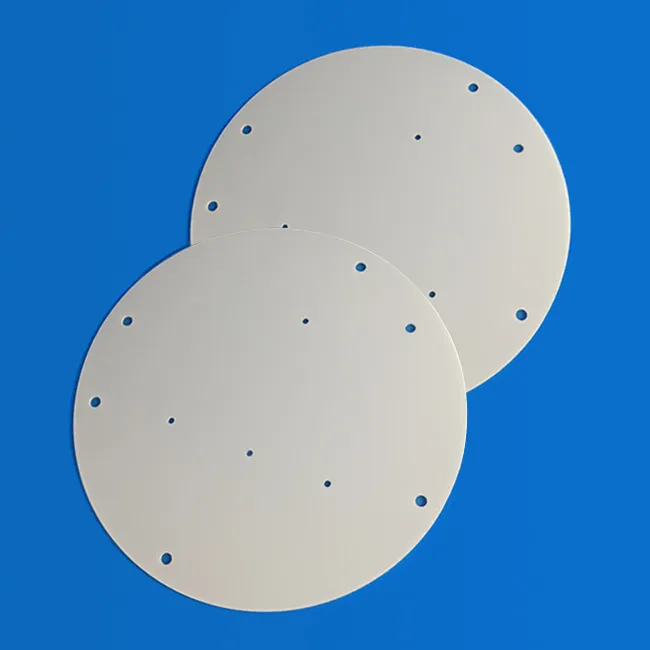

Aluminum nitride circular PCB stands out in the electronics industry due to its unique properties. Whether used in high-performance LED applications or precision circuits, this PCB material offers significant benefits over traditional ceramic PCBs. The circular Aluminum Nitride PCB belongs to the category of ceramic PCB substrates. In this blog, weāll dive into the specific advantages of aluminum nitride circular PCBs, including their thermal conductivity, machining ability, and their superiority in many industrial applications.

Can Aluminum Nitride Be Machined?

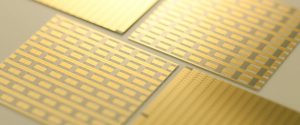

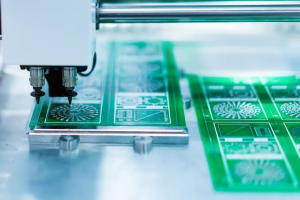

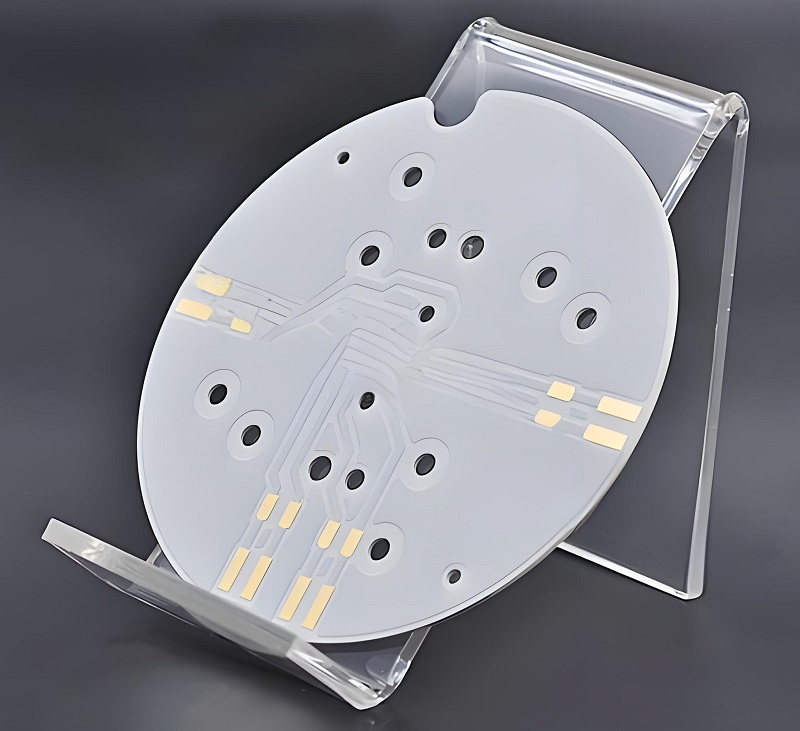

One of the most appealing features of aluminum nitride circular PCBs is their ability to be machined. Unlike many ceramics, aluminum nitride can be precisely processed to fit specific design requirements. Its flexibility in manufacturing makes it an ideal choice for custom and intricate circuit designs. The material can be milled, drilled, and cut using standard machining methods, which helps reduce production times and costs. This machining capability is particularly beneficial in industries where rapid prototyping and small-batch production are crucial.

What is the Thermal Conductivity of Aluminum Nitride PCB?

When it comes to thermal performance, aluminum nitride PCB is hard to beat. With a thermal conductivity of up to 170 W/mK, it surpasses many other PCB materials, including standard ceramic substrates. This excellent thermal conductivity allows heat to dissipate efficiently, making aluminum nitride circular PCBs ideal for high-power applications like LED lighting and power electronics. The ability to manage heat reduces the risk of component failure, improving the overall reliability and longevity of electronic devices.

