Aerospace PCB manufacturers play a critical role in enabling high-reliability electronics for aviation, satellites, and defense systems. These manufacturers build boards that can withstand harsh environments, including extreme temperatures and high altitudes. That’s why quality, consistency, and standards matter more than ever in this field. In this blog, we’ll walk you through something you should know—from HDI PCB production to U.S. and U.K.-based aerospace board makers. If you’re in aerospace, defense, or high-end electronics, this blog is for you.

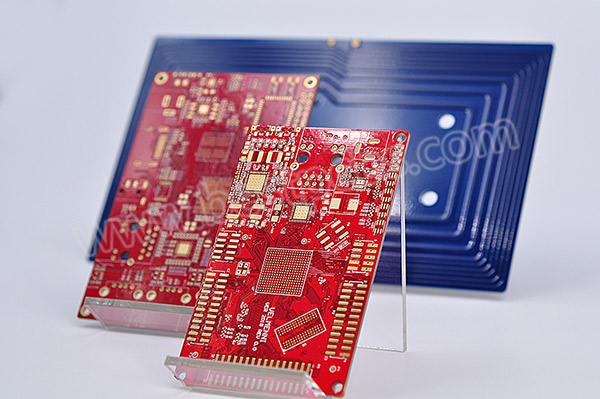

Best Technology specializes in aerospace PCB manufacturing, quick-turn aerospace PCB prototypes, HDI PCBs, rigid-flex PCBs, FR4 PCBs, and RF PCBs. Moreover, we focus heavily on quality control, traceability, and thermal performance to ensure every board meets strict aerospace standards. In addition, Best Technology is an AS9100D, IATF 16949, ISO9001, and ISO13485 certified factory.

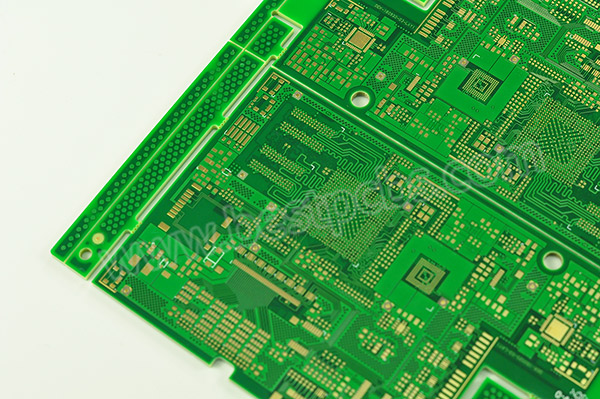

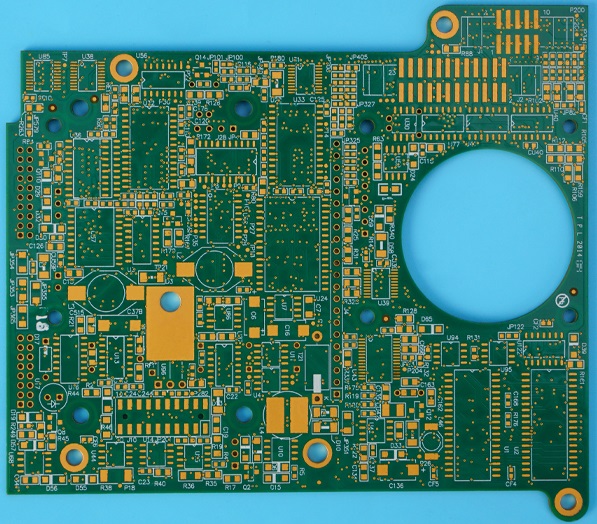

All the aerospace PCBs in Best Technology go through rigorous testing and are manufactured under ISO 9001 and AS9100D certified processes. To support different needs, our Production Line 1 is dedicated to prototypes, small-volume production, and special boards, such as 30-ounce heavy copper boards and 0.15mm extra thin FR4 PCBs. Meanwhile, Production Line 2 is equipped with automated copper etching and plating lines, with a monthly capacity reaching up to 100,000 square feet. Over 1,700 customers across 40 countries trust us for their low-volume aerospace PCB production. If you’re looking for a reliable partner, we warmly invite you to contact Best Technology at sales@bestpcbs.com to schedule a factory tour and learn more about our capabilities.

What is PCB in aerospace?

