What is Thermal Conductivity?

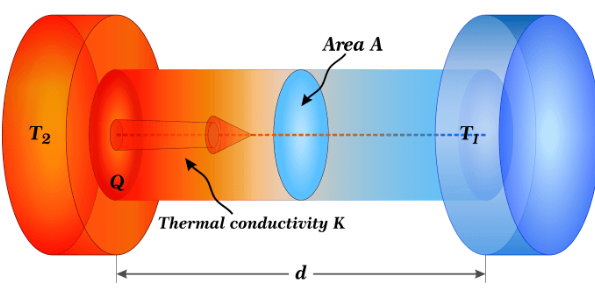

Thermal conductivity refers to a material’s ability to conduct heat. It’s a physical property that indicates how easily heat can pass through a substance when there is a temperature difference. In scientific terms, thermal conductivity is measured in watts per meter-kelvin (W/m·K), describing how much heat (in watts) is transferred through a material for every meter of thickness when there’s a one-degree temperature difference across it.

For ceramic materials, thermal conductivity plays a pivotal role in determining their usability in various industrial and electronic applications. Materials with high thermal conductivity can transfer heat quickly, so it is important in situations where heat must be dissipated rapidly to avoid damage to components, like in electronics or aerospace industries. On the other hand, materials with low thermal conductivity are used for thermal insulation, preventing unwanted heat transfer in applications like kiln linings or fireproofing.

Do Ceramic Materials Have High Thermal Conductivity?

Ceramic materials are generally known for their thermal insulation properties, meaning they typically have low thermal conductivity. However, not all ceramics are insulators. There are a few exceptions with significantly higher thermal conductivity, making them valuable for heat-dissipating applications.

