Turnkey PCBA assembly service has become an essential part of the manufacturing industry, particularly in electronics. It provides a complete solution for companies needing printed circuit board assemblies (PCBAs) but lacking the resources or expertise to handle the intricate process themselves.

What is Turnkey PCB Assembly?

Turnkey PCB assembly is a full-service solution for the production of printed circuit boards (PCBs) and their assembly into functional electronic products. This service includes everything from designing the circuit boards to sourcing the components, assembling the PCBs, and delivering the final product. The term ‚Äúturnkey‚ÄĚ refers to a ready-to-use product, where you simply provide the specifications, and the service provider takes care of the rest.

In a typical turnkey PCBA assembly service, the manufacturer handles every step in the process, ensuring that the product meets the client’s requirements without the need for them to get involved in the details. This eliminates the need for multiple suppliers, reducing costs and saving time.

What Does Turnkey Mean in Manufacturing?

In manufacturing, turnkey refers to a complete solution where the service provider is responsible for every aspect of production. This includes design, sourcing materials, manufacturing, and testing. Once the project is completed, the product is ready for immediate use, hence the term “turnkey.” It offers simplicity for clients, as they can rely on a single supplier for all their manufacturing needs.

For PCB assembly, this means that the manufacturer will take care of everything from sourcing the necessary components to assembling and testing the final product. The client’s only responsibility is to supply the initial design or specification.

What is the Difference Between PCB and PCB Assembly?

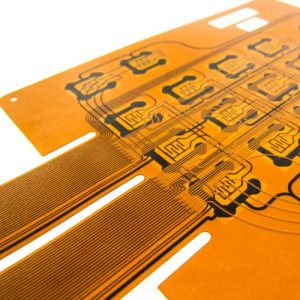

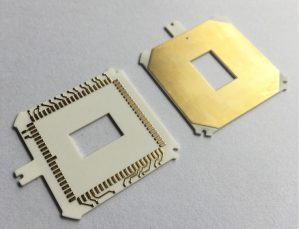

A PCB (Printed Circuit Board) is a flat, rigid board used to mechanically support and electrically connect electronic components. It serves as the base for the circuit components that make up an electronic device, such as resistors, capacitors, and chips. The PCB itself does not perform any function until components are attached.

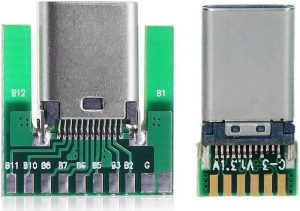

PCB assembly, on the other hand, refers to the process of placing and soldering these electronic components onto the PCB. The result is a complete, functional assembly, often called a PCBA (Printed Circuit Board Assembly). The assembly process involves precise placement, soldering, and testing of components to ensure the board works as intended.

What Specific Services Are Included in Turnkey PCBA Assembly Service?

A turnkey PCBA assembly service typically includes the following services:

1. PCB Design: If you don’t have a design yet, some providers offer PCB design services, creating the layout and schematic based on your specifications.

2. Component Sourcing: This includes purchasing all the components necessary for your project, ensuring they meet the required standards.

3. PCB Manufacturing: This is the process of producing the actual PCB, including layer stacking, etching, drilling, and other steps to create the board itself.

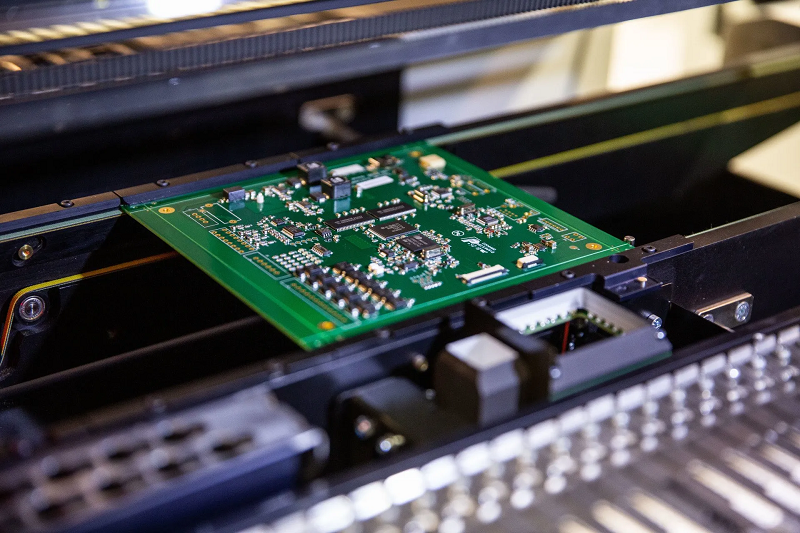

4. PCB Assembly: The components are placed on the PCB and soldered into place, often using automated machines for precision.

5. Testing and Inspection: Quality checks such as functional testing, X-ray inspection, and visual inspection ensure that the PCB is properly assembled and functional.

6. Packaging and Delivery: The final product is packaged and shipped to the client, ready for integration into the final product.

