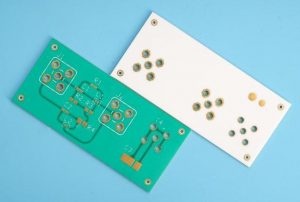

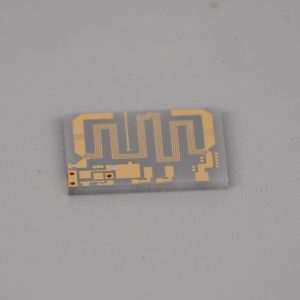

In the world of printed circuit board (PCB), ceramic PCB stands out as a reliable choice for applications requiring superior thermal conductivity, high-frequency performance, and robust electrical insulation. Ceramic multilayer PCB, in particular, offers an added advantage by combining multiple layers of ceramic material to enhance the performance and reliability of electronic devices. In this article, we’ll explore what ceramic PCBs is, its different types, and its specific advantages compared to other materials like FR4.

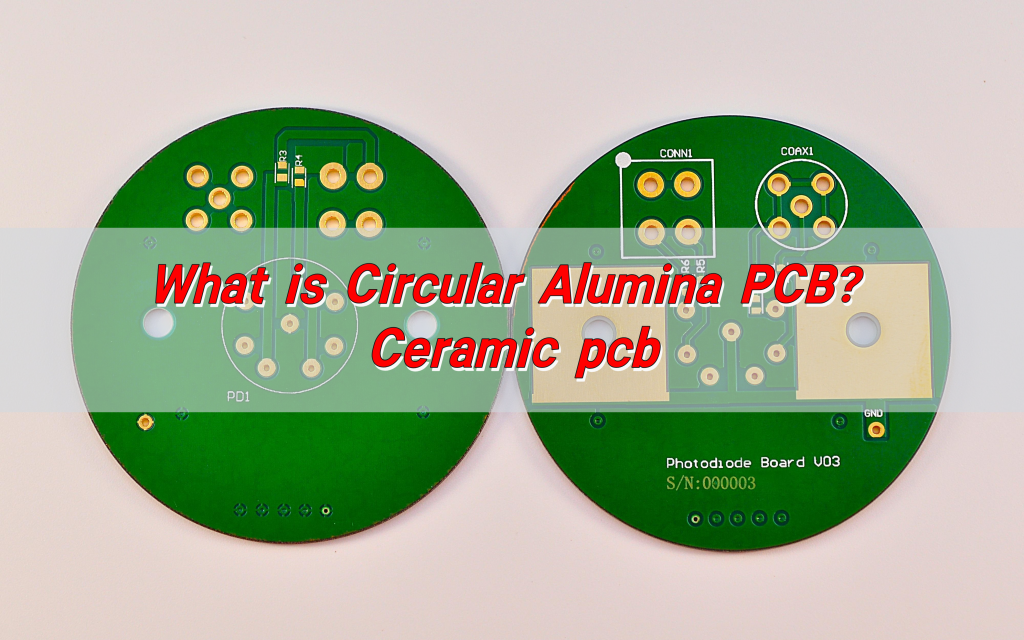

What is a Ceramic PCB?

