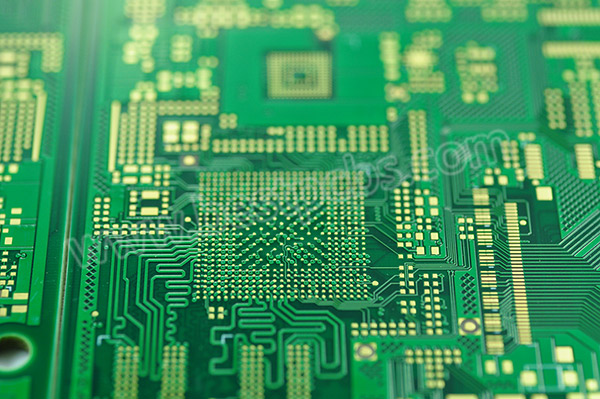

PCB Heavy Copper‚Äč refers to printed circuit boards manufactured with copper weights significantly higher than the standard 1oz or 2oz, typically starting at 3oz per square foot and extending to 20oz or more, to manage high current and intense thermal loads. This article provides a comprehensive guide to everything from the fundamentals of thick copper PCBs and their design to selecting a trustworthy manufacturer for your custom projects.

Are you struggling with these common challenges for your custom heavy copper PCB projects?

- Thermal Failure:‚Äč Standard PCBs overheat and fail under high power, causing premature device breakdown.

- Current Limitations:‚Äč Thin traces cannot carry the required amperage, leading to voltage drops, trace burnout, and fire risks.

- Mechanical Weakness:‚Äč Inferior boards with poor plating or lamination suffer from pad lifting, via cracking, and broken connections under thermal stress.

- Complex Design Hurdles:‚Äč Finding accurate heavy copper PCB design‚Äč guidelines and reliable PCB copper weight calculator‚Äč tools is difficult.

- Manufacturer Capability Gap:‚Äč Many standard circuit board manufacturers lack the specialized equipment and expertise for extreme heavy copper PCB‚Äč fabrication, resulting in poor yield and long lead times.

The solution lies in partnering with a specialist manufacturer who masters the entire process‚ÄĒfrom custom heavy copper PCB‚Äč design support to precision manufacturing. Here‚Äôs how we address these core issues:

- Superior Thermal Management:‚Äč We integrate PCB copper heatsink‚Äč structures and use high-Tg materials to effectively dissipate heat, preventing thermal failure.

- High-Current Carrying Capacity:‚Äč Our expertise in heavy copper PCB manufacturing‚Äč ensures traces and planes with low impedance, safely handling hundreds of amps.

- Enhanced Mechanical Integrity:‚Äč Advanced plating and controlled lamination processes create robust interconnects and strong adhesion, ensuring reliability in harsh environments.

- Expert Design Collaboration:‚Äč We provide clear heavy copper PCB design guidelines‚Äč and support to navigate challenges like aspect ratios and etching tolerances for your customized heavy copper PCB.

- Dedicated Production & Quick Turn:‚Äč Our factory is equipped for heavy copper PCB‚Äč production, offering professional heavy copper thickness multilayer PCB services, including quick turn heavy copper PCB‚Äč options without compromising quality.

At BEST Technology, we are a specialized heavy copper PCB factory‚Äč with deep expertise in fabricating reliable, high-performance boards. We combine advanced process with rigorous quality control to deliver solutions that meet the most demanding electrical and thermal requirements. For your custom heavy copper PCB circuit board‚Äč needs, pls feel free to contact us at sales@bestpcbs.com.

What Is PCB Heavy Copper?

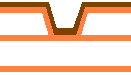

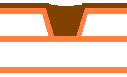

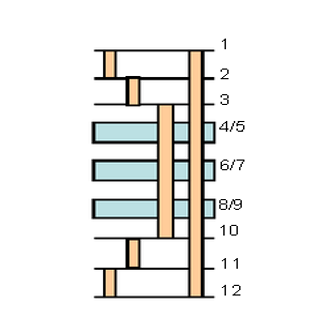

Heavy copper PCBs are defined by their exceptional conductor thickness. While standard PCBs use 1oz (35¬Ķm) or 2oz (70¬Ķm) copper, heavy copper starts at 3oz (105¬Ķm) and can exceed 20oz (700¬Ķm). This isn’t just about thicker foil; it involves specialized processes to plate and etch these massive copper weights, often creating unique cross-sectional profiles for traces and planes.

