Hardware designers requiring√ā¬†turnkey PCB assembly services usually face tremendous obstacles for their need of prototyping and small batches. Large companies with huge inventory needs and long delivery horizons can wait for days or weeks for a proposal, while accepting large minimum quantity requirements. For them, delays associated with overseas manufacturing are no big deal. However, these conditions are simply unacceptable for small industries, engineers, makers, and entrepreneurs.

Best Practices of PCB Assembly Vendor

Selecting the professional PCB assembly company at the beginning determines the success of a project. Therefore, picking the right PCB assembly services provider becomes a highly important decision to be made. One must watch out for those offering very low prices, but subsequently are unable to provide the services, record of accomplishment, infrastructure, and technology to back up their promises. Rather, one must insist the√ā¬†PCB assembly services√ā¬†have the essential features, offer the services, and follow business practices such as:

Instant Quotations

Waiting for days or weeks and trading a bunch of emails only to find out the cost of a√ā¬†PCB assembly, is not only a waste of time, it is expensive. A vendor offering instant, online quotations is always preferable. In general, although all vendors will start by sending a quotation for the project, therefore, selecting one who gets the process off painlessly is advisable. Moreover, selecting the vendor who gives an estimate in terms of quantity offtake√ā¬†helps in determining capital needs and product prices.

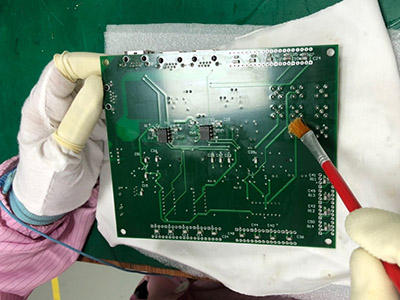

Prototyping Requirements

Most customers, before placing their order, want to make√ā¬†sure their PCB works exactly as intended. This may require making a few iterations to perfect the design. So far, prototyping was a big challenge under the old manufacturing model. However,√ā¬†Best Technology is√ā¬†willing to handle even a single quantity.

Minimum Order Requirements

Earlier,√ā¬†PCB assembly services√ā¬†were unable to accept production runs of small quantities. Older technology did not allow profitability in smaller numbers, which turned out to be a major challenge for everyone. However, use of modern technologies allows easy combination of small orders into larger ones, while switching from one task to another is no longer a major hurdle. Therefore, professional PCB assembly providers accept all types of order, regardless of quantity, and execute them at reasonable prices.

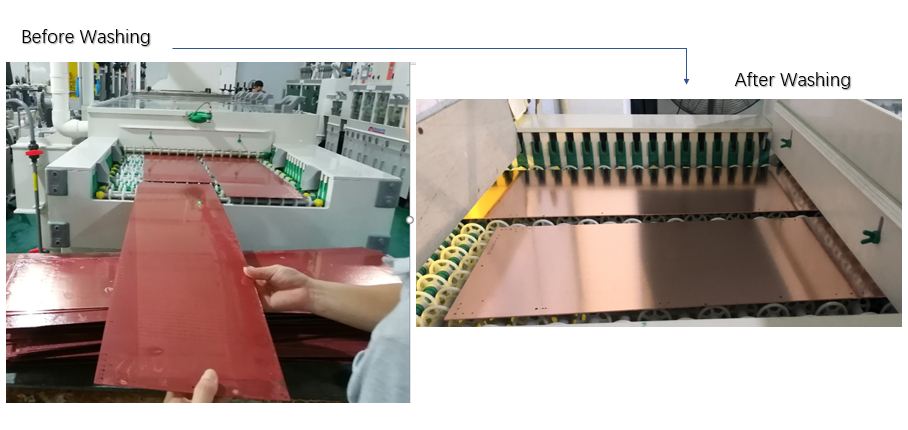

Seamless Manufacturing

With advancement in PCB assembly technologies, it is no longer necessary to track multiple vendors and suffer long lead times. A modern PCB assembly solution such as the Best Technology, offers a platform to resolve any assembly problems, online and from anywhere√ā¬†and takes over the sourcing, purchasing, and assembly of the components. With this approach, the product√ā¬†can be expected√ā¬†to be available in days.

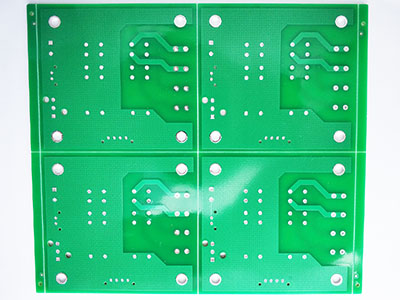

Looking Beyond PCB Assembly

The PCB happens to be only the first step of the many for most inventions and products and PCB Assembly is an especially non-negligible√ā¬†process. Quality can only be assured by finding a reliable company.

Tags: PCB Assembly, PCB Assembly FAB