What is Fast Turn PCB?

Fast turn PCB refers to a process where printed circuit boards are manufactured in a much shorter time frame compared to the standard process. This expedited service is often used during the prototyping phase, where companies need to validate designs quickly before moving on to mass production. The process is designed to keep pace with the rapidly changing demands of industries like consumer electronics, automotive, aerospace, and telecommunications. Fast turn PCB prototypes are not just a luxury; they are often necessary to meet tight deadlines and ensure product success.

Advantages of Fast Turn PCB Prototypes

The most obvious benefit of fast turn PCB prototypes is speed. However, the advantages extend far beyond just saving time:

Quicker Fabricate Cycles: When a design change is necessary, waiting weeks for a new PCB is no longer acceptable. Fast turn PCB allows you to make design tweaks and receive updated prototypes in a matter of days. This reduces downtime and lets your team stay productive.

Early Issue Detection: When you get your prototype faster, it means you can start testing sooner. This leads to earlier detection of potential issues, allowing you to resolve them before the design moves into mass production. Catching problems early minimizes the risk of costly errors.

Faster Time to Market: In industries where technology changes quickly, getting a product to market before your competitors is vital. Fast turn PCBs enable faster product development, giving you an edge in launching new and innovative products ahead of your competitors.

Design Flexibility: Quick prototyping means youâre free to experiment with different designs without losing valuable time. Whether youâre optimizing a layout or testing new materials, fast turn PCBs provide the flexibility you need to find the perfect solution.

Increased Customer Confidence: For those working with clients, the ability to quickly provide prototypes can enhance customer relationships. When you demonstrate speed and reliability, clients gain confidence in your ability to deliver high-quality final products.

