CEM1 (Composite Epoxy Material) is a popular material used in the electronics industry for printed circuit boards (PCBs). While newer materials like FR4 have gained popularity, CEM1 still holds an important place in the market. This material offers a cost-effective solution for many electronic devices, especially when the application does not require the highest levels of durability or thermal resistance. But what makes CEM1 such a mainstay? And how does it stack up against other materials like CEM2, CEM3, and FR4?

In this blog, weâll dive into the details of CEM1 PCB material, exploring its specifications, advantages, and the reasons itâs still commonly used. Weâll also compare it to other PCB materials, helping you understand when itâs the right choice for your project.

What is CEM1 PCB Material?

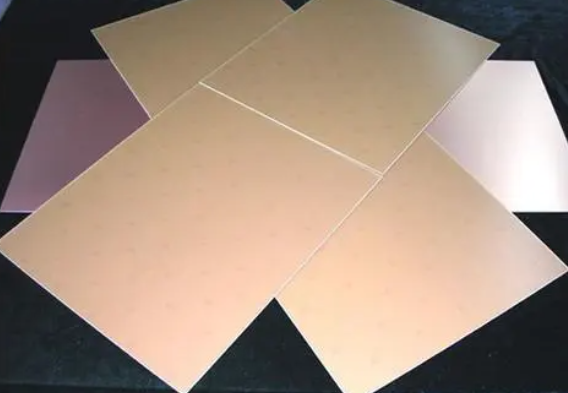

First, itâs essential to understand that CEM-1 is a material grade representing a specific type of composite base copper-clad laminate. CEM-1 material is made from multiple layers of cellulose or cotton pulp fiber paper and glass fiber cloth, all of which are reinforced with flame-retardant epoxy resin. Usually has milky-white color. While itâs considered a low-grade material, it is still widely used in the PCB industry, especially for single-sided PCBs.

You might wonder why CEM-1 remains popular despite the rapid advancements in technology, where electronic products are becoming thinner and more compact. The reason lies in its cost-effectiveness. Even though new, high-quality materials are now available, they tend to be more expensive. In contrast, CEM-1 offers a significantly lower cost while still providing decent electrical properties.

CEM-1 PCBs are typically single-sided, meaning components are mounted on just one side of the board. This limits its use in high-performance applications, but it remains an excellent choice for many consumer electronics, where both performance and budget constraints are critical. On the other hand, CEM-3 laminates feature a chopped fiberglass core, which provides added strength and durability. CEM-3 shares similar performance characteristics with the more commonly used FR-4 material.

CEM-3 is often chosen for applications where flame resistance and reliability are key factors. Unlike CEM-1, which is confined to single-sided boards, CEM-3 is suitable for double-sided and multilayer PCB designs, making it a more versatile option in more complex applications.

CEM-1 Material Specifications

CEM-1âs specifications reveal its balance between performance and affordability. Hereâs a breakdown of some key specs:

| Property | Value |

| Substrate Thickness | 1.0mm, 1.2mm, 1.5mm, 1.6mm |

| Copper Thickness | 35um, 70um |

| Color | Milky-white |

| Sheet Dimension | 927*1230mm, 1020*1030mm, 1044*1245mm |

| Dielectric Constant | 4.5 (depends on frequency) |

| Thermal Conductivity | In middle level |

| Working Temperature | 130C (highest) |

| Water Absorption | <0.3% |

| Flammability | UL94V-0 |

These specifications show that while CEM1 canât handle extreme conditions like high temperatures or stress, itâs adequate for a wide range of general applications.

CEM1 vs FR4

CEM1 and FR4 are two of the most widely used PCB materials. FR4 is fiberglass-reinforced and offers greater durability and thermal performance. So why use CEM1?

The key reason is cost. CEM1 is significantly cheaper than FR4, making it a perfect choice for applications that donât require the superior mechanical and thermal properties of FR4. For example, if youâre designing a simple consumer product, CEM1 may offer all the performance you need at a fraction of the cost.

Additionally, FR4 is typically used for multi-layer PCBs, while CEM1 is commonly found in single-layer designs. If your product doesn’t need multi-layer complexity, CEM1 can save both time and money in manufacturing.

