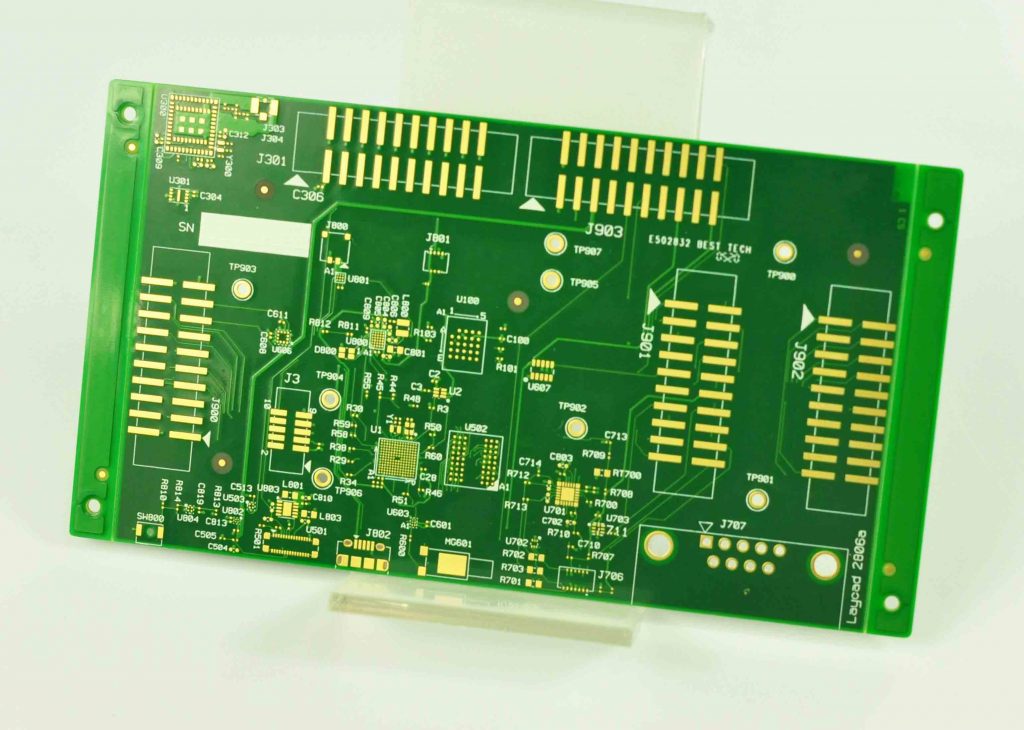

Bluetooth technology has become a major component of modern electronics, enabling wireless communication between devices. At the heart of this technology is the Bluetooth PCB board (printed circuit board), which is a key component that promotes the functionality and efficiency of Bluetooth devices.

The magic of Bluetooth is everywhere in electronic products such as mobile phones and computers, and it is all made possible by the functionality of Bluetooth PCB boards.

What is Bluetooth PCB board?