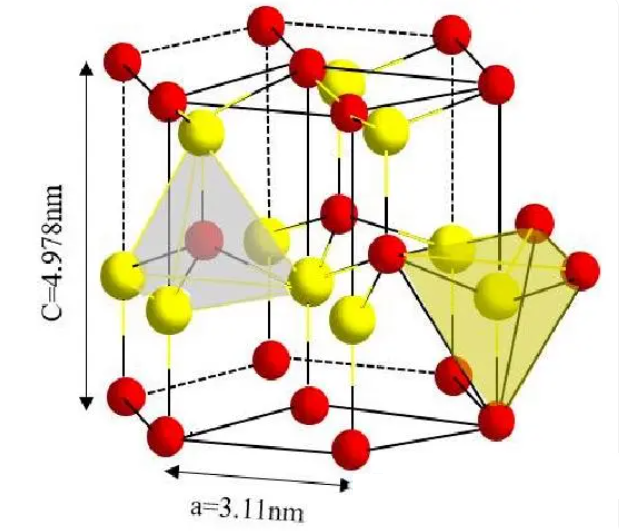

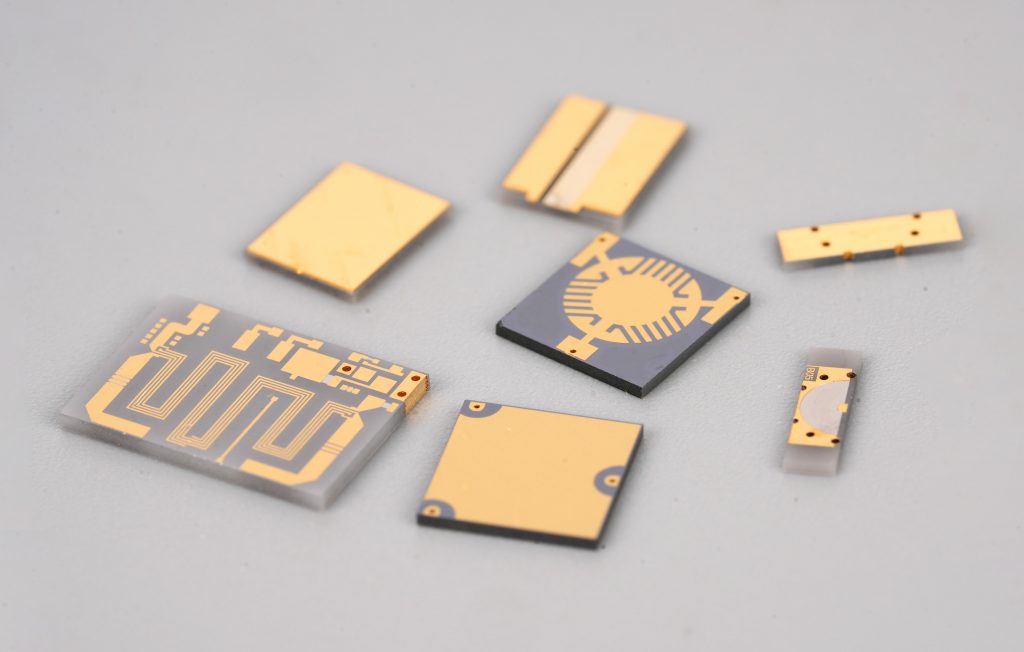

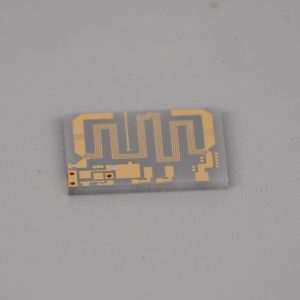

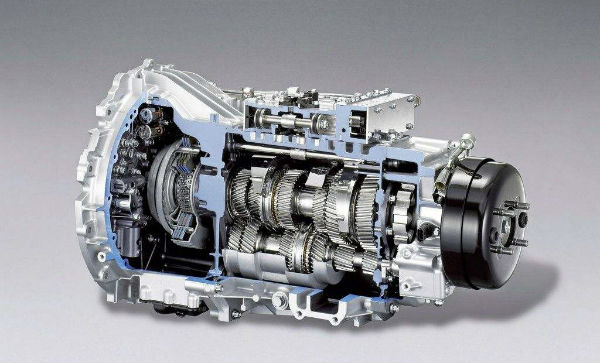

Traditional ceramics such as alumina and zirconia are typically poor conductors of heat due to their atomic structure, which restricts the movement of heat. However, advanced ceramics like aluminum nitride (AlN) and silicon carbide (SiC) exhibit impressive levels of thermal conductivity. These materials are increasingly being used in industries like electronics, aerospace, and automotive manufacturing, where managing heat efficiently is critical to the performance and safety of equipment.

High thermal conductivity ceramics, though less common, have opened new avenues for using ceramic materials in areas where heat transfer was traditionally a limiting factor. So, while most ceramics are not known for high thermal conductivity, advancements in ceramic technology have led to the development of high-performance materials that challenge this generalization.

Why is Thermal Conductivity Important for Ceramic Materials?

Thermal conductivity in ceramics is a key factor that dictates where and how these materials can be used. There are several reasons why thermal conductivity matters for ceramic materials:

