PCB manufacture and assembly is the backbone of every modern electronic device. From design to final product, every step matters. With technology moving fast, having one trusted partner to handle both manufacturing and assembly saves time and improves product quality. This article will guide you through what makes this process unique and why a one-stop solution can be a smart choice.

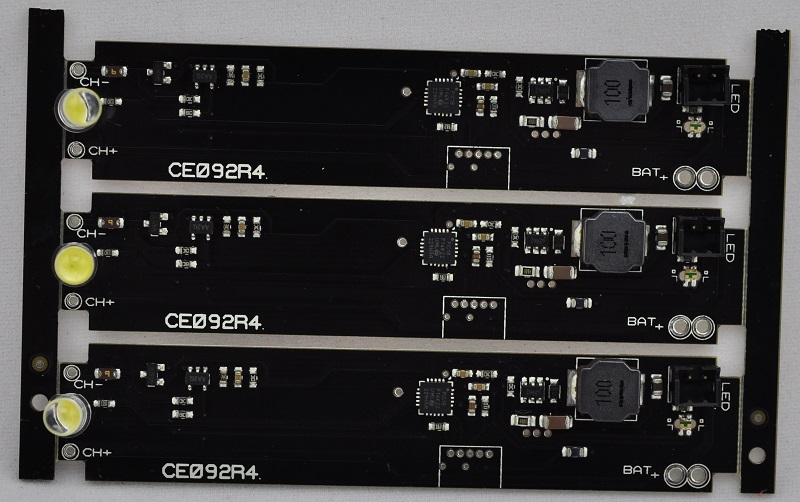

Best Technology has specialized in PCB manufacture and assembly service for about 19 years. We offer a variety of PCBs, including FR4, ceramic PCB, MCPCB, and PCB assembly since 2006. Our company vision is to be the most reliable one-stop fast solution provider of electronics and circuit boards in the world. High quality and fast lead time are the competitive advantages of Best Technology. We have 2 YAMAHA and 3 JUKI production lines in our Chinese SMT factory. In our Vietnam SMT factory, Best Technology has 6 SMT production lines, on which each line has the automated PCB loaders and the GKG automated solder paste printer.

Best Technology has the MES system in our PCB manufacturing and assembly factory, which gives us access to full-process visual tracking. All materials are traceable from this system. We are the original factory providing one-stop PCB manufacture and assembly service, if inquiries related to PCB design, PCB prototyping, DFM analysis, or PCB assembly, please do not hesitate to contact us at sales@bestpcbs.com. Our team is here to provide expert support.

What is the difference between PCB manufacturing and assembly?

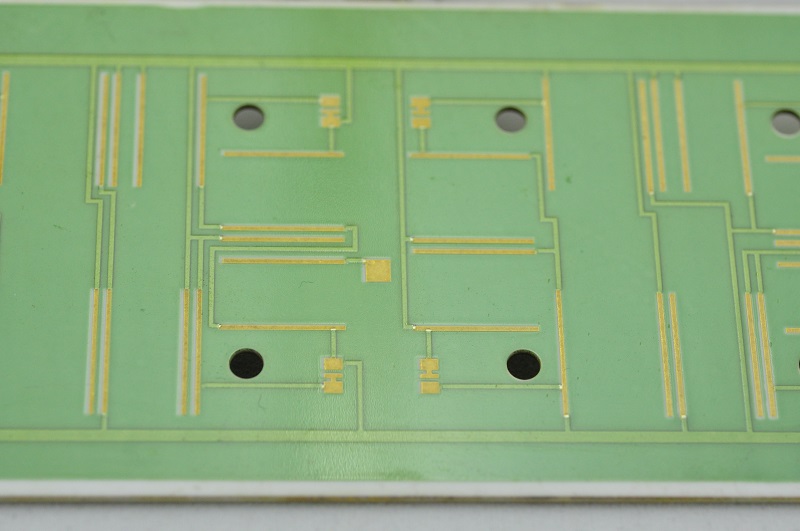

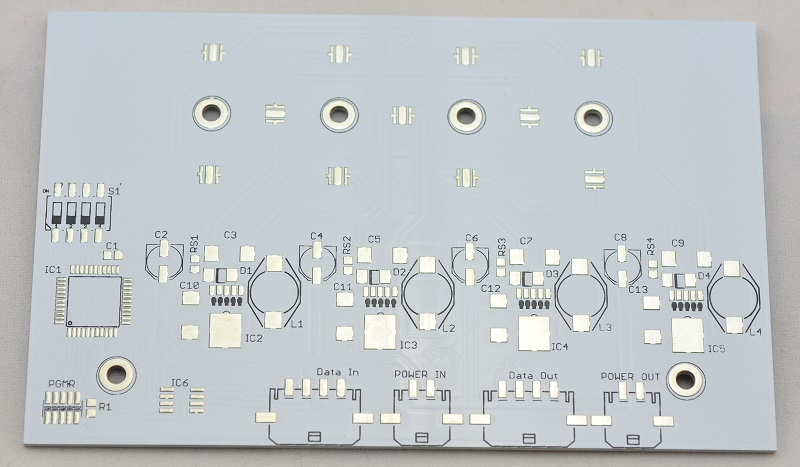

PCB manufacturing is the process of creating the board. This includes layering, etching copper, drilling holes, and applying surface finishes. It’s about building the actual platform where your components will sit.

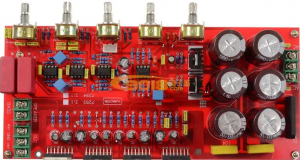

PCB assembly, on the other hand, places electronic parts on that board. This includes mounting resistors, capacitors, ICs, and connectors. Assembly may use manual or automated methods, depending on the volume and complexity.