PCBs used in aerospace are not your standard circuit boards. They must function reliably in mission-critical applications. Whether in satellites or fighter jets, these boards operate under vibration, shock, radiation, and severe thermal cycles.

These boards connect complex systems like navigation, communication, radar, and control systems. They’re usually made with high-Tg materials, low-loss laminates, and precise impedance control. Aerospace PCBs often go through rigorous quality testing, including thermal cycling, X-ray inspection, and even real-time functional testing.

In short, aerospace PCBs are the backbone of modern flight technology—so choosing the right manufacturer is essential.

Aerospace PCB Design Standards

To serve the aerospace market, PCB design must follow specific standards. These guidelines make sure that the board will function consistently under stress.

Some common standards include:

- IPC-6012DS: This defines the quality and reliability levels for rigid PCBs used in space and military systems.

- AS9100D: A quality standard tailored for aerospace manufacturers.

- MIL-PRF-31032: U.S. military standards for printed circuit boards.

Besides compliance, top aerospace PCB manufacturers invest in robust design reviews. This step ensures all aspects—material, stack-up, impedance, trace widths—match the application’s requirement before going into production.

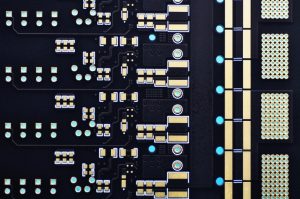

Who is HDI PCB Manufacturer?

An HDI PCB manufacturer specializes in high-density interconnect technology. In essence, these boards provide more functionality within a smaller footprint. This becomes especially valuable in aerospace applications, where space and weight are tightly restricted. As a result, choosing a reliable HDI PCB manufacturer is critical for aerospace projects where performance, size, and durability all play a vital role. When it comes to proven expertise, manufacturers like Best Technology, Sanmina, and Unimicron lead the way with precision manufacturing and full compliance with aerospace standards.

