What is a SMT stencil printer? SMT stencil printer is a key equipment used in surface mount technology (SMT) production, mainly used to accurately print solder paste or conductive glue onto PCB pads. It ensures that solder paste can be accurately deposited at the specified position through high-precision stencil alignment and printing process, thus providing a reliable foundation for subsequent electronic component placement.

What is a stencil print?

A stencil print refers to the technique of transferring a design onto a surface using a template or screen. The process involves applying ink or paste through cutouts in the stencil to create an image, text, or design.

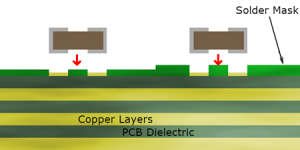

Stencil printing is widely used for everything from fabric printing to PCB assembly. In electronics, the stencil acts as a mask to allow solder paste to only apply to certain areas of the board, ensuring accuracy and reliability.

In PCB manufacturing, the stencil provides an efficient way to apply solder paste to the pads or soldering points on the board. Once the solder paste is applied, the PCB is ready for components to be placed, which are later soldered in the reflow oven or via hand soldering.

What is a SMT stencil?

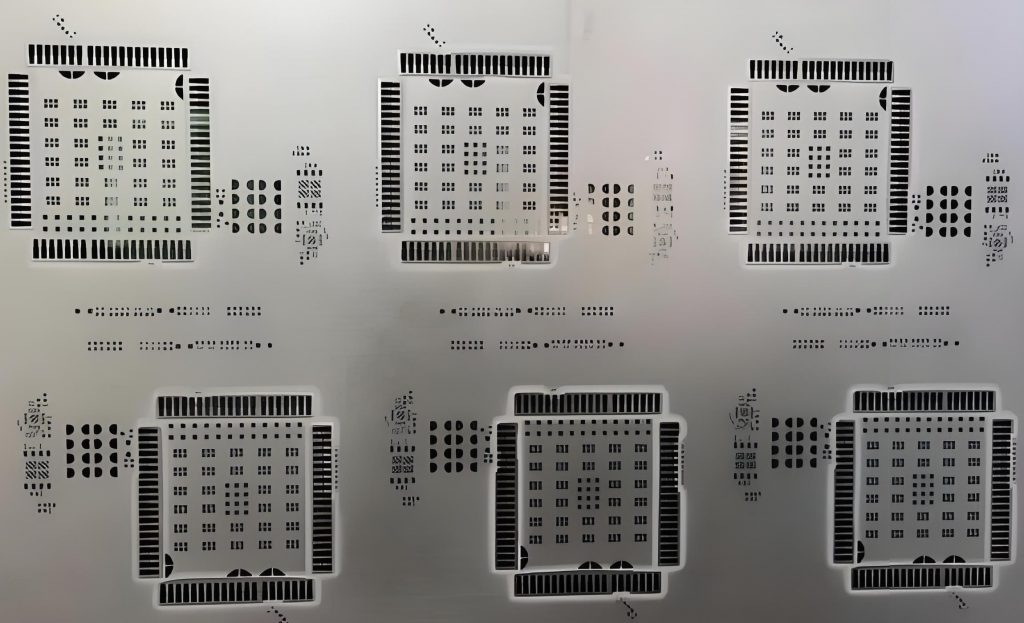

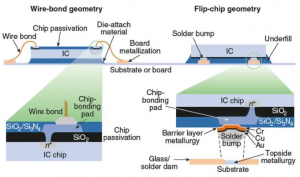

SMT (Surface-Mount Technology) stencils are specifically designed for the printing of solder paste onto PCBs, where surface-mount components (SMCs) will later be placed. These stencils are usually made from stainless steel or other materials that offer both precision and durability.

The SMT stencil works as a template to apply the precise amount of solder paste on the board’s pads, ensuring accurate soldering for all surface-mount components.

