In the PCB manufacturing, we always heard a word â DFM, do you know what is DFM? And how does it affect the manufacturing? Herein, Best Team would like to explain the DFM and its benefits for you.

What is DFM?

DFM stands for Design for Manufacturing. It is an engineering approach focused on designing products in a way that optimizes their manufacturability, testability, and reliability right from the beginning stages of product development.

The goal of DFM is to simplify the manufacturing process, reduce production costs, and improve the overall quality of the final product. This involves considering manufacturing constraints and capabilities early in the design phase to minimize complexities, facilitate assembly, and enhance efficiency in production. By integrating DFM principles, manufacturers and engineers/designers can achieve cost savings, faster time to market, and higher-quality products.

What We Should Considered About Design for Manufacturing?

Design for Manufacturing (DFM) is guided by several key principles aimed at optimizing the design of products for efficient and cost-effective manufacturing processes. Here are five fundamental principles and considerations must know of DFM:

- Design

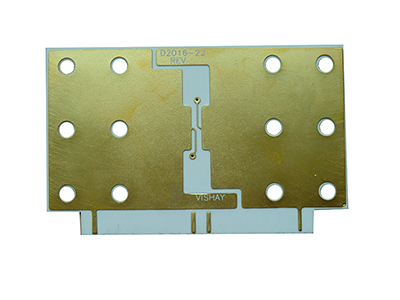

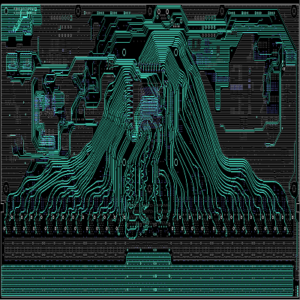

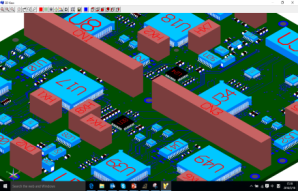

We all know the more complex the design, the greater the risk during the manufacturing. Therefore, keep the design as simple as possible while meeting the functional requirements of the product. Simplifying the design including reduce the number of parts, assembly steps, and manufacturing processes involved, which in turn lowers production costs and minimizes the risk of errors or defects.

- Standardization

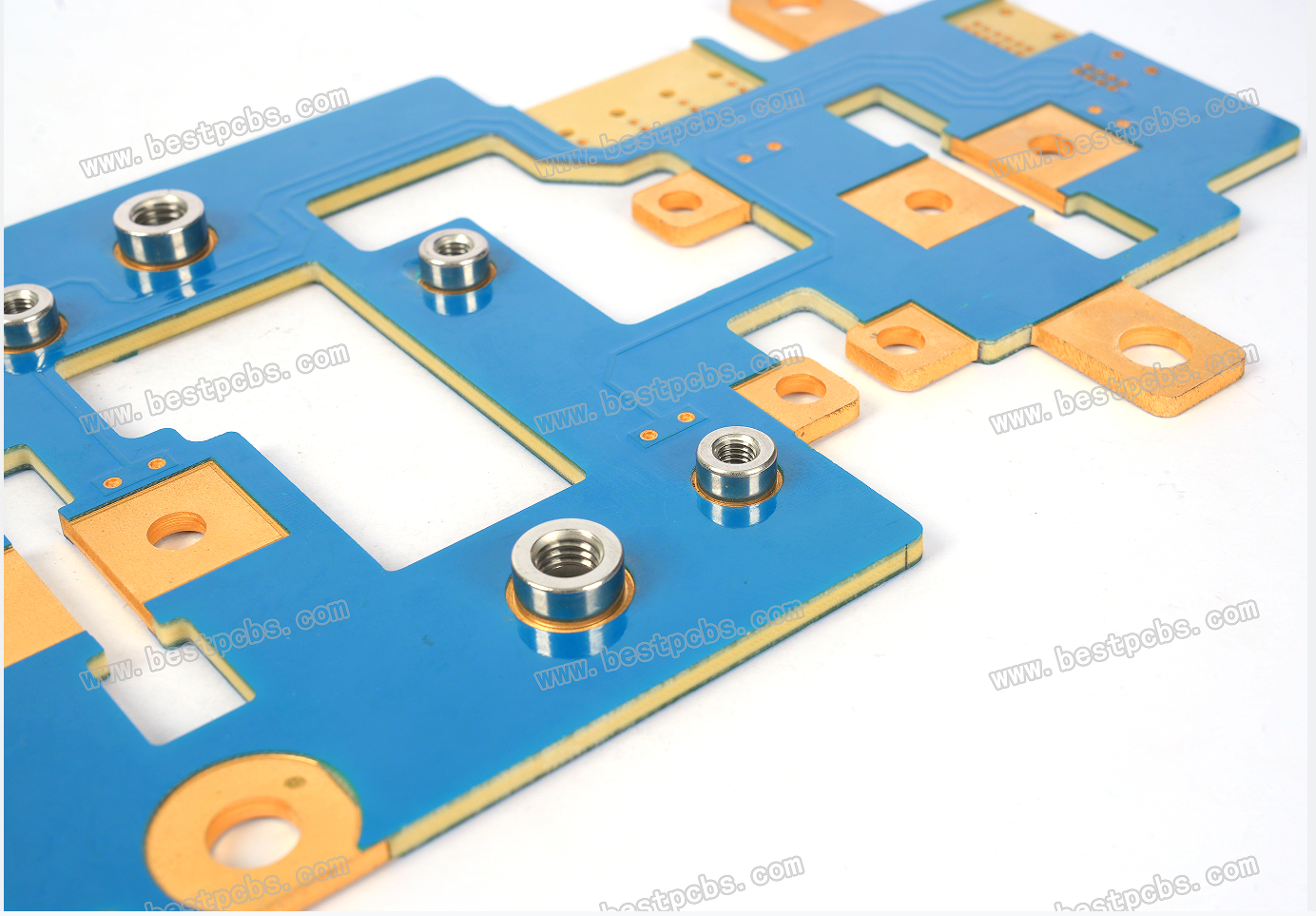

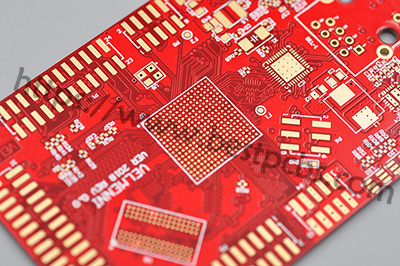

In the PCB industry, there is an IPC standard to standardized all the elements design in PCB, this involved the line width, line spacing, solder mask thickness, text height and so forth. By using standardized parts and processes, manufacturers can take advantage of economies of scale, reduce lead times, smooth the manufacturing process and simplify supply chain management. Standardization also ensures the interchangeability, repair, and maintenance of products.

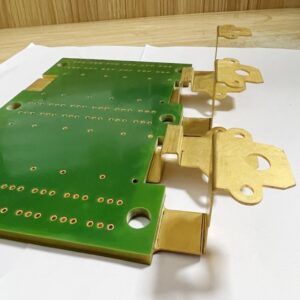

- Design for Assembly (DFA)

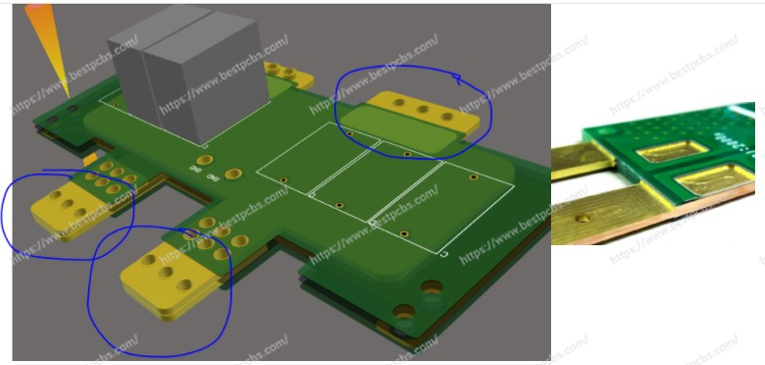

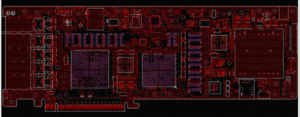

If you are trying to mount some components to keep and enhance the performance of product, then DFA is must to take into account. Arrange components on the PCB layout in a way can minimize signal interference, reduces trace lengths, and simplifies assembly. Placing components strategically can improve signal integrity, reduce electromagnetic interference (EMI), and facilitate automated assembly processes.

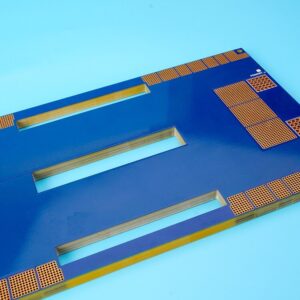

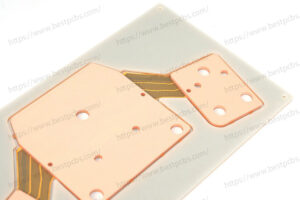

- Material

Select materials and manufacturing processes that are readily available, cost-effective, and well-suited to the intended application. Consider factors such as material properties, availability, recyclability, and environmental impact when making material choices. Designing for materials involves optimizing designs to minimize material waste and maximize efficiency in material usage.

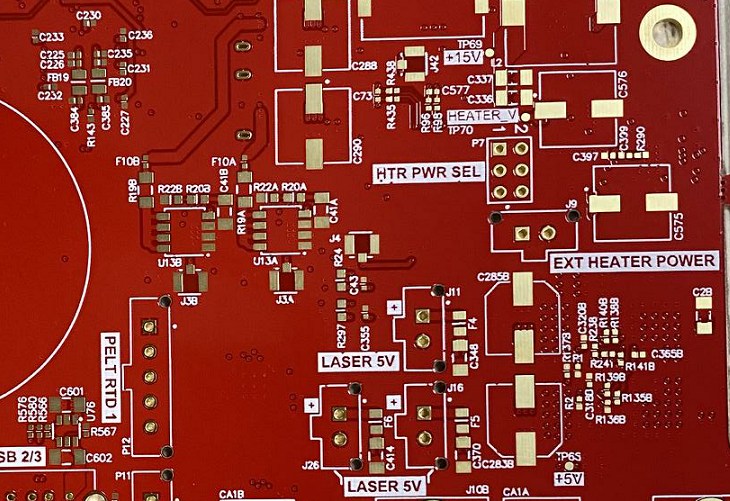

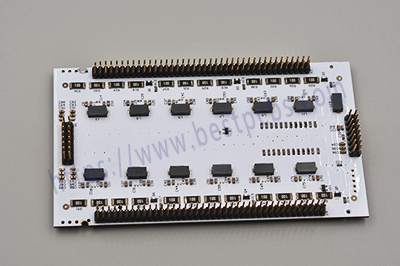

- Testability and Debugging

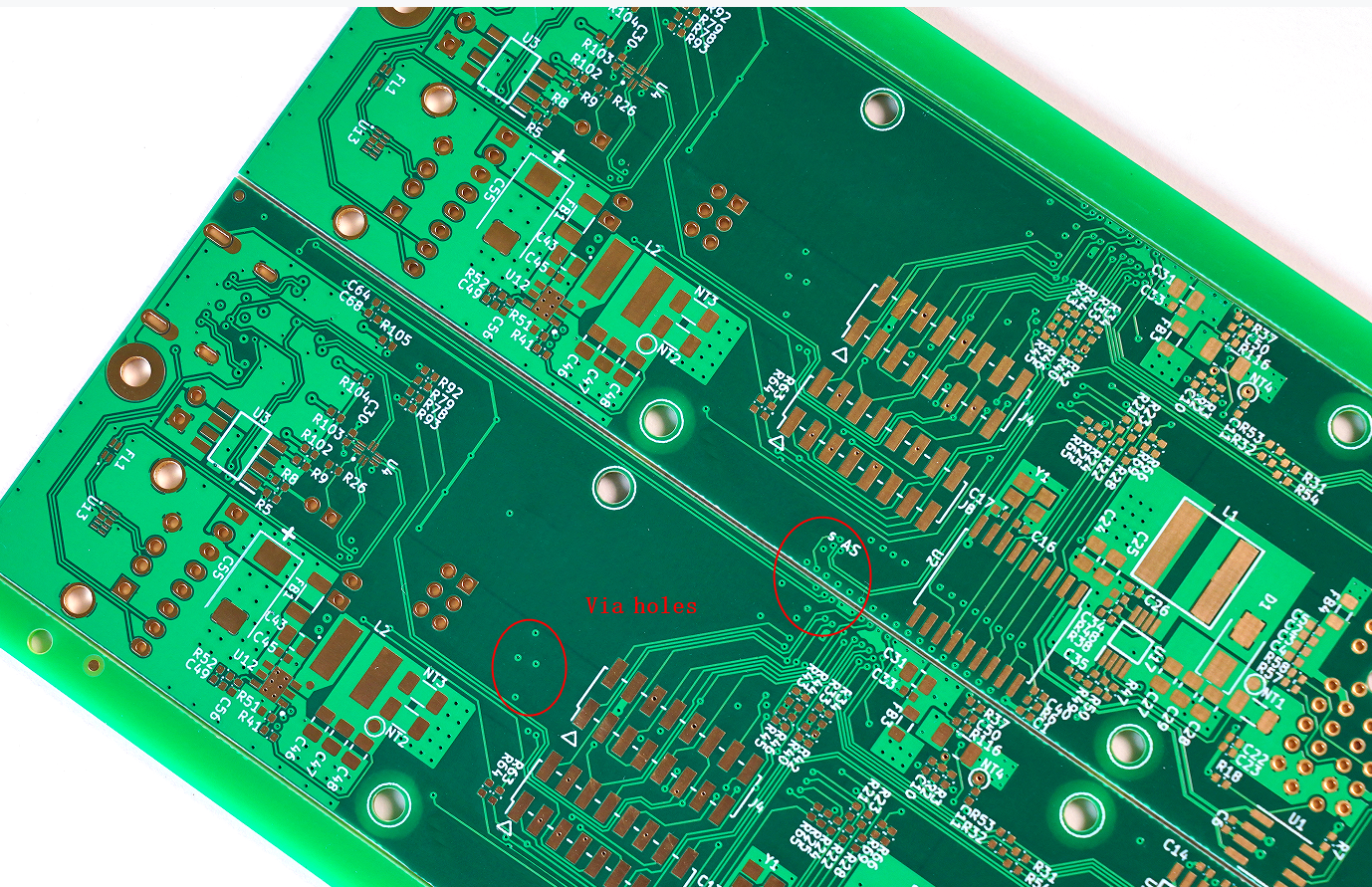

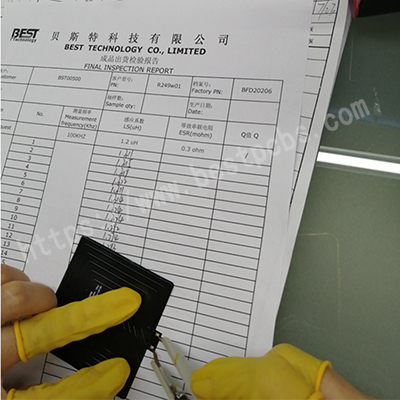

Design PCBs with features that facilitate testing, troubleshooting, and debugging during manufacturing and assembly. Include test points, debug headers, and built-in self-test (BIST) circuitry to simplify testing and diagnostics. Design PCBs with clear labeling, documentation, and accessibility to aid in maintenance and repair.

What Are the Benefits of DFM Analyzing?

The mainly benefits of using DFM is save cost. You know, when creating a new project, we need put much money and time in designing and prototyping. DFM helps identify potential manufacturing issues early in the design phase, allowing for cost-effective modifications before production starts. By optimizing designs for manufacturability, companies can avoid expensive rework and reduce overall production costs. Statistically, we can save around 170 thousand dollars one year by adopting DFM analyzing (human cost, trail-production cost and repair cost). In addition, DFM offers numerous benefits including:

