In the rapidly developing electronics industry, aluminum substrates, as a key electronic component carrier, have a direct impact on the reliability and stability of electronic products through their quality and performance. Choosing a reliable aluminum pcb suppliers is crucial for electronics manufacturers.

What is an aluminum substrate?

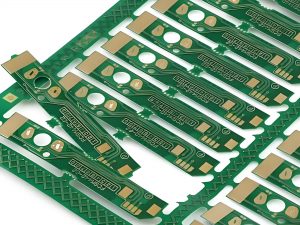

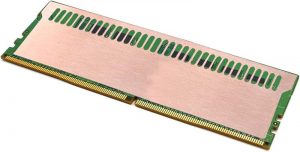

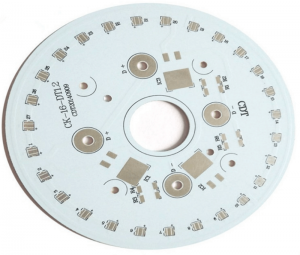

Aluminum substrate, the full name of which is aluminum-based copper clad laminate, has good heat dissipation, electrical insulation and mechanical processing performance. It is widely used in LED lighting, power modules, automotive electronics, communication equipment and other fields.

In these fields, aluminum substrates can effectively dissipate the heat generated by electronic components quickly, thereby ensuring the normal working temperature of electronic components and extending their service life. At the same time, the high insulation performance of aluminum substrates can prevent the occurrence of safety problems such as electrical short circuits and leakage.

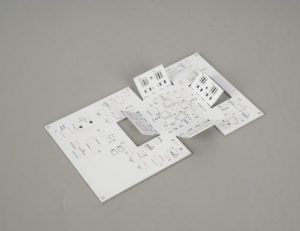

In addition, the mechanical processing performance of aluminum substrates also enables it to adapt to various complex electronic equipment structure design requirements.

How to choose an aluminum pcb suppliers?

1. Conduct market research

- Before choosing an aluminum pcb supplier, you need to conduct sufficient market research. Understand the product quality, technical strength, production capacity, service quality and price of different suppliers, and make comparisons and analyses.

- You can get more information about suppliers through online searches, industry exhibitions, and consulting industry insiders. At the same time, you can also refer to the evaluations and recommendations of other customers to understand the reputation and credibility of the supplier.

2. On-site inspection of suppliers

- After determining some potential suppliers, you can conduct on-site inspections. On-site inspections can give you a more intuitive understanding of the supplier’s production equipment, production processes, quality control systems, and management levels.

- During the on-site inspection, you can communicate with the supplier’s technical personnel and management personnel to understand their technical strength and service level. At the same time, you can also view the supplier’s product samples to understand the quality and performance of the products.

3. Conduct sample testing

- Before selecting an aluminum pcb supplier, you can ask the supplier to provide samples for testing. Sample testing can give you a more intuitive understanding of the supplier’s product quality and performance, and whether it meets your needs.

- When conducting sample testing, you need to test according to your actual use requirements, such as heat dissipation performance, electrical insulation performance, mechanical processing performance, etc. At the same time, you also need to check the appearance quality of the sample to ensure that there are no obvious scratches, stains, and defects.

How strong is BEST Technology?

BEST Technology has a strict quality control system. From raw material procurement to production and processing to product testing, every link is strictly controlled. And BEST Technology’s products have passed many international certifications, such as ISO9001 quality management system certification, UL certification, etc.

BEST Technology also has a strong technical R&D team, which can continuously launch new products and technologies to meet the needs of the market and customers. For example, the high thermal conductivity aluminum substrate they developed has a heat dissipation performance that is more than 30% higher than that of traditional aluminum substrates, and has been widely praised by customers.

BEST Technology also has advanced production equipment and process technology, using automated production lines and advanced surface treatment technology to ensure product production efficiency and quality. Their production capacity is in a leading position in the industry and can ensure on-time delivery of orders.

What are the classifications of aluminum-based PCBs?

Aluminum-based PCB (aluminum-based copper-clad laminate) is mainly divided into the following categories:

- General-purpose aluminum-based copper-clad laminate: The insulation layer of this type of aluminum-based copper-clad laminate is composed of epoxy glass cloth bonding sheets, which is suitable for the manufacture of general electronic products, providing basic electrical insulation and certain heat dissipation performance.

