Custom LED PCB have revolutionized lighting solutions across industries, offering tailored performance for specialized applications. Let’s explores custom LED PCB from materials to manufacturing processes, helping you make informed decisions for your next project.

At Best technology, we focus on one stop solution PCB solution for custom LED PCB over 18 years. We support ODM and OEM customized LED PCB boards, and we have our own exclusive electronic supply chain, which can achieve low MOQ, multiple varieties, fast delivery, and professional engineers provide free technical services online one-to-one 24 hours a day. Welcome to contact us sales@bestpcbs.com if you have any request for custom LED PCB.

What Is LED PCB?

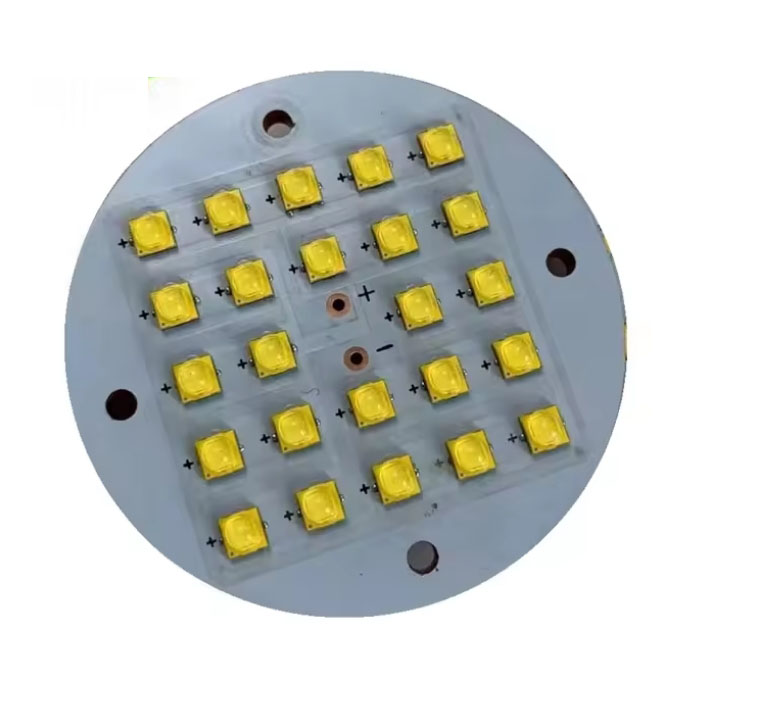

A LED PCB (Light-Emitting Diode Printed Circuit Board) is a specialized board designed to power and control LED arrays. Unlike standard PCBs, these boards prioritize thermal management, high-density layouts, and optical precision to maximize LED performance and lifespan. Custom LED PCBs are engineered to meet specific requirements such as brightness, color temperature, and environmental resilience.

What Are the Materials of LED PCB?

- Aluminum Base-Excellent heat dissipation, cost-effective, best for automotive lighting.

- FR-4-Low cost, standard insulation, best for Consumer electronics.

- Ceramic Base-Ultra-high thermal resistance, best for aerospace systems.

- Flexible Base-Bendable, lightweight design, best for wearables, curved displays.

What Are the Advantages of LED PCB?

- High Reliability-Withstand extreme temperatures (-40°C to 150°C), humidity, and vibrations.

- Superior Thermal Management-Aluminum and ceramic substrates dissipate heat 5-10x faster than FR-4, preventing LED degradation.

- Design Flexibility-Custom shapes, sizes, and LED densities (up to 200 LEDs/sq. inch) for unique applications.

- Energy Efficiency-Optimized circuits reduce power loss by 15-30% compared to traditional wiring.

- Cost-Effective Scaling-Bulk production cuts costs by 40-60% for large orders.

What Are the Application of Custom LED PCB?