Our Quick Turnaround PCB Services Include

- PCB Prototype Assembly

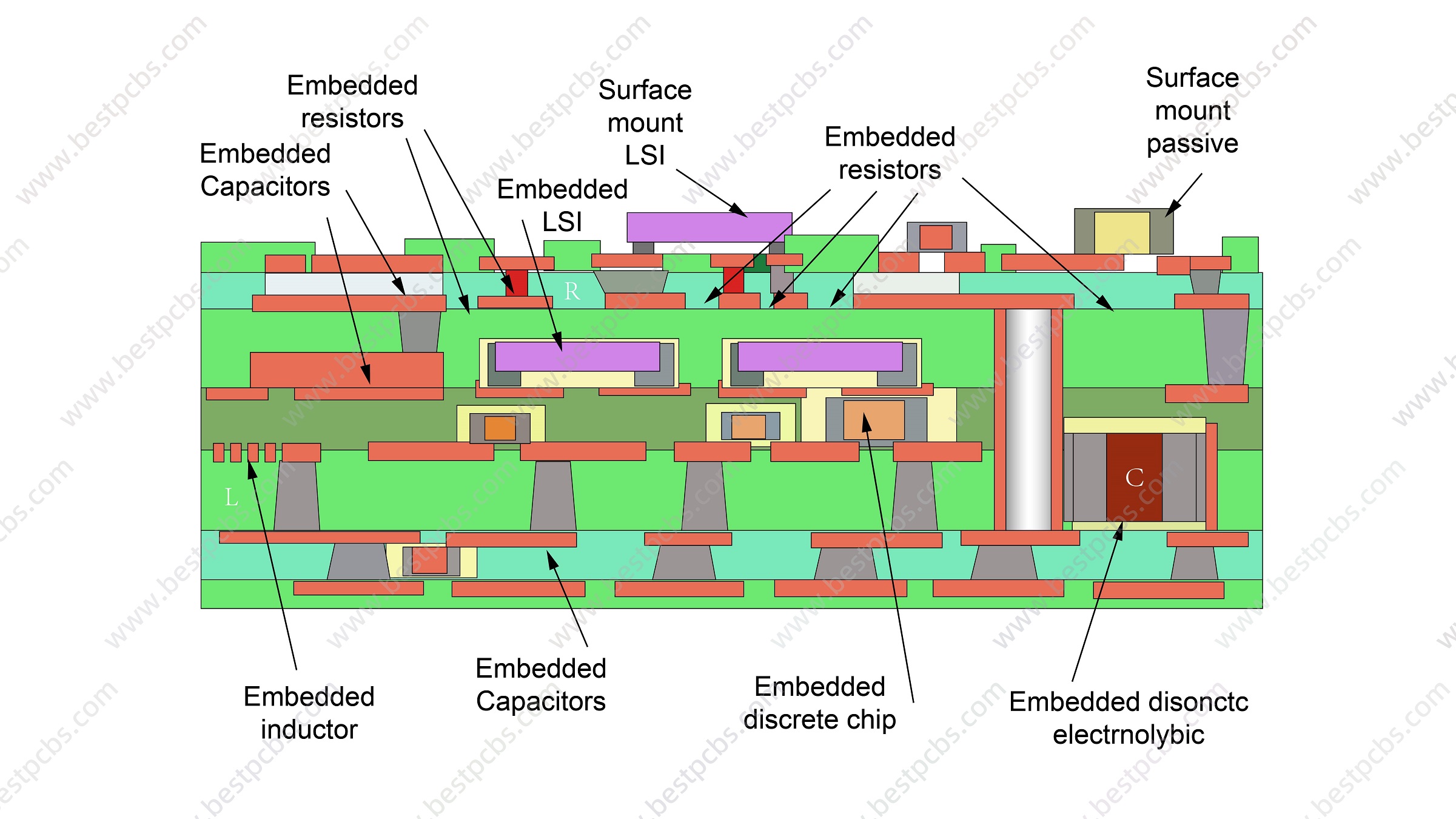

- Rigid-Flex PCBs

- HDI PCB Fabrication

- Flexible PCBs

- PTFE Teflon PCBs

- Heavy-copper PCBs & Busbar PCB

- Metal Core PCBs

- BGA Pad pitch down to 0.15mm

- Cavity Process

- Back drill Process

- IC substrate

- Extra thin PCBs

- Ceramic PCBs

- Drone PCB/Bluetooth PCB

- High speed PCB

- RF PCB

- High Tg PCB

- Impedance control PCB

Best Technologyâs Typical Turnaround Lead Time for Fast Turn PCB

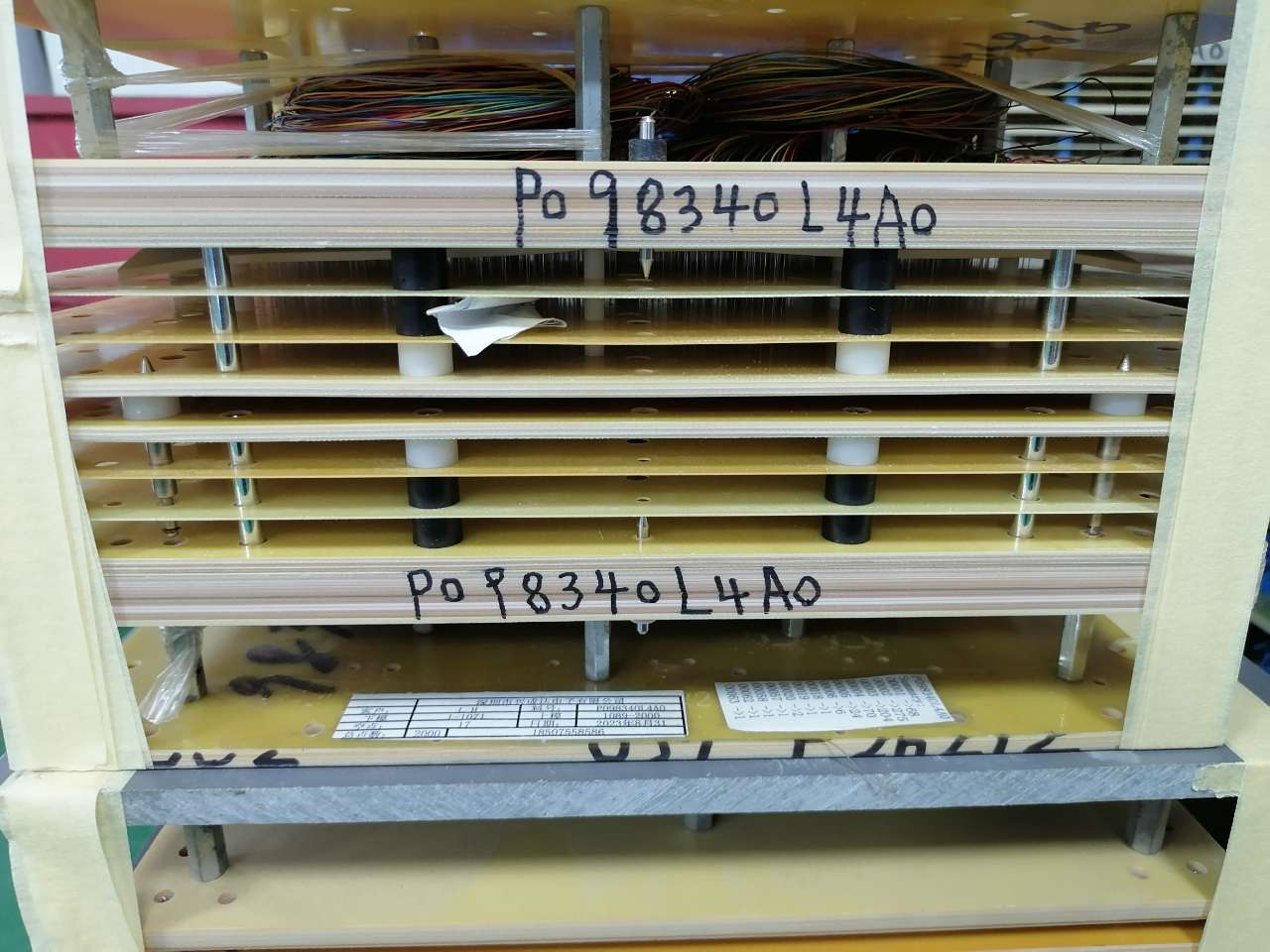

Our commitment to speed is reflected in our turnaround times. For basic, single-layer PCBs, we can often deliver in as little as 24 hours. More complex designs, such as multi-layer boards or rigid-flex PCBs, may take 3 to 5 days. No matter the complexity of your design, we work diligently to meet your timeline without compromising quality. More details please see below chart:

| Prototype (<m2) | Layers | Normal Service | Expedited Service |

| FR4 PCB | 1 Layer | 1-2 Days | 24 Hours |

| 2 Layers | 1-2 Days | 24 Hours | |

| 4 Layers | 2-3 Days | 48 Hours | |

| 6 Layers | 3-4 Days | 72 Hours | |

| 8 Layers | 6-8 Days | 72-96 Hours | |

| 10 Layers | 10-12 Days | 120-168 Hours | |

| HDI (1+N+1, 2+N+2) | 2.5-3.5 Weeks | TBD |

This fast pace doesnât mean we cut corners. Every PCB prototype undergoes rigorous testing to ensure it meets the highest quality standards. From initial design review to final inspection, we ensure that your prototype will perform exactly as expected.

Custom Quote for Fast Turn PCB Prototypes

If you have specific requirements or a tight deadline, we offer custom quotes tailored to your project. Simply provide us with your design files, including details like layer count, material type, and any specific finishing options, and weâll give you a competitive quote with a guaranteed delivery date. Our team is ready to work with you to find the best solution for your projectâs unique needs.

Factors That Affect Lead Time of PCB Prototypes

While we strive to meet tight deadlines, there are several factors that can influence the lead time for your PCB prototype:

- Design Complexity

You must know, the more layers and components your PCB requires, the longer it may take to manufacture. Single-layer boards can be produced quickly, while multi-layer designs or HDI boards typically take more time.

- Material Availability

Certain materials, like high-frequency laminates or specific copper weights, may not always be immediately available. If your design requires specialized materials, itâs best to check availability early with Best Team in the process to avoid delays.

- Finishing Options

