A circuit card is the backbone of any electronic device, providing a structured platform for electrical components to function seamlessly. Whether in consumer electronics, automotive systems, medical devices, or aerospace applications, circuit cards enable efficient signal transmission and power distribution. Understanding circuit card design, materials, prototyping, and manufacturing processes is crucial for producing high-quality electronic products. This guide explores the key aspects of circuit card development, from design considerations to final assembly, helping engineers and manufacturers optimize their processes.

What is a Circuit Card?

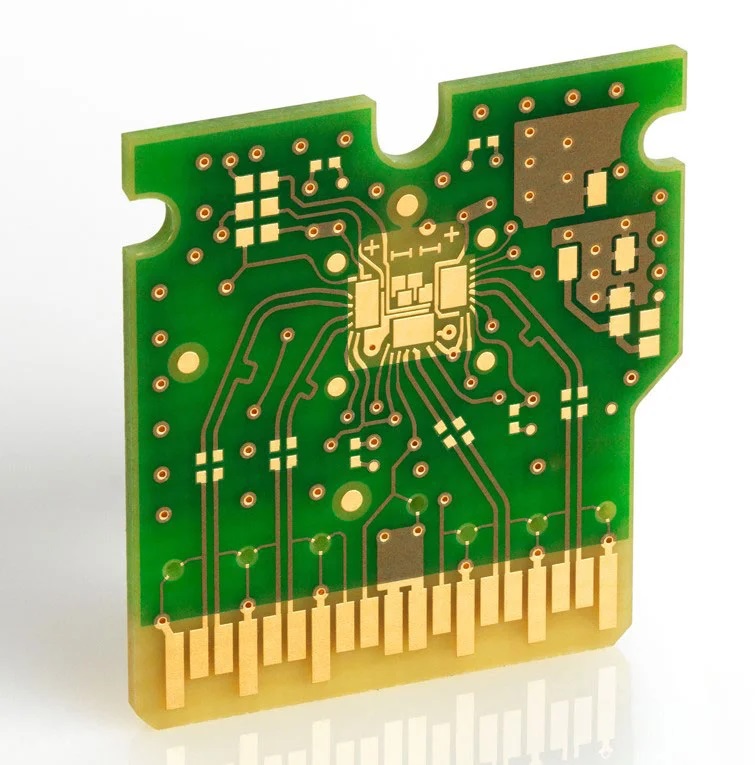

A circuit card is an electronic board that houses and connects various electrical components. It consists of a substrate, conductive traces, and mounted components like resistors, capacitors, and integrated circuits. Circuit cards are used in virtually every electronic device, ensuring signal integrity and efficient functionality. Unlike traditional wiring methods, they provide a compact and stable solution for electronic designs.

What Are the Different Types of Circuit Cards?

1. Classification by Structure

Single-Sided Circuit Card

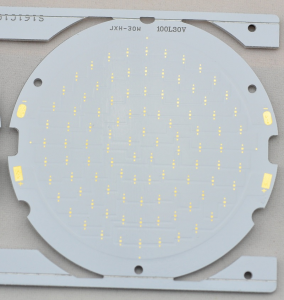

A single-sided circuit card has conductive traces on only one side of the substrate. Components are mounted on one surface, making it a cost-effective solution for simple electronic devices like calculators, power supplies, and LED lighting.

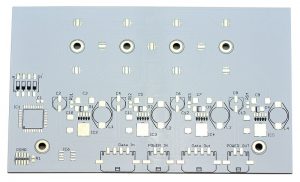

Double-Sided Circuit Card

A double-sided circuit card features conductive layers on both sides of the substrate, connected through vias. This design improves circuit density and functionality, making it suitable for industrial controls, power management, and communication devices.

