What is a 6 Layer PCB?

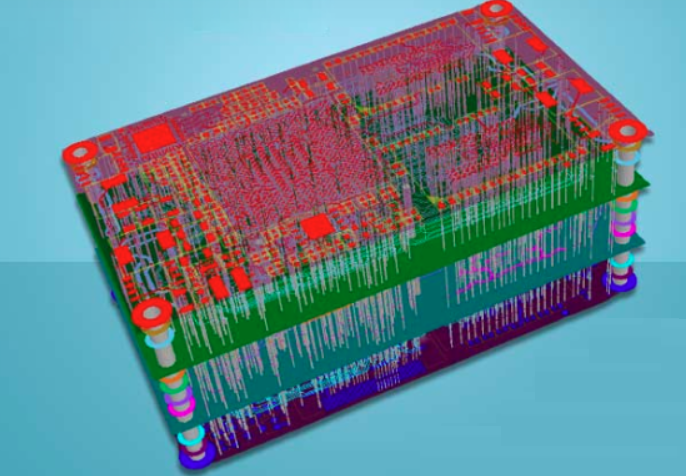

A 6 layer PCB is a printed circuit board that has six conductive layers. It consists of 4 inner layers and 2 outer layers, of which the inner layer is made of copper foil and located in the center of the board (we cannot see it by our eyes), while the outer layer is located on the top and bottom of the board. This design packs a punch, letting you fit more complex circuitry into a smaller space. Itâs perfect for small electronic devices that need to do a lot.

6 Layer PCB Structure

In a typical 6 layer PCB stackup, the conductive layers are numbered from top to bottom, starting with Layer 1. Hereâs what a standard configuration looks like:

- Layer 1: Top Layer

- Layer 2: Reference Plane 1

- Layer 3: Signal or Plane Layer 2

- Layer 4: Signal or Plane Layer 3

- Layer 5: Reference Plane 2

- Layer 6: Bottom Layer

The top and bottom layers are the two most common layers in a 6-layer PCB. They are often used to mount large components and connectors. The main role of the top and bottom layer is to provide the structure and support of the circuit board, and can also be used to connect external devices. The middle layers handle signals and reference planes (like ground and power).

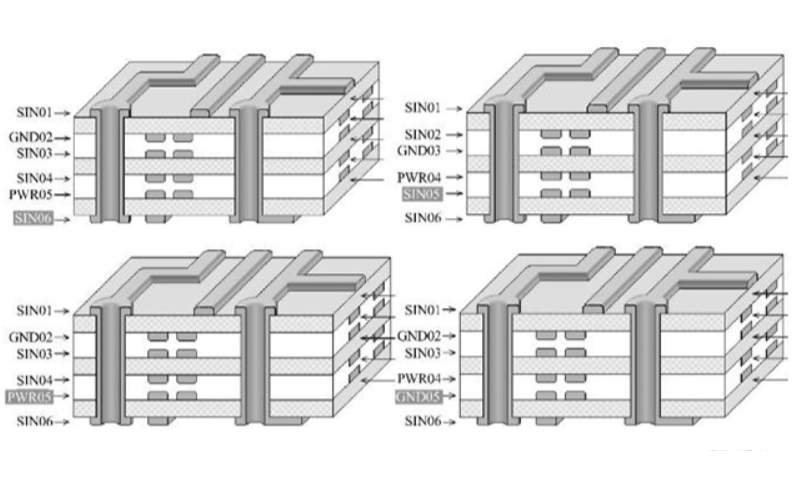

Common 6 Layer PCB Stack-Up

When it comes to stacking up those layers, you have a few common configurations:

Stack-Up Option 1: S G S S P S

- Top Layer (Signal)

- Layer 2 (Ground)

- Layer 3 (Signal)

- Layer 4 (Signal)

- Layer 5 (Power)

- Bottom Layer (Signal)

This kind of stack up has more signal layers, which is conducive to the wiring work between components; Because POWER and GND are far apart and not tightly coupled, the signal layers are directly adjacent, which is easy to cause crosstalk. Therefore, staggered wiring is required during wiring. When the power supply impedance is low.