Here are main application of custom LED PCB:

- Automotive headlights

- Airport runway landing lights

- Street lighting

- Highway tunnel lighting

- Photovoltaic (solar) lighting

- Flashlights and lanterns

- Traffic and signal lighting

- Lighting in hospital operating rooms

- High growth plant lighting

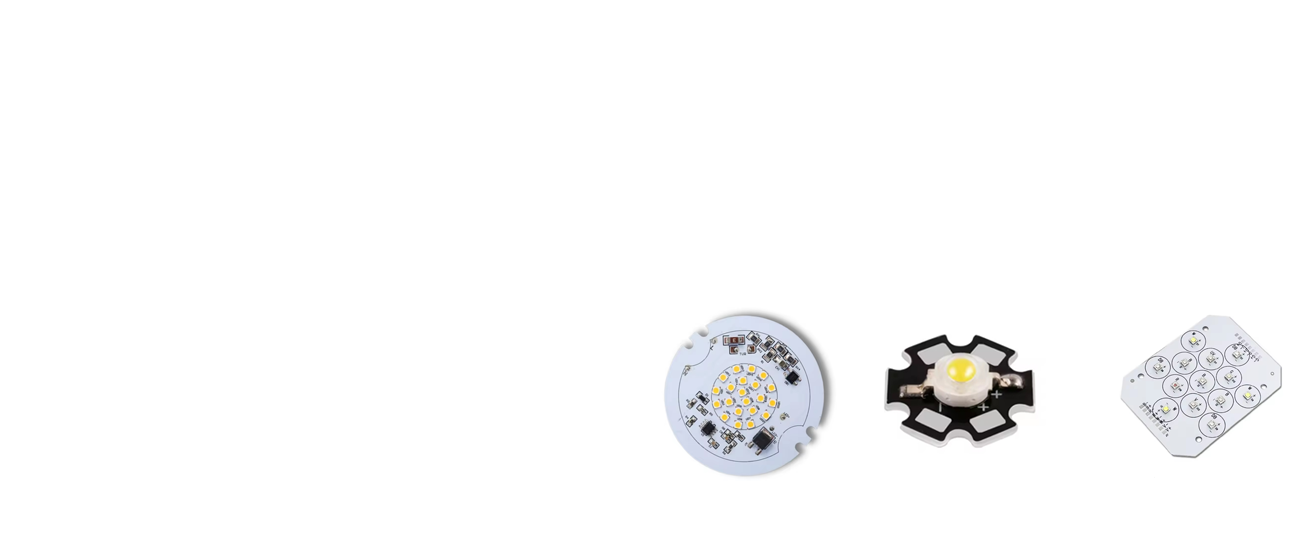

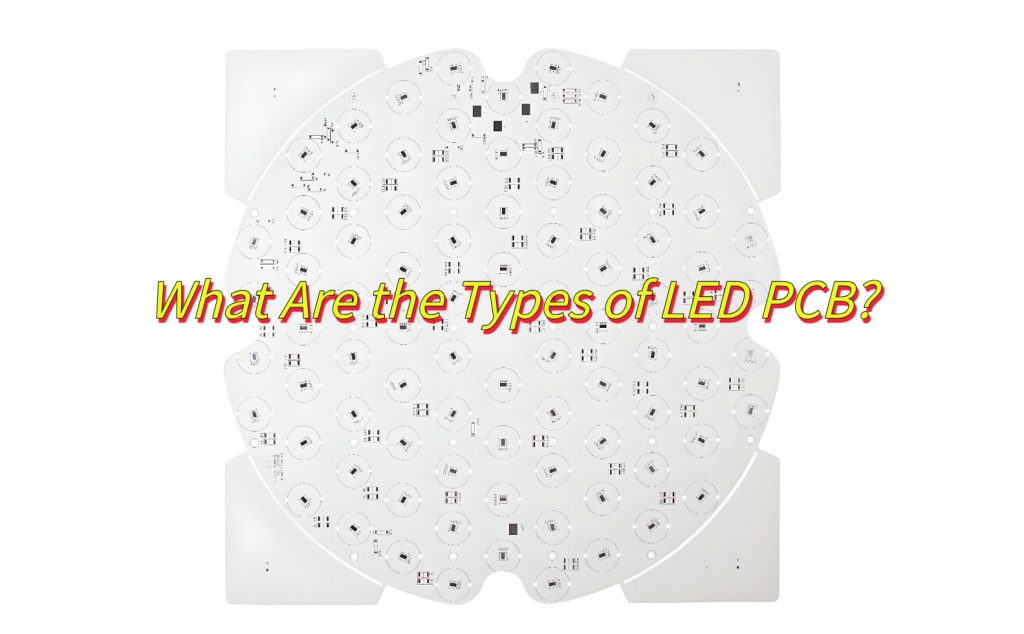

What Are the Types of Custom LED PCB?

Here are types of custom LED PCB board:

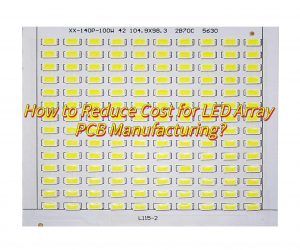

Single-layer PCB:

- Features: Single-sided wiring, lowest cost, suitable for simple circuits.

- Applications: Basic LED signs, small lighting modules.

Double-layer PCB:

- Features: Double-sided wiring + via connection, support for medium-complexity circuits.