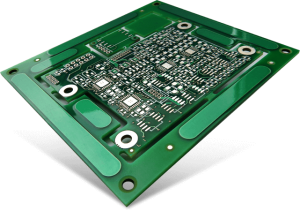

Multilayer Circuit Card

A multilayer circuit card consists of three or more layers of conductive material stacked together. These layers are insulated from each other by dielectric materials and connected through plated vias. High-density integration, reduced electromagnetic interference (EMI), and improved performance make multilayer cards ideal for high-speed computing, 5G networks, and aerospace electronics.

Rigid Circuit Card

A rigid circuit card is built on solid substrates such as FR4 (fiberglass epoxy), aluminum, or ceramic. It provides structural stability and durability, making it suitable for automotive electronics, industrial automation, and medical equipment.

Flexible Circuit Card

A flexible circuit card is made from polyimide (PI) or polyester (PET) materials, allowing it to bend and fold without damage. These cards are used in wearable devices, smartphones, and compact electronics where space-saving and durability are essential.

Rigid-Flex Circuit Card

A rigid-flex circuit card combines rigid and flexible sections in a single board. This hybrid design enhances mechanical stability and electrical reliability, making it suitable for military avionics, medical implants, and robotics.

2. Classification by Function and Application

Processing & Control Circuit Cards

These circuit cards act as the brain of electronic systems, handling computations and control tasks.

- Motherboards – Found in computers, industrial control systems, and embedded computing.

- GPU Cards – Used in graphics processing, AI computations, and gaming systems.

- FPGA/ASIC Accelerator Cards – Custom computing solutions for AI inference, video processing, and financial modeling.

Storage Circuit Cards

Storage-related circuit cards are responsible for data retention and high-speed access.

- Memory Modules (DRAM, SRAM) – Installed in computers and servers for fast data processing.

- Solid-State Drive (SSD) Control Boards – Manage data storage, encryption, and read/write operations in SSDs.

Communication Circuit Cards

These circuit cards facilitate data transmission and wireless communication.

- Network Interface Cards (NIC) – Enable wired and wireless network connections.

- RF Circuit Cards (Wi-Fi, Bluetooth, Radar Modules) – Used in IoT devices, automotive radar, and wireless communication systems.

Interface & Expansion Circuit Cards

These cards expand device capabilities and enable connections between peripherals.

- PCIe Expansion Cards – Used for data acquisition, sound processing, and graphics rendering.

- Signal Conversion Boards (USB, HDMI, DisplayPort) – Convert signals for different display and connectivity standards.

Power Management Circuit Cards

These circuit cards regulate voltage and power distribution for various applications.

- Power Distribution Boards (PDN) – Found in data centers, industrial machinery, and energy storage systems.

- Inverter Control Boards (DC-AC Conversion) – Used in solar power systems, electric vehicles, and motor drives.

Sensor & Actuator Circuit Cards

These cards process sensor inputs and control actuators in automation and robotics.

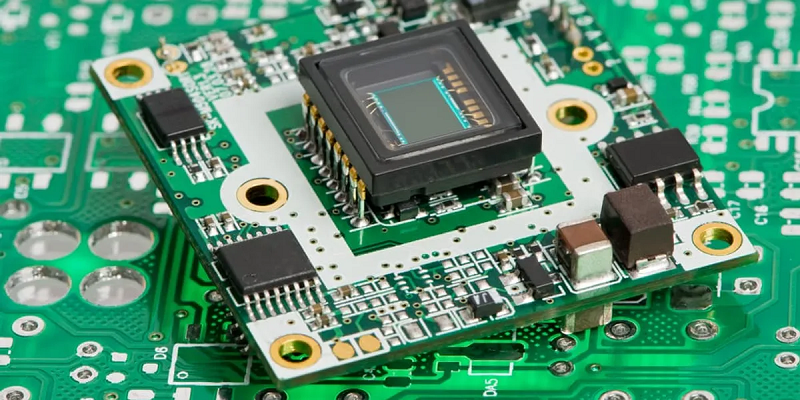

- Sensor Interface Boards – Used in temperature, pressure, and image acquisition systems.