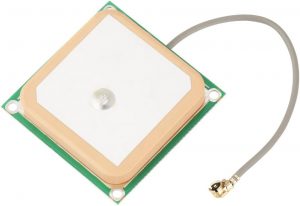

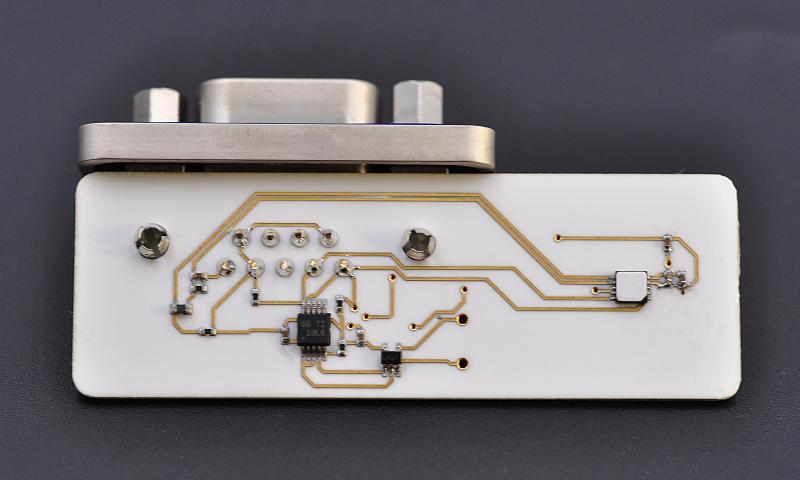

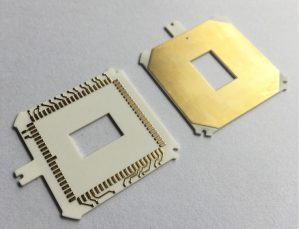

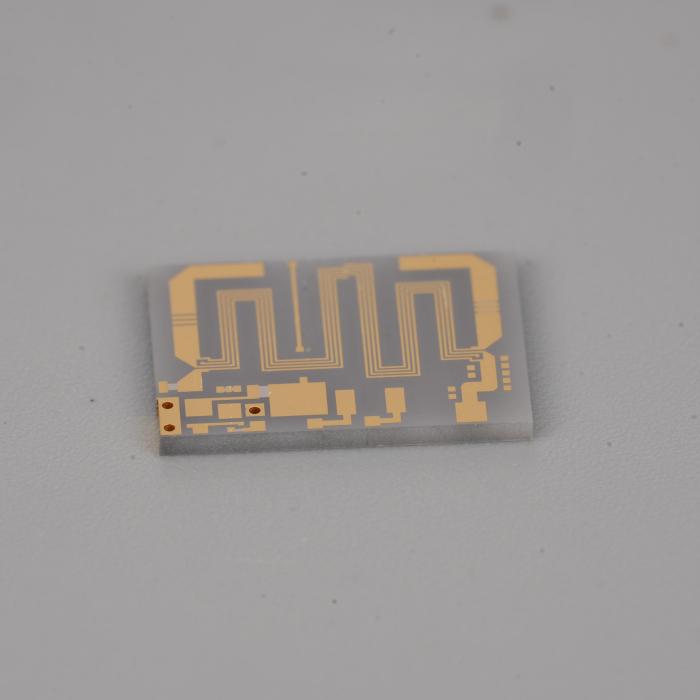

A ceramic PCB is a type of printed circuit board made using ceramic materials instead of traditional fiberglass-based boards. Ceramic substrates are known for their excellent thermal conductivity, high dielectric strength, and resistance to high temperatures. These properties make ceramic PCBs ideal for use in high-performance electronic devices that need to withstand extreme conditions.

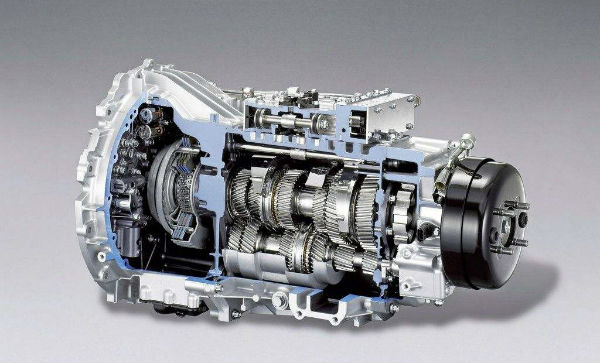

Ceramic PCB is widely used in applications like power electronics, automotive electronics, and telecommunications, where heat dissipation and stability are critical. Unlike FR4, which is a common base material for most PCBs, ceramic materials can handle much higher operating temperatures, which is essential in many industrial applications.

What Are the Different Types of Ceramic PCB?