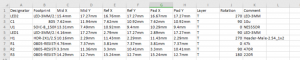

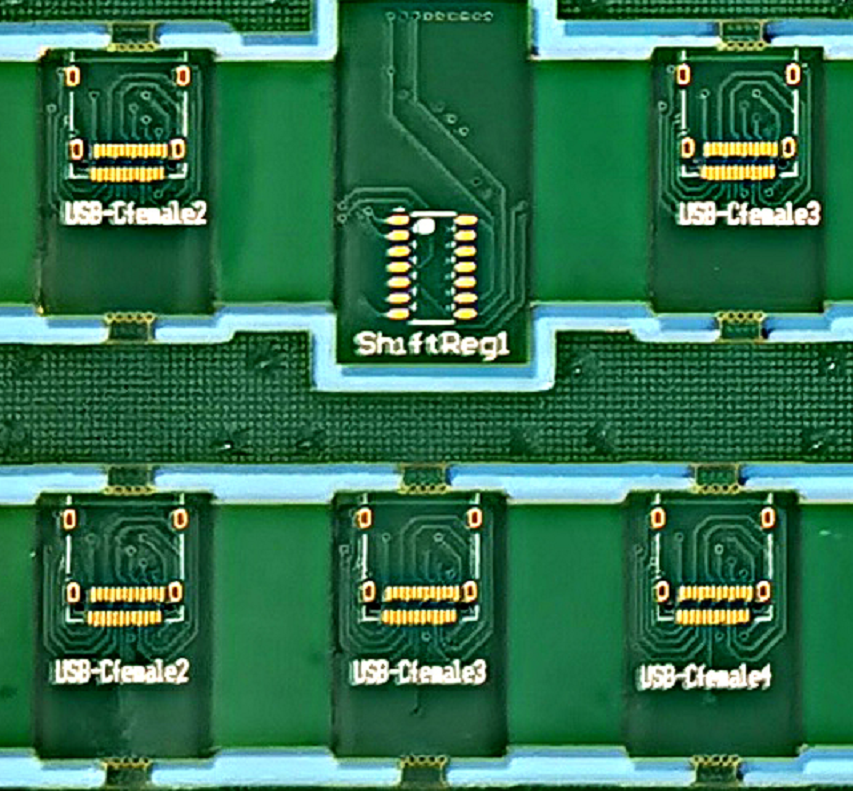

The stencil itself has fine holes or apertures precisely cut to match the footprint of the pads where components will be mounted. The size and shape of these holes depend on the component’s size and the required solder paste volume for that particular PCB design.

What is a PCB stencil printer?

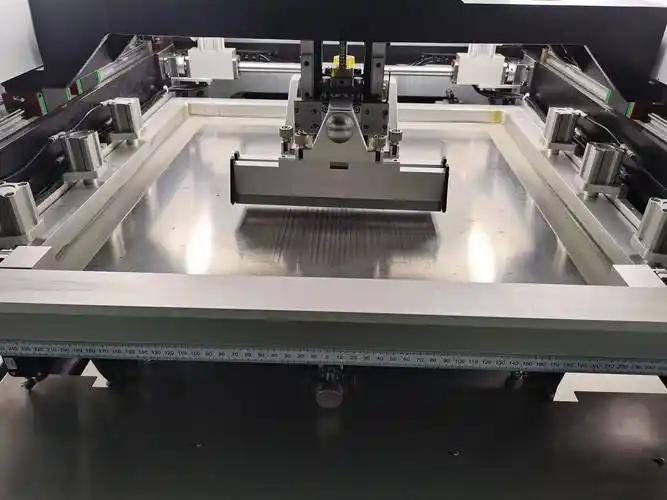

A PCB stencil printer is an automated machine used to apply solder paste to PCBs using SMT stencils. This printer typically involves a printing platform, stencil holder, squeegee, and a precise system for aligning the stencil to the board.

The printer’s main function is to ensure uniform solder paste deposition onto the PCB pads, which is essential for making strong electrical connections and ensuring reliable performance.