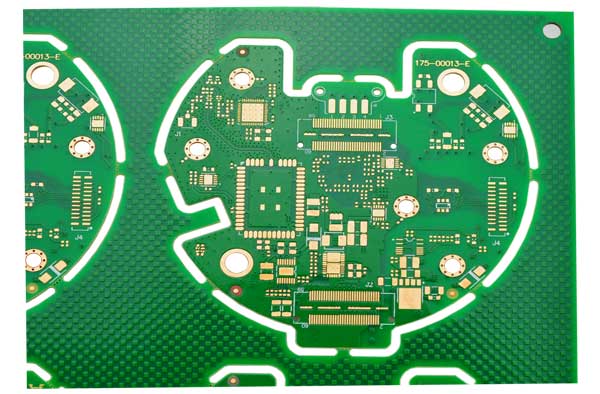

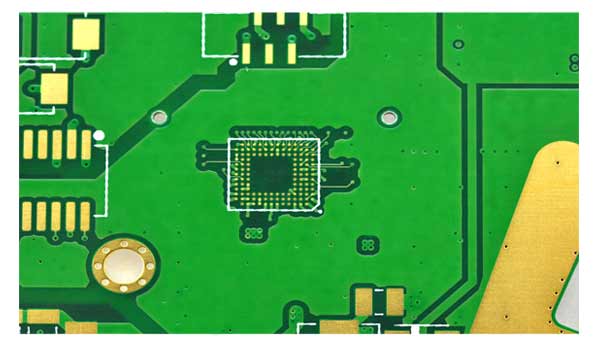

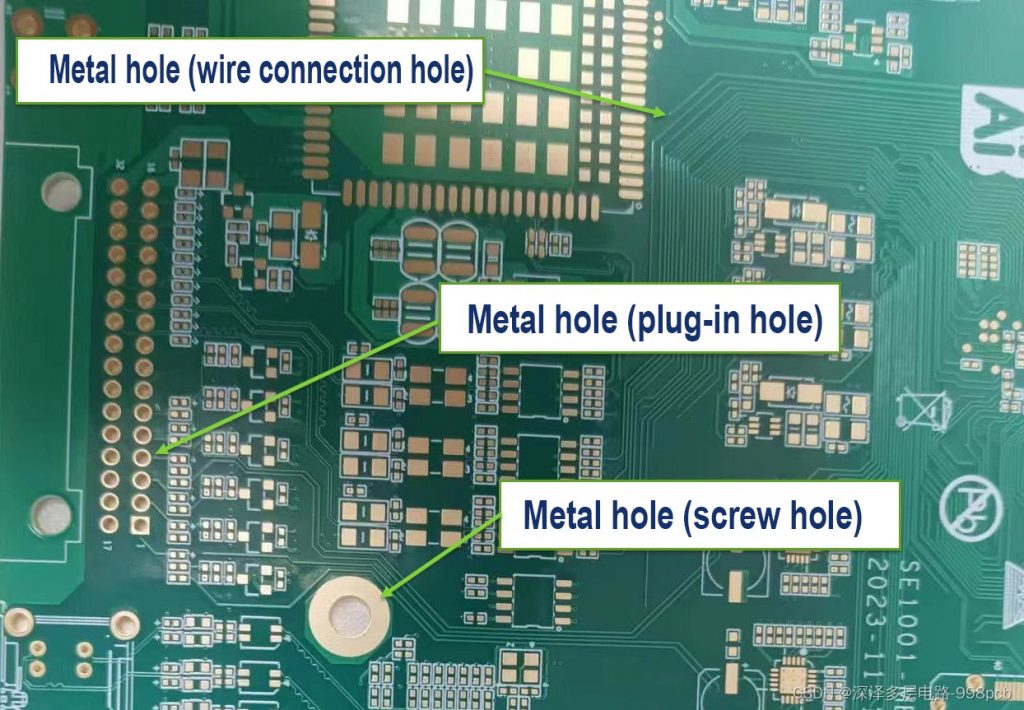

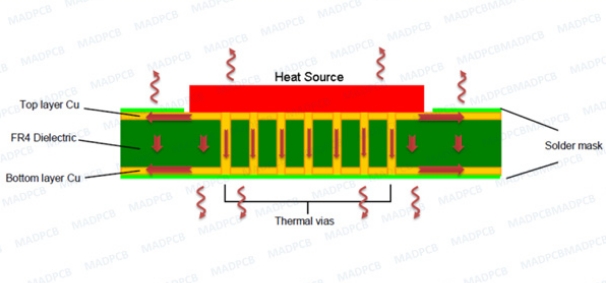

Heat Management in Electronics

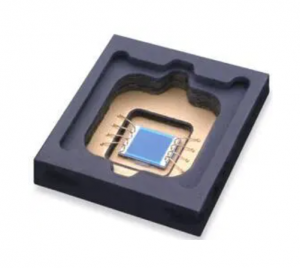

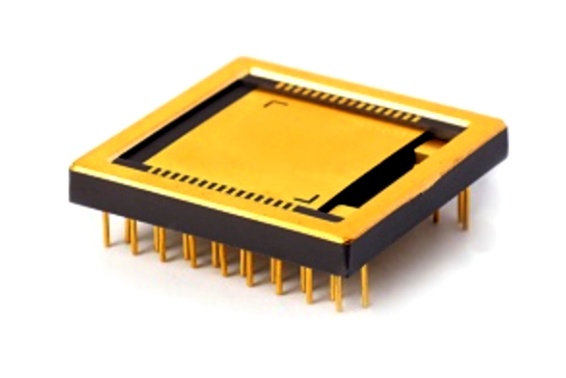

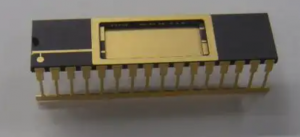

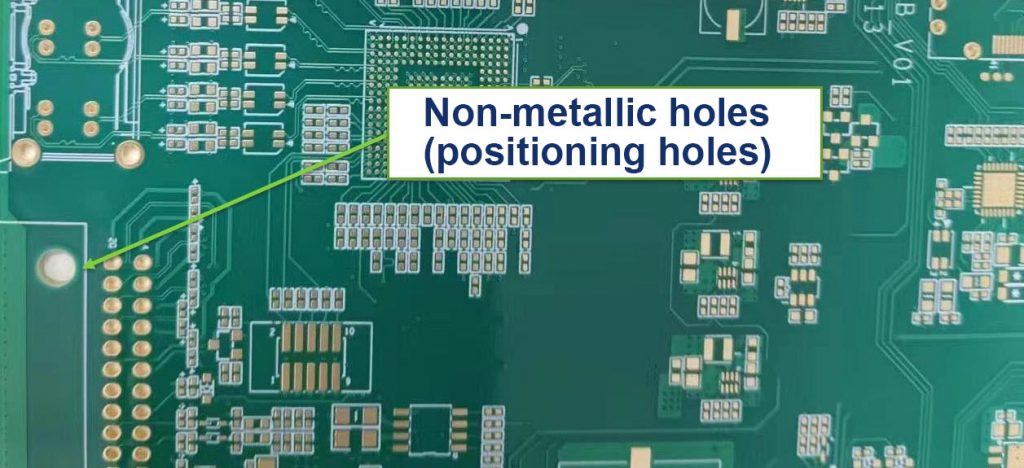

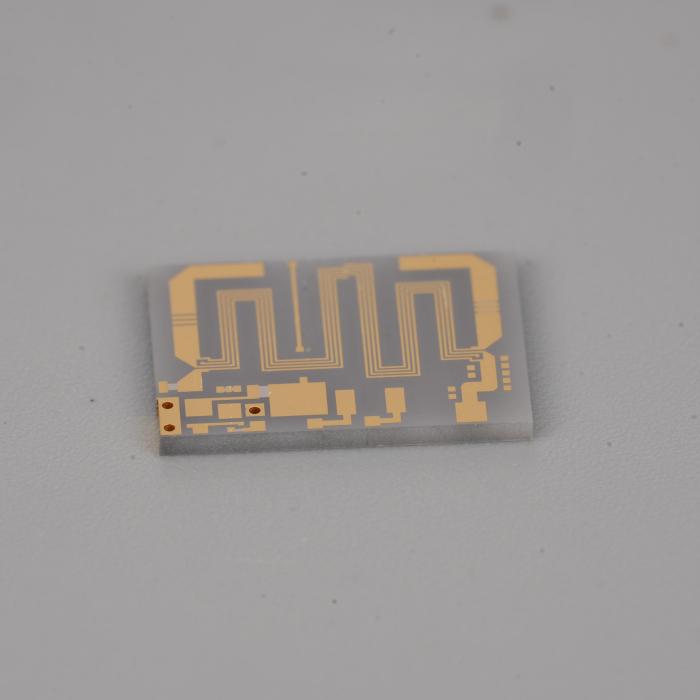

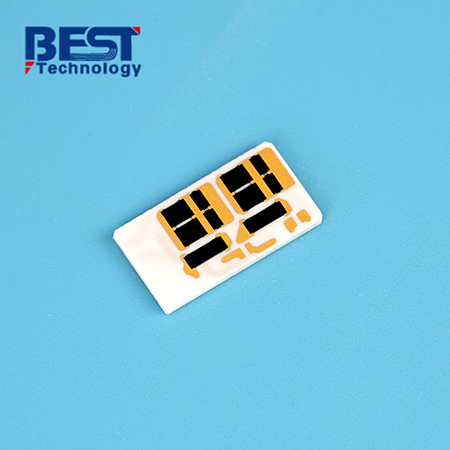

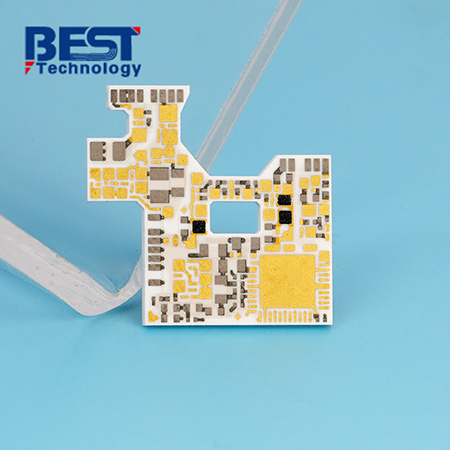

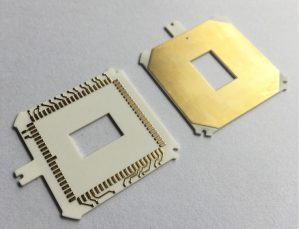

In electronics, high thermal conductivity ceramics are crucial to ensure that components do not overheat during operation. Many electronic devices produce heat as a byproduct, and if this heat is not managed properly, it can lead to equipment failures. Ceramic materials like AlN and BeO are widely used in applications such as LED packaging, power electronics, and semiconductor manufacturing due to their ability to transfer heat away from sensitive components quickly and efficiently.

Thermal Insulation