Is Aluminum Nitride Electrically Conductive?

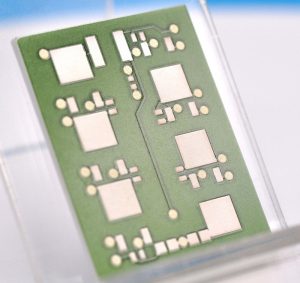

Unlike metals, aluminum nitride is an insulator, meaning it does not conduct electricity. This is an essential property for PCBs used in high-voltage or high-frequency circuits. Aluminum nitride circular PCBs can offer the perfect balance between thermal management and electrical insulation, making them ideal for applications that require both heat dissipation and isolation of electrical components. This non-conductive property is why aluminum nitride is preferred in sensitive electronic designs, ensuring that circuits remain stable and secure.

Is Aluminum Nitride Piezoelectric?

Aluminum nitride has piezoelectric properties, which means it can generate an electric charge in response to mechanical stress. However, when used in PCB applications, this characteristic is typically not utilized. In most designs, the focus is on aluminum nitrideās excellent thermal conductivity and electrical insulation. While this materialās piezoelectric nature could be beneficial in specialized sensors or actuators, its primary advantage in PCB manufacturing lies in its thermal and insulating properties.

Is Aluminum Nitride Brittle?

Although aluminum nitride has a high level of thermal conductivity, it is still a ceramic material, which means it can be somewhat brittle under certain conditions. However, with the proper design and handling, this brittleness can be mitigated. Aluminum nitride circular PCBs can still be robust enough for most applications, as long as they are not subjected to excessive mechanical stress. The key lies in the careful design and integration of aluminum nitride PCBs into a circuit that can protect the material from sudden impacts or extreme forces.

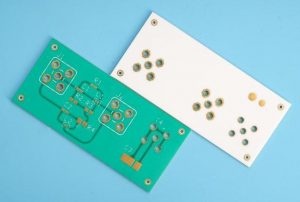

What Makes Aluminum Nitride Circular PCBs Better Than Ceramic PCBs?

Aluminum nitride circular PCBs offer several advantages over traditional ceramic substrates. First and foremost, the thermal conductivity of aluminum nitride is far superior to most ceramic PCBs. This means aluminum nitride is better at dissipating heat, reducing the risk of overheating in electronic components. Additionally, aluminum nitride can be machined to precision, which is not always the case with ceramic substrates. These benefits make aluminum nitride circular PCBs ideal for use in high-power applications, such as LED lights, power electronics, and RF circuits.

What Industries Benefit Most from Aluminum Nitride Circular PCBs?

Several industries can benefit from the use of aluminum nitride circular PCBs, including:

LED Industry: The exceptional heat management properties of aluminum nitride make it a perfect material for high-performance LED applications.

Power Electronics: Aluminum nitride is ideal for use in power supplies, converters, and inverters due to its superior thermal conductivity and electrical insulation.

Telecommunications: The high-frequency capabilities of aluminum nitride circular PCBs make them suitable for RF applications, ensuring reliable signal transmission.

Automotive Electronics: With increasing demand for power-efficient systems, aluminum nitride PCBs are often used in automotive applications that require both high heat dissipation and electrical insulation.

These industries benefit from the unique combination of aluminum nitrideās properties, offering improved performance and durability in their products.

How to Optimize Aluminum Nitride Circular PCB Performance in Designs?

To maximize the performance of aluminum nitride circular PCBs, several factors should be considered during the design process:

Thermal Management: Proper thermal design is essential to ensure the efficient heat dissipation that aluminum nitride is known for. Using thermal vias and optimizing component placement can help maximize the heat flow.

Material Selection: While aluminum nitride is an excellent thermal conductor, itās important to match the materialās properties to the specific needs of your application. This ensures the best balance between performance and durability.

Machining Techniques: Since aluminum nitride can be machined, itās crucial to use the right equipment and techniques to avoid cracking or damaging the PCB during production. Ensuring the right tolerances can also improve the functionality and reliability of the final product.

Stress Resistance: Although aluminum nitride is generally robust, itās still a ceramic material, so designs should be built to protect the PCB from mechanical stress during use. Reinforcements, proper encapsulation, and protective layers can prevent potential damage.

By addressing these factors, you can optimize the performance of aluminum nitride circular PCBs in your designs.

In conclusion, aluminum nitride circular PCBs stand out for their superior thermal conductivity, machinability, and electrical insulation. These qualities make them a top choice for a variety of industries, from LED lighting to automotive electronics. While they do have some brittleness due to their ceramic nature, with proper design and handling, their benefits far outweigh the drawbacks. Whether you are looking to improve the heat management of your circuit or need a reliable material for high-performance applications, aluminum nitride circular PCBs offer a compelling solution.

When choosing the right PCB material for your next project, consider aluminum nitride for its performance advantages. Itās a highly versatile option that can meet the demands of modern, high-tech designs, providing a perfect balance of thermal efficiency and electrical safety. Looking for top-quality aluminum nitride circular PCBs? At Best Technology, we provide a wide range of PCB solutions tailored to your needs. Contact us at sales@bestpcbs.com for inquiries or further details.