Key Characteristics:

- Copper Weight:‚Äč Ranges from >3 oz/ft¬≤ to 20+ oz/ft¬≤.

- Construction:‚Äč Can be used on inner layers, outer layers, or both in multilayer boards.

- Purpose:‚Äč Primarily for high-current paths, power distribution, and thermal dissipation.

How Does PCB Heavy Copper Differ From Standard PCBs?

The difference extends far beyond a simple thickness measurement, impacting design, manufacturing, and performance.

| Aspect | Standard PCB (1-2 oz) | Heavy Copper PCB (3-20+ oz) |

|---|---|---|

| Primary Function‚Äč | Signal routing, low-power circuits | High-current carrying, thermal management |

| Trace Width/Spacing‚Äč | Fine features possible | Wider traces and spacing required |

| Thermal Performance‚Äč | Moderate, relies on external heatsinks | Excellent, acts as an integral PCB copper heatsink‚Äč |

| Mechanical Strength‚Äč | Standard | Superior (stronger vias, plated holes, and substrate bond) |

| Manufacturing Process‚Äč | Standard etching & plating | Specialized sequential lamination, plating, and differential etching |

| Cost‚Äč | Lower | Higher due to material use and complex process |

In summary, heavy copper PCB boards‚Äč are engineered solutions for power, not just carriers for signals.

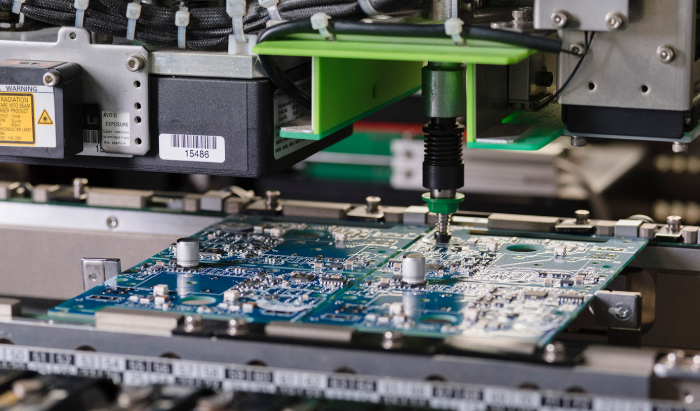

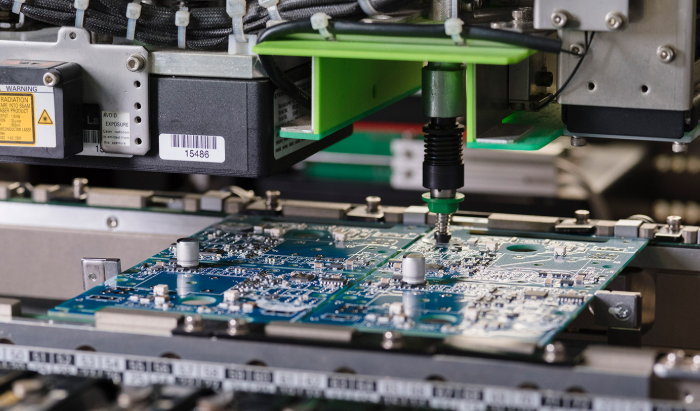

What Equipment Is Required in Heavy Copper PCB Factory Production?

Producing heavy copper PCBs demands specialized machinery beyond a standard PCB line.

- High-Capacity Plating Lines:‚Äč Essential for electroplating thick copper layers onto hole walls and surfaces to achieve the target PCB copper weight.

- Deep Etching Systems:‚Äč Equipment capable of differentially etching thick copper with precise control to maintain fine tolerances on sidewalls.

- Controlled Lamination Presses:‚Äč High-pressure and high-temperature presses that ensure proper resin flow and bonding without voids when laminating thick copper cores.

- Laser Direct Imaging (LDI):‚Äč For accurately patterning thick copper-clad laminates, where standard photo tools may struggle with light penetration and sidewall reflection.

- Advanced Drilling & Routing:‚Äč Robust drilling machines for creating clean holes in thick copper stacks and routing tools for separating the heavy, robust panels.

How PCB Thick Copper Improves Current Carrying and Thermal Performance?

The performance benefits are rooted in fundamental physics.

First, current carrying capacity is directly related to cross-sectional area. Doubling copper thickness doubles the area for a given trace width, drastically reducing resistance (R = ŌĀL/A). This minimizes I¬≤R losses and voltage drop.

