefits, customization options, and more.

What Is Electric Heating Film?

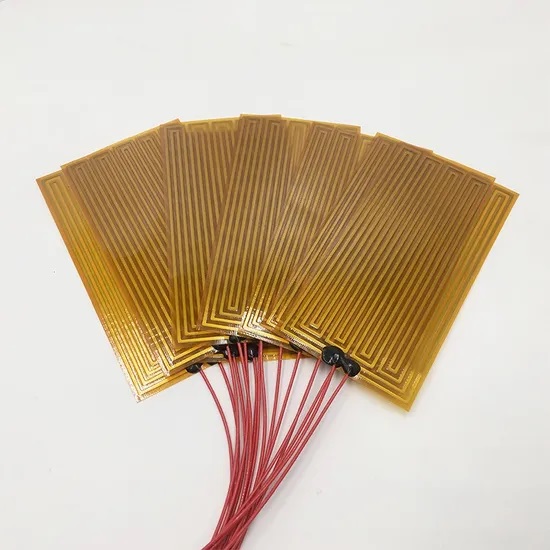

Electric heating film is a thin, flexible layer that generates heat when an electric current passes through it. Made from materials like carbon or polyimide, these films are designed to efficiently convert electrical energy into heat. Unlike traditional heating methods, electric heating films are lightweight and easy to install in a variety of environments. They can be used in homes, vehicles, or even commercial spaces to provide consistent warmth without taking up too much space.

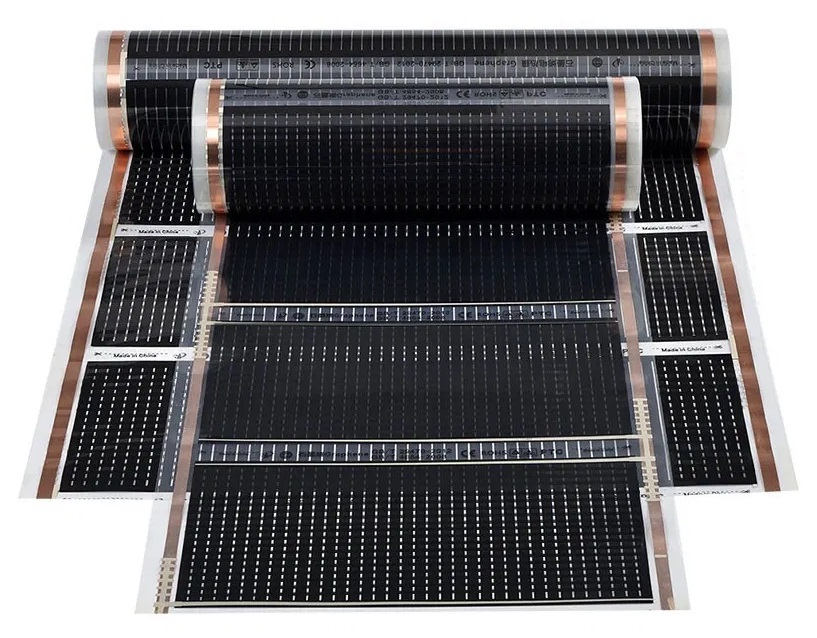

There are several types of electric heating films, such as electric carbon heating films, which are known for their durability and heat distribution. These films can be used for a variety of heating needs, from personal comfort to industrial heating solutions.

Where Is Electric Heating Film Used?

Electric heating films are incredibly versatile and can be used in a wide range of applications. Some of the most common uses include:

Underfloor Heating: Electric underfloor heating carbon films provide warmth across large areas, making them a popular choice for residential homes and commercial spaces. This method allows heat to be distributed evenly from the floor up, offering a comfortable and efficient heating solution.

Glass Surfaces: Electric heating films for glass, including electrically heated window films, are used to defrost windows in cars and buildings. They are also used to provide warmth in conservatories and other glass-based structures.

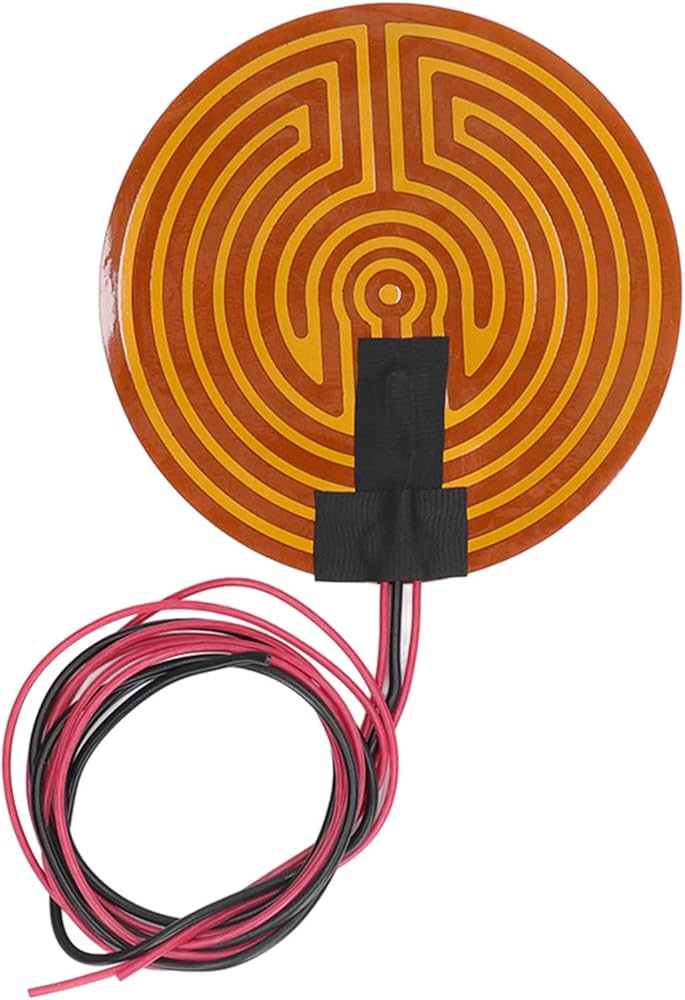

Portable Heaters: Electric carbon heating films are often used in portable heaters or custom heating pads, offering flexible and mobile heating options.