Different surface finishes require different processing times. For example, ENIG or immersion silver might take longer than standard HASL finishes. Itâs important to choose a finish that fits both your timeline and your design needs.

- Quality Assurance Testing

If your design requires additional testing or certifications, this can add time to the process. However, testing is critical to ensure that your prototype meets all necessary performance and safety standards. Best Technology always perform strict testing to control the PCB quality.

Prototype PCB Assembly Services

Beyond manufacturing the PCB itself, we also offer prototype assembly services. This means that once your PCB is produced, we can quickly assemble all the necessary components, giving you a fully functional prototype in a short amount of time. Our assembly services include both surface-mount (SMT) and through-hole technology (THT) processes.

By combining fast turn PCB production with our assembly services, you save valuable time and resources, as you donât need to coordinate between multiple vendors. We handle everything in-house, ensuring a smooth process from start to finish.

Choosing the Right Fast Turn PCB Prototype Manufacturer

When it comes to selecting a fast turn PCB manufacturer, you want to partner with a company that not only offers speed but also reliability and quality. Rushing a prototype through the production process without the proper quality checks can lead to poor performance and wasted time.

At Best Technology, we are proud of our reputation for delivering high-quality prototypes quickly. Our team of experienced engineers and technicians ensures that every prototype is carefully reviewed and tested before it leaves our facility. We use only the highest-quality materials and components, so you can trust that your prototype will perform as expected.

Additionally, our customer service team is always available to answer your questions, offer technical support, and provide updates on your projectâs progress.

Why Should You Choose Best Technology as Your Preferred Partner?

At Best Technology, we donât just manufacture PCBs â we create solutions. Our fast turn PCB services are designed to help you move through the product development process faster, without compromising on quality. We offer:

1. With turnaround times as fast as 24 hours for simple designs, we help you meet even the most demanding deadlines.

2. Every prototype we produce undergoes strict quality control and it can meet your exact specifications.

3. We can accommodate a wide range of PCB types and materials, including flexible PCBs, HDI boards, and high-frequency designs.

4. Our team is dedicated to helping you one-time succeed. From design review to final delivery, weâre here to support you every step of the way.