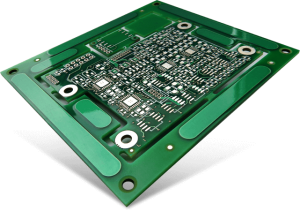

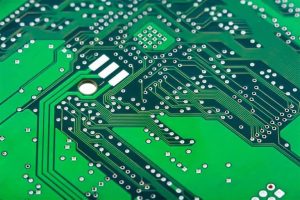

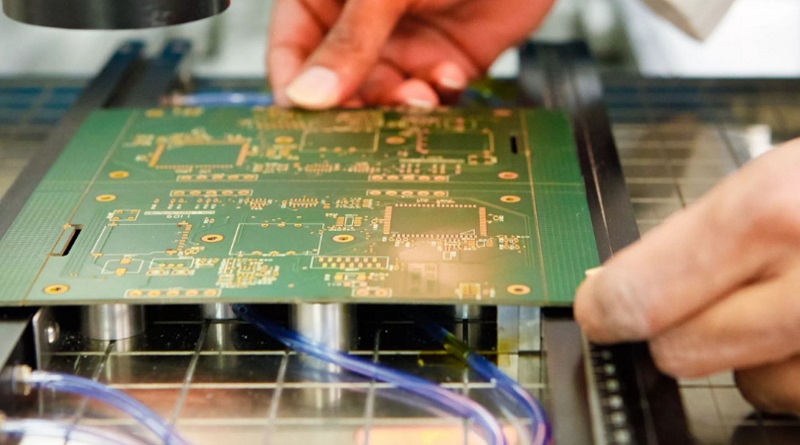

PCB design services are essential for creating high-quality, functional circuit boards. In today’s world, printed circuit boards (PCBs) are a fundamental part of most electronics, from smartphones to medical devices and automotive systems. PCB design services play a crucial role in ensuring that these boards are functional, reliable, and efficient. But what exactly is PCB design, and how does it impact the electronics you use every day?

What is PCB Design Services?

PCB design services refer to the process of planning and creating a circuit board layout that connects different electronic components, ensuring they work together correctly. The design involves everything from schematic creation to the final layout of the PCB. PCB design is a specialized field that requires advanced knowledge of both electrical engineering and design software. The goal is to create a board that performs its intended function effectively while minimizing errors and ensuring ease of manufacturing. At Best Technology, our PCB design services are backed by 18 years of expertise, ensuring that every design is optimized for both performance and manufacturability, delivering reliable results for a wide range of applications

Does PCB Design Require Coding?

Many people assume that designing a PCB requires coding, but that’s not always the case. While some aspects of PCB design may involve programming—especially when designing components like microcontrollers or programmable logic devices (PLDs)—the main design process itself doesn’t necessarily require coding. Instead, it focuses on creating a layout of components on the board and ensuring that they are connected in the right way to function as intended.

That said, PCB designers do use software tools, which may include scripting languages or built-in code for specific tasks, like automating the routing process or checking for design rule violations. But for the most part, the core of PCB design is visual and structural, not a coding-heavy task.

Is PCB a CAD Design?

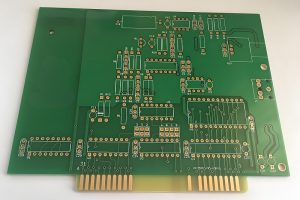

Yes, PCB design is essentially a form of computer-aided design (CAD). PCB design software allows designers to create a digital version of the circuit board before it is physically manufactured. CAD tools help with placing components, creating the electrical connections (traces), and optimizing the layout for factors like size, functionality, and manufacturability.

Some of the most popular PCB design software includes tools like Altium Designer, Eagle, and KiCad. These tools offer both 2D and 3D visualizations of the PCB, enabling designers to check for potential issues before sending the design to production. So, in a way, PCB design and CAD design are closely linked, with CAD software playing a key role in the process.

What Does a PCB Design Include?

A complete PCB design encompasses several crucial elements. First, the designer creates a schematic diagram that defines the electrical connections between components. This is followed by the layout phase, where the components are physically placed on the board, and the electrical traces (which act as wires on the PCB) are drawn.

Beyond the schematic and layout, PCB design also involves creating a bill of materials (BOM), which lists all the components that will be used. This document is critical for both manufacturing and sourcing the necessary parts. Additionally, designers must consider factors such as the board’s power requirements, signal integrity, and thermal management.

Some PCB design services also include testing and validation to ensure the design will perform as expected in real-world conditions.

How to Calculate PCB Design Cost?

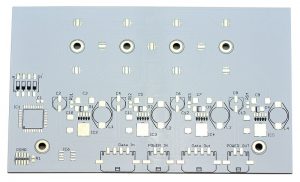

The cost of PCB design services can vary significantly based on several factors. Generally, the complexity of the design, the size of the board, and the number of layers (single-layer, multi-layer) play a major role in determining the price.

Here are some key elements that can impact the overall cost:

Design Complexity: A simple PCB for a small electronic device will be cheaper to design than a multi-layer, high-frequency PCB.

Size and Layers: Larger boards or designs with more layers tend to be more expensive due to the added complexity.

Custom Components: If your design includes custom parts or components, it will increase the cost.

Prototype Testing: If you require prototypes for testing, this will add to the cost, especially if iterative testing and redesign are needed.

Typically, the cost is either an hourly rate for the designer or a flat fee per project. It’s important to discuss these factors with your PCB design service provider to get an accurate estimate.

Is PCB Design Difficult?

PCB design is a specialized skill, and like any engineering field, it can be challenging. Designers must have a deep understanding of electronics, the function of different components, and how they interact within a circuit. The process requires precision and attention to detail, especially when it comes to ensuring that components are properly connected, with no errors or potential for electrical shorts.

However, PCB design tools have advanced considerably over the years, making the process easier and more efficient. With the right tools and knowledge, designing a PCB can be a rewarding experience. For beginners, many software platforms offer tutorials, and professional design services are always available if the design process seems daunting. At Best Technology, our experienced team understands the intricacies of PCB design services, tailoring each project to meet both your functional and budgetary needs.

What Is the Difference Between PCB Design and Layout Services?

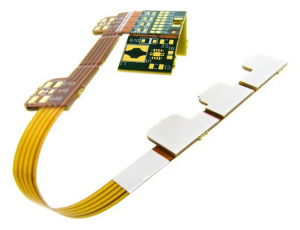

PCB design and PCB layout are often used interchangeably, but they refer to different aspects of the process. PCB design generally includes the creation of the circuit schematic and the overall functionality of the board. It’s about determining what components are needed and how they will be connected.

PCB layout, on the other hand, focuses on arranging the physical components on the board and routing the electrical connections. This stage involves translating the design into a practical layout that can be manufactured. The layout process also includes ensuring that the traces don’t overlap, the components fit, and that the board will meet performance requirements.

Both services are integral parts of creating a functional PCB, and many service providers offer both design and layout services as part of a complete package. With a strong focus on both PCB design and layout services, Best Technology ensures that every step of the process is optimized for high performance and efficient manufacturing.

How Do PCB Design & Manufacturing Services Work Together?

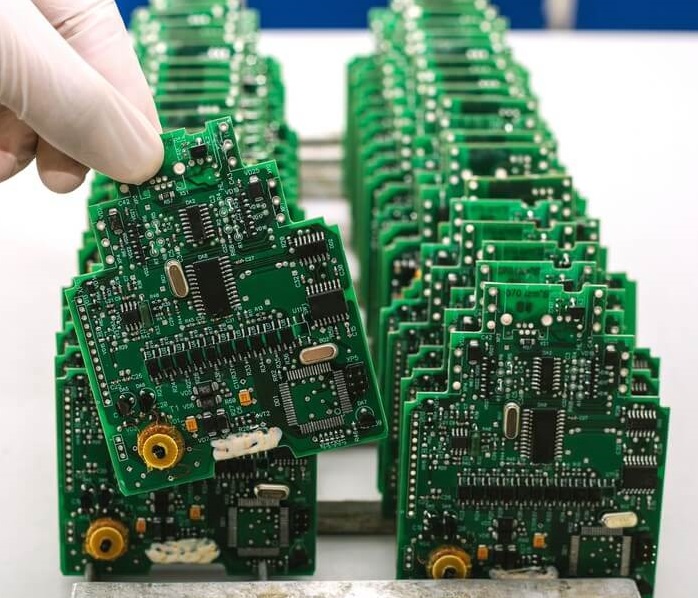

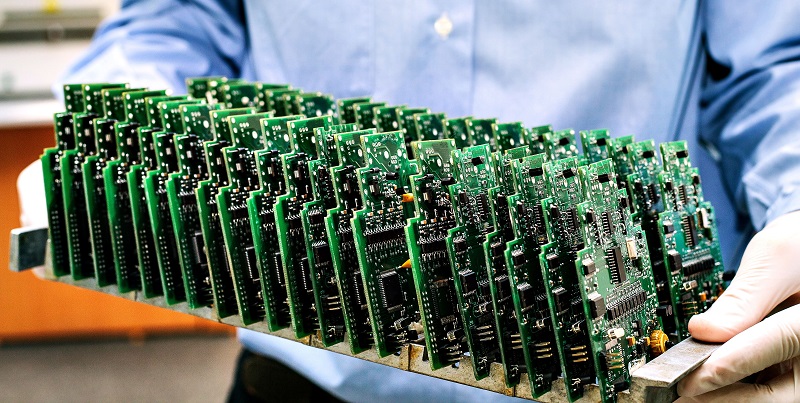

PCB design and manufacturing services are closely linked, as the quality of the design will directly impact the ease and cost of manufacturing. In many cases, it’s beneficial to work with a provider that offers both design and manufacturing services, as they can ensure that the design is optimized for efficient production.

When PCB design and manufacturing work together, the design is specifically tailored to the capabilities of the manufacturer, ensuring that the finished product meets all specifications. This can reduce the likelihood of design errors, improve the quality of the board, and speed up the production process. Additionally, working with a single service provider can simplify communication and reduce potential delays.

How to Choose the Right PCB Design Service for Your Needs?

Choosing the right PCB design service provider is crucial for the success of your project. Here are some factors to consider when making your decision:

Experience and Expertise: Look for a service provider with a proven track record in your industry.

Tools and Software: Ensure they use the latest PCB design tools and software to ensure efficiency and quality.

Customization Options: If you need a custom PCB design, check if they offer tailored services to meet your specific requirements.

Testing and Prototyping: It’s important to select a provider who offers testing and validation of designs to ensure functionality before full-scale manufacturing.

Customer Support: Choose a company that provides good communication and support throughout the design and manufacturing process.

Choosing the right PCB design service is crucial, and at Best Technology, we provide custom solutions that are designed to match your unique requirements and ensure reliable, high-quality results.

In conclusion, PCB design services are an essential part of developing functional, high-quality circuit boards. From the initial schematic to the final layout and manufacturing, these services ensure that your electronics perform as expected. Understanding how PCB design works, the costs involved, and how to choose the right service can help you make informed decisions when developing your next electronic product.

At Best Technology, we offer comprehensive PCB design and manufacturing services, ensuring high-quality designs optimized for production. If you need a custom PCB design service, warm welcome to reach us at sales@bestpcbs.com.

Tags: custom pcb design service, custom pcb design services, PCB, pcb board design services, pcb design, pcb design & manufacturing services, pcb design and layout services, pcb design services china, pcb design service, pcb design software, pcb design tools, printed circuit board, printed circuit board design services