Stack-Up Option 2: S S G P S S

- 1. Top Layer (Signal)

- 2. Layer 2 (Signal)

- 3. Layer 3 (Ground)

- 4. Layer 4 (Power)

- 5. Layer 5 (Signal)

- 6. Bottom Layer (Signal)

POWER and GND are tightly coupled, but the plane reference is too far away and the signal isolation is not good, which is easy to cause crosstalk.

Stack-Up Option 3: S G S G P S (preferred solution)

- 1. Top Layer (Signal)

- 2. Layer 2 (Ground)

- 3. Layer 3 (Signal)

- 4. Layer 4 (Ground)

- 5. Layer 5 (Power)

- 6. Bottom Layer (Signal)

POWER and GND layers are tightly coupled, with good EMI characteristics, and the signal layer is directly adjacent to the internal electrical layer, and is effectively isolated from other signal layers, which is not easy to crosstalk.

Stack-Up Option 4: S G S P G S

- 1. Top Layer (Signal)

- 2. Layer 2 (Ground)

- 3. Layer 3 (Signal)

- 4. Layer 4 (Power)

- 5. Layer 5 (Ground)

- 6. Bottom Layer (Signal)

POWER and GND are tightly coupled. The signal layer is adjacent to the ground layer, the power layer is paired with the ground layer, the impedance of each line layer can be better controlled, and the magnetic field line can be well absorbed by both layers. This layered scheme is suitable for the design of high chip density and high clock frequency.