Second, thermal performance improves because copper is an excellent thermal conductor. A PCB thick copper‚Äč plane acts as a distributed copper core PCB‚Äč heatsink, spreading heat away from hot components (e.g., power MOSFETs, inductors) to the board edges or designated thermal pads.

Formula for Trace Resistance:‚Äč R = ŌĀ * (L / (T * W))where ŌĀ=resistivity, L=length, T=thickness, W=width. Increasing T‚Äč directly reduces R.

PCB Copper Weight Explained and Why It Matters in Heavy Copper Designs?

PCB copper weight‚Äč is the mass of copper per unit area, expressed in ounces per square foot (oz/ft¬≤). It defines the finished thickness of the copper conductor.

- 1 oz copper:‚Äč Means 1 oz of copper spread over a 1 sq ft area, resulting in a thickness of ~1.37 mils (0.0348 mm). 1 oz copper thickness mm‚Äč is approximately 0.035mm.

- 4 oz copper PCB:‚Äč Has a copper thickness of ~5.5 mils (0.14 mm).

- 20 oz copper PCB:‚Äč Represents an extreme thickness of ~27.4 mils (0.7 mm).

In heavy copper PCB design, specifying the correct weight is critical. It determines the current rating, thermal mass, and mechanical requirements of the board, directly impacting safety, reliability, and size.

Heavy Copper PCB Design Guidelines for High-Current Applications

Designing a reliable PCB heavy copper with custom design‚Äč requires adherence to specific rules to avoid manufacturing defects and ensure performance.

- Aspect Ratio:‚Äč Maintain a sensible drill diameter to board thickness ratio (typically < 10:1 for heavy copper) to ensure proper via plating.

- Trace Width/Spacing:‚Äč Use a PCB copper weight calculator‚Äč (based on IPC-2152) to determine adequate trace width for your current. Allow for extra spacing due to etching undercut.

- Thermal Relief:‚Äč Always use thermal relief connections for components soldered to heavy copper planes to facilitate soldering heavy copper PCB.

- Corner Design:‚Äč Use 45-degree angles or rounded corners on traces to improve plating uniformity and reduce stress points.

- Layer Transition:‚Äč For multilayer boards, use multiple vias in parallel when connecting heavy copper layers to handle the current and reduce inductance.

- Material Selection:‚Äč Specify high-Tg (e.g., >170¬įC) and high thermal reliability materials to withstand the stresses of thick copper lamination.

Maximum PCB Copper Thickness and Practical Manufacturing Limits

The maximum PCB copper thickness continues to increase as heavy copper manufacturing technology advances. In standard PCB production, commonly used copper weights include 1 oz (35 ¬Ķm), 2 oz (70 ¬Ķm), 3 oz (105 ¬Ķm), 4 oz (140 ¬Ķm), and 6 oz (210 ¬Ķm), with 1 oz copper remaining the most widely adopted option for general-purpose electronics.

For applications involving higher current loads, designers typically select 2 oz copper or thicker to reduce resistive losses and improve thermal dissipation. As current demand increases, thicker copper becomes essential to maintain electrical stability and avoid excessive temperature rise.

In contrast, high-frequency applications often favor 1 oz copper or thinner. Thinner copper helps minimize conductor loss and signal attenuation, which is critical for maintaining signal integrity at higher frequencies.

As requirements move beyond standard designs, 20 oz copper thickness in heavy copper PCB is already commercially available. Some specialized heavy copper PCB factories are capable of processing copper thicknesses of 30 oz or more by using advanced techniques such as embedded copper PCB structures, copper inlays, or pre-formed copper inserts.

However, the practical manufacturing limits of PCB heavy copper are not determined by copper weight alone. They are defined by several key process constraints:

- Etching capability

The ability to form controlled trace geometries without excessive undercut becomes increasingly challenging as copper thickness increases. - Plating uniformity

Ensuring even copper distribution in deep vias, plated features, and across the entire panel is critical for electrical and mechanical reliability. - Lamination challenges

Very thick copper layers increase the risk of resin starvation, poor adhesion, and void formation during lamination, especially in multilayer structures.

In most real-world power and industrial applications, 10 oz to 12 oz copper offers an optimal balance between current-carrying capacity, thermal performance, cost efficiency, and manufacturability. Copper thickness beyond this range is typically reserved for highly specialized designs where extreme electrical or thermal demands justify the added complexity and cost.