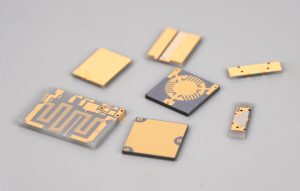

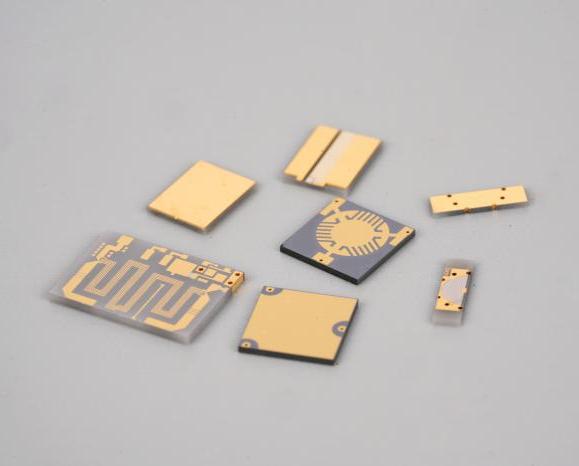

There are several types of ceramic PCBs, each with unique properties that cater to specific needs. Here are the most commonly used:

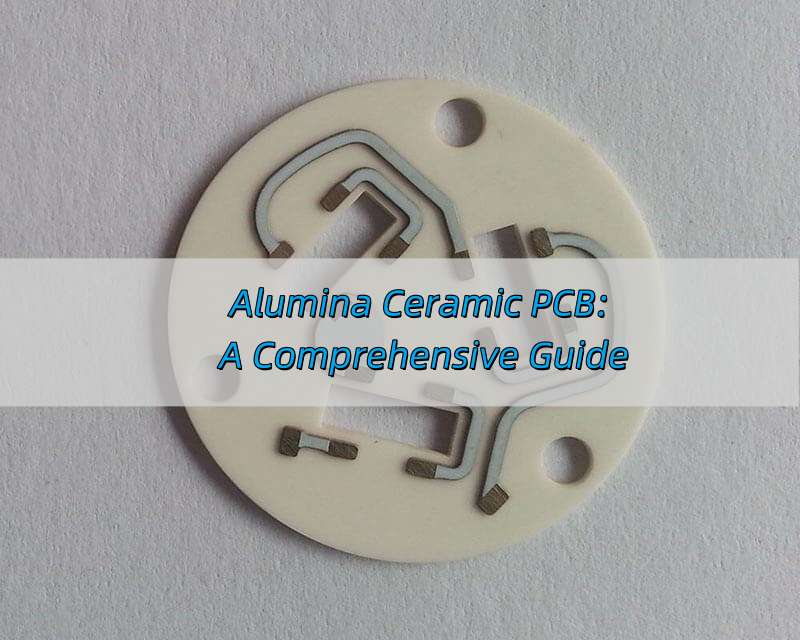

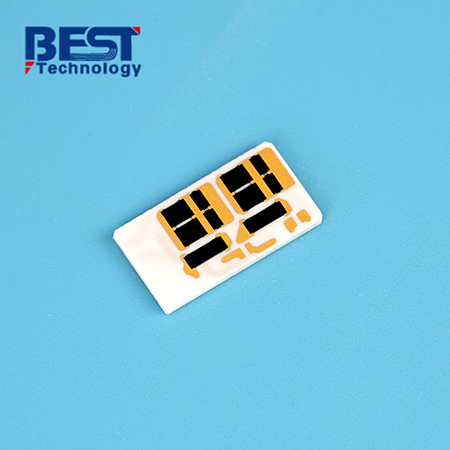

1. Alumina (Al2O3) PCBs: Alumina ceramic PCBs are the most common type. They are highly versatile and used in various applications, from consumer electronics to medical devices.

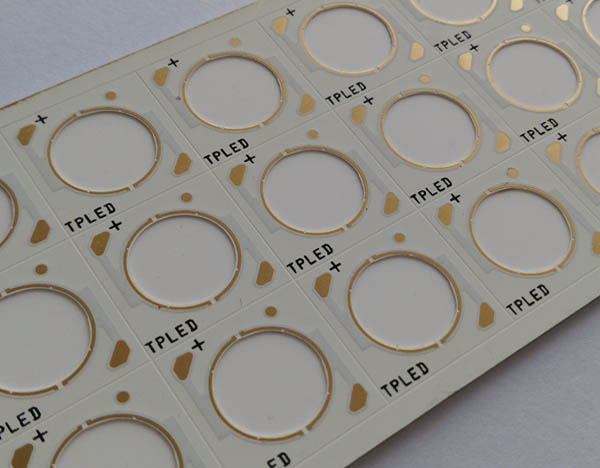

2. Aluminum Nitride (AlN) PCBs: Known for their outstanding thermal conductivity, AlN ceramic PCBs are often used in high-power applications like LED lighting, automotive systems, and power supplies.

