What is the difference between electroless nickel and electroplating? In PCB, chemical nickel plating relies on redox reaction, does not require external power supply, has good uniformity, strong bonding, and good solderability, but has slow deposition speed, difficult thickness control, and high cost. It is suitable for PCBs with high density, flexibility, aerospace and other high requirements. Electroplating relies on external current, has fast deposition speed, strong thickness controllability, and relatively low cost. It is more suitable for high-power, large-scale production and PCBs with special performance requirements.

“PCB finition nickel or electrolytiqueâ” refers to the finishing process applied to printed circuit boards (PCBs) using nickel or electrolytic techniques.

This finishing helps enhance the durability, conductivity, and overall performance of the PCB by providing a smooth, corrosion-resistant surface. Nickel plating, often applied through electroplating, is commonly used to improve solderability and enhance the reliability of connections.

What is PCB electroplating?

PCB electroplating refers to the process of depositing metal on the surface of a printed circuit board (PCB) through electrolysis to form a uniform, dense and well-bonded metal coating. This process is crucial in PCB production and directly affects the integration, conductivity, signal transmission and function of the PCB.

Electroplating is the process of depositing a metal or alloy layer on the surface of a substrate through electrolysis. Specifically, PCB electroplating is the process of depositing metal on the surface of a PCB using electric current electrolysis to form a metal coating. This process does not include chemical copper plating, but is achieved through electrolysis.

What material is used in PCB plating?

The materials commonly used in PCB electroplating include metals such as copper, nickel, gold, silver, as well as electroplating solutions and various additives. These materials play different roles in the electroplating process and jointly ensure the quality and stability of the electroplated layer.

Main electroplating materials and their functions

- 1. Copper: As the basic conductive layer of the circuit board, it has good conductivity and solderability.

- 2. Nickel: As a barrier layer, it can effectively prevent the copper layer from oxidizing, while improving the hardness and wear resistance of the plating.

- 3. Gold: Due to its excellent conductivity and corrosion resistance, it is often used as a contact surface plating layer to improve the reliability and life of the circuit board.

- 4. Silver: Although it has excellent conductivity, it is expensive and easy to oxidize, and is mostly used in special occasions.

What is the difference between electroless nickel and electroplating?

The main differences between PCB chemical nickel plating and electroplating nickel are the principles, process steps, application areas, plating quality and environmental protection.

1. Principle and process steps

- Electroplating nickel: Using an external current, a nickel layer is deposited on a conductive object (cathode) through electrolysis. The anode is usually pure nickel, and the current passes through the nickel salt (such as nickel sulfate, nickel chloride, etc.) in the plating solution to form a nickel layer on the surface of the object.

- Chemical nickel plating: No external current is required, but a chemical nickel plating solution is used to reduce nickel ions to metallic nickel in the solution, which is deposited on the surface of the object that has been specially treated, that is, catalyzed, to form a nickel plating layer.

2. Application areas and plating quality

- Electroplating nickel: It is widely used on metal parts that need to enhance conductivity, wear resistance or appearance decoration. The thickness of the electroplated nickel layer is easy to control, which can be achieved by adjusting the current and plating time, and a high-gloss nickel layer can be obtained.

- Chemical nickel plating: It is suitable for nickel plating of complex shapes or non-conductive materials. The uniformity of the chemically plated nickel layer is good, and even objects with complex geometric shapes can obtain a uniform thickness of the plating.

3. Environmental protection and cost

- Electroplating nickel: Due to the need for external current and complex equipment, the cost is relatively high.

- Chemical nickel plating: Most of the additives used are food grade, and no harmful substances such as lead, cadmium, and cyanide are used, so it is more environmentally friendly.

4. Binding strength and color

- Binding strength: The binding strength of chemical nickel plating is generally higher than that of electroplated nickel.

- Color: Currently, chemical nickel plating technology only has one color of pure nickel-phosphorus alloy on the market, while electroplating can achieve multiple colors.

What are the advantages of electroless plating over electroplating?

