What is Press-Fit Technology?

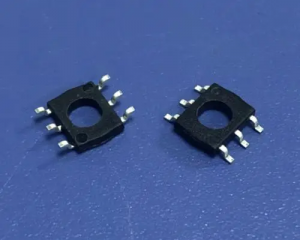

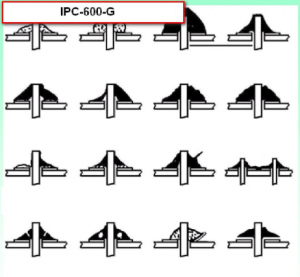

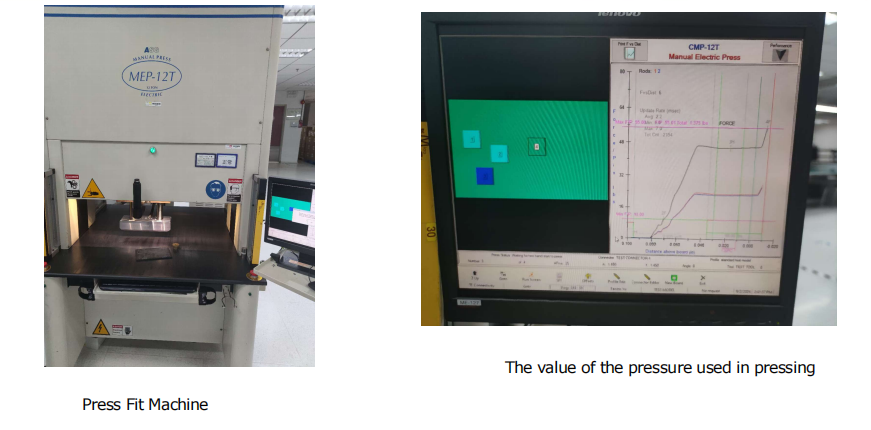

Press-Fit technology is a solderless connection method used to install connectors, pins, or other components into a PCB. The components have specially designed pins that are slightly larger than the PCB’s plated through-holes (PTH). These pins are pressed into the holes with sufficient force, creating a secure and reliable mechanical and electrical connection through compression.

The key feature of this technology is that it eliminates the need for soldering. Instead of using heat and solder to establish the connection, the mechanical force ensures that the contact between the pin and the wall of the hole is firm enough to create a stable electrical pathway. This method offers high durability and is especially useful in environments where temperature fluctuations, vibrations, or mechanical stress are present.

Advantages of Press-Fit Technology in SMT

1. No Heat Damage

Traditional soldering processes expose components to high temperatures, which can sometimes damage sensitive parts. Press-Fit technology avoids this by using a mechanical press to insert the pins, preserving the integrity of temperature-sensitive components.

2. High Reliability

The press-fit connection creates a strong and stable bond, even in challenging environments such as automotive and industrial applications. The mechanical compression between the pin and the hole ensures excellent electrical contact without the risk of thermal cycling or solder joint cracking over time.

3. Maintenance and Repair

One of the significant advantages of Press-Fit technology is its ease of repair. Since the connections are mechanical rather than soldered, they can be easily removed or replaced if needed without damaging the PCB or the component.

4. Environmental Benefits

By eliminating the need for solder and flux, press-fit technology is also a more environmentally friendly solution. This method reduces the use of hazardous materials and can help meet stricter environmental standards

Application of Press-Fit in SMT

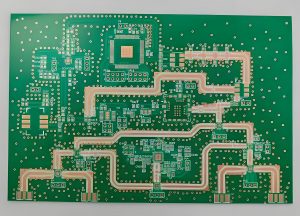

In our SMT assembly process, Press-Fit technology is typically applied to connectors and other components that require robust, high-density connections. This technology is particularly popular in automotive electronics, telecom infrastructure, medical devices, and other high-reliability sectors.

Press-Fit connectors are also ideal for multi-layer PCBs, where a strong and stable connection is essential across various layers of circuitry. By using this technology, we ensure that our products meet the highest standards of performance and durability, especially in critical applications where failure is not an option.

Press-Fit technology is a critical component of modern SMT assembly, providing a highly reliable, solderfree connection method. Its mechanical strength, ease of maintenance, and suitability for harsh environments make it a preferred choice for various high-demand applications. As electronics continue to advance, Press-Fit technology offers a robust and environmentally friendly solution to meet the needs of the industry

Tags: Press-Fit Technology, SMT