3. Beryllium Oxide (BeO) PCBs: These PCBs are excellent in terms of thermal conductivity and electrical insulation. They are commonly used in high-frequency applications such as microwave systems.

4. Silicon Nitride (Si3N4) PCBs: These are known for their strength and thermal stability. Silicon Nitride PCBs are often used in devices that require a combination of electrical insulation and heat resistance.

Each type of ceramic material has its own set of advantages, and selecting the right one depends on factors like the operating temperature, power requirements, and the environment in which the PCB will be used.

What is the Difference Between Ceramic Substrate and FR4?

Ceramic substrates and FR4 serve similar functions in PCBs, but they differ in their material properties. FR4 is a glass-reinforced epoxy laminate, typically used in most PCBs due to its cost-effectiveness and ease of fabrication. However, it doesn’t perform well in high-temperature or high-frequency applications.

On the other hand, ceramic substrates, like alumina, have a much higher thermal conductivity and can withstand much higher temperatures, making them ideal for applications that require robust heat management. Additionally, ceramic substrates have superior electrical insulation properties compared to FR4, which is a key factor in high-power and high-voltage circuits.

In short, while FR4 is affordable and effective for everyday applications, ceramic substrates are preferred for demanding environments where thermal management and high-frequency performance are essential.

How Thick is Ceramic PCB?

The thickness of ceramic PCBs can vary depending on the application and the type of ceramic material used. Typically, ceramic PCBs range in thickness from 0.25mm to 3.0mm, but thicker versions are possible for applications requiring more robust structural support or additional layers for signal routing.

The thickness also impacts the overall thermal conductivity of the board. Thicker ceramic PCBs provide better heat dissipation but may also reduce the flexibility for complex circuit designs. Choosing the right thickness is critical to ensure optimal performance and efficiency in the final product.

What is the Thermal Conductivity of Ceramic PCB?

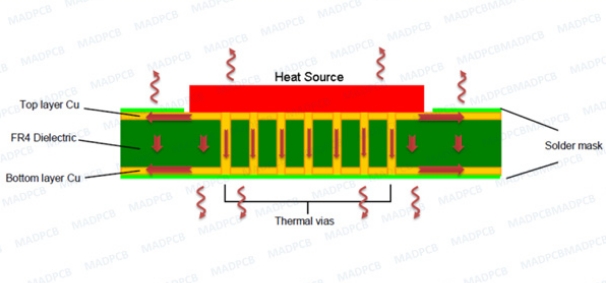

One of the standout features of ceramic PCBs is their thermal conductivity. Ceramic materials like aluminum nitride, beryllium oxide, and alumina have significantly higher thermal conductivity compared to traditional PCB materials like FR4. For example, aluminum nitride has a thermal conductivity of around 170 W/m·K, while alumina is typically around 30 W/m·K.

This high thermal conductivity allows ceramic PCBs to efficiently dissipate heat, preventing overheating and damage to sensitive components in high-power applications. In contrast, FR4 has relatively low thermal conductivity, which limits its use in environments where heat management is crucial.

How Are Ceramic PCBs Made?