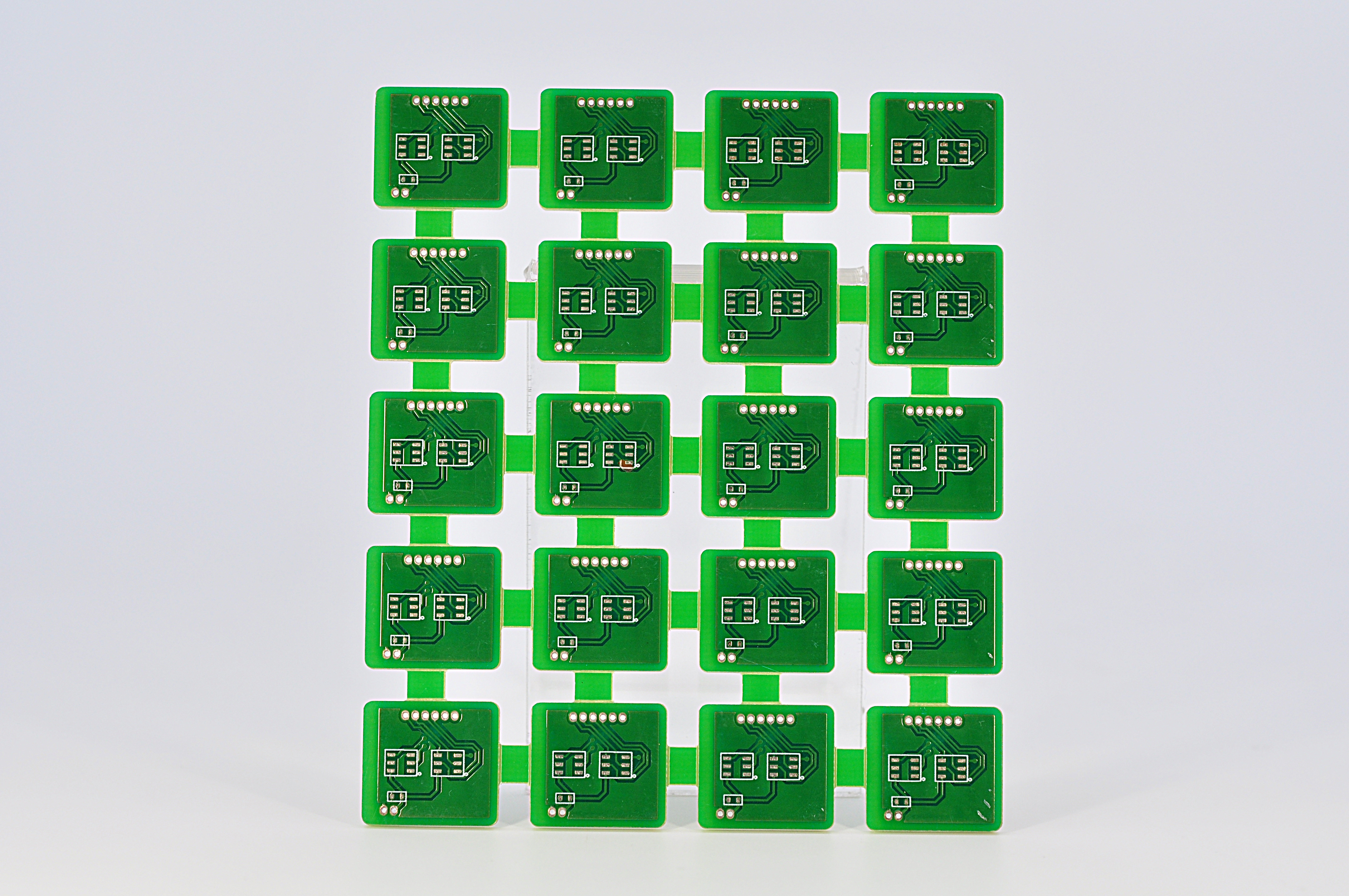

These printers are designed to handle high-volume production efficiently, and they are equipped with features to ensure accuracy and speed, minimizing human error and reducing production time.

Stencil printers are critical for achieving high-quality PCB prototypes, ensuring that the solder paste is evenly spread and properly aligned with the pads.

How to make screen printing stencils?

Creating screen printing stencils for PCBs requires a high level of precision, as these stencils need to be made with exact dimensions and placement for optimal solder paste application.

- Design Creation: The first step involves creating a precise design that matches the PCB layout. This includes the exact pad dimensions and locations where solder paste is to be applied.

- Stencil Material Selection: A suitable material, often stainless steel or nickel, is chosen for its ability to resist corrosion and its ability to hold fine details.

- Laser Cutting or Etching: The stencil material is then cut or etched using lasers to form the holes in the stencil. The size of the holes directly correlates with the size of the pads and components.

- Coating and Cleaning: Once the stencil is cut, it is often coated to prevent solder paste from sticking where it shouldn’t. Afterward, it is cleaned to ensure no contaminants that could affect the printing process.

- Inspection: After the stencil is made, it’s inspected under a microscope to ensure that the holes are properly aligned and sized to apply the correct amount of solder paste.

How do SMT Stencil Printers work?

SMT stencil printers operate through a combination of automation and precision mechanics.

