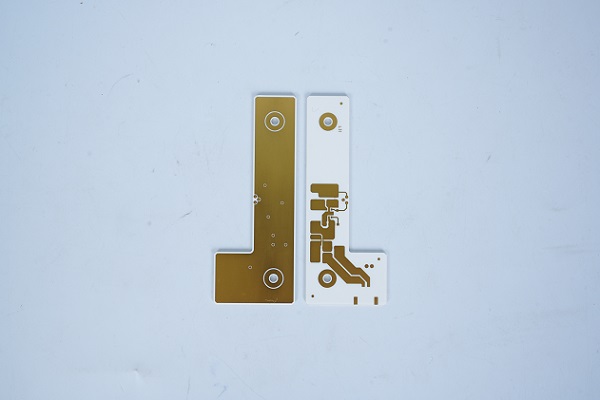

Ceramic PCB is a type of emerging PCB in the recent years, they are known for their high thermal conductivity and low expansion coefficient. Except this, it has numerous advantages that normal FR4 PCB can not achieved. And even for metal core PCB (MCPCB). Today, we are going to introduce their characteristics in detail.

1. High thermal conductivity

The core metal content of ceramic circuit boards is as high as 96-98%, which makes them have extremely high thermal conductivity. Compared with ordinary FR4 circuit boards, the thermal conductivity of ceramic circuit boards can reach 170-230 W/mK, while the thermal conductivity of FR4 boards is usually only 0.3-0.4 W/mK. Higher thermal conductivity allows for more efficient heat dissipation, avoiding the problem of damage to electronic components due to overheating. This is particularly important in high-power applications, such as LEDs and power semiconductors.

2. Low thermal expansion coefficient

Ceramic materials have a very low coefficient of thermal expansion (CTE), usually between 6-8 ppm/┬░C. In contrast, FR4 material has around 14-16 ppm/┬░C CTE. This means that ceramic materials hardly expand or contract when temperature changes. The low thermal expansion coefficient improves the reliability of the circuit board, reduces the influence of the thermal cycle on the circuit board structure and the connection of electronic components. Especially suitable for use in the environment with frequent temperature changes.

3. High surface hardness

The surface hardness of ceramic materials is up to 9 Mohs, which is harder than aluminum oxide and silicon. It means ceramic PCB has more wear-resistant, scratch resistant, and not easy to damage. It enables to run stably for a long time even in harsh physical environments, extending the service life of the board. That is why ceramic PCB is always recommended to use in military.

4. High compressive strength

The compressive strength of the ceramic circuit board can reach 450-500 MPa, which can withstand large mechanical pressure without deformation or rupture. This characteristic makes them excellent in applications that require them to withstand mechanical stress, such as industrial automation and aerospace.

5. High dielectric strength

Ceramic PCB has very high dielectric strength, usually between 15-25 kV/mm. And it can withstand higher electric fields without electrical breakdown.

6. Ability to withstand higher temperatures

Ceramic circuit boards can operate at temperatures up to 1000┬░C without degradation or damage. While FR4 circuit boards typically operate at an upper limit of 140-170┬░C. Ceramic circuit boards are suitable for electronic devices in high temperature environments, such as electric vehicles and high-power lasers.

7. High breakdown voltage

The high breakdown voltage of the ceramic circuit board can reach 20-35 kV, ensuring reliable operation under high voltage conditions. It is well suitable for use in high-voltage power supplies and power electronic equipment, providing higher safety.

8. Does not absorb water

The water absorption of ceramic materials is usually less than 0.1%, while the water absorption of FR4 materials is 0.1-0.2%. The non-water absorbing feature prevents performance degradation and damage caused by water absorption in a humid environment. It is ideal for Marine, medical, and other applications that require moisture resistance.

9. Low loss at high frequency

In high-frequency applications, the dielectric loss Angle tangent (Df) of ceramic circuit boards is usually between 0.0001-0.001, while the loss Angle tangent of FR4 materials is 0.02-0.03. Low loss ensures signal integrity and transmission efficiency, which is suitable for communication equipment and high-frequency electronic equipment.

10. Resistance to cosmic rays

Ceramic materials can resist the impact of cosmic rays, will not be degraded or damaged by rays. They are suitable for satellite electronic equipment, ensuring the stability and reliability of the circuit board in a high radiation environment.

11. No organic ingredients

Ceramic circuit boards do not contain organic components, so they have high chemical stability, are not susceptible to chemical corrosion and decomposition. They are good choice to use in harsh chemical environments.

12. High-density assembly

Ceramic circuit boards support high-density assembly with line/pitch resