What is the smt meaning? SMT, or Surface Mount Technology, is an advanced manufacturing process that directly mounts electronic components on the surface of a printed circuit board (PCB). It replaces the traditional through-hole insertion technology with an efficient and precise automated production method, and achieves miniaturization and high-density integration of electronic components.

What does smt mean?

SMT stands for Surface Mount Technology, a revolutionary approach to assembling electronic circuits. Instead of using traditional through-hole components, where pins pass through drilled holes, SMT enables components to be directly mounted onto the surface of a PCB.

This advancement has led to more compact and lightweight electronic devices, transforming industries such as consumer electronics, automotive, medical, and aerospace. By eliminating the need for large holes and complex routing, SMT increases design flexibility and enhances overall performance.

What does SMD and SMT stand for?

- SMD (Surface Mount Device): These are electronic components specifically designed for surface mounting. They are smaller than through-hole components and have no long leads, allowing for denser and more complex PCB layouts.

- SMT (Surface Mount Technology): This refers to the entire process of placing, soldering, and inspecting SMDs on a PCB. SMT is now the standard in electronics manufacturing, replacing traditional methods due to its superior efficiency, cost-effectiveness, and capability to handle high-density designs.

What are the different types of SMT?

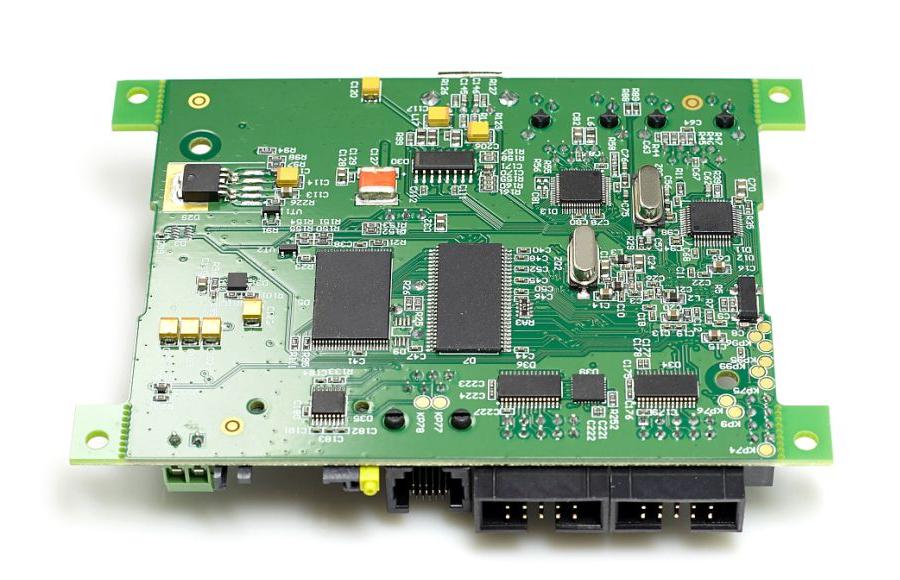

SMT technology encompasses various component types and mounting techniques. The main types include:

- Passive Components: Small resistors, capacitors, and inductors designed to be surface-mounted, helping regulate voltage and current flow.

- Active Components: Transistors, diodes, and integrated circuits that drive processing and logic functions in electronic devices.

- Fine-Pitch Components: Used in high-performance applications, these components have closely spaced terminals that require precision soldering.

- Ball Grid Array (BGA): A package type where solder balls are placed under the component, offering improved thermal performance and electrical connections.

- Chip-Scale Packages (CSP): Miniature packages designed to be nearly the same size as the silicon chip itself, essential for mobile and compact devices.

- Quad Flat Package (QFP): Integrated circuits with leads extending from four sides, commonly used in microcontrollers and processors.

What are the features of SMT?

SMT offers numerous advantages that have made it the preferred technology in PCB assembly:

- Compact Design: SMT components are much smaller than their through-hole counterparts, allowing for lightweight and space-saving designs.

- Higher Component Density: With no need for drilled holes, more components can fit within a given board area, increasing functionality.

- Improved Electrical Performance: Shorter electrical paths minimize resistance and inductance, enhancing signal transmission speed and reducing power loss.

- Automated Assembly: SMT allows for high-speed, automated component placement, reducing human error and increasing production efficiency.

- Lower Manufacturing Costs: Reduced material waste, automated processing, and high production throughput lead to significant cost savings.

- Better Thermal Management: SMT designs allow for better heat dissipation, which is crucial for high-power applications.

- Stronger Mechanical Performance: Components mounted using SMT are more resistant to vibrations and mechanical stress, making them ideal for aerospace and automotive industries.

Why is SMT used?

The widespread adoption of SMT stems from its numerous benefits in electronics manufacturing. Companies prefer SMT because:

- It enables miniaturization: Modern electronic devices require compact and lightweight designs, which SMT facilitates.

- It enhances production speed: Automated SMT assembly lines can place thousands of components per hour, boosting manufacturing efficiency.

- It improves product reliability: Stronger mechanical connections and reduced solder joint defects lead to more durable and long-lasting products.

- It reduces manufacturing costs: Automated SMT processes lower labor costs while increasing yield rates.

- It supports high-performance applications: SMT minimizes electrical noise, making it suitable for fast processors, 5G technology, and other advanced applications.

What are the processes of SMT?

The SMT assembly process consists of multiple steps, each requiring precision and expertise to ensure high-quality PCB production:

- PCB Preparation: The bare PCB is cleaned to remove contaminants and treated with coatings to prevent oxidation and improve solder adhesion.

- Solder Paste Application: Solder paste, a mixture of flux and metal particles, is applied to PCB pads using stencils or jet printing, ensuring precise placement.

- Component Placement: Automated pick-and-place machines position SMDs onto the solder-pasted PCB with extreme accuracy, ensuring proper alignment.

- Reflow Soldering: The assembled PCB is passed through a controlled heating process, where the solder paste melts and forms strong electrical connections.

- Inspection and Quality Control: Techniques such as Automated Optical Inspection (AOI) and X-ray testing detect defects like misalignment, solder bridging, and voids.

- Final Cleaning and Packaging: Flux residues are removed, and the PCBs are tested and packaged for delivery to clients.

- Functional Testing: Completed PCBs undergo rigorous functional tests to verify performance and compliance with industry standards.

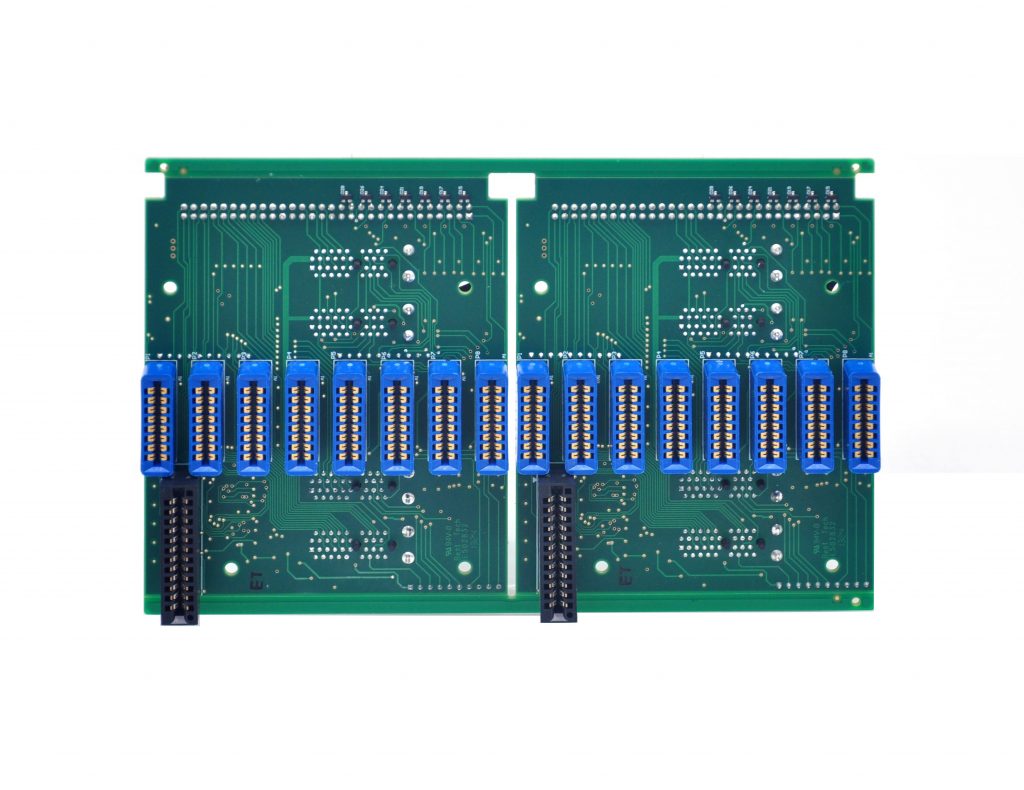

What is SMT and THT?

Two primary methods exist in PCB assembly: Surface Mount Technology (SMT) and Through-Hole Technology (THT). While SMT has largely replaced THT, both technologies serve specific applications.

Key Differences:

- Size & Weight: SMT components are smaller and allow for lighter devices, whereas THT components are larger and bulkier.

- Assembly Efficiency: SMT supports automation, enabling fast and precise production, while THT often requires manual assembly, making it slower.

- Application Suitability: SMT is preferred for consumer electronics, telecommunications, and medical devices, whereas THT is used in military, aerospace, and high-power applications.

- Reliability: SMT offers excellent electrical performance, while THT provides stronger mechanical bonds for applications exposed to extreme stress.

Conclusion:

Surface Mount Technology has revolutionized modern electronics, making devices smaller, more powerful, and cost-efficient. With its high-speed production, improved electrical performance, and ability to support complex designs, SMT has become the industry standard.

For high-quality SMT PCB solutions, reach out to Best Technology at sales@bestpcbs.com