- Applications: Smart home lighting, advertising light boxes.

Multi-layer PCB (4 layers and above):

- Features: High-density wiring, integrated heat dissipation layer and signal layer.

- Applications: Industrial-grade LED control systems, automotive smart headlights.

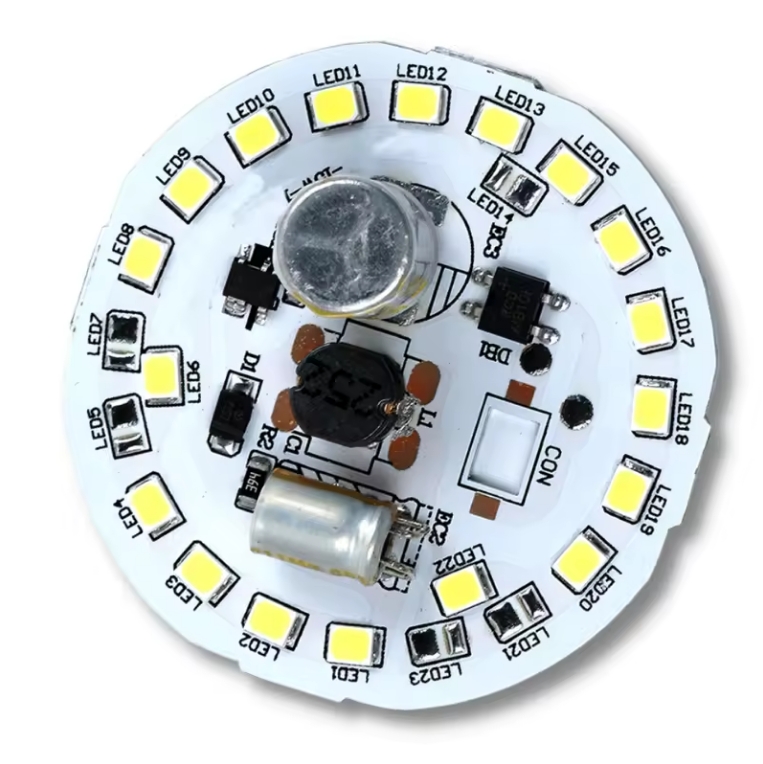

Manufacturing Process of Custom LED PCB Board

- Aluminum substrate cutting: Cut aluminum substrate according to design size (heat dissipation optimization)

- PCB manufacturing: Drilling → Copper deposition → Etching → Surface treatment (Spray tin/immersion gold)

- SMT patch: Fully automatic patch machine solders LED chips, resistors, capacitors and other micro components

- Surface protection: Coating green oil to protect the circuit to prevent oxidation and solder short circuit.