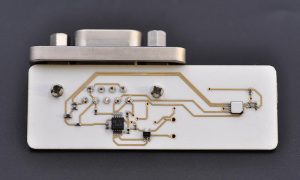

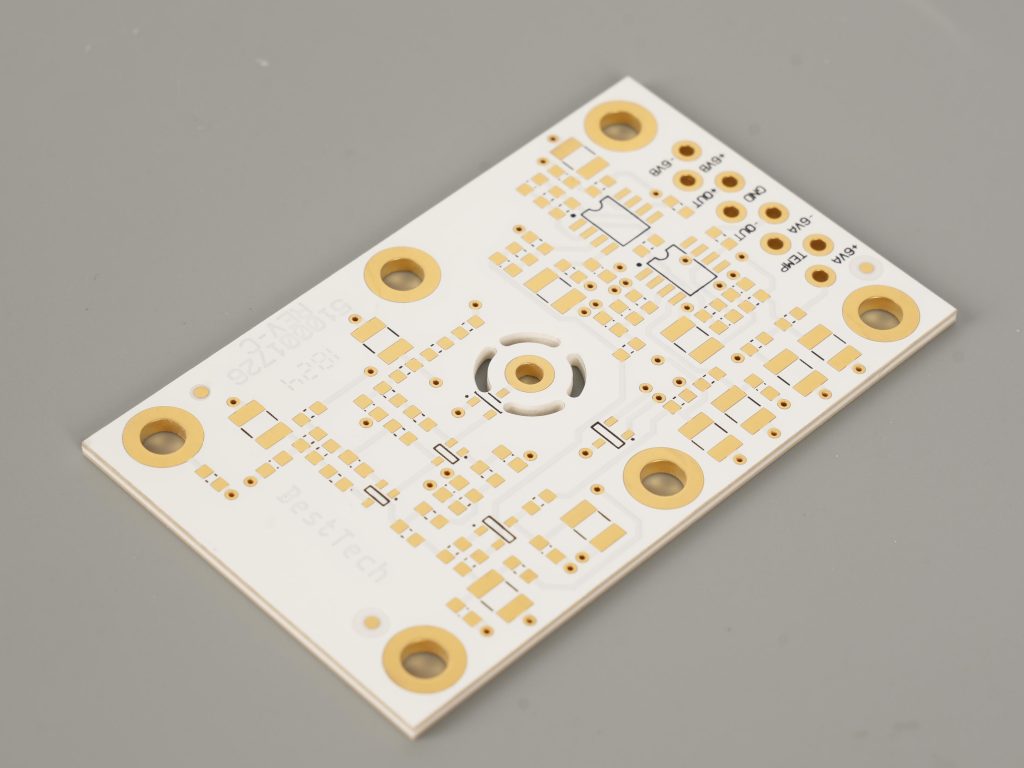

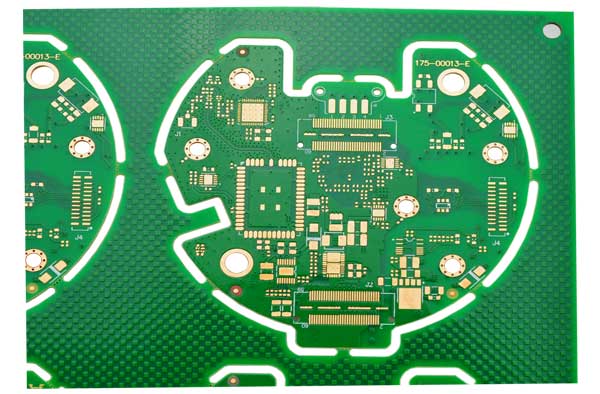

The manufacturing process of ceramic PCBs is quite different from traditional FR4-based PCBs. Here’s a simplified overview of the process:

