What Is a Battery Eliminator Circuit?

A battery eliminator circuit can be short for BEC, it is a circuit that replaces batteries to provide power. Battery eliminator circuits were originally used in applications where the mains was converted to battery power. They are now used in battery-driven applications where high and low power are required, and can be used to save battery demand. For example, when the motor requires 12V and the control board requires 5V, a 12V to 5V battery eliminator circuit is required, and only one set of 12V batteries is required.

Early commercial battery eliminators were produced by Edward Rogers in 1925 as a supplement to his line of “battery-free” radio receivers. Another early battery eliminator manufacturer was Galvin Manufacturing Company (later known as Motorola), which was founded on September 25, 1928 by Paul Galvin and his brother Joseph E. Galvin to build battery eliminators for radio receivers installed in cars.

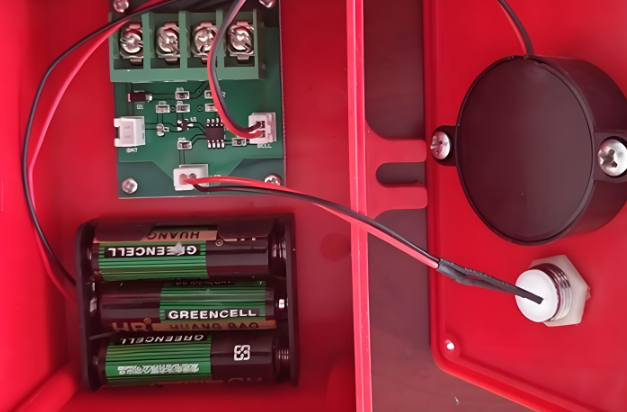

BECs are also used in some motorcycles and all-terrain vehicles to reduce the use of batteries in order to reduce the weight of the load. The part that originally required the battery is replaced by a large-capacity capacitor, which can be used to reduce the pulse fluctuations produced by the alternator.

Why Is a Battery Eliminator Circuit Important?

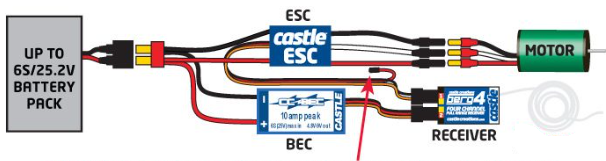

Many electronic circuits require different voltage levels to function correctly. For example, in an RC aircraft or drone, the motor runs on a high-voltage battery pack, but the flight controller, servos, and receiver need a much lower voltage (usually 5V or 6V). Without a BEC, a separate battery would be required for the receiver and servos, adding extra weight and complexity. A BEC solves this issue by stepping down the voltage and supplying consistent power to these essential components.

In addition to this, intercell static electricity is a common phenomenon in electronics, which can produce a transient high voltage in electronic devices, resulting in damage to batteries and devices. And the static electricity between batteries may cause problems such as short circuit, leakage, and overheating of batteries, or even fire and explosion. The battery eliminator circuit connects the electrostatic charge between the battery and the ground through the grounding principle, so that the charge is lost, so as to protect the safety of the battery and equipment.

Types of Battery Eliminator Circuits

There are two main types of BECs in the electronics, each with distinct advantages and applications:

1. Linear BEC

A linear battery eliminator circuit uses a linear voltage regulator to reduce voltage. It is commonly used in remote-controlled (RC) models, especially as part of an electronic speed controller (ESC). This circuit allows the RC model to operate with a single battery pack that powers both the motor and control electronics, eliminating the need for a separate battery for the receiver and servos.

A BEC within the linear regulator often includes a low-voltage cutoff function to prevent excessive battery discharge, which could lead to system failure. It is typically installed according to the manufacturer’s recommendations, and the regulated voltage is optimized for the RC receiver.

2. Series BEC (SBEC)

A series battery eliminator circuit is a design that uses a basic series switching regulator to provide a stable DC voltage output. It is commonly used in 9V DC applications, with a maximum current not exceeding 100mA. This circuit includes components such as a transformer, filter capacitor, and push-pull rectifier, which help step down the voltage and provide isolation protection.

When unloaded, the circuit outputs approximately 18V DC, and under full load, the voltage drops to around 12V DC. Additionally, it features an output buffer amplifier, which enhances current gain and voltage regulation.

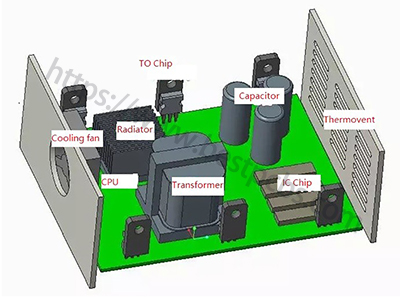

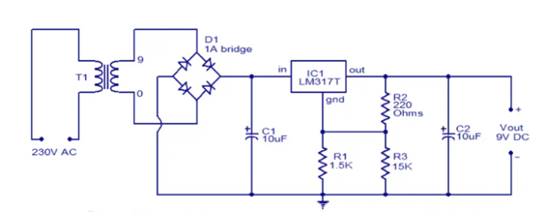

Battery Eliminator Circuit Diagram

A BEC battery eliminator circuit consists of several key components that regulate voltage and maintain stability. A basic battery eliminator circuit diagram includes:

- Voltage Regulator – The core component that steps down voltage.

- Capacitors – Stabilize the output voltage and filter noise.

- Diodes – Provide reverse polarity protection to prevent damage.

- Input and Output Terminals – Allow connection to a power source and the electronics that need power.