CEM1 vs CEM3

CEM-1 and CEM-3 are comparable in some aspects but differ in specific characteristics. Both materials are impregnated with epoxy resin. CEM-1 is composed of a paper core and woven glass fabric layers, all bonded with epoxy resin. It offers easy punching, excellent electrical properties, and better flexural strength compared to paper-based laminates. This makes it a popular choice in the PCB industry, especially for single-sided boards, where it can be punched up to a thickness of .093âł.

On the other hand, CEM-3 is more similar to FR-4 in terms of performance. Instead of woven glass fabric, it uses chopped glass fibers, which gives it a milky white appearance and a smoother surface. CEM-3 is flame-retardant and is typically used in double-sided and multilayer PCBs, making it a versatile alternative to FR-4. Itâs a relatively new substrate material developed with characteristics similar to FR-4.

CEM-3 incorporates glass mat fibers, which provide better mechanical strength and durability compared to CEM-1. This makes CEM-3 more suitable for applications that require higher impact resistance and reliability. However, CEM-3 is generally more expensive due to its added strength. For applications where the extra strength of CEM-3 isn’t necessary, CEM-1 remains a more cost-effective option, as both materials offer similar thermal properties.

Advantages and Disadvantages of CEM1 PCB

Advantages:

- Lower cost: The cost of CEM1 PCB is lower than that of glass fiber cloth copper clad plate, but higher than that of paper based copper clad plate.

- âGood machinability: CEM1 PCB has excellent machinability and is easy to press.

- âGood electrical performance and bending strength: compared with paper grades, CEM1 PCB has excellent electrical performance and higher bending strength.

- âWide range of application: suitable for electronic products with low performance requirements and low cost, such as toys and household appliances.

- It has a suitable glass transition temperature, better heat dissipation, and electric energy storage.

âDisadvantages:

- Mechanical properties and heat resistance slightly inferior: compared with FR4, the mechanical properties and heat resistance of CEM1 PCB is slightly inferior.

- âLimited application scenarios: mainly applicable to electronic products with low performance requirements, not suitable for high mechanical strength and heat resistance.

What are the Applications of CEM1 PCBs?

CEM1 is used in a wide variety of products that require a cost-effective yet reliable PCB solution. Here are a few typical applications:

1. Consumer Electronics: Products like calculators, remote controls, and basic home appliances often use CEM1 due to its affordability and performance for low-stress applications.

2. LED Lighting: In some low-heat LED lighting applications, CEM1 is a preferred choice because of its lightweight nature and reasonable thermal properties.

3. Automotive Electronics: Some automotive systems that donât require high-end PCBs may opt for CEM1 due to its cost-efficiency.

4. Computers: CEM-1 PCB acts as heat redundant in PCs. Computer processors generate a lot of heat, therefore cooling PC parts like computer chips.

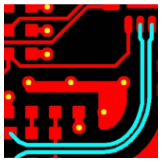

Which Software Is the Best When Designing CEM1 PCB?

When designing CEM1 PCBs, the right software helps optimize the layout and improve performance. Popular software options include:

- Altium Designer: Known for its robust design tools and ease of use.

- KiCad: An open-source solution thatâs ideal for smaller projects or hobbyists.

- EAGLE: Offers strong features for both professionals and beginners, with a user-friendly interface.

Some other software like Easy EDA, Circuit Maker also available.

Steps in Manufacturing CEM1 PCBs

The manufacturing process of CEM1 PCBs involves several steps:

- Design and Output

- Transfer the file to film

- Print the image on the surface

- Removing unnecessary copper

- level alignment and optical inspection

- Layer up and Bonding

- Final Etching

- Application of Solder Mask

- Surface Finish

- Silkscreen

- Testing PCB Electronically

Why Choose Best Technology as Your CEM1 PCB Manufacturer?

Best Technology offers extensive experience in manufacturing CEM1 PCBs, delivering high-quality products at competitive prices. We understand the nuances of CEM1 material and its ideal applications. Our engineers are skilled in working with CEM1 material, ensuring your PCBs meet performance expectations. We offer pricing that fits within your budget without compromising quality. Lastly, we know how important speed is in electronics production, and we prioritize delivering your products on time.