- Surface treatment: Surface spray tin or immersion gold treatment to enhance welding performance and corrosion resistance

- Plug-in welding: Manual/mechanical supplementary installation of large-size plug-ins (such as connectors)

- Functional test: Power on to detect LED brightness, color temperature and circuit stability

- Final inspection and shipment: Appearance inspection + packaging shockproof treatment

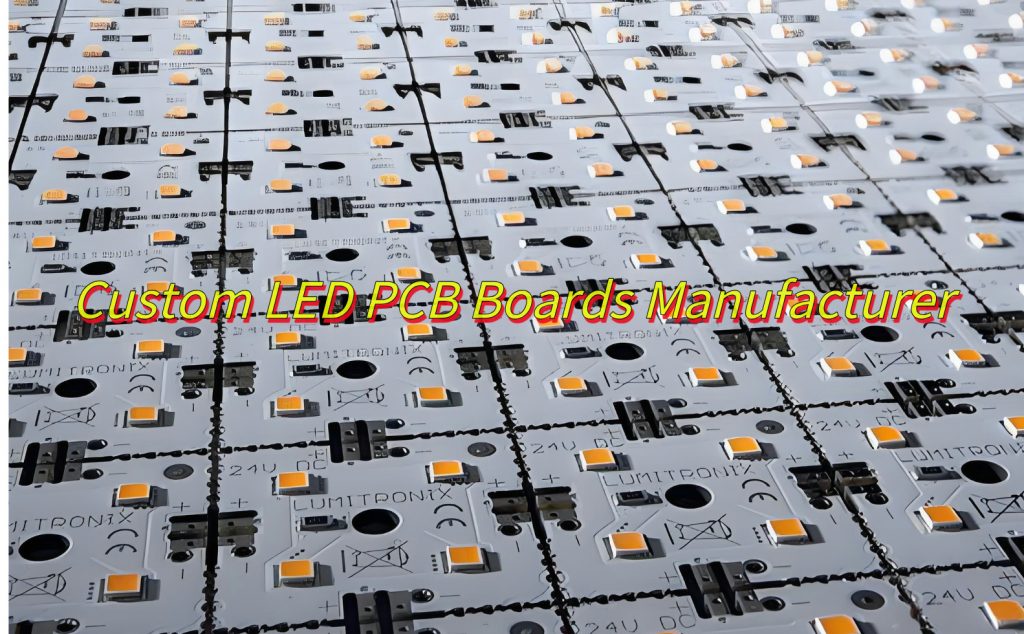

Custom LED PCB Boards Manufacturer

As a custom LED PCB boards manufacturer, Best Technology, establish on June 28, 2006, is a Hong Kong registered company whom focus on custom LED PCB boards manufacturing. We are dedicated to be your best partner of advance and custom LED PCB boards manufacturer. Here are more information about us:

- Quality assurance both for our products and before/after-sales service.

- Accept small order and mixed order, samples are welcomed.

- Discounts are offered base on large order quantities with custom led PCB.

- Great variety of LED PCB products with competitive price, welcome OEM and ODM.

- Provide expedited custom LED PCB board prototyping service.

If you are interested in our service, welcome to contact us at any time.

FAQs of Custom LED PCB

1.How to improve heat dissipation in custom LED PCBs?

Use aluminum substrates with 2-3 oz copper layers and thermal vias.

2.What’s the minimum order quantity (MOQ) of custom led PCB?

Best Technology accept one piece MOQ for custom led PCB prototyping.

3.Can custom LED PCBs be repaired?

Yes, but rework costs often exceed replacement costs for high-density boards.

4.How much does a custom LED PCB cost?

Price range from $0.50-$20 per piece normal FR-4 board.

5.What’s the lifespan of custom LED PCBs?

Properly designed boards last 50,000-100,000 hours (5-11 years).

To sum up, that’s all about custom LED PCB. Start your project today by partnering with a certified PCB manufacturer to turn your design into reality.