Below is a series circuit diagram of the battery eliminator circuit, which can be used as a replacement for the 9VPP3 battery. The circuit given here can be used to power any device powered by a 9V battery. Transformer T1 reduces the supply voltage and bridge D1 performs rectification. Capacitor C1 is a filter. The ICLM317T is a voltage regulator. If the values of R1, R2, and R3 are selected, the output voltage of IC1 will be stable at 9 volts.

What Does a Battery Eliminator Circuit Do?

A battery eliminator circuit provides a stable and regulated power supply to electronic components that would otherwise require a separate battery. It ensures that these components receive the correct voltage level, preventing damage due to overvoltage or undervoltage. The mainly functions of a BEC including:

- Voltage Regulation – Converts high voltage from the main power source into a stable lower voltage for sensitive electronics.

- Weight Reduction – Eliminates the need for extra batteries, making devices lighter and more efficient.

- Power Management – Protects components from voltage fluctuations and power surges.

- Improved Efficiency – Reduces power wastage and enhances performance in drones, RC models, and embedded systems.

For example, in an RC car, the motor may run on a 7.4V or 11.1V battery pack, but the receiver and servos require only 5V or 6V.

How Does a Battery Eliminator Circuit Work?

A battery eliminator circuit works by taking power from a high-voltage source, regulating it, and supplying a stable output voltage. The working principle varies based on whether it is a linear BEC or a switching BEC.

A linear BEC operates like a traditional voltage regulator, reducing voltage by converting excess energy into heat. For instance, if a 12V input is required to provide 5V output, the extra 7V is dissipated as heat. This method is simple but inefficient for high-power applications since it generates excess heat.

While different with linear BEC, a series BEC (also known as SBEC or UBEC) uses a high-frequency switching regulator to convert voltage without significant heat loss. Instead of dissipating excess voltage, it switches the power on and off rapidly, storing and releasing energy efficiently.

Battery Eliminator Circuit Uses

A BEC is used in various applications where a stable power source is needed. Some of the most common uses include:

- RC Vehicles and Drones – Powers receivers, servos, and electronic speed controllers (ESCs).

- FPV Systems – Supplies steady voltage for cameras, video transmitters, and OSD modules.

- Embedded Systems – Provides regulated power to microcontrollers, sensors, and digital circuits.

- Power Tools – Eliminates the need for disposable batteries in low-voltage applications.

- Testing and Prototyping – Used in laboratories and research to power circuits with precise voltage levels.

What Is the Difference Between BEC and UBEC?

A BEC and UBEC (Universal Battery Eliminator Circuit) serve the same function but differ in design and efficiency.

| Feature | BEC | UBEC |

| Type | Can be linear or switching | Always a switching regulator |

| Efficiency | Lower for linear BECs | Higher efficiency |

| Heat Generation | Higher in linear BECs | Minimal due to switching technology |

| Current Handling | Limited | Can handle higher currents |

| Ideal Use | Low-power applications | High-power RC and drone systems |

A UBEC is a more advanced version of a BEC, commonly used in RC drones, FPV systems, and high-current applications where power efficiency is crucial.

BEC in FPV Drone Flight Controllers

In FPV (First-Person View) drones, a battery eliminator circuit drone is used to maintain stable voltage levels across different electronic components. Flight controllers, video transmitters, and cameras all require a reliable power source to function properly. Without a BEC, these components would need separate batteries, adding unnecessary weight and complexity to the drone.

Drones typically use high-voltage LiPo (Lithium Polymer) batteries, often rated at 3S (11.1V), 4S (14.8V), or even higher. However, many essential components operate at lower voltages, such as 5V or 9V. A BEC steps down the voltage from the main battery and ensures that all connected components receive the correct power level. By integrating BEC into a FPV drone, it functions:

- Stable Flight Controller Operation

The flight controller (FC) is the central processing unit of the drone, managing stabilization, motor control, and sensor inputs. A BEC prevents voltage fluctuations, ensuring smooth operation and reducing the risk of crashes due to power instability.

- Reliable Power for FPV Cameras

FPV cameras require a steady voltage to avoid video signal noise or sudden blackouts. A BEC eliminates power spikes, which could interfere with video transmission and affect flight visibility.

- Consistent Power to Video Transmitters (VTX)

The video transmitter (VTX) sends live footage from the drone to the FPV goggles or monitor. Inconsistent power can cause signal drops, static, or overheating. A BEC delivers a clean, regulated voltage, improving video signal stability.

- Prevents Overheating and Component Damage

Directly connecting a high-voltage battery to low-voltage components can cause overheating and failure. A BEC protects these parts, extending their lifespan and reducing the chance of mid-flight failures.

Many modern flight controllers include an integrated BEC, simplifying power distribution. However, for higher power demands, external switching BECs (UBECs) provide better efficiency and handle larger current loads without overheating.

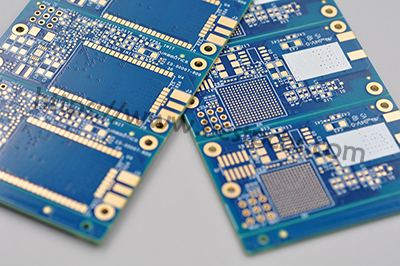

At Best Technology, we provide drone printed circuit boards with battery eliminator circuits. We have passed AS9100D certifications, and set a specialized QA system according to AS9100D, build up procedure to aim specifically at the prevention of problems and the elimination of root causes, provides complete traceability of material and detailed processing history for all products manufactured. If you are interested in the manufacturing of drone PCB with BECs, you are welcome to touch us for more details.

Tags: battery eliminator circuit, battery eliminator circuit drone, bec battery eliminator circuit