6 Layer PCB Thickness

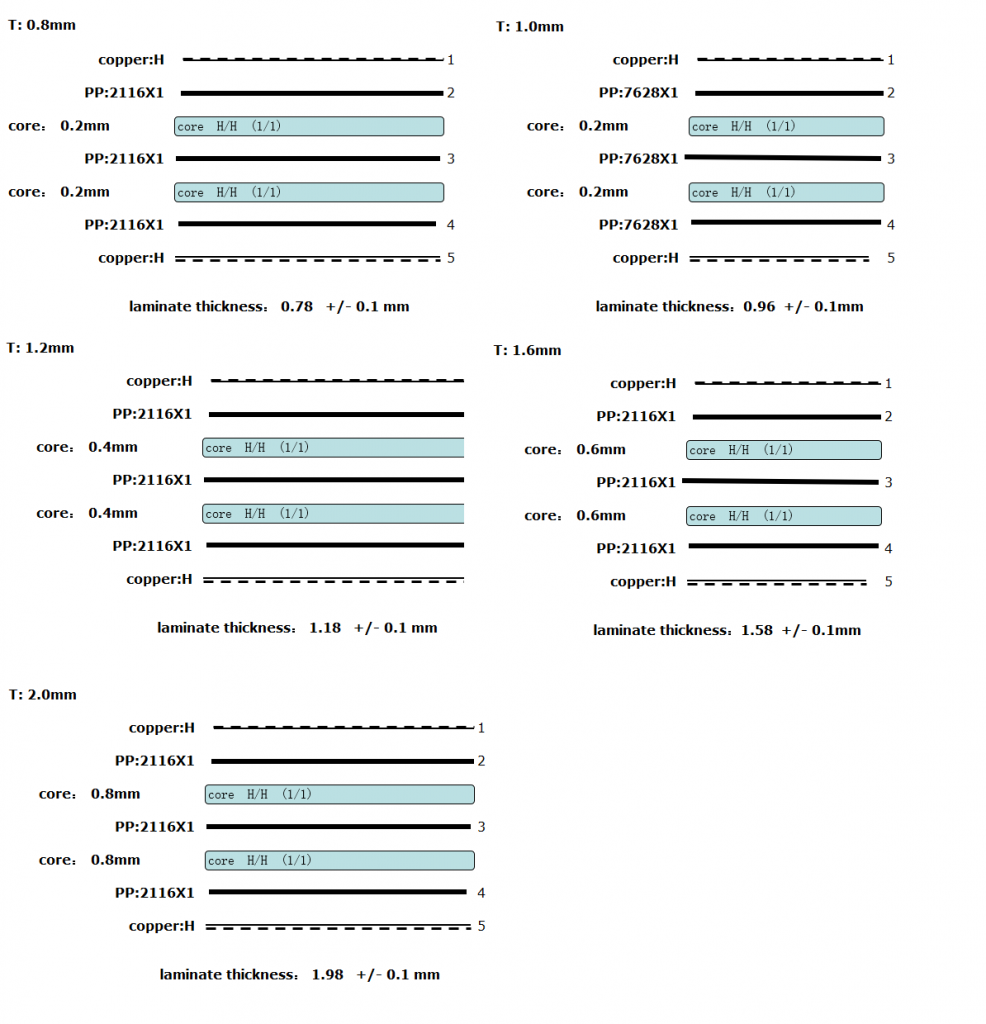

The total thickness of a 6 layer PCB usually ranges from 0.8 mm to 2.0 mm. Of course, this can vary based on materials and what youâre aiming for. Each layer contributes to this thickness, and the copper thickness often ranges from 1 oz to 3 oz. Thicker boards tend to offer better durability and heat dissipation, but they can also be less flexible, which is something to consider depending on your application. The common thickness structure are showing as below:

Above are the common structure and thickness of a 6 layer multi-layer PCB, if you want thicker thickness, welcome to contact with us, our expertise team will give you the best and cost-effective solution!

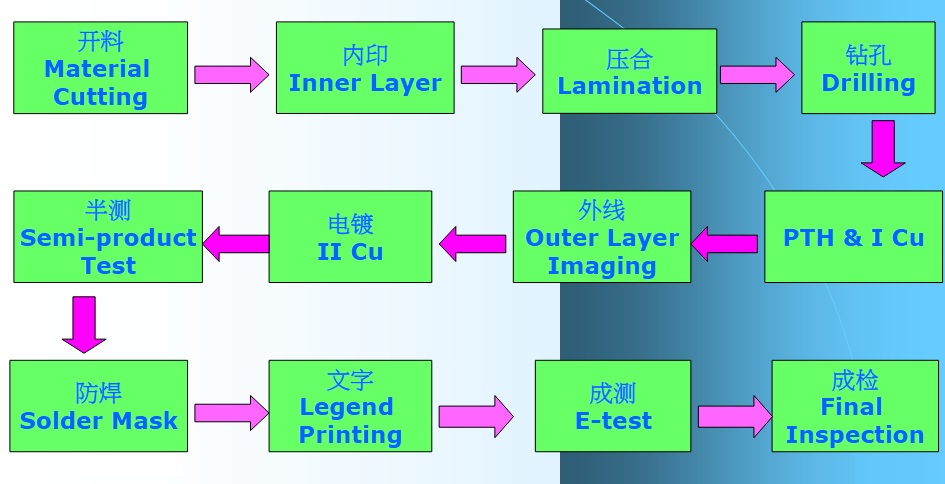

6 Layer PCB Manufacturing Process

6 Layer PCB Price

The price of a 6 layer PCB doesnât have a standard number/value. It varies based on factors like material, size, and complexity. Generally, they are more expensive than simpler designs due to the increased number of layers and the advanced manufacturing processes involved. However, the investment often leads to improved performance and durability. Here are some factors that will effect your 6 layer PCB price:

- Design complexity: If the design is intricate, expect a higher price.

- Material quality: Premium materials can drive up the cost but often improve performance.

- Volume: Producing in bulk usually lowers the cost per unit.

- Manufacturing process: The more difficult process, it will cost much more. Like a normal 6 layer FR4 PCB with through holes is cheaper than 6layer HDI PCB with blind or buried via holes.

- Surface treatment: Different treatment you choose will affect your overall price.

In general, youâre looking at prices that range from $5 to $50 or more per unit. It might sound steep, but investing in a quality 6 layer PCB can really pay off in terms of performance and reliability.