- Reduce potential quality defects

- Facilitate production process improvement

- Decrease trial production cycles

- Quick time to market

- Enhanced product quality and stability

- Mitigate risks associated with personnel changes

How to Find a Manufacturer with DFM Service?

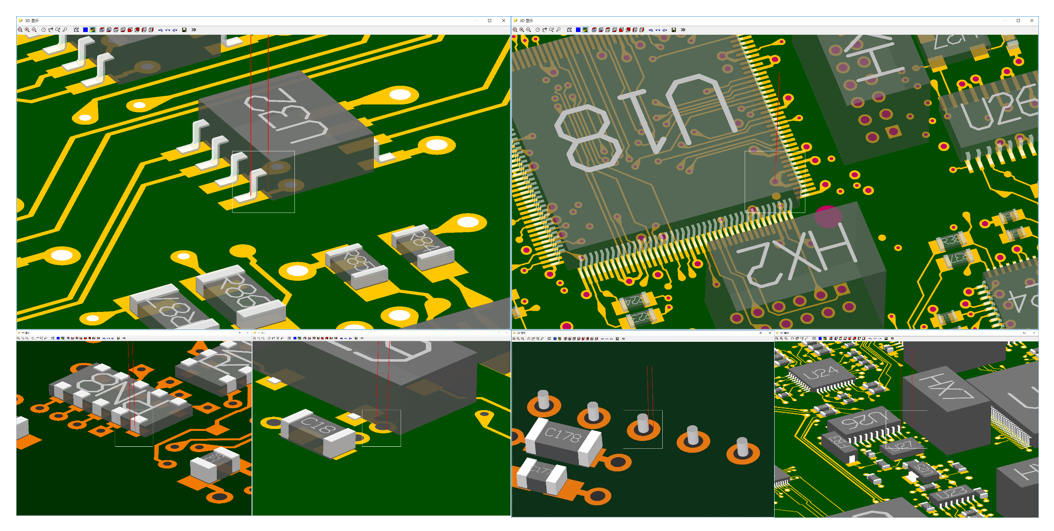

Finding a reliable DFM manufacturer is essential for ensuring the success of your product development. Best Technology engaging in PCB manufacturing for more than 17 years, and we have many experts that can help to solve and provide PCB solution for you. Meanwhile, we have professional DFM system that can help to quickly diagnose the design exception such as components missing, trace layout, open/short circuit. With our expertise and advanced tools, we ensure that your PCB designs are optimized for efficient manufacturing, resulting in high-quality products that meet your specifications and exceed expectations. Trust Best Technology to be your partner in achieving excellence in PCB manufacturing.