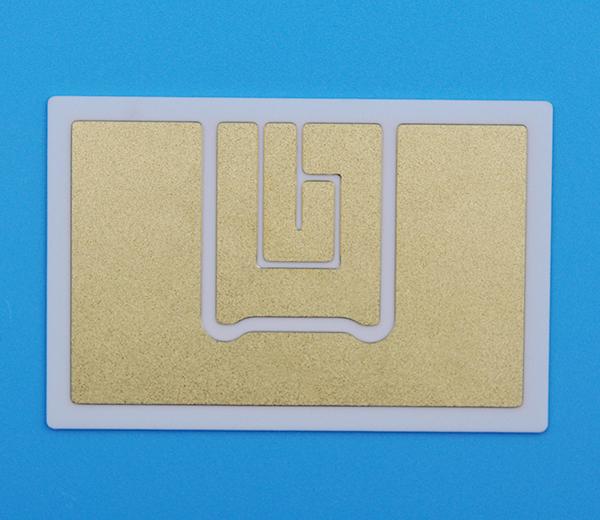

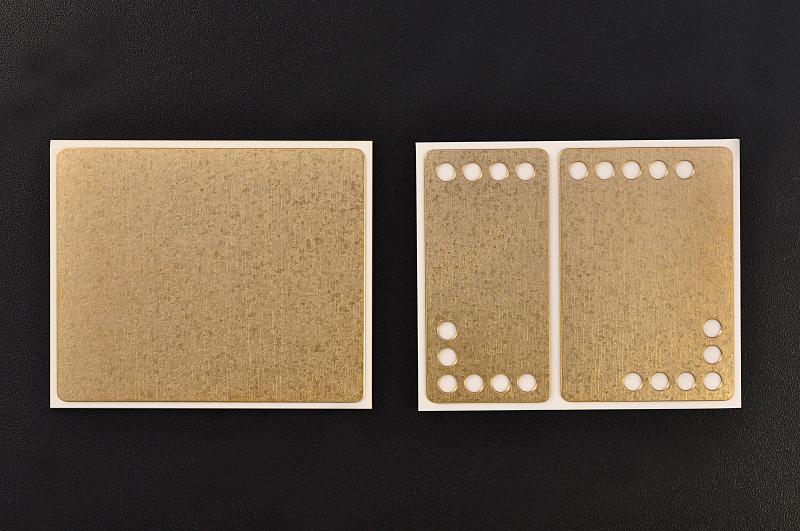

1. Substrate Preparation: The ceramic material is first prepared, typically in the form of thin ceramic sheets. The material is chosen based on its thermal and electrical properties.