Industrial and Automotive Applications: Electric heating films are also used in industrial and automotive settings for tasks such as de-icing, warming equipment, or even as part of a heating system in vehicles.

With such a wide range of applications, it’s easy to see why electric heating films are gaining popularity as a modern, efficient heating solution.

Is the Heating Film a Complete Circuit with Microcontroller, etc.?

Electric heating films are not typically sold as a complete circuit with a microcontroller. However, many systems that incorporate heating films do use a circuit or controller to regulate the flow of electricity. This ensures the heating film operates at the desired temperature and avoids overheating.

In most cases, electric heating films are sold as standalone components. You can easily integrate them into your existing circuit or heating system. For example, an electric polyimide film heater can be connected to a power supply with a controller to adjust the heat level. The use of controllers also adds an element of safety, ensuring the heating film doesn’t exceed its intended temperature range.

Is the Heating Film Sold as a Part of a Circuit That We Need to Build Ourselves?

While some electric heating films come as part of a pre-built kit, others are sold as individual films that require additional components to make them functional. If you’re purchasing an electric heating film, it’s important to know whether it comes with the necessary connectors, controllers, and power supply.

In most cases, you’ll need to add your own circuit or control system. For example, an electric transparent heating film used for windows will typically need a power source and a way to regulate temperature. However, there are easy-to-use kits available that include everything you need to set up the system. These kits often include a controller and sensors, so all you need to do is install the film and connect the components.

How Does Electric Heating Film Work?

Electric heating films are designed to convert electrical energy into heat through a process called resistance heating. When electricity flows through the film, it meets resistance, which causes the film to heat up. The materials used in the film, such as carbon or polyimide, are highly effective at conducting electricity and distributing heat evenly.

One of the key advantages of electric heating films is their ability to provide uniform heat distribution. This ensures that there are no cold spots in the heated area. The film’s thin profile also makes it an efficient heating solution, as it can be easily applied to surfaces without adding bulk.

The way these films are designed allows for precise temperature control. Many systems include sensors and controllers to monitor the temperature and adjust the power supply accordingly. This ensures that the film operates efficiently and safely.

What Are the Benefits of Using Electric Heating Film?

There are several reasons why people choose electric heating films over other heating methods. Some of the main benefits include:

Energy Efficiency: Electric heating films are highly efficient at converting electrical energy into heat. This allows for lower energy consumption compared to traditional heating methods, saving you money on your energy bills.

Flexibility and Versatility: Electric heating films can be applied to almost any surface, including floors, walls, windows, and even custom heating pads. This flexibility makes them ideal for both residential and commercial uses.

Ease of Installation: Since electric heating films are thin and lightweight, they are easy to install. Whether you’re adding them to your underfloor heating system or applying them to a glass surface, the installation process is straightforward.

Safe and Reliable: Electric heating films are designed with safety in mind. Many systems include temperature sensors and controllers that ensure the film operates within safe limits, preventing overheating and damage.

Long-lasting and Durable: Electric heating films are built to last, with many offering several years of reliable performance. The materials used, such as polyimide and carbon, are highly durable and resistant to wear and tear.

How Long Does Electric Heating Film Last and What Is Its Maintenance?

Electric heating films are designed to last for many years with proper care and maintenance. Most high-quality heating films have a lifespan of 10 years or more, depending on the specific product and application. The durability of the film is influenced by factors such as the environment, usage frequency, and installation method.

Maintaining electric heating films is relatively simple. Regular cleaning is essential to keep the films free from dust and debris. It’s also important to ensure the system is not exposed to extreme conditions that could cause damage. For example, avoid placing heavy objects on top of the heating film or exposing it to moisture unless it’s specifically designed for wet environments.

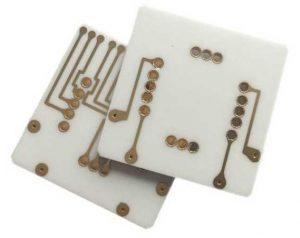

Can Electric Heating Film Be Customized for Specific Applications?

Yes, electric heating films can be customized to suit various needs. Whether you need a specific size, voltage, or type of heating film, many manufacturers offer customizable options. For instance, electric polyimide film heaters can be tailored to fit your exact specifications, making them ideal for specialized industrial or automotive applications.

Customization also allows you to choose films that meet specific power requirements. For example, electric carbon heating films can be designed to work with 12V systems, while other types may be suitable for higher voltage applications. This flexibility ensures that the heating film meets your exact needs, whether you’re using it for home heating or in a more specialized setting. At Best Technology, we understand the importance of both quality and speed, providing customized electric heating film products that exceed expectations. Just feel free to reach out to us at sales@bestpcbs.com for any doubts or any inquiries.

In conclusion, electric heating films are an excellent choice for a wide range of heating applications. From underfloor heating to glass surfaces and industrial uses, these films offer energy efficiency, flexibility, and durability. With easy installation and the ability to customize for specific needs, electric heating films are revolutionizing how we think about heating solutions. Whether you’re upgrading your home heating system or looking for a reliable heating solution for your business, electric heating films are worth considering.