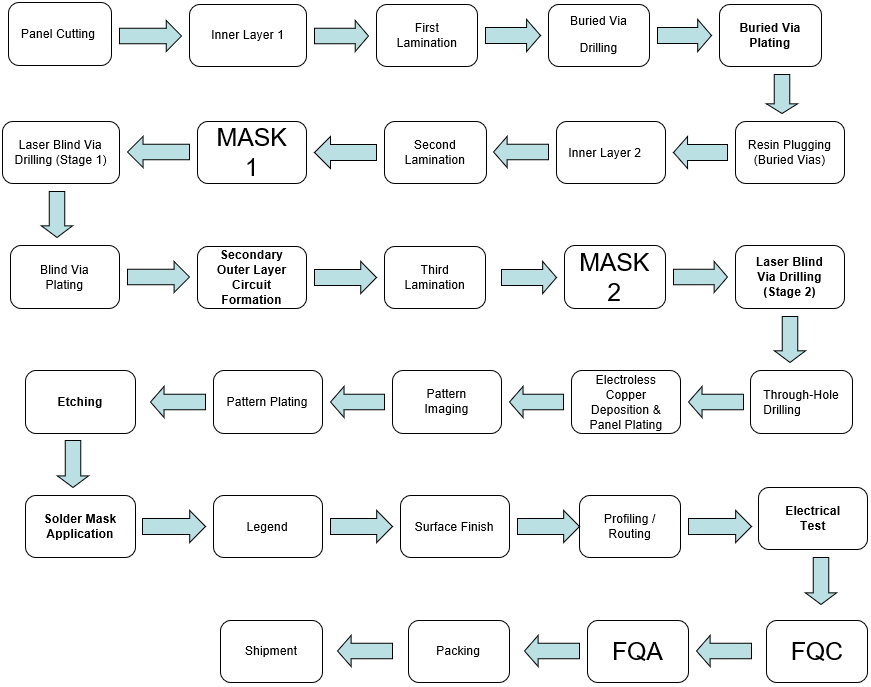

Heavy Copper PCB Manufacturing Process and Key Technical Challenges

The heavy copper PCB manufacturing‚Äč process is nuanced.

- Core Preparation:‚Äč Starting with a thick copper-clad laminate.

- Drilling:‚Äč Creating holes for vias and PTHs.

- Electroplating:‚Äč The critical step of depositing copper to build up thickness on surfaces and in holes. This often requires multiple plating cycles.

- Patterning & Etching:‚Äč Using a thick, robust resist to define the circuit pattern and then chemically etching away the unwanted copper. Controlling the etch factor is a major challenge.

- Lamination (for multilayer):‚Äč Stacking and bonding layers. Managing the PCB copper density‚Äč and resin flow is crucial to avoid delamination.

- Surface Finish & Testing:‚Äč Applying finishes like ENIG or HASL and conducting rigorous electrical and thermal tests.

- Key Challenges:‚Äč Avoiding plating voids, controlling sidewall profile during etching, preventing inner layer separation during lamination, and ensuring even copper distribution.

How to Check PCB Copper Thickness?

Accurate verification of PCB copper thickness is critical for quality control, electrical performance, and reliability. In practice, manufacturers and laboratories use a combination of destructive and non-destructive measurement methods, depending on accuracy requirements, board structure, and testing conditions.

Commonly used PCB copper thickness measurement methods include:

- Cross-Sectioning (Metallographic Analysis)

This is the most accurate and authoritative method. A PCB sample is cut, mounted, polished, and examined under a metallographic microscope or scanning electron microscope (SEM) to directly measure copper thickness. It is widely used for process validation and failure analysis. - X-ray Fluorescence (XRF)

XRF is a non-destructive technique commonly used to measure surface copper plating thickness. It provides fast and accurate results for outer layers and is widely adopted in production inspection. - Micro-Resistance Measurement

This method calculates copper thickness by measuring the electrical resistance of a trace with a known length and width. It is useful for estimating average copper thickness and is often applied during process monitoring. - Eddy Current Measurement

Based on electromagnetic induction, eddy current testing allows non-contact and non-destructive copper thickness measurement, particularly effective for surface copper layers. - Weight Difference (Gravimetric Analysis)

By weighing a panel before and after etching, manufacturers can indirectly calculate the average copper weight. This method is mainly used for process comparison and verification, rather than precise local measurement. - Chemical Etching and Coulometric Methods

These techniques determine copper thickness by controlled chemical removal or electrochemical reactions. They are accurate but destructive, and typically used in laboratory environments. - Optical and Image-Based Measurement Systems

High-resolution optical instruments and image measurement systems can quickly visualize and measure copper thickness, especially when combined with calibrated reference standards. - Ultrasonic and Laser Measurement Techniques

These methods are applied in specific cases, such as complex multilayer boards, where non-contact measurement is required. Their effectiveness depends heavily on material structure and calibration.

