Printed Circuit Boards are the core of the electronics devices, and they exist in everywhere and be everything from your electronic equipment such as mobile phone, computers, so what are they? Let’s explore the secrets together and know why they become more common as technology advances.

What are Printed Circuit Boards?

A printed circuit board also known as PCB for short, is an electronic board for connecting metal circuits by mounting different electronic components in a device and have it do its functions.

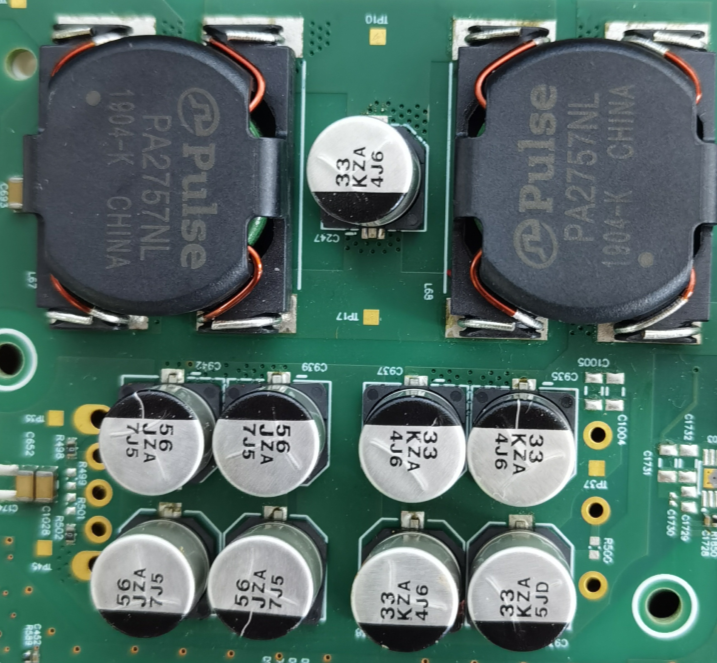

PCB is made of fiberglass and laminate materials or a composite epoxy with conductive, it can be made to varies shapes and sizes depends on what applications it will be used for—some have many holes on it while some only have several pads or traces.

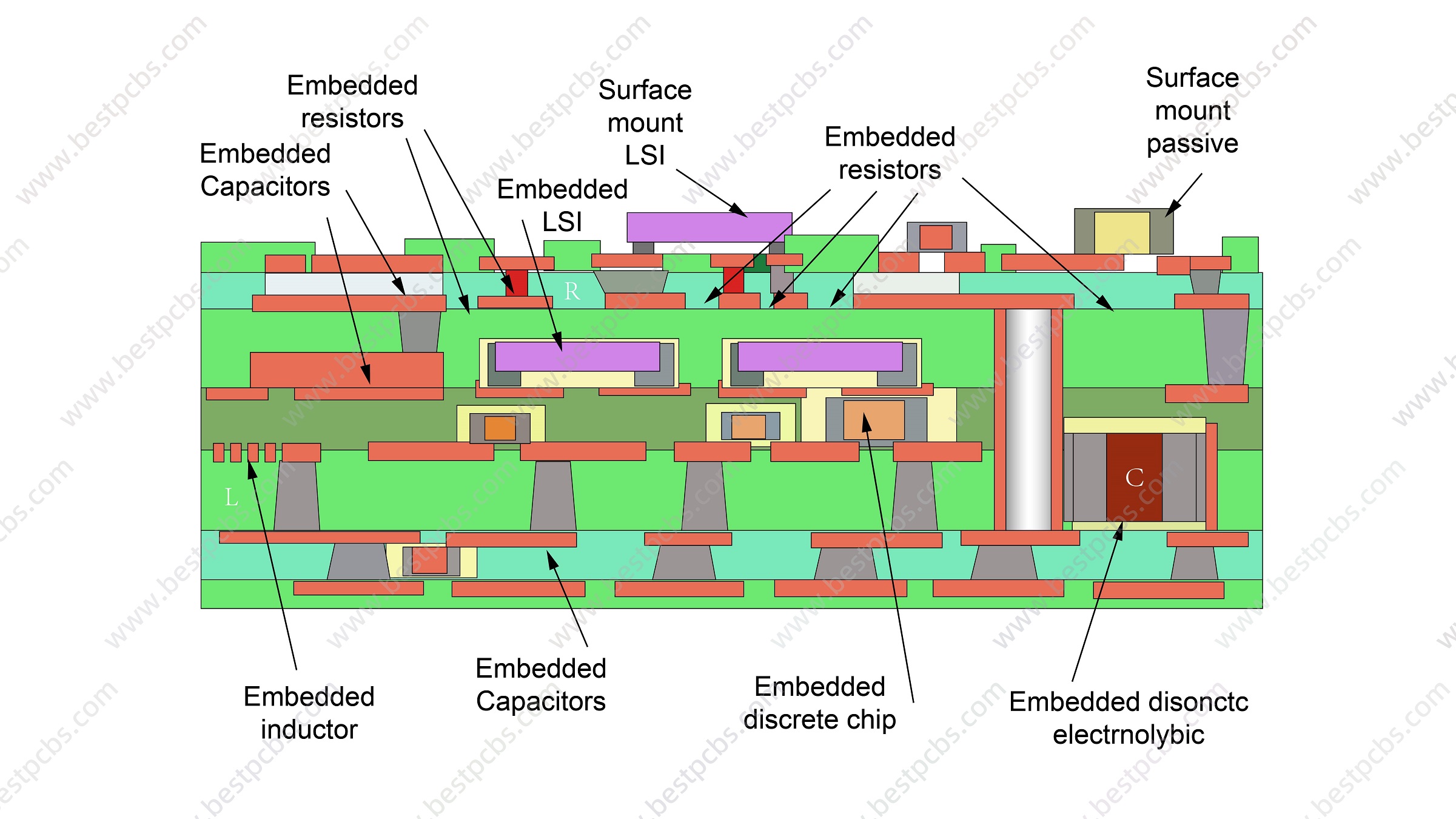

In most of devices, we can see there are many components or wires mounted or connected on the surface of PCB, which comes into two different pathways –surface mount and through-hole. Surface mount is a technology that can be abbreviated as SMT, it is a famous technical that mount electronic components (typically SMDs) attached on top of a pad by melted solder paste. Through-hole generally refers to components that have wires through the plated-through-holes that drilled into the circuit board. Both ways are commonly use, but currently with the fast development of the technology advance, surface mount is more popular than through-hole as it is more convenient for production.

What the Functions of Printed Circuit Boards?

The main functions of a PCB is to connect different components and achieve a communication between components and devices, that can be used for everywhere you can think of – Computer, phones, televisions, tablets, cameras, projectors, and so on….

For a simple example, a phone has a PCB that can connect screen, the buttons, cameras, and the circuits on the both sides. Without this board, those components wouldn’t be able to transmit signals and talk to each other and the phone would cease to function.

In addition, electronic equipment using printed board enable to avoid the error of manual wiring, and can realize the automatic insertion or installation of electronic components, automatic soldering, automatic detection by communicate with each other, to ensure the quality of electronic products, improve labor productivity, protect components from damaged, reduce costs, and easy to maintenance.

The advantages of Printed Circuit Boards

PCB performs a number of advantages in electronic industries, a most significant feature is they make products be smaller and more portable as its density circuits and components communication. The density circuits on PCB allows it take up much space for components so you can get a smaller product.

- High density

Over the past decades, the high density of printed boards has been developed with the improvement of integrated circuits and the advancement of installation technology.

- High reliability

Through a series of checks, tests and aging tests, the PCB can be guaranteed to work reliably for a long time (generally 20 years).

- Designability

For various performance (electrical, physical, chemical, mechanical, etc.) requirements, can PCB be achieved to such requirements in short time and high efficiency according to design standard rules.

- Maintainability

By means of standard PCB design rules, once the program or device failure, users fix the devices quickly.

- Cooling abilities

Overheating is one of the biggest reasons of electronics failure, so by keeping them cool with a PCB, you can increase the lifetime of your product.

Types of Printed Circuit Boards

Best Technology provides different kinds of PCBs and PCBAs for our customers, for a quickly reviewing, we listing as below:

- Rigid Printed Circuit Board (FR4-PCB)

- Flex Printed Circuit Board (FPCB)

- Rigid-Flex PCB

- Metal Core Printed Circuit Board (MCPCB)

- Ceramic Board

- SinkPAD Board

- Other special PCB such as heavy copper PCB, HDI PCB, RF PCB, and so forth

- PCB assembly

In a word, with the development of electronics, it’s necessary to have a functional part like the PCB that can keep up with the demand. Next step, contact us if you have PCB demands.