This comprehensive approach reduces lead times and ensures that clients receive a finished product that meets their expectations.

What is the Major Difference Between a Turnkey Project and a Design Build?

The primary difference between a turnkey project and a design build lies in the scope of responsibility.

Turnkey Projects: In a turnkey project, the service provider is responsible for every aspect of the project, from start to finish. The client hands over the specifications, and the provider handles design, procurement, manufacturing, and testing. Once completed, the product is ready for use.

Design Build Projects: In a design-build project, the client has more involvement. The service provider is typically responsible for the design and construction, but the client may still need to source components or provide additional input during the process. The client may need to manage more aspects of the project compared to a turnkey approach.

While both models aim to streamline production, turnkey projects are more hands-off for the client and typically offer greater convenience and efficiency.

What Files Are Needed for PCB Assembly?

To begin the PCB assembly process, several files are necessary. These files provide the information needed for manufacturing and assembling the PCB:

1. Gerber Files: These are the standard files for PCB design and detail the layers of the PCB, including copper layers, silkscreen layers, and soldermask layers.

2. Bill of Materials (BOM): A list of all the components required for the PCB assembly, including their specifications and quantities.

3. Pick-and-Place Files: These files contain precise information about where each component should be placed on the PCB, ensuring accurate placement during assembly.

4. Assembly Drawings: These drawings provide a visual reference for the assembly process, often showing where components should be placed.

5. Test Specifications: Details about the tests that need to be performed on the finished PCB to ensure quality and functionality.

These files ensure that every aspect of the production process is well-defined and can be accurately followed.

How Does PCB Assembly Work?

The PCB assembly process is a multi-step procedure that involves placing and soldering electronic components onto the PCB. The basic steps are as follows:

1. Component Sourcing: The required components are sourced and inspected for quality.

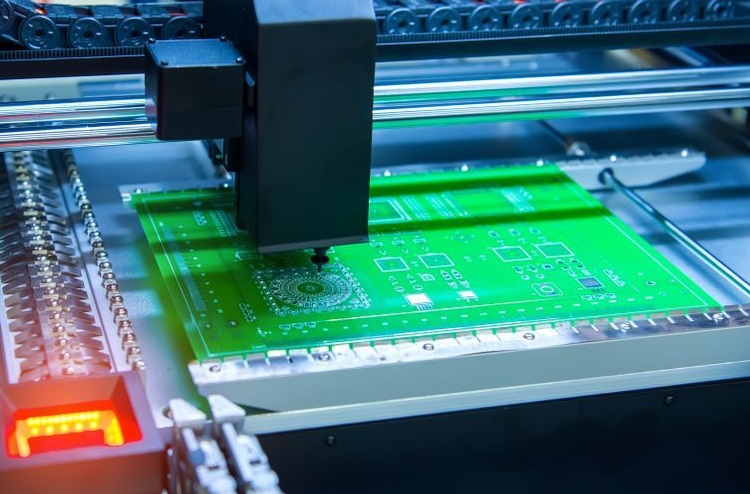

2. Solder Paste Application: Solder paste is applied to the PCB in areas where components will be placed.

3. Pick-and-Place: Using automated machines, components are placed precisely on the PCB.

4. Soldering: The PCB passes through a reflow oven, where the solder paste is melted and bonds the components to the board.

5. Inspection and Testing: The assembled PCB is inspected for errors and tested to ensure functionality.

6. Final Assembly: After testing, the board is packaged and shipped to the client.

Each step requires precision and attention to detail to ensure that the final product is functional and reliable.

What Are the Advantages of Turnkey Projects?

Turnkey projects offer several advantages that make them highly attractive, especially for businesses that want a hassle-free solution:

1. Simplified Process: The client only needs to provide initial specifications, with no need to worry about the intricacies of the manufacturing process.

2. Cost Efficiency: By bundling all services under one provider, turnkey solutions often result in lower costs, especially in terms of supply chain management and reduced overhead.

3. Time Savings: The provider handles all aspects of production, resulting in faster project timelines.

4. Quality Assurance: With a single provider responsible for all phases of production, consistency and quality are easier to maintain.

5. Focus on Core Competencies: Clients can focus on their product’s design and marketing while leaving the manufacturing details to the experts.

In short, turnkey PCBA assembly services offer a seamless, efficient, and reliable way to get your PCBs assembled and ready for integration into your electronic products.

Turnkey PCBA assembly services provide a comprehensive solution that simplifies the process of getting your PCBs designed, assembled, and ready for use. With services ranging from component sourcing to final delivery, it offers businesses a one-stop shop for all their assembly needs. By choosing a turnkey provider, companies can enjoy cost savings, faster timelines, and a hassle-free manufacturing experience. Best Technology provides turnkey PCBA assembly service, delivering high-quality products with quick turnaround times. If you’re interested in our turnkey PCBA assembly service, feel free to contact us at sales@bestpcbs.com for more information.

Tags: pcb design, PCBA, printed circuit board, Turnkey PCBA Assembly Service