- Motor Driver Boards – Control stepper motors, servo systems, and robotic actuators.

Choosing the appropriate circuit card depends on design complexity, performance requirements, and environmental conditions. Whether you need high-speed processing, rugged durability, or flexible designs, selecting the right type is crucial for achieving optimal system performance.

At Best Technology, we specialize in custom circuit card solutions, offering advanced manufacturing, precise engineering, and expert consultation to meet your project’s unique requirements.

What Materials Are Used to Make Circuit Cards?

Selecting the right materials is crucial for a circuit card’s durability and performance. Common materials include:

- FR4 (Fiberglass Epoxy) – Offers good insulation, mechanical strength, and cost-effectiveness.

- Polyimide – Used in flexible circuit cards for its heat resistance and flexibility.

- Metal Core (Aluminum or Copper) – Enhances heat dissipation in high-power applications.

- Ceramic Substrates – Provides excellent thermal and electrical stability for high-frequency designs.

Circuit Card Design

How to design a circuit card? Designing a circuit card requires precision and careful planning. The key steps include:

- Define Requirements – Determine the circuit’s function, power needs, and layout constraints.

- Create a Schematic – Develop a blueprint showing the electrical connections between components.

- Select Components – Choose resistors, capacitors, ICs, and other parts based on application needs.

- Design PCB Layout – Arrange components and route traces to ensure signal integrity and thermal efficiency.

- Simulate and Validate – Test the design virtually before creating a circuit card prototype.

- Prototype and Test – Build an initial version and conduct performance testing before mass production.

What Are the Benefits of a Circuit Card?

Circuit cards offer numerous advantages in electronic design and manufacturing:

- Compact and Lightweight – Saves space while maintaining high functionality.

- Enhanced Reliability – Reduces wiring complexity, minimizing failure risks.

- Improved Electrical Performance – Ensures stable signal transmission and power distribution.

- Cost-Effective Manufacturing – Supports mass production with minimal errors.

- Scalability – Allows easy modification for different applications.

What Are the Applications of Circuit Cards?

Circuit cards are integral to a wide range of industries:

- Consumer Electronics – Found in smartphones, computers, and home appliances.

- Automotive Systems – Used in engine controls, infotainment, and safety systems.

- Medical Devices – Enables precision in imaging systems, diagnostic tools, and monitoring equipment.

- Aerospace and Defense – Provides reliability for avionics, satellites, and military equipment.

- Industrial Automation – Supports robotics, sensors, and control systems.

Circuit Card Manufacturer

Why choose Best Technology as your circuit card manufacturer? Choosing the right circuit card manufacturers is critical to ensuring product reliability, performance, and long-term success. At Best Technology, we go beyond basic manufacturing to offer comprehensive, high-quality solutions tailored to your exact needs. Here’s why we are the preferred choice for circuit card design, prototyping, and mass production.

1. Full Turnkey Circuit Card Solutions

- We provide end-to-end circuit card services, from initial design and prototyping to full-scale production. Whether you need a standard circuit card or a customized solution optimized for complex layouts, high-speed signals, or extreme environments, our team ensures seamless development at every stage.

2. Over 18 Years of Manufacturing Excellence

- With nearly two decades of expertise, we understand the challenges of modern electronics manufacturing. Our in-house engineers specialize in material selection, layout optimization, and high-precision circuit card assembly to deliver superior circuit card performance. Our extensive experience allows us to handle high-frequency, high-power, and multi-layer designs with ease.