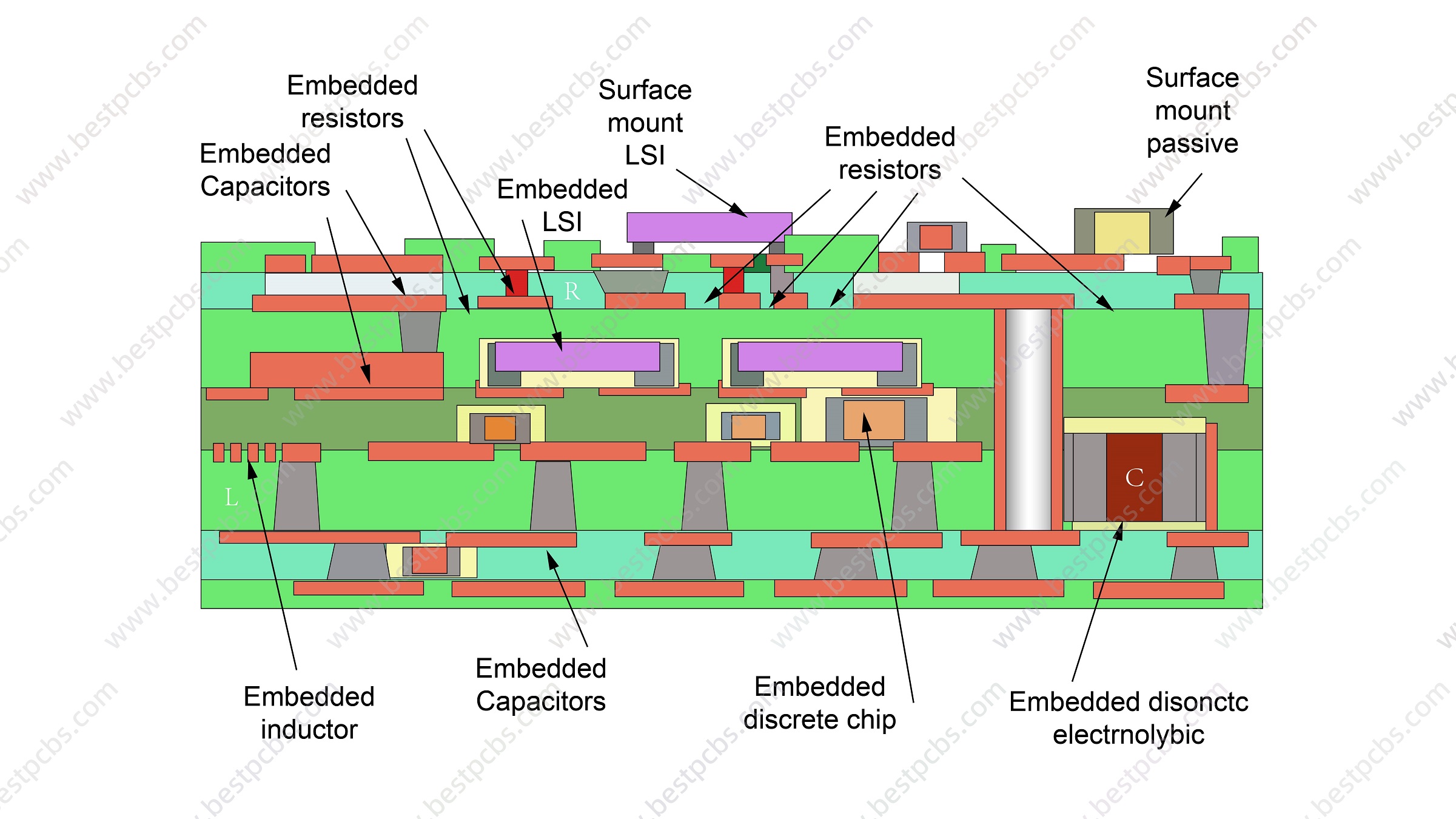

HDI boards feature:

- Micro vias and blind/buried vias

- High layer counts

- Tight line and space width

- Controlled impedance routing

In aerospace systems, HDI PCBs are widely used in sensors, communication systems, and satellite controls. Therefore, choosing the right HDI PCB manufacturer is essential to ensure reliability through high-quality materials, fine-pitch components, and proper EMI shielding—all of which are critical in flight-sensitive equipment.

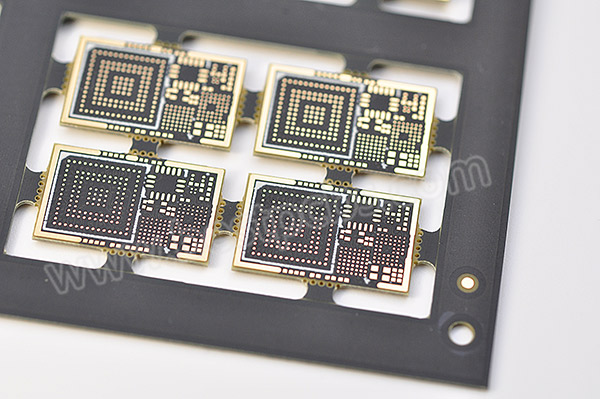

At Best Technology, we are recognized for our high-precision fabrication and strong reliability in demanding sectors, especially aerospace. Furthermore, our HDI PCB manufacturing capabilities include stacked and staggered micro vias, laser-drilled vias, and support for 2 to 16-layer PCB designs. In addition to that, Best Technology offers HDI PCB prototyping as well as small-batch and high-volume production to meet various customer needs. As a trusted partner, we proudly support several aerospace OEMs with consistent quality and dependable service.

Aerospace PCB Manufacturers in USA

Aerospace PCB manufacturers in the USA are known for strict quality processes and strong compliance. Working with a U.S.-based company ensures easier communication, faster lead times, and traceable material sourcing. Many U.S. companies are ITAR-registered, which is important when working on defense contracts. Some offer full services—from layout to final assembly. Others focus on rigid-flex or HDI boards for space applications. Here are three top aerospace PCB manufacturers based in the United States.

Advanced Circuits

- Advanced Circuits is one of the most established names in the U.S. PCB market. They specialize in aerospace and defense boards, offering Class 3 production, high-Tg materials, and full MIL-PRF-31032 certification.

Sierra Circuits

- Sierra Circuits offers end-to-end solutions including PCB layout, fab, and assembly. They focus on complex boards with tight tolerances, including HDI, rigid-flex, and RF for avionics and satellite applications.

Summit Interconnect

- Summit Interconnect is a growing force in the aerospace and defense PCB space. With ITAR registration and AS9100D certification, their facilities can handle HDI, flex, RF, and hybrid builds across multiple U.S. locations.

Working with aerospace PCB manufacturers in the USA not only ensures quality but also offers direct communication and faster prototyping. These manufacturers bring decades of experience and full certification to the table, making them strong partners for demanding aerospace programs.