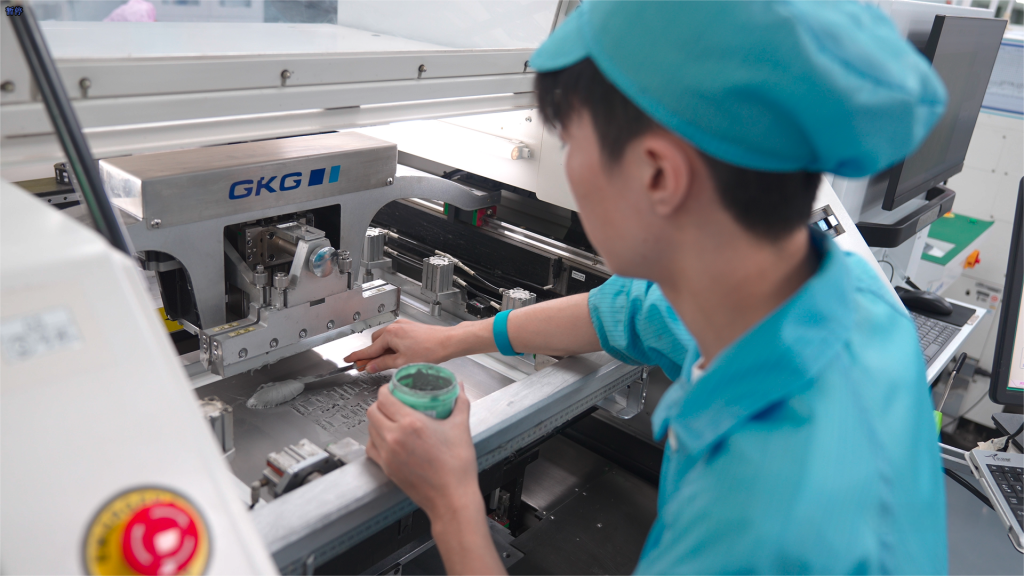

- Board Placement: The PCB is first placed onto the printer’s platform, usually with an automated feeder system for high-volume production.

- Stencil Alignment: The SMT stencil is then carefully aligned over the board’s pads using a vision system or manual adjustment. This ensures that the stencil’s holes line up precisely with the pads on the PCB.

- Solder Paste Application: A squeegee is used to spread solder paste evenly over the stencil. The paste flows through the stencil holes onto the pads of the PCB. This process requires careful control of the squeegee pressure to ensure the paste is applied uniformly.

- Removal of Excess Paste: After the solder paste is applied, the stencil is lifted off the PCB, leaving behind a fine layer of solder paste on the pads. The PCB is then ready for the next step—component placement.

- Curing: The printed PCB is often passed through a reflow oven to cure the solder paste, bonding the components to the PCB securely.

Why use a PCB stencil?

Using a PCB stencil is important for several reasons:

- Precision: It ensures that the correct amount of solder paste is applied to each pad, reducing the risk of faulty joints or shorts.

- Consistency: Since the stencil is a reusable tool, it offers high repeatability. Every PCB in a batch receives the same quality of paste application.

- Speed: Stencil printing is fast and can handle high volumes of production, making it ideal for industrial applications.

- Cost-Effective: Compared to other methods, stencil printing is relatively inexpensive and doesn’t require as much time to set up.

- Quality: Accurate paste application helps ensure that components are soldered properly, improving the overall quality and reliability of the PCB.

What are the different types of PCB stencils?

There are several types of PCB stencils designed for different types of applications. The most common types include:

- Laser-cut Stencils: These stencils are made by cutting the material with a laser to produce precise apertures. They are highly accurate and suitable for high-density boards.

- Electroformed Stencils: These are made by electroplating a stencil design onto a metal sheet. They are more durable and provide consistent paste deposits, especially for fine-pitch components.

- Engraved Stencils: These are stencils that have been etched or engraved to create holes. While less commonly used than laser-cut or electroformed stencils, they still find applications in certain scenarios.

- Fine-pitch Stencils: These stencils are used for PCBs that contain fine-pitch components, requiring very small apertures to apply solder paste precisely.

Conclusion:

In conclusion, SMT stencil printers are a vital part of the PCB manufacturing process, ensuring the precise application of solder paste.

At Best Technology, we specialize in advanced PCB manufacturing and prototype services, offering high-quality stencils and printing equipment for all your PCB needs. Email: sales@bestpcbs.com

Tags: stencil printer, stencil printing, stencil screen printing