To ensure reliable results, several practical considerations must be followed:

- Samples should be cleaned and pre-treated before measurement to remove contaminants.

- Measuring instruments must be properly calibrated prior to use.

- Measurement points should be carefully selected to ensure representative data.

- Environmental factors such as temperature and humidity should be controlled.

- Multiple methods may be combined to cross-verify results, as each technique has inherent limitations.

In summary, no single method is suitable for all PCB copper thickness measurements. Cross-sectioning and XRF remain the most widely trusted techniques in the PCB industry, while electrical, electromagnetic, optical, and chemical methods provide valuable complementary data. The appropriate measurement approach should always be selected based on accuracy requirements, board structure, and inspection purpose.

What Applications Require PCB Heavy Copper Circuit Boards?

These boards are essential in high-power, high-stress industries:

- Power Converters & Supplies:‚Äč UPS systems, industrial SMPS, welding equipment.

- Automotive & EV:‚Äč Battery management systems (BMS), motor controllers, charging infrastructure.

- Renewable Energy:‚Äč Solar inverter combiner boxes, wind turbine control systems.

- Industrial Equipment:‚Äč Motor drives, high-power LED lighting, power distribution backplanes.

- Aerospace & Defense:‚Äč Radar systems, power distribution units (PDUs), avionics.

- High-Voltage Applications:‚Äč Heavy copper PCB vacuum high voltage‚Äč equipment like X-ray generators and particle accelerators.

How Do Heavy Copper PCB Factories Control Etching and Plating Quality?

Top-tier heavy copper PCB manufacturers‚Äč implement stringent controls:

- Plating:‚Äč Use pulse or periodic reverse plating for better throwing power and uniformity. Monitor bath chemistry, temperature, and current density in real-time.

- Etching:‚Äč Employ spray etchers with precise chemistry control and multi-stage rinsing. They carefully balance etch rate to achieve the desired heavy copper PCB thickness chart‚Äč specifications without over-etching fine features.

- Process Qualification:‚Äč Running test coupons on every panel for cross-sectional analysis to validate plating thickness in holes and on surfaces.

- Automated Optical Inspection (AOI):‚Äč To catch etching defects like nicks, mouse bites, or insufficient copper removal.

What Is Driving Growth in the Heavy Copper PCB Market?

The heavy copper PCB market‚Äč is expanding due to several key trends:

- Electrification:‚Äč The boom in EVs, charging stations, and renewable energy demands robust power electronics.

- Miniaturization with Higher Power:‚Äč Devices are getting smaller but more powerful, increasing power density and thermal management needs.

- Reliability Demand:‚Äč Industries like automotive and aerospace require longer lifespans and higher reliability under thermal cycling, which heavy copper provides.

- Advancements in Technology:‚Äč Improved manufacturing processes are making heavy copper PCB boards‚Äč more accessible and cost-effective.