Aerospace PCB Board Manufacturer UK

If you’re based in Europe, working with a UK aerospace PCB board manufacturer offers several benefits. These include faster logistics, easier audits, and better regional compliance with EU aerospace directives. Let’s take a look at three notable aerospace PCB board manufacturers in the UK.

Stevenage Circuits Limited (SCL)

- Stevenage Circuits specializes in complex rigid and flex-rigid PCBs for defense and aerospace. Based in Hertfordshire, they’re AS9100 and ISO 9001 certified. Their facility supports prototype through low-volume production with strong documentation and traceability.

Exception PCB

- Based in Wiltshire, Exception PCB is known for their work with high-reliability boards used in aviation, satellites, and unmanned systems. Their facility is AS9100D certified, with a strong focus on controlled impedance and high-layer-count boards.

Merlin PCB Group

- Merlin PCB, part of Finmasi Group, operates out of Llantarnam, Wales. They offer complex multilayer PCBs and have extensive experience in aerospace and military projects. Their capabilities include RF and microwave boards, thermal management, and metal-backed PCBs.

UK aerospace PCB manufacturers provide advanced solutions with the benefit of proximity for European partners. These companies bring proven quality systems, technical expertise, and strong customer support, ensuring that every board meets aerospace reliability standards.

Why Choose Top Aerospace PCB Manufacturers for HDI PCB Needs?

Here’s where things get real: Not all HDI manufacturers are ready for aerospace demands. But top aerospace PCB manufacturers can bring serious advantages when it comes to HDI work. Let’s break it down:

- 1. Reliability: They understand reliability isn’t optional—it’s a requirement.

- 2. Quality Control: Every layer, via, and connection is inspected and tested.

- 3. Advanced Capability: They use stacked micro vias, sequential lamination, and ultra-fine features.

- 4. Certification Ready: They support MIL-Specs, AS9100, and IPC Class 3 standards.

- 5. Material Expertise: They choose laminates that meet your altitude, frequency, and heat requirements.

Working with top-tier suppliers also means your project will be supported by engineers who understand both HDI complexity and aerospace constraints.

How Do Aerospace PCB Manufacturing Services Ensure Reliable Mass Production?

Mass production in aerospace isn’t about churning out volume—it’s about repeatable precision. The best aerospace PCB manufacturing services use:

- Automated Optical Inspection (AOI)

- Flying Probe and ICT testing

- In-line X-ray inspection

- Environmental stress testing

They also run Statistical Process Control (SPC) systems to catch and correct deviations early. More importantly, these services come with robust documentation, lot traceability, and manufacturing records. That’s crucial for aerospace audits and traceability demands. If you’re scaling from prototype to full production, these services help maintain consistency from the first board to the last.

Why Should You Choose Best Technology as One of Your Aerospace PCB Manufacturers?

At Best Technology, we understand the stakes in aerospace electronics. For over 18 years, we’ve delivered precision PCBs for flight-critical systems, satellite modules, and military equipment. Here’s why 1700 clients around 40 countries trust us:

1. Full Capabilities

- From HDI to rigid-flex, from RF boards to aluminum-backed PCBs—we can build what your application needs.

2. Certified Manufacturing

- We’re ISO 9001, ISO 13485, and UL certified. We also meet IPC Class 3 and MIL-STD design criteria.

3. Mass Production Ready

- Whether you need a small quantity or a large volume, our facility supports stable production with real-time quality tracking.

4. Global Support

- We work with aerospace clients across the U.S., Europe, and Asia. Our bilingual engineering and sales teams make collaboration easy. We have established SMT factories in China and Vietnam respectively. And we will set up the U.S. office shortly to better support the customers’ projects.

6. Fast Response, Always

- Your deadlines matter. That’s why we respond quickly, ship on time, and keep you informed at every step. There are 97% on-time delivery rate in Best Technology. Our lead time policy in our PCB manufacturing is 2-3 weeks, which shortens the product time-to-market schedule for our global customers.

In conclusion, choosing the right aerospace PCB manufacturers is not a small decision. It affects your product’s performance, reliability, and even your company’s reputation. Whether you’re building for space, avionics, or defense, you need a manufacturing partner who gets it right every time. From HDI design to RF circuits, from flexible layers to rigid boards, Best Technology is here to offer the best aerospace PCB manufacturing service to you. A warm welcome to contact us via sales@bestpcbs.com to get a free quote and PCB specifications.