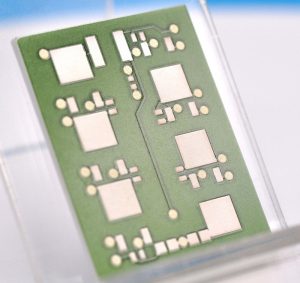

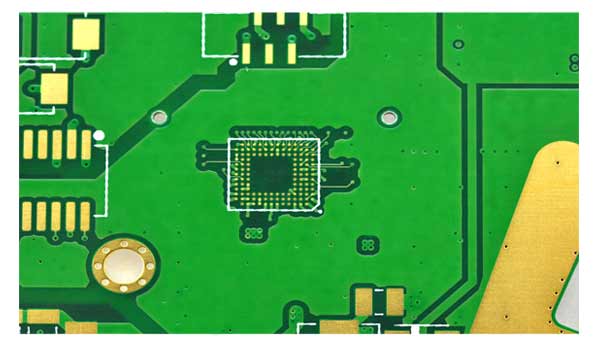

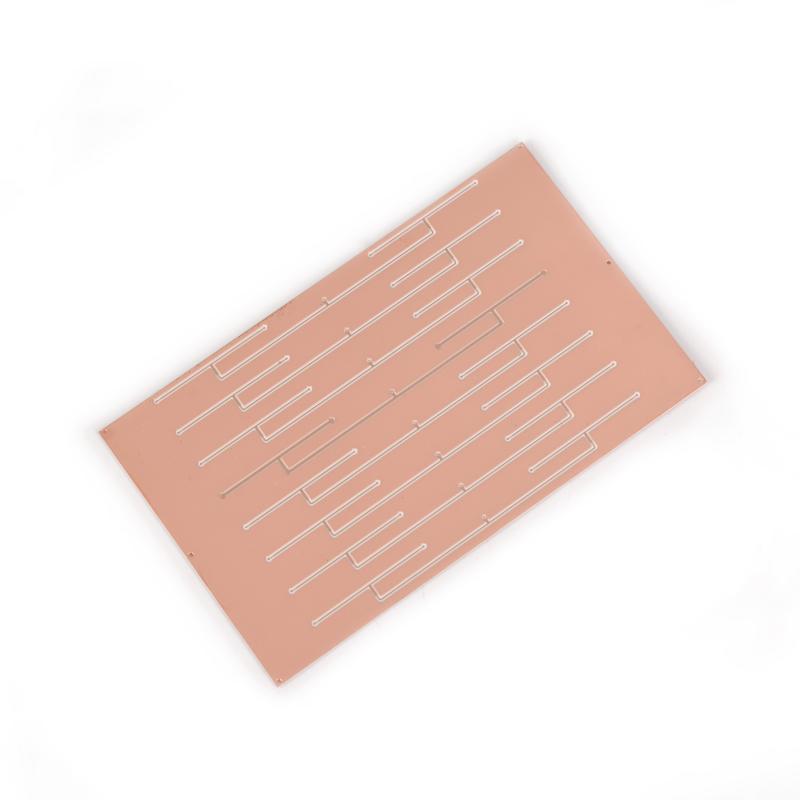

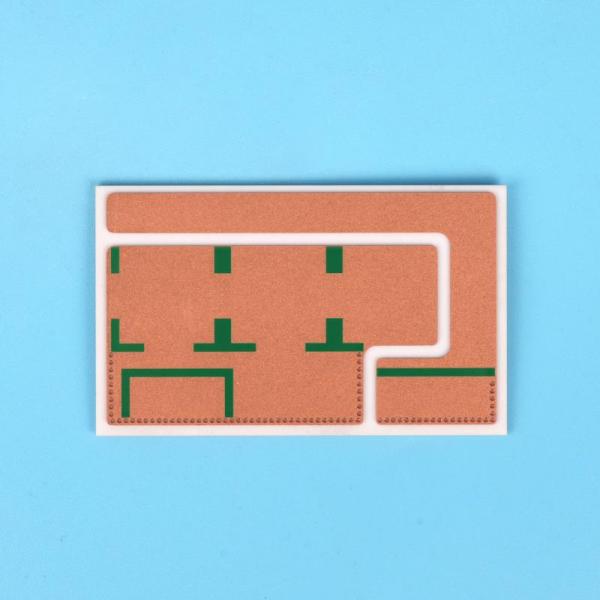

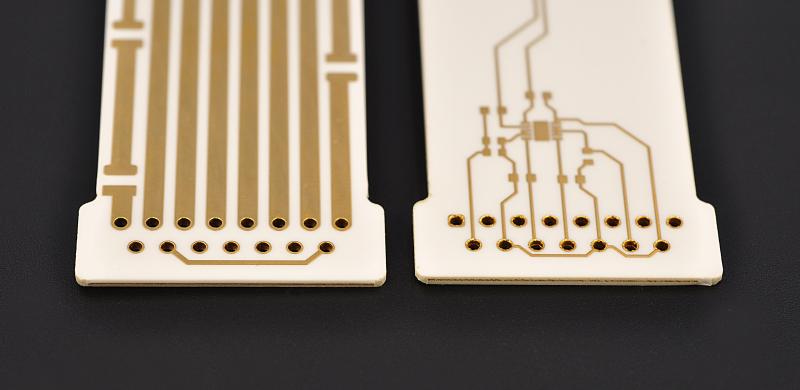

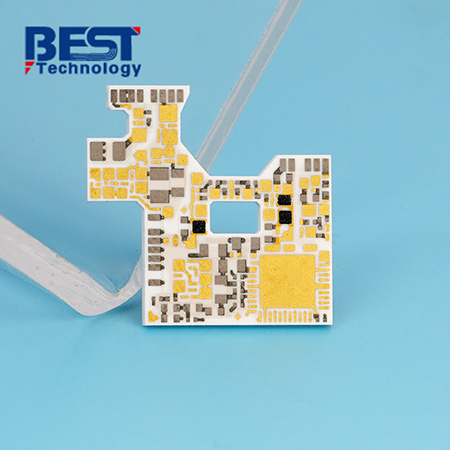

2. Layering: For multilayer ceramic PCBs, multiple layers of ceramic material are stacked together. These layers are often coated with a conductive metal layer, such as copper, to create the circuitry.

3. Etching: The copper layers are then etched to form the desired circuit pattern. This process is similar to traditional PCB manufacturing but requires special equipment due to the hardness of the ceramic materials.

4. Firing: The entire assembly is fired in a kiln to ensure that the layers bond together and the copper traces are firmly attached to the ceramic substrate.

5. Testing: Finally, the ceramic PCB is tested for electrical performance, thermal conductivity, and structural integrity. This ensures the board meets the required standards for its intended application.