On the flip side, some ceramic materials with low thermal conductivity are perfect for insulation. In industries like metallurgy or construction, materials like silicon oxide or zirconia are used to keep heat in or out, making them excellent choices for furnace linings, kilns, and thermal barrier coatings.

Thermal Shock Resistance

Many ceramics with low thermal conductivity also possess high thermal shock resistance, meaning they can withstand rapid temperature changes without cracking or breaking. This is important in applications such as aerospace, where materials are often exposed to extreme temperature variations.

Energy Efficiency

Thermal conductivity affects the energy efficiency of systems. In applications like heating elements, components with good thermal conductivity allow heat to be transferred more effectively, leading to better energy efficiency and lower operational costs. Ceramics that balance both thermal insulation and conductivity provide optimized energy management, crucial for industrial processes.

5 Typical High Thermal Conductivity Ceramic Materials

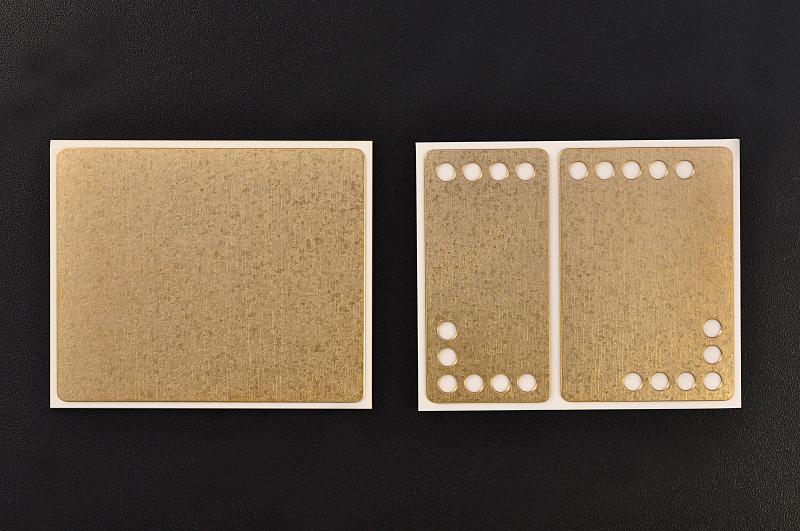

- Aluminum Nitride (AlN)

