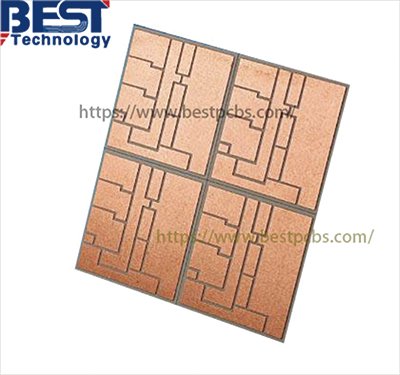

With the continuous upgrading and optimization of electronic products, the PCBs as the carrier of components have also been continuously improved, and ceramic circuit boards have appeared. So, compared with traditional glass fiber (FR-4), aluminum-based and copper-based, what’s the advantages of ceramic PCB?

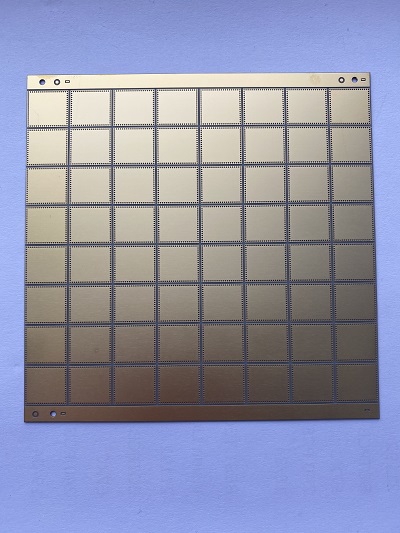

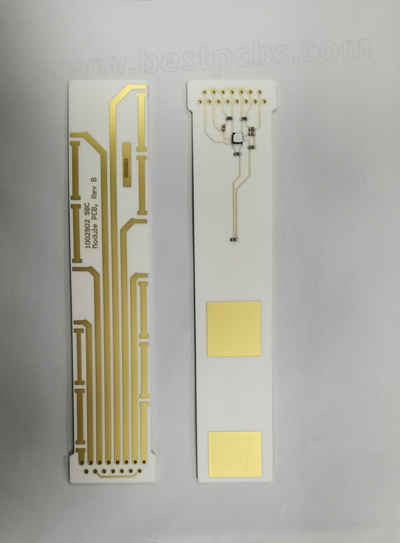

1. Stable flatness

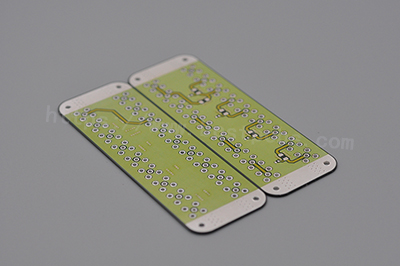

Ordinary PCB is usually made by bonding copper foil and substrate, and the substrate material is mostly glass fiber (FR-4), phenolic resin (FR-3), aluminum-based, copper-based, PTFE, composite ceramics and other materials. The mixture is usually phenolic, epoxy, etc. Due to thermal stress, chemical factors, improper production technology and other reasons during PCB processing, or due to asymmetric copper paving on both sides during the design process, it is easy to cause the PCB board to warp to varying degrees.

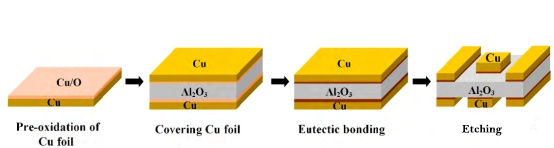

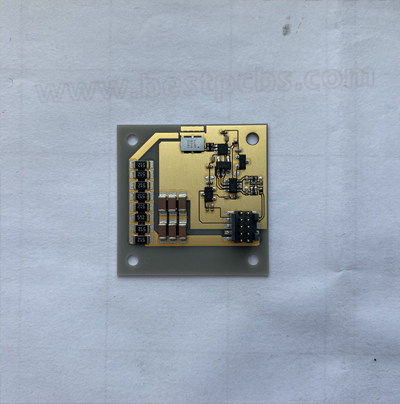

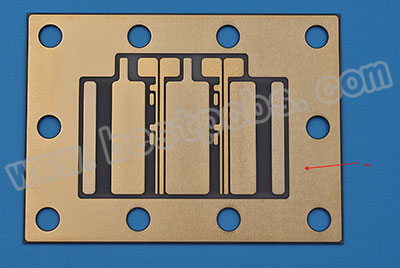

The ceramic circuit board isà hard with good heat dissipation performance, and low thermal expansion coefficient. At the same time, the ceramic circuit board is bonded to the base material by magnetron/vacuum sputtering. The bonding force is strong and the copper foil will not fall off. High reliability, thus avoiding the

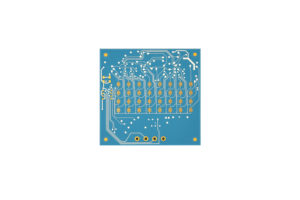

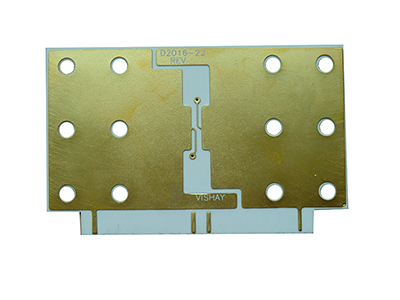

2. Large current carrying capacity:

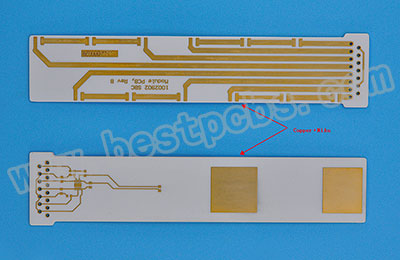

100A current continuously passes through the 1mm 0.3mm copper board, and the temperature rise is about 17°C; 100A current continuously passes through the 2mm 0.3mm board, and the temperature rise is only about 5°C.

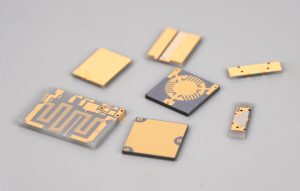

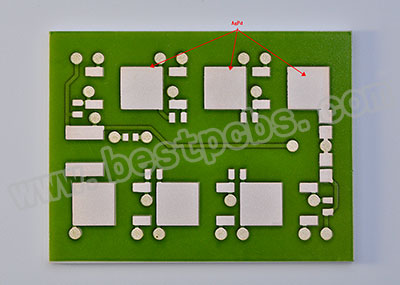

3. Thermal conductivity:

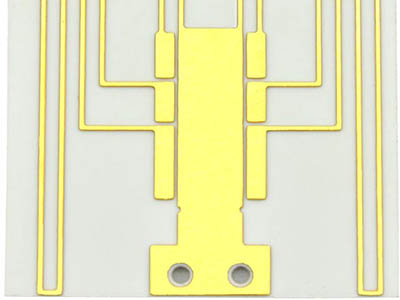

The thermal conductivity of alumina can reach 15~35, and that of aluminum nitride can reach 170~230. Because in the case of high bonding strength, its thermal expansion coefficient will be more matched, and the tested tensile value can reach 45 MPa.

4. Thermal conductivity:

The thermal conductivity of the high thermal conductivity aluminum substrate is generally 1-4W/M. K, and the thermal conductivity of the ceramic substrate can reach about 220W/M. K depending on its preparation method and material formula.

5. Low thermal resistance:

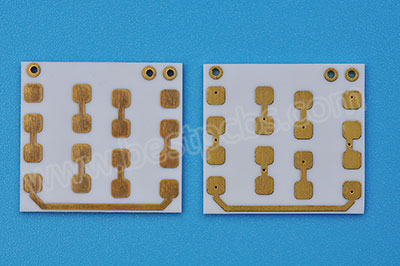

The thermal resistance of a 10â10mm ceramic substrate is 0.63mm thick. The thermal resistance of a ceramic substrate is 0.31K/W, the thermal resistance of a 0.38mm thick ceramic substrate is 0.19K/W, and the thermal resistance of a 0.25mm thick ceramic substrate is 0.14K /W.

Â

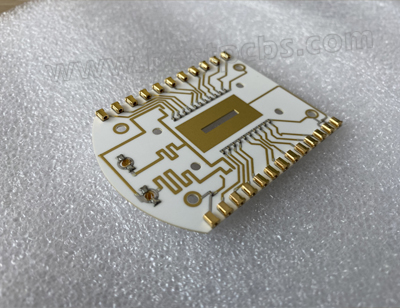

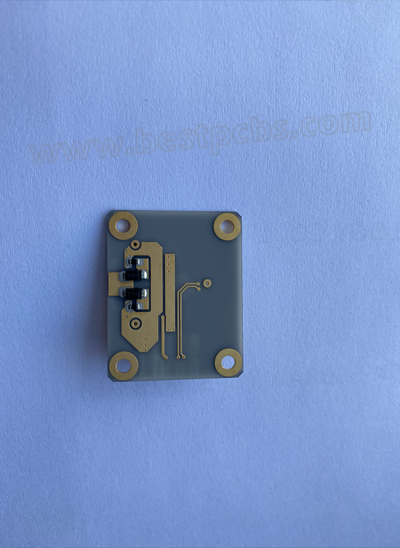

6. Good insulation performance, high pressure resistance, protection of personal safety and equipment, strong bonding force, bonding technology, copper foil will not fall off, high reliability, stable performance in high temperature and high humidity environments.

7. Stable high-frequency performance, AK and DK values are lower than its PTFE, in line with ceramics.

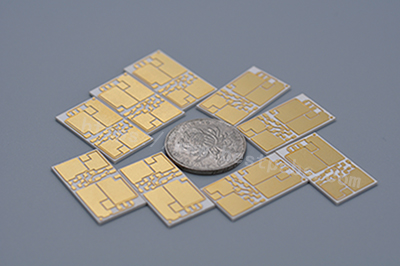

In summary, with its advantages, ceramic circuit boards have been used in high-power power electronic modules, solar panel components, high-frequency switching power supplies, solid state relays, automotive electronics, aerospace, military electronics, high-power LED lighting products, and communications Antennas, automotive sensors, refrigeration sheets and other fields are widely used.