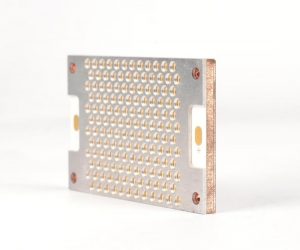

- High heat dissipation aluminum-based copper-clad laminate: Its insulating layer is composed of highly thermally conductive epoxy resin or other resins, which is designed to provide better heat dissipation and is suitable for high-power electronic devices.

- Aluminum-based copper-clad laminate for high-frequency circuits: The insulating layer of this type of copper-clad laminate is composed of polyolefin resin or polyimide resin glass cloth bonding sheet, which is particularly suitable for electronic devices that require high-speed signal transmission and high integration.

What are the characteristics of aluminum-based PCBs?

The characteristics of aluminum-based PCBs mainly include excellent heat dissipation, dimensional stability, insulation, durability, lightness and environmental protection.

- Excellent heat dissipation: Aluminum-based PCBs have excellent thermal conductivity because they use aluminum as the base material, which can effectively transfer heat from heating devices or important devices, thereby improving the overall performance of the product.

- Dimensional stability: The dimensional stability of aluminum substrates is higher. Compared with printed boards made of insulating materials, the dimensional changes of aluminum substrates are smaller, which helps to improve the reliability and durability of products.

- Insulation: Aluminum substrates have good insulation properties and can provide the electrical isolation required by electronic devices. At the same time, they are hard and can replace easily broken ceramic plates, effectively reducing the actual area required for printed circuit boards, so that products do not need to install radiators, etc., thereby improving the heat dissipation of products and improving product efficiency and reducing costs.

- Durability: Due to its high hardness, aluminum substrates can reduce the risk of accidental damage during production, handling and daily use, and provide strength, toughness and durability that glass fiber substrates cannot provide.

- Lightweight: Aluminum substrates enhance the strength and elasticity of products without adding extra weight, which helps to reduce the overall weight of products.

- Environmental protection: Aluminum is non-toxic and recyclable, which helps to reduce the impact of electronic waste on the environment.

In summary, aluminum-based PCBs provide electronic products with multiple advantages such as efficient heat dissipation, dimensional stability, excellent electrical performance, durability, lightness and environmental protection through their unique physical and chemical properties, making aluminum-based PCBs widely used in high-end electronic devices.

What are the application scenarios of aluminum-based PCBs?

The application scenarios of aluminum-based PCBs are very wide, mainly including the following aspects:

- High-power LED lighting: Aluminum-based PCBs can quickly and effectively transfer the heat generated by LEDs to the external environment, reduce the impact of high temperature on the life of LED chips, and improve the life and reliability of lamps.

- Power supply equipment: Such as switching power supplies, DC/AC converters, voltage regulators and other high-power density power modules, aluminum-based PCBs can quickly dissipate heat to ensure stable operation of the circuit.

- Audio equipment: The heating elements in audio devices such as audio amplifiers, power amplifiers, and preamplifiers can be well managed by aluminum-based PCBs.

- Communication electronic equipment: Components in communication systems such as high-frequency devices, filters, signal transmission and reception circuits, etc., use aluminum-based PCBs to improve system reliability.

- Computers and peripherals: Some areas on the motherboard, power supply modules, and hardware such as graphics cards may use aluminum-based PCBs to improve the heat dissipation effect.

- Office automation equipment: Motor drivers and other components that require effective heat dissipation.

- Automotive electronics: Including electronic speed regulators, ignition devices, power controllers and other vehicle-mounted applications.

- Industrial control field: High heat density circuit boards inside industrial control equipment such as frequency converters and inverters.

Aluminum-based PCBs are widely used in many fields due to their excellent heat dissipation and electrical insulation properties, especially in situations where efficient heat dissipation and stable operation are required.

Choosing a high-quality aluminum pcb supplier is crucial for electronics manufacturers. When choosing a supplier, it is necessary to consider the key points comprehensively. Choose a suitable aluminum pcb suppliers through market research, field visits and sample testing.