6 Layer PCB vs. 4 Layer PCB

6 layer PCB is different with 4 layer PCB, from the board thickness, cost, line width and spacing and etc. Here we listing three main differences between them:

1. Board thickness

The thickness of the PCB board is the thickness of the fingerboard, usually in millimeters. There is a difference in thickness between six-layer and four-layer plates. The thickness of the six-layer plate is usually between 1.6mm and 2.0mm, while the thickness of the four-layer plate is between 1.0mm and 1.6mm. Therefore, the thickness of the six-layer plate is thicker than that of the four-layer plate.

2. Line width

The line width refers to the width of the wire on the circuit board. There is also a difference in line width between six-ply and four-ply panels. The line width of a six-layer board is wider than that of a four-layer board. This is because in a six-layer board, there are more circuit layers, so it is easier to accommodate a wider line width.

3. Drilling

Drilling is an indispensable part of the PCB board production process. It is usually used to punch holes in the board so that electronic components can be installed. There is also a difference in the number of holes drilled between six-ply and four-ply panels. Because the six-layer board has more circuit layers, the number of holes is relatively high.

Impedance Control for 6 Layer PCB

âThe impedance control of 6-layer PCB is to control the impedance value of signal transmission by designing the geometry and material of the circuit board to improve the speed and quality of signal transmission, and reduce signal reflection and interference. â Common methods of controlling impedance include adjusting parameters such as the width, spacing and thickness of the signal lines, using differential lines to reduce signal interference and noise, and using interlayer isolation to prevent signal interference.

In the 6-layer PCB design, the specific implementation methods of impedance control include:

- Signal line width and spacing control

Signal line width and spacing is a key factor affecting the impedance. Strictly control the line width tolerance within ±10%, and pay attention to the possible pinholes, notches, dents and other problems on the wire, which will further affect the line width and impedance.

- Dielectric layer thickness control

Dielectric layer thickness has a significant effect on impedance. Use advanced manufacturing technology and equipment to ensure the uniformity and consistency of the thickness of the medium layer, and strictly control the thickness tolerance of the medium layer within the design requirements.

- âThe use of differential line

Differential line can effectively reduce signal interference and noise, improve the quality of signal transmission and anti-interference ability.

- Partially filled with copper and grounded

Fill the area without components or wires with copper, and ensure that the copper filled area is connected to the internal ground layer or power layer at multiple points. The distance between the connection holes does not exceed 1/20 of the highest harmonic wavelength of the signal â

6 Layer PCB Design Considerations

When youâre designing a 6 layer PCB, there are several things to keep in mind:

Reference Plane Placement

For the best performance, reference planes (usually ground and power) should be placed next to the routing layers. This setup helps maintain controlled impedance, which is critical for high-speed designs. Having a continuous ground plane right next to signal layers is a great practice.

Plane Splits

Sometimes, reference planes need to be divided into separate sections for analog and digital power. This keeps the analog circuitry isolated from the digital side, which helps reduce noise in sensitive areas.

Symmetry in Design

Itâs usually best to keep the stackup symmetrical, with reference planes both above and below the signal layers. This arrangement improves signal integrity. But in some cases, asymmetrical designs are used depending on specific design needs.

Thermal Management

Consider how to manage heat, especially in high-power scenarios, to ensure reliability.

Signal Routing

High-speed or noise-sensitive signals should be routed on the inner layers between reference planes. Keeping these signals away from the outer layers helps minimize interference.

Breakout Vias

When transitioning from inner layers to outer layers, breakout or stub vias should be used. These vias help manage any stub effects, keeping things tidy and controlled.

Minimum Spacing

Lastly, always follow the board fabricatorâs guidelines for minimum trace width, spacing, and annular ring sizes. This ensures the board meets the necessary standards and avoids any manufacturing issues.

Simulation Tools

Use simulation software to identify potential issues before manufacturing, which can save you time and hassle.

Best Technology is a reliable PCB manufacturer in China. As one of the highly experienced circuit board suppliers, our products and services include a wide range of printed circuit boards such as rigid PCBs, flex PCBs, rigid-flex PCBs, aluminum PCBs, RF Microwave PCBs, high-speed PCBs, high-frequency PCBs, HDI PCBs, etc. If you have such demands, welcome to contact us.