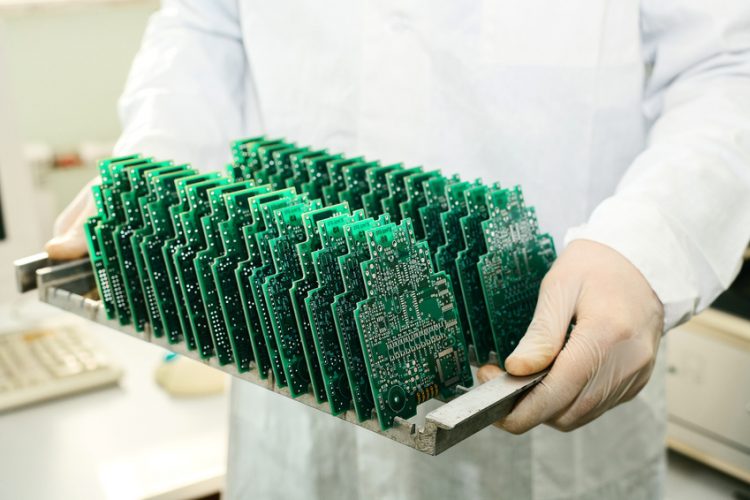

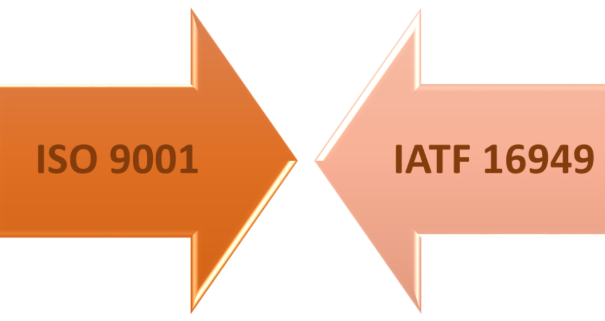

How to Choose a Reliable Heavy Copper PCB Manufacturer for Custom Projects?

Selecting the right partner is crucial for success. Look for:

- Proven Expertise & Specialization:‚Äč Seek a professional heavy copper thickness multilayer PCB manufacturer, not just a generalist. Review their portfolio for similar projects.

- Technical Support & DFM:‚Äč They should offer proactive heavy copper PCB design‚Äč review and strong Design for Manufacturability (DFM) feedback.

- Advanced Capability Portfolio:‚Äč Can they handle your required maximum PCB copper thickness, layer count, and incorporate features like copper core PCB‚Äč or embedded copper?

- Transparent Communication & Pricing:‚Äč They should provide clear heavy copper PCB quotes, a detailed heavy copper PCB pricelist‚Äč breakdown, and realistic timelines.

- Robust Quality Certifications:‚Äč Certifications like IATF 16949 (automotive), AS9100 (aerospace), and ISO 9001 are strong indicators of a quality system.

- Geographic Consideration:‚Äč While there are many China heavy copper PCB manufacturers, also consider heavy copper PCB USA‚Äč or heavy copper PCB UK‚Äč suppliers for proximity and IP protection if needed.

To summarize, PCB Heavy Copper‚Äč is an enabling technology for the most demanding power electronics, offering unmatched current capacity, thermal dissipation, and mechanical robustness. This guide has explored its design, manufacturing, applications, and selection criteria to empower your next high-power project.

For a reliable PCB heavy copper with custom design‚Äč that meets your exact specifications and performance benchmarks, partner with a specialist. BEST Technology possesses the dedicated equipment, engineering expertise, and rigorous quality controls to deliver superior heavy copper PCB circuit boards. We support projects from prototype to volume production, including quick turn‚Äč needs. A warm welcome to contact our team to discuss your requirements: sales@bestpcbs.com.

FAQs

How Thick Is a Heavy Copper PCB?

- A heavy copper PCB typically refers to a printed circuit board with copper thickness greater than 3 oz (105 ¬Ķm) per layer. Common heavy copper ranges include 4 oz, 6 oz, 10 oz, and in specialized applications, 20 oz or more, depending on current, thermal, and mechanical requirements.

What Type of Copper Is Used in PCBs?

- Most PCBs use electro-deposited (ED) copper foil, which is well suited for standard and heavy copper applications. For high-frequency or signal-sensitive designs, rolled annealed (RA) copper may be used due to its smoother surface and better flexibility, especially in flex and rigid-flex PCBs.

How Thick Is 1 oz Copper on a PCB?

- 1 oz copper on a PCB has a nominal thickness of approximately 35 ¬Ķm (0.035 mm). This is the most commonly used copper thickness for standard PCBs and is suitable for general signal and low-current applications.

How Thick Is 3 oz of Copper on a PCB?

- 3 oz copper corresponds to a thickness of approximately 105 ¬Ķm (0.105 mm). It is often used in designs that require higher current capacity or improved thermal performance compared to standard 1 oz or 2 oz copper.

How to Choose PCB Copper Thickness?

- PCB copper thickness should be selected based on several key factors, including current requirements, thermal dissipation needs, signal frequency, board size, and manufacturing capability. Thicker copper is typically chosen for high-current or power electronics, while thinner copper is preferred for high-frequency signal integrity and fine-line routing.

What Is the Average Thickness of a PCB?

- The average thickness of a PCB is usually around 1.6 mm, which is the industry standard for most applications. However, PCB thickness can vary widely depending on layer count, material selection, and application requirements, ranging from less than 1.0 mm to over 3.2 mm.