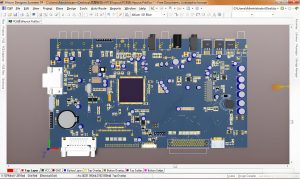

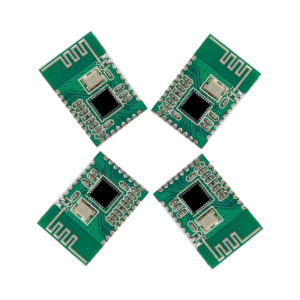

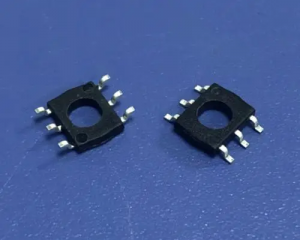

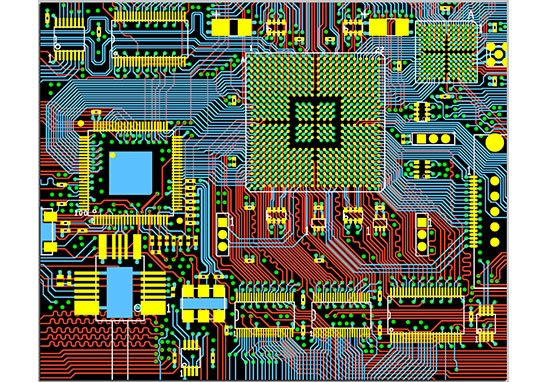

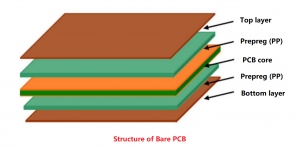

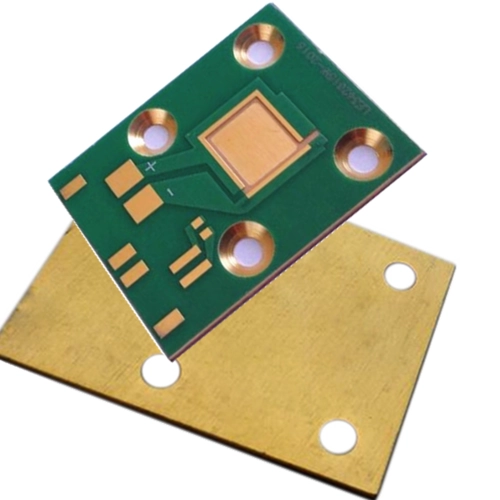

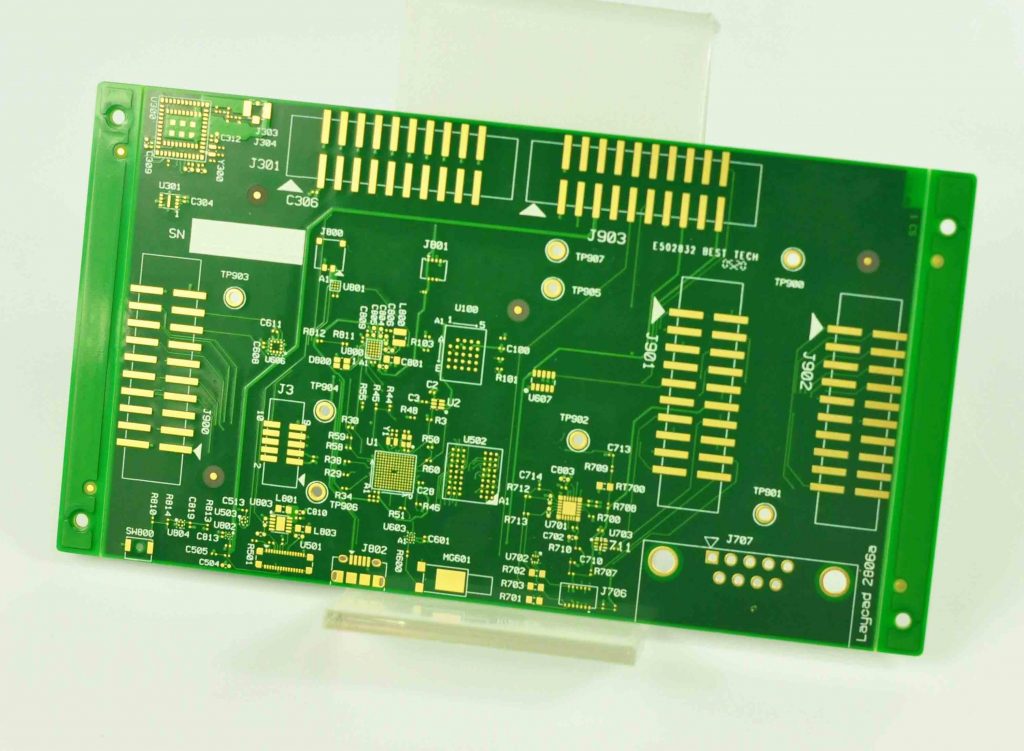

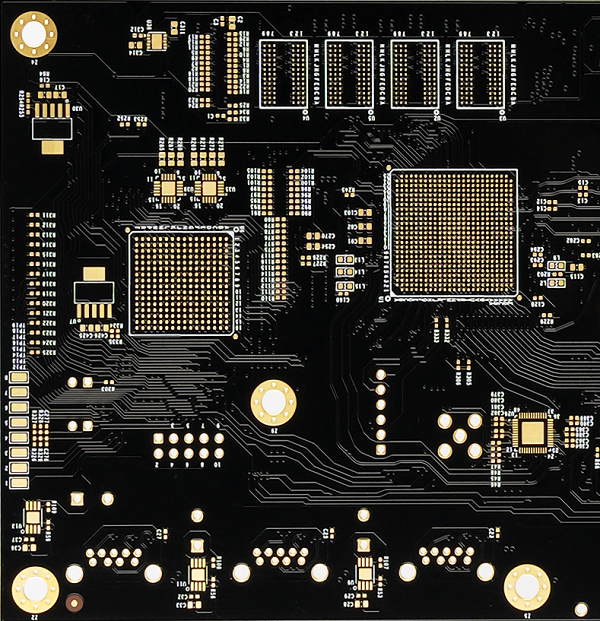

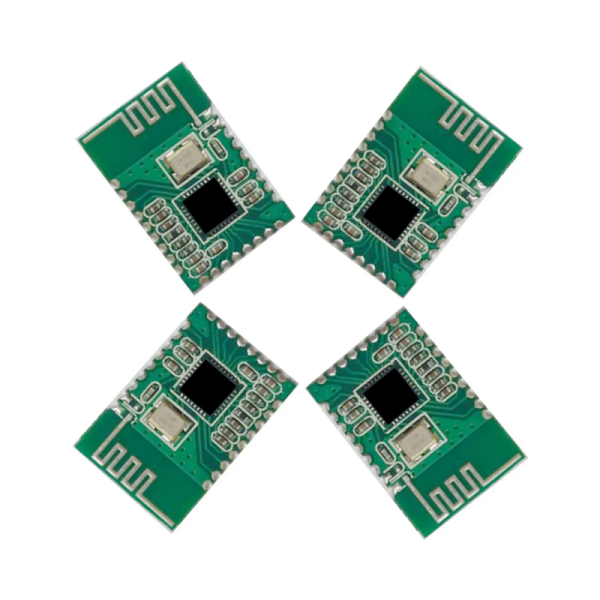

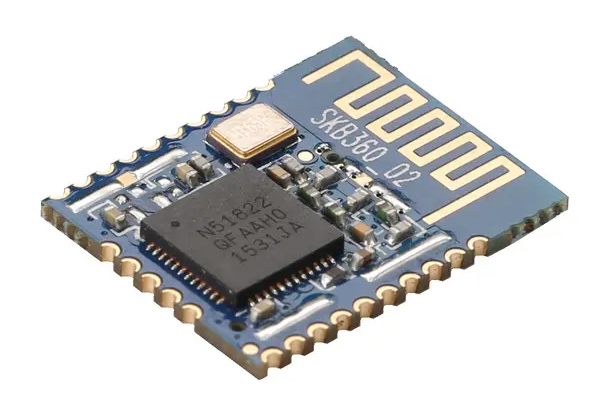

A Bluetooth PCB board (printed circuit board) is a specially designed circuit board that integrates the components required for Bluetooth communication into electronic devices. It is the backbone for wireless transmission and reception of data between devices, allowing devices such as smartphones, headphones, and smart home devices to connect without cables.