What is a Ceramic Substrate Used For?

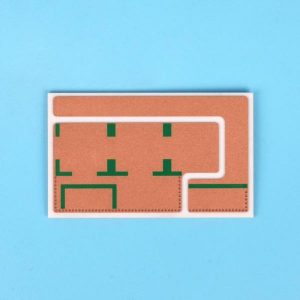

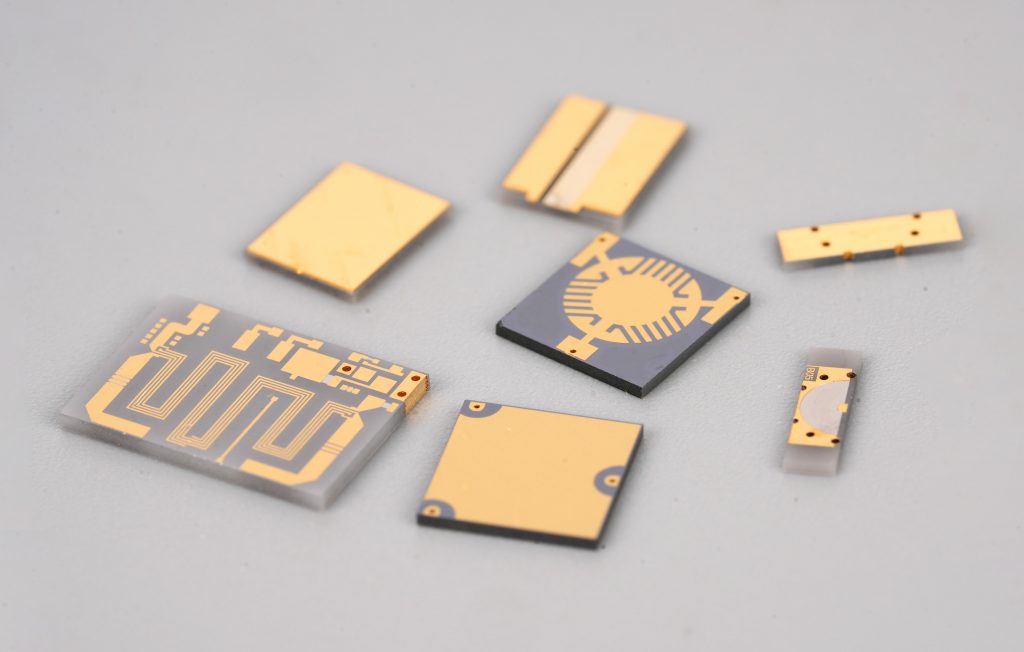

Ceramic substrates are used in a wide range of applications due to their excellent thermal management, electrical insulation, and mechanical strength. Some common uses include:

Power Electronics: Ceramic substrates are used in power semiconductors, where heat management is critical for performance.

LED Lighting: The high thermal conductivity of ceramic substrates makes them perfect for LED assemblies, where efficient heat dissipation is essential for long-term reliability.

Telecommunications: Ceramic PCBs are used in high-frequency circuits, such as microwave and RF applications, where their low signal loss and thermal stability are advantageous.

Automotive Electronics: The demanding environment in automotive electronics calls for ceramic substrates that can withstand high temperatures and vibrations while ensuring reliable electrical performance.

The versatility of ceramic substrates makes them an essential component in industries that demand high-performance, reliable electronics.

Ceramic multilayer PCBs offer a range of advantages, from superior thermal conductivity to electrical insulation and high-frequency performance. They are well-suited for applications where reliability and durability are paramount, such as in power electronics, telecommunications, and automotive systems. While ceramic PCBs may be more expensive than traditional FR4 boards, their performance benefits often outweigh the cost in high-performance applications.

Whether you’re designing a high-power LED system, a complex RF circuit, or any other advanced electronic device, ceramic PCBs provide the stability, heat dissipation, and electrical insulation needed for long-lasting and efficient operation. If you’re in need of ceramic PCBs, Best Technology can provide high-quality, customized solutions tailored to your specific requirements. Reach out to us at sales@bestpcbs.com to learn more about how we can support your project with advanced ceramic PCB technology.