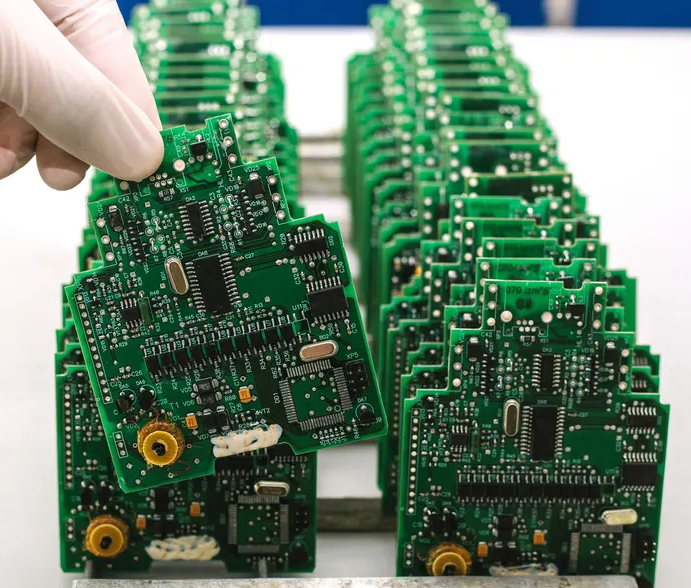

3. No Minimum Order Quantity (MOQ) Requirement

- We support projects of any scale—from small prototype batches for testing to large-volume production for mass deployment. Our flexible manufacturing approach allows you to scale production as needed while maintaining consistent quality at every stage.

4. Certified Manufacturing Facilities for Global Standards

We adhere to strict industry certifications to meet the highest quality and safety standards. Our manufacturing facilities comply with:

- ISO 9001 – Quality Management System

- ISO 13485 – Medical Device Manufacturing Standard

- IATF 16949 – Automotive Industry Standard

- AS9100D – Aerospace Industry Certification

- RoHS & REACH Compliance – Environmentally Friendly Production

5. Industry-Specific Expertise & Customization

Each industry has unique requirements, and we tailor our solutions to match specific applications, including:

- Automotive Electronics – High-reliability circuit cards for vehicle control systems.

- Medical Devices – Precision circuits for imaging, diagnostics, and monitoring.

- Aerospace & Defense – High-performance, ruggedized circuit cards for critical missions.

- Industrial Automation – Custom solutions for robotics, control systems, and sensors.

6. Dedicated Technical Support & Engineering Consultation

- Our customer-first approach means that you receive expert guidance at every stage. Whether you need design assistance, performance optimization, or troubleshooting, our experienced engineers are available 24/7 to provide technical support and consultation.

FAQs Of Circuit Card

1. What Does a Circuit Card Do?

- A circuit card connects and supports electronic components, allowing signals and power to flow efficiently between them. It acts as the foundation for any electronic system, ensuring stable operation.

2. What is the Difference Between a Circuit Card and a PCB?

- A circuit card is a complete electronic assembly that includes a printed circuit board (PCB) and mounted components. A PCB is just the bare board before component placement.

3. How Does a Circuit Card Work?

- A circuit card works by transmitting electrical signals through its copper traces, enabling communication between different electronic components. This controlled flow allows the device to perform specific functions.

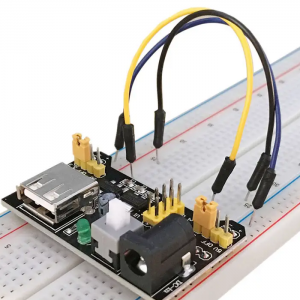

4. How Do You Use a Circuit Card?

- Circuit cards are integrated into electronic devices during the assembly process. They are placed inside enclosures, connected to other systems, and powered to perform designated tasks.

In a nutshell, a well-designed circuit card is essential for reliable and efficient electronics. From material selection to assembly, every stage plays a crucial role in ensuring performance and durability. If you need expert guidance, Best Technology offers high-quality circuit card solutions tailored to your requirements. Reach out to us at sales@bestpcbs.com for more details.

Tags: circuit card assembly, Circuit Card Design, Circuit Card Manufacturers, Circuit Card Prototype, PCB, pcb design, PCBA, printed circuit board