PCB chemical nickel plating has the following advantages over electroplating:

- All-over plating ability: The chemical nickel plating layer has a higher all-over plating ability. As long as the solute exchange is sufficient in the place where the plating solution can be immersed, the chemical nickel plating layer will be very uniform. The electroplating layer will have a weaker all-over plating ability than chemical nickel plating due to the influence of current density.

- Applicability: The chemical nickel plating process can plate the entire surface of any shape of workpiece, and there is no special requirement for the shape of the workpiece, and it is more universal.

- Binding strength and corrosion resistance: The binding strength of the chemical nickel plating layer is generally higher than that of the electroplated nickel layer, which affects the later corrosion resistance and acid and alkali resistance of the workpiece. Chemical nickel plating performs better in terms of corrosion resistance.

- Production efficiency and cost: The generation speed of chemical nickel plating is faster than that of electroplating, which greatly improves production efficiency and saves energy and manpower.

What are the disadvantages of electroless nickel plating?

The main disadvantages of electroless nickel plating on PCB include:

- High cost: Compared with traditional surface treatment technology, chemical nickel plating requires professional equipment and technical investment, resulting in high cost.

- Coating thickness limit: Theoretically, the thickness of the coating should be unlimited, but in actual operation, the thickness of the coating is limited and it is difficult to plate thick.

- Slow deposition rate: The deposition rate of chemical nickel plating is slow, and it takes a long time to complete the coating.

- Poor brightness: The brightness of chemical nickel plating is worse than that of decorative electroplating.

- Environmental impact: During the treatment process, waste liquid containing difficult-to-degrade chemicals will be generated. It takes a lot of manpower and material resources to treat these waste liquids, which has a certain impact on the environment.

- Poor plating solution stability: The plating solution of chemical nickel plating has poor stability, complex composition, troublesome maintenance, adjustment and regeneration, and high material cost.

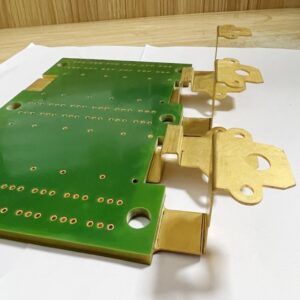

What is the standard PCB plating?

The standards for PCB plating mainly include two main standards: IPC-4552 and IPC-6012. The IPC-4552 standard specifies two main forms of gold plating: hard gold salt plating and soft gold salt plating. For hard gold salt plating, the minimum thickness is 1.27Îźm and the maximum thickness is 2.54Îźm; for soft gold salt plating, the minimum thickness is 0.23-0.76Îźm and the maximum thickness is 1.91Îźm.

- Material standard: The nickel purity of the nickel plating is usually high, generally above 99%. High-purity nickel can ensure the basic properties of the plating, such as good corrosion resistance and stability.

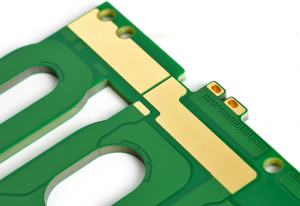

- Thickness standard: When nickel is used as a protective plating (such as under the gold plating), the thickness is generally between 3-10Îźm. It can effectively resist the erosion of the underlying metal by the external environment, ensuring that the PCB maintains good performance during long-term use.

- Appearance standard: The surface of the nickel plating should have a uniform color, generally a slightly shiny silver-white. If the color is uneven, it may indicate inconsistent plating thickness or uneven plating solution composition, which may affect its corrosion resistance and decorative properties.

- Smoothness requirements: The surface of the plating should be relatively smooth and should not have obvious roughness. At the microscopic level, its surface roughness must meet certain standards to avoid affecting subsequent processing technology and electrical performance. At the same time, the surface should not have obvious pits, protrusions, pinholes and other defects.

- Plating adhesion: Commonly used tape or cross-grid test method, the general electronics industry is qualified if the shedding area does not exceed 5%, and the high reliability industry has stricter requirements, not exceeding 1%.

How durable is electroless nickel plating?

The durability of PCB chemical nickel plating is mainly reflected in its hardness, wear resistance, corrosion resistance and bonding strength.

The hardness of the chemical nickel plating layer is usually high, generally 400-700HV. After proper heat treatment, the hardness can be further increased to approach or even exceed the hardness of the chromium plating layer, so it has good wear resistance.

In addition, the chemical nickel plating layer has a low porosity and easy passivation of the plating surface, showing high corrosion resistance, especially in media such as acid, alkali, salt, ammonia and seawater. Its corrosion resistance is even better than that of stainless steel.

The bonding force between the chemical nickel plating layer and the substrate is generally high, which helps to maintain the integrity and stability of the plating layer during long-term use.

How long does nickel electroplating last?

The service life of PCB nickel electroplating mainly depends on the use environment and maintenance. Specifically, the replacement cycle of the nickel electroplating plate is not fixed, but varies according to the use environment and conditions.

The main factors affecting the service life of the nickel electroplating plate include:

- Wear degree: The nickel electroplating plate will gradually wear due to friction during use. When the surface wear degree exceeds 30%, the protection performance will drop significantly, and replacement should be considered at this time.

- Surface scratches: If visible scratches appear on the surface of the nickel electroplating plate, especially when the scratch depth exceeds 1mm, it will not only affect the appearance, but also may reduce its corrosion resistance, and it needs to be replaced in time.

- Oxidation and rust: In a humid or corrosive environment, the nickel electroplating plate is prone to oxidation and rust. When the surface is oxidized or rusted too heavily, the protective effect will be greatly reduced, and it should be replaced at this time.

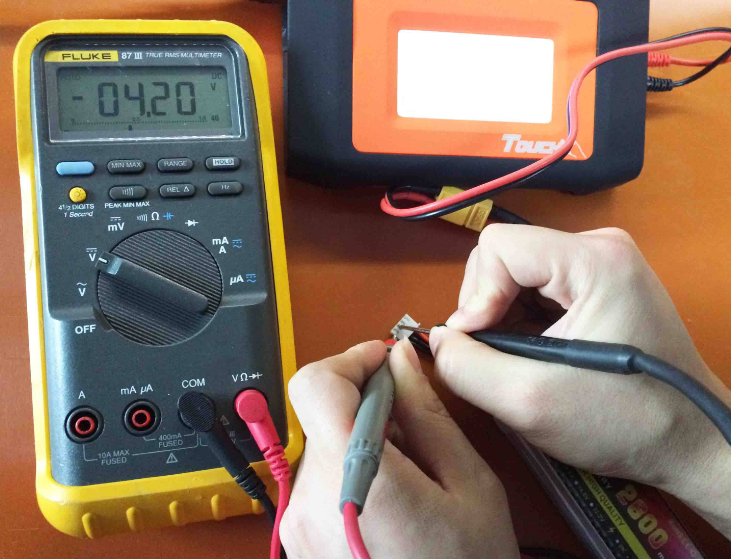

What voltage is needed for nickel electroplating?

The voltage required for PCB nickel electroplating is generally between 1.5 and 6 volts. However, this varies depending on many factors. In actual operation, the selection of the appropriate voltage value depends on the specific electroplating needs and conditions.

First, a basic voltage range needs to be determined based on the composition and properties of the electroplating solution. Then, the optimal voltage value is found through experiments and adjustments to obtain the desired electroplating layer thickness, uniformity and quality.

In addition, other factors such as current density and temperature need to be considered for the effect of electroplating. Generally, increasing the current density or raising the temperature can speed up the electroplating speed, but it may also have an adverse effect on the quality of the electroplating layer. Therefore, when selecting the voltage value, various factors need to be considered comprehensively to achieve the best electroplating effect.

In summary, chemical nickel plating and electroplating each have their own advantages and disadvantages in PCB manufacturing, and the appropriate surface treatment method should be selected based on specific application requirements and cost considerations.