Both stages are vital. Manufacturing builds the structure; assembly brings the board to life. When these are handled by separate vendors, communication gaps may appear. That’s why many turn to a one-stop PCB manufacture and assembly service.

What is the process of PCB manufacturing?

PCB manufacturing follows a step-by-step workflow:

- Design Check: The process starts with verifying your PCB design (Gerber files).

- Material Selection: The board material (usually FR4, Rogers, or metal core) is selected.

- Layer Construction: Copper layers are laminated and patterned.

- Drilling: Holes are drilled for vias and components.

- Plating and Etching: Conductive paths are formed.

- Solder Mask and Silkscreen: These protect and label the board.

- Surface Finish: Finishes like ENIG or HASL are applied.

Every step needs precision. Errors in early stages may ruin the board. That’s why experienced PCB manufacture and assembly companies use quality control from start to end.

What is PCB assembly process?

PCB assembly brings the board into its working form:

- Solder Paste Application: A stencil is used to apply solder paste to pads.

- Component Placement: SMT or through-hole components are placed.

- Reflow or Wave Soldering: Heat melts the paste and fixes parts in place.

- Inspection: AOI (Automated Optical Inspection) checks for defects.

- Testing: Functional tests confirm if the board works properly.

This process can be manual for prototypes or fully automatic for large runs. Choosing a partner with full PCB manufacture and assembly service simplifies coordination.

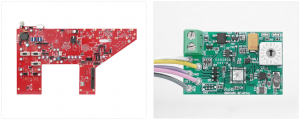

What is the difference between a circuit card assembly and a PCB?

A PCB (Printed Circuit Board) is a blank board with no parts on it. It’s the foundation.

A circuit card assembly (CCA) is a completed board with all electronic parts installed. This includes ICs, connectors, and other components. In short, a PCB becomes a CCA after assembly.

Knowing this difference helps avoid confusion when talking to suppliers. When choosing a one-stop PCB manufacture and assembly partner, you get both the board and the assembly done in one place.

How is a PCB via made?

Vias connect different layers of a PCB. They’re tiny holes that help route signals across layers.

Here’s how they’re made:

- Holes are drilled (mechanically or by laser).

- The inside of each hole is plated with copper.

- This connects the layers electronically.

Types of vias include through-hole, blind, and buried. The right choice depends on your design. Professional PCB manufacture and assembly services help guide that decision.

What are the cost factors in PCB manufacture and assembly?

Cost depends on several things:

- Board Complexity: More layers and smaller traces cost more.

- Quantity: Larger orders lower the per-unit price.

- Components: High-end parts can raise the cost.

- Turnaround Time: Faster delivery adds extra charges.

- Testing Requirements: More testing increases price but improves reliability.

While cost matters, value is more important. A reliable PCB manufacture and assembly service saves you from rework and delays.

Why choose a one-stop PCB manufacture and assembly service?

Here’s why many customers choose one-stop services:

- Less Hassle: You don’t need to manage multiple vendors.

- Faster Delivery: Fewer hand-offs mean quicker results.

- Better Quality: One team manages all stages, reducing errors.

- Easy Communication: One point of contact simplifies everything.

- Cost Efficiency: Integrated services often come with bundled pricing.

One-stop PCB manufacture and assembly is ideal for startups, OEMs, and design houses. It helps bring your ideas to life with less risk.

How to evaluate a reliable PCB manufacture and assembly partner?

Look for these signs:

- Experience: Years in the industry matter. In Best Technology, the CEO Peter and some engineers in the R&D departments, the account managers, and the sales engineers, all these professionals have rich experience in the PCB manufacture and assembly industry for over 10 years.

- Certifications: ISO, UL, and IPC compliance ensure standards. Best Technology is certified by ISO9001, ISO13485, IATF16949, and AS9100D. Every PCB manufacture and assembly process is abided by the ISO standards.

- Equipment: Modern machines mean better output. Best Technology has invested in new equipment in our PCB manufacture and assembly factories every year to better coordinate the production speed and optimize the PCB manufacture and assembly cost for our clientele.

- Capabilities: Check if they can handle your board type and volume. Best Technology is equipped with professionals, most of whom have over 10 years of expertise and specialize in PCB engineering. Our R&D departments have handled special PCBs with complex layers during manufacturing and assembly for 1,700 clients across 40 countries. Besides, there are no MOQ requirements for PCB manufacture and assembly projects in Best Technology.

- Customer Support: Fast and clear answers show reliability. Best Technology has prompt before and after-sales service. For any inquiries about PCB manufacture and assembly, our account managers and engineers will get back to you within 24 hours.

Don’t choose based on price alone. A reliable partner will guide you, not just follow instructions. Best Technology, for example, has over 18 years of experience, offering full PCB manufacturing and assembly services globally.

In conclusion, PCB manufacture and assembly is not just about making a board and placing components. It’s about working with a partner that understands your goals. A one-stop service gives you full control, reduces delays, and improves final product quality.

Best Technology offers full turnkey PCB manufacture and assembly services. We support low to high volumes, simple to complex boards, and have customers from USA, India, and China. With fast response, high precision, and quality assurance, we aim to be your long-term PCB partner. Welcome to contact Best Technology at sales@bestpcbs.com for helping you solve your PCB manufacture and assembly project to market—faster and smarter.

Tags: One-stop PCB Manufacture And Assembly Service, pcb manufacture and assembly