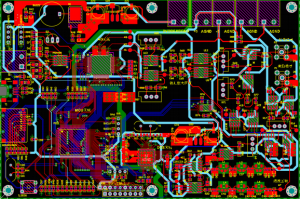

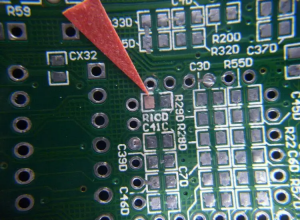

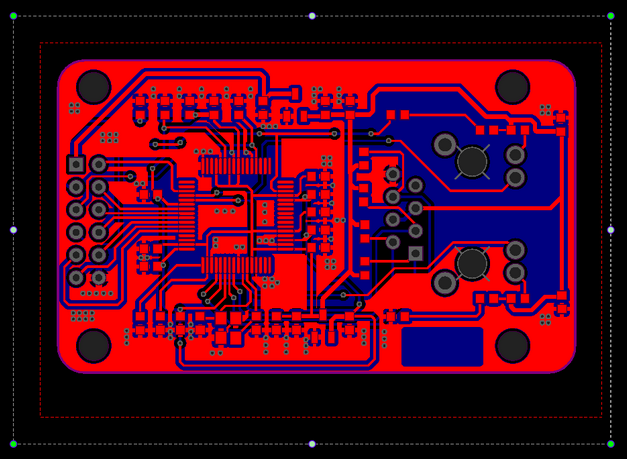

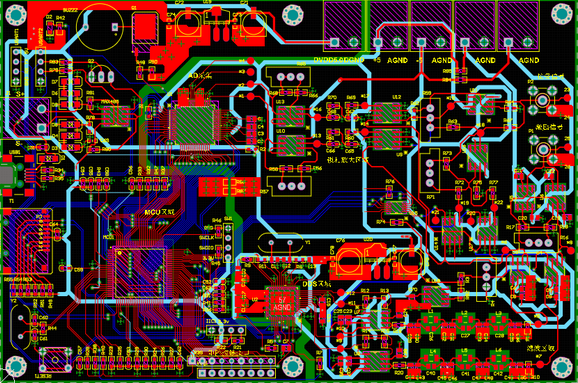

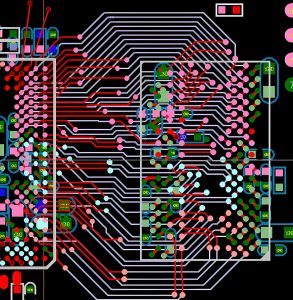

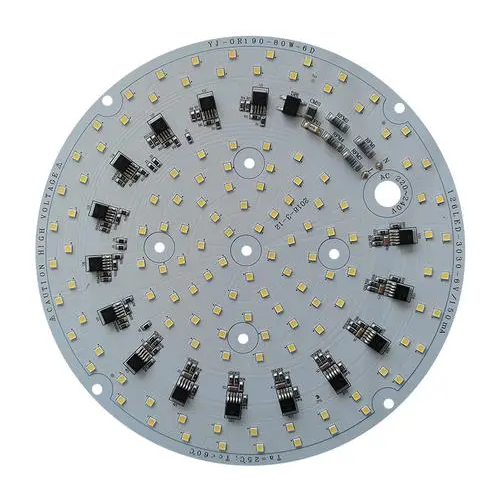

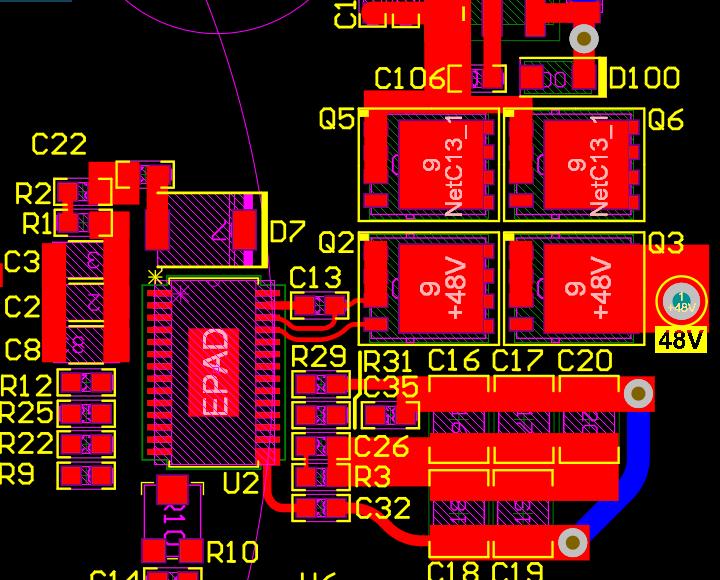

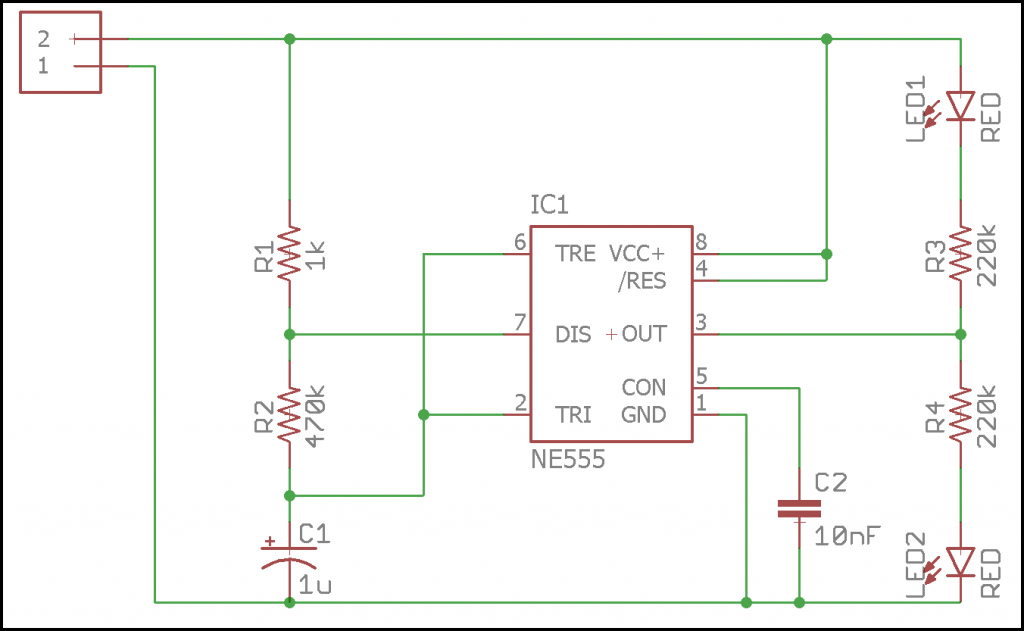

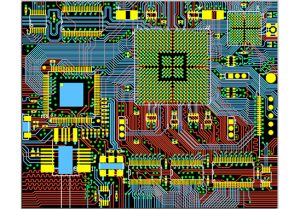

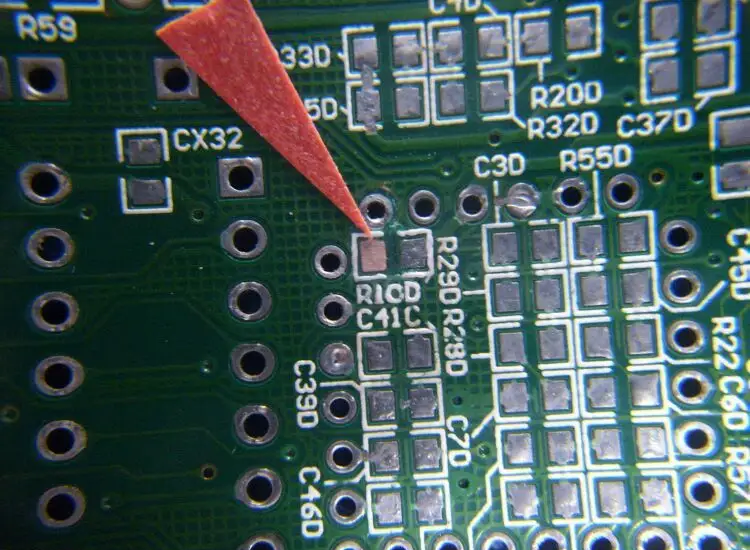

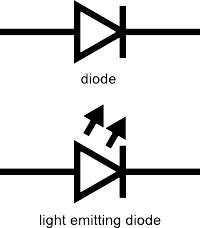

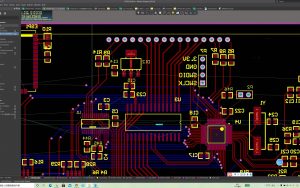

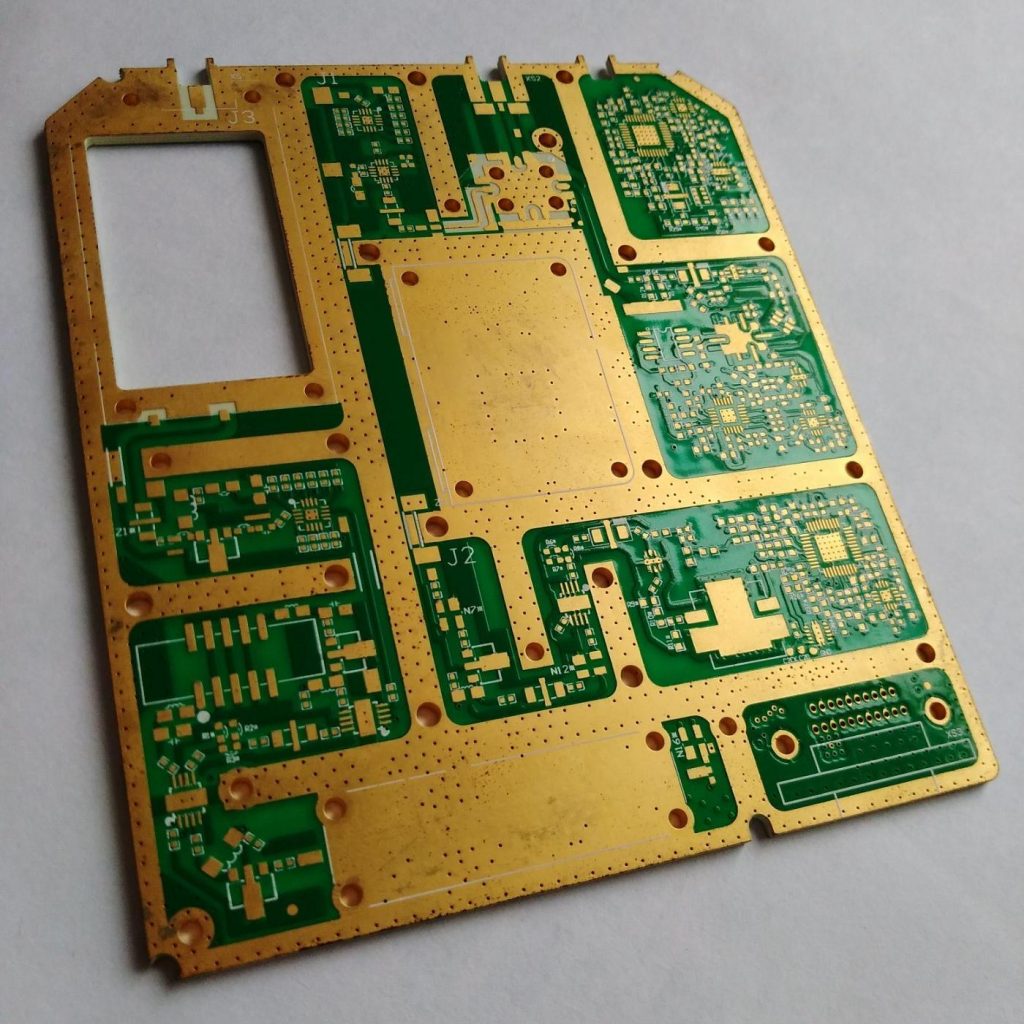

PCBs are filled with various components, including Bluetooth chips, antennas, resistors, capacitors, and other components necessary for the Bluetooth functionality of devices. The layout of these components is carefully planned to optimize signal strength, reduce interference, and ensure efficient power consumption.

What does a Bluetooth PCB board do?

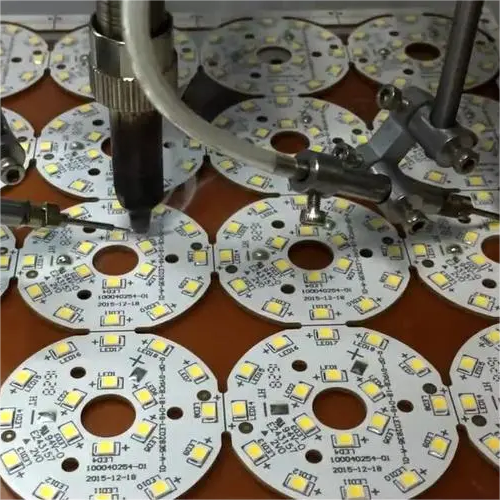

The Bluetooth PCB board plays a vital role in Bluetooth devices. Its main roles include providing reliable electrical connections, enabling compact layout of components, reducing production costs and improving production efficiency, and facilitating repairs and upgrades.

Essentially, a Bluetooth PCB board enables devices to communicate wirelessly over short distances. The PCB provides a platform where all the necessary electronic components are interconnected, allowing them to work seamlessly together.

The main role of a Bluetooth PCB is to manage the transmission and reception of data, ensuring that information is accurately sent and received between devices. It needs to filter and process signals to maintain a clear, stable connection, and also protect the data being transmitted to prevent unauthorized access.

How does a Bluetooth PCB board work?

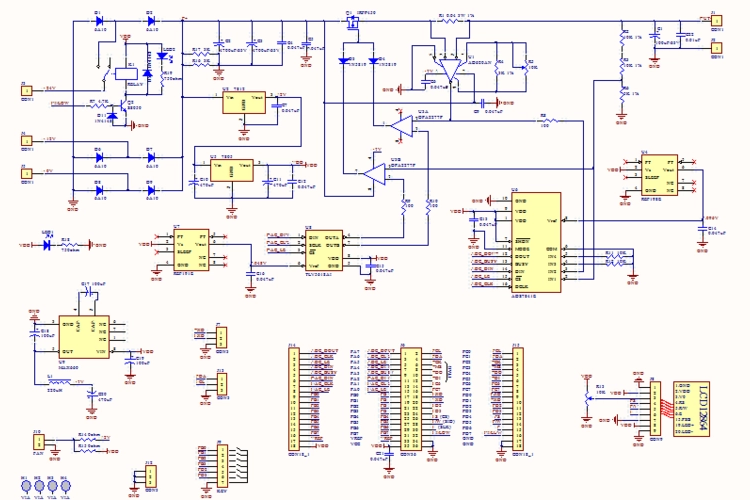

The working principle of a Bluetooth PCB board mainly relies on its integrated main control chip, audio power amplifier chip, RF antenna and other components, as well as the layout and wiring principles in PCB design to ensure stable wireless communication and high-quality audio output.

When two Bluetooth-enabled devices are within range, they establish a connection through a process called “pairing”. This involves exchanging unique identifiers and agreeing on a communication protocol. After pairing, the devices can send and receive data over the Bluetooth connection, which is assisted by the components of the PCB.

The Bluetooth PCB board plays a key role in this process, managing RF signals, filtering out noise, and ensuring that data is accurately transmitted and received. The design of the board is critical to minimizing interference and maximizing the range and reliability of Bluetooth connections.

What is the technical principle of Bluetooth?

Bluetooth is a form of communication that uses radio frequencies to connect different devices. It can operate at 2.4 GHz, similar to other forms of wireless communication such as Wi-Fi.

A master Bluetooth device can remotely connect to 7 other Bluetooth devices, paired devices exchange information with the master Bluetooth device in a serial manner, and the interaction between paired devices can be carried out through the master Bluetooth device, which acts as a facilitator.

The Bluetooth frequency range is 1 cm to 100 meters, and each connection requires device approval using a unique code. When there is no active information exchange, Bluetooth devices can remain idle, thereby reducing energy consumption.

The Bluetooth protocol is designed to be energy-efficient and is ideal for battery-powered devices. It achieves energy conservation through low-power modes and adaptive power management techniques that adjust power output based on the distance between connected devices.

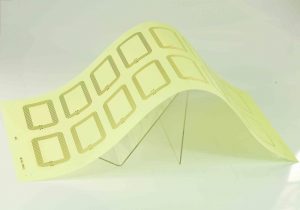

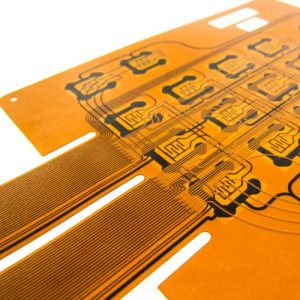

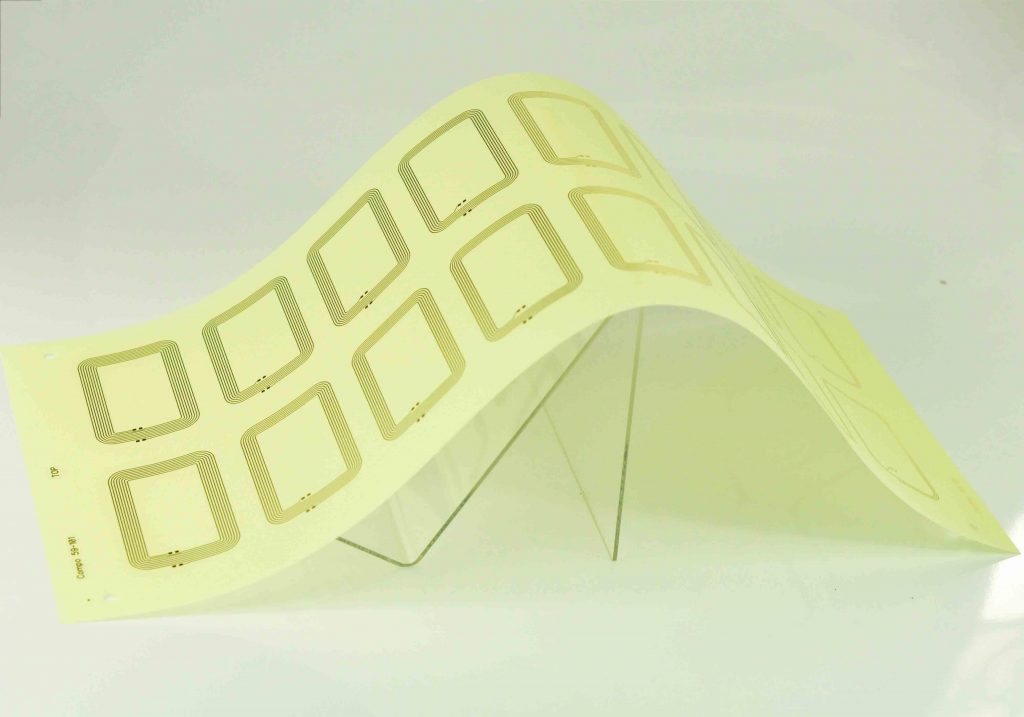

Bluetooth circuit boards are the main force driving wireless headphones, remote controls, wireless speakers to the Internet of Things (IoT) applications. They are double-layer PCBs, but only one board.

What is the principle of Bluetooth PCB board?