Thermal Conductivity: ~170-230 W/m·K

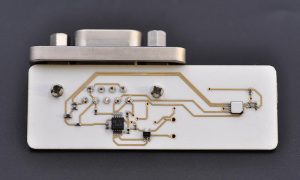

Aluminum nitride is one of the most well-known ceramics for high thermal conductivity. It is electrically insulating, which makes it an ideal material for electronic substrates and heat sinks in devices like LEDs and power modules. Its ability to rapidly dissipate heat while maintaining electrical isolation makes it a popular choice in electronics where heat management is critical.

- Silicon Carbide (SiC)

Thermal Conductivity: ~120-270 W/m·K

Silicon carbide is not only known for its excellent thermal conductivity but also its incredible hardness and mechanical strength. It is used in high-temperature applications, such as in gas turbines and heat exchangers. Its ability to withstand harsh conditions while transferring heat efficiently makes it invaluable in aerospace and automotive industries.

- Beryllium Oxide (BeO)

Thermal Conductivity: ~200-330 W/m·K

Beryllium oxide offers one of the highest thermal conductivities among ceramics, rivaling some metals. Its superior ability to conduct heat while remaining electrically insulating makes it ideal for high-performance electronic devices. However, its use is limited due to the toxic nature of beryllium, requiring careful handling during manufacturing.

- Alumina (Al2O3)

Thermal Conductivity: ~20-35 W/m·K

Alumina is a widely used ceramic due to its good combination of thermal conductivity, mechanical strength, and electrical insulation. Though not as high in thermal conductivity as AlN or SiC, alumina’s affordability and versatility make it a common choice in many industrial applications, including substrates for electronics and thermal barriers.

- Silicon Nitride (Si3N4)

Thermal Conductivity: ~20-30 W/m·K

Silicon nitride is a material prized for its thermal shock resistance and mechanical strength. Though it does not have the highest thermal conductivity, its ability to withstand extreme temperatures and thermal cycling makes it valuable in engines and high-performance bearings.

What Ceramic Materials Are Best for Thermal Conductivity?

Aluminum nitride is one of the most suitable ceramic materials for conducting heat. aluminum nitride (AlN) has a thermal conductivity of 170-230 W/mK, is one of the best thermal conductivity ceramic substrate materials, especially suitable for high power density and high-frequency electronic devices heat. Aluminum nitride is suitable for heat conduction, mainly for the following reasons:

1. High thermal conductivity: aluminum nitride has extremely high thermal conductivity and can effectively transfer heat from one area to another.

2. Excellent mechanical properties: aluminum nitride not only has good thermal conductivity, but also has high mechanical strength and chemical stability, can maintain the stability of its structure and properties in a variety of environments.

3. Wide application: aluminum nitride is widely used in the heat dissipation of high power density electronic devices and high-frequency electronic devices to meet the needs of modern electronic equipment for efficient heat dissipation.

What are the Thermal Properties of Ceramic Materials?

The thermal properties of ceramic materials mainly include melting point, heat capacity, thermal expansion and thermal conductivity. The melting point of ceramic materials is generally higher than that of metals, up to 3000℃ or more, and has excellent chemical stability at high temperatures.

The heat capacity of ceramic materials refers to the heat required to increase the temperature of ceramic materials by 1℃ per unit mass. Ceramic has a lower heat capacity, which means that it is less able to absorb heat when heated.

The coefficient of thermal expansion of ceramic materials is small, much lower than that of metal. This means that when the temperature changes, the size of the ceramic changes less and has good dimensional stability.

The thermal conductivity of ceramic materials is lower than that of metal materials, but its thermal conductivity depends on the specific type of ceramic. Some ceramics are good thermal insulation materials, while some ceramics are good thermal conductivity materials, such as boron nitride and silicon carbide ceramics.

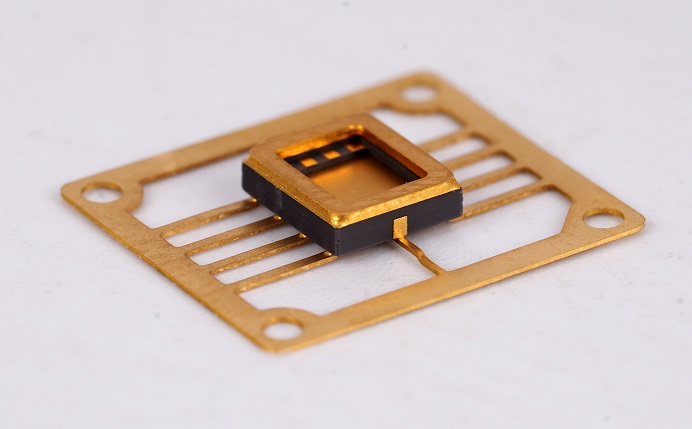

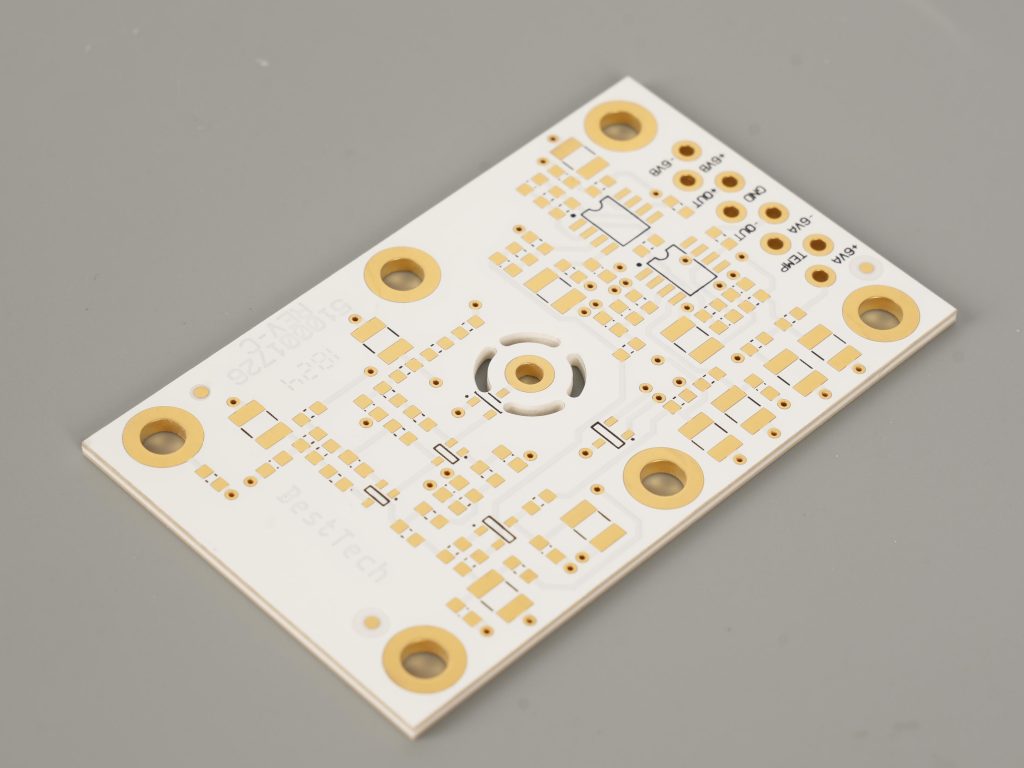

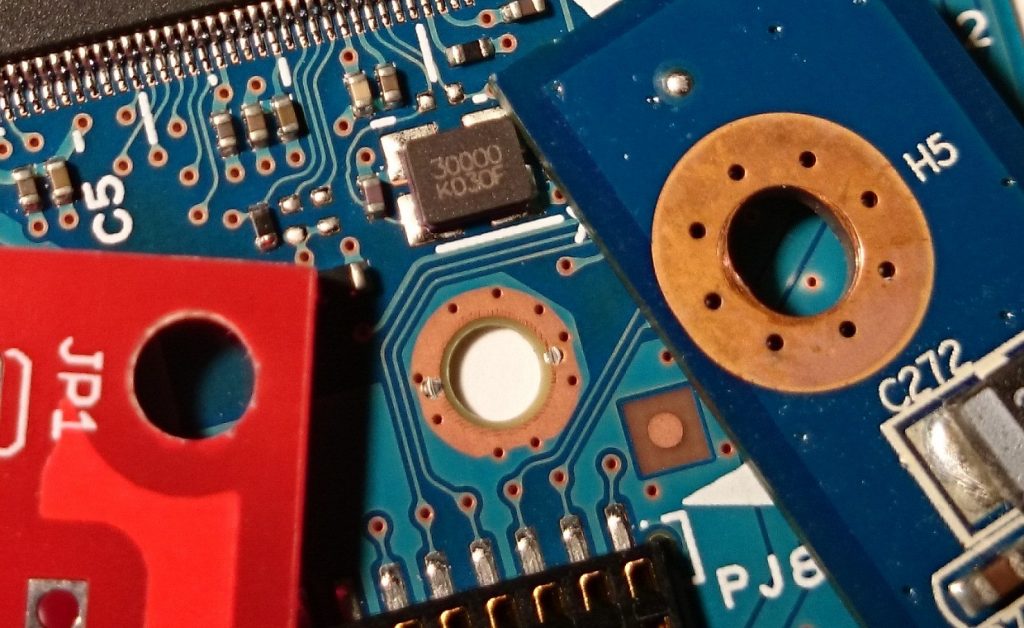

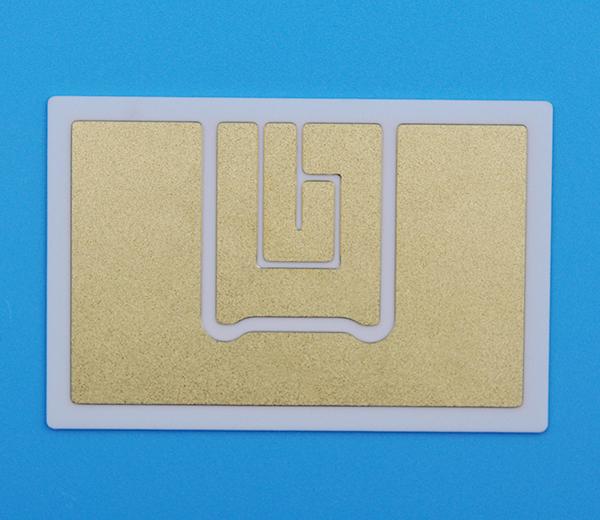

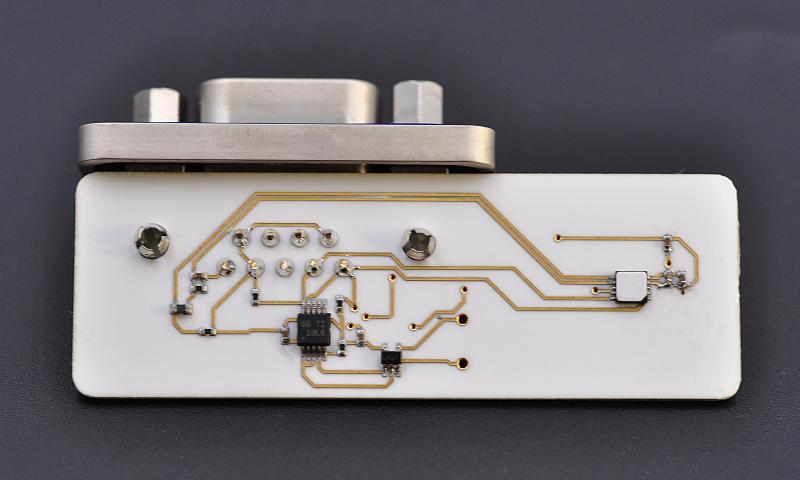

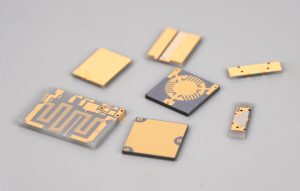

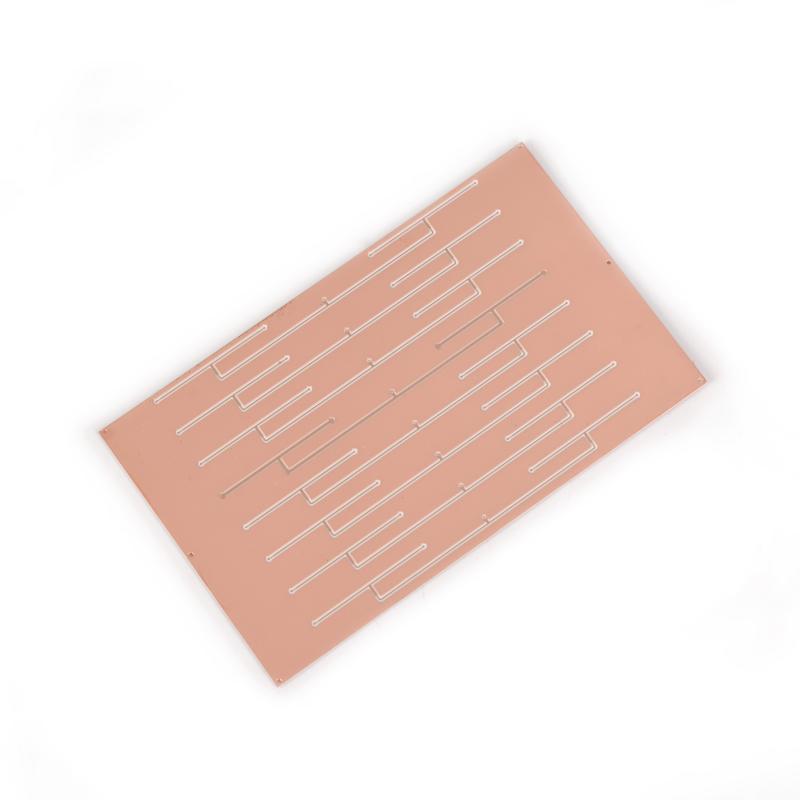

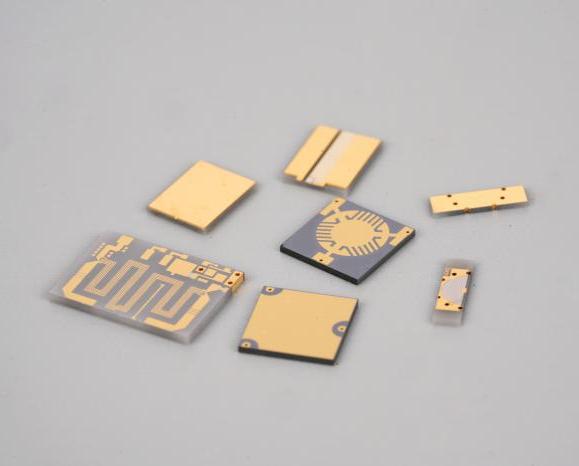

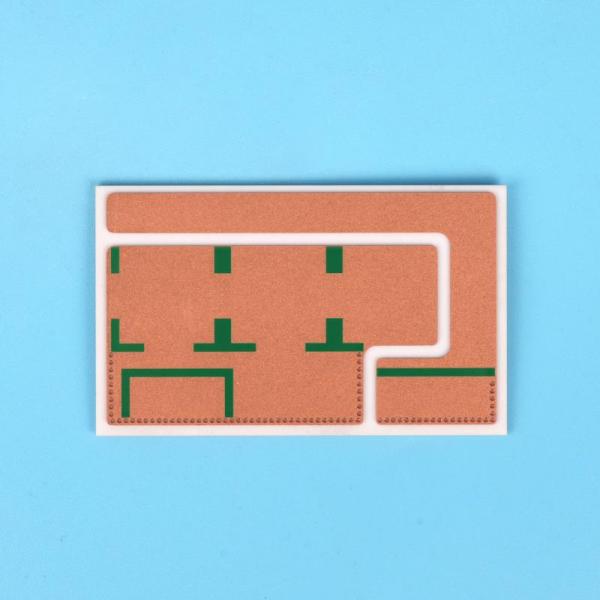

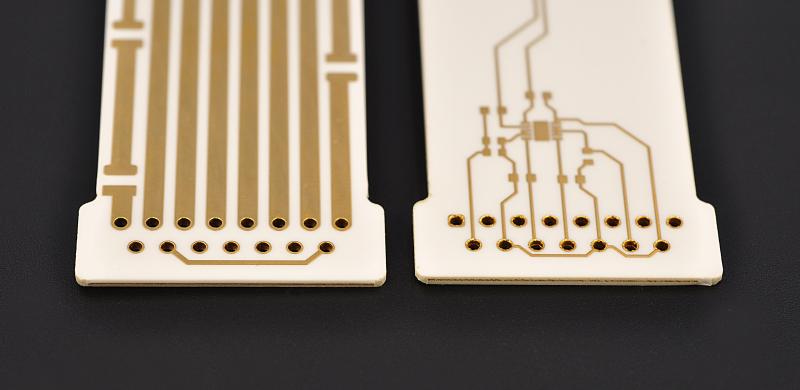

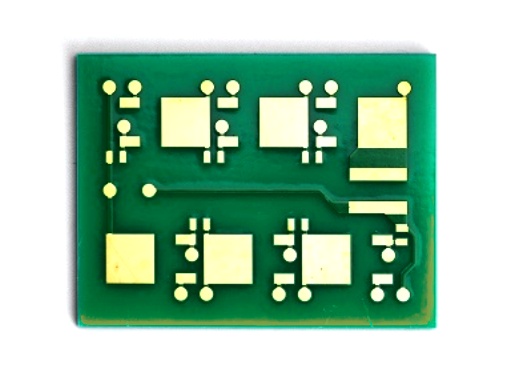

Your Most Reliable Ceramic PCB Manufacturer – Best Technology

When it comes to finding a reliable manufacturer for ceramic PCBs, Best Technology stands out in the market. As a leader of ceramic material and ceramic PCB manufacturer, Best Technology has over 18 years experience, we are so confident that we can provide the highest quality and high specification PCB for you! Backing up with a group of professional engineers, and well established quality system. Best Technology has grown to become a major PCB manufacturer in Asia to serve in diverse customers base. At Best Technology, you can enjoy a full turn-key service from IC substrate design, prototyping, mass production and ceramic PCB assembly.

Whether you need ceramic materials with high thermal conductivity for your electronics, or specialized products for unique applications, we have the expertise and the technology to deliver. Trust Best Technology to provide you with the best in ceramic PCB manufacturing, ensuring that your projects are completed to the highest standards.