The working principle of Bluetooth PCB board is simple. There is an antenna on the Bluetooth PCB that receives the signal from the Bluetooth device. The information is processed inside the board and sent to the output.

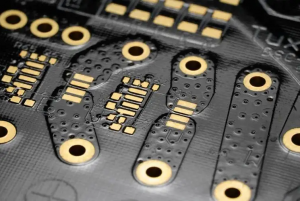

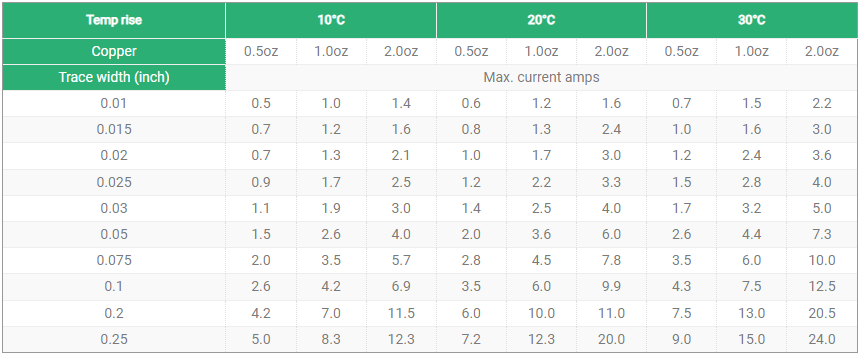

One of the key principles behind Bluetooth PCB design is impedance matching. Impedance matching ensures that the electrical signal transmitted through the PCB is transmitted with minimal reflection or loss. This is especially important for antennas, which must be carefully matched to the rest of the circuit to maximize signal strength and range.

Another important principle is electromagnetic compatibility (EMC). The PCB must be designed to minimize electromagnetic interference (EMI) that can interfere with Bluetooth signals. This involves careful placement of components, shielding, and the use of specific materials that reduce EMI.

Depending on the application of the Bluetooth device, different Bluetooth profiles can be used to facilitate communication between devices. For example, the Audio/Video Remote Control Profile (AVRCP) is used to communicate with audio video equipment and can be used for remote controls for hi-fi equipment and TVs.

What are the types of applications for Bluetooth PCB board?

The wide range of applications for Bluetooth PCB board reflects the versatility and convenience of Bluetooth technology.

1. Consumer electronics: Bluetooth PCBs are found in smartphones, tablets, laptops, headphones, and speakers, enabling wireless audio streaming and data transfer.

2. Smart home devices: Bluetooth PCBs power smart home devices such as thermostats, lights, door locks, and security cameras, allowing them to be wirelessly controlled from a central hub or smartphone.

3. Wearable devices: Fitness trackers, smart watches, and health monitors rely on Bluetooth PCBs to sync data with smartphones and other devices.

4. Automotive systems: Bluetooth PCBs are used in automotive infotainment systems, enabling hands-free calling, music streaming, and integration with smartphones.

5. Medical devices: Bluetooth PCBs are increasingly used for remote monitoring and data collection in medical devices, such as blood glucose monitors and heart rate sensors.

6. Industrial automation: Bluetooth PCBs are used in a variety of industrial applications, including wireless sensors, control systems, and machine-to-machine (M2M) communications.

Conclusion:

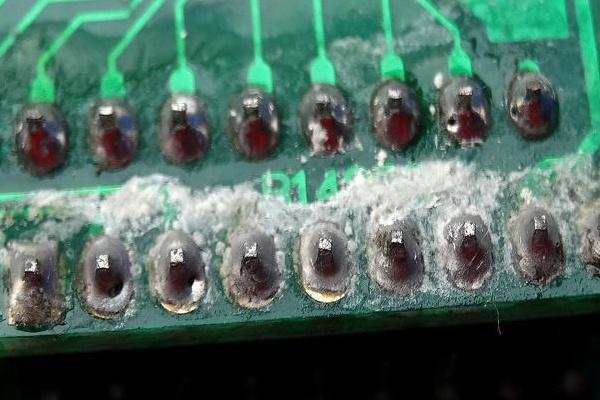

Bluetooth PCB boards are the backbone behind wireless connectivity, which has become a cornerstone of modern life. These boards are designed with complexity to ensure that devices can communicate seamlessly and efficiently. From consumer electronics to industrial applications, Bluetooth PCB plays a key role in achieving wireless communications for the Internet. BEST Technology has extensive experience in manufacturing PCB boards of various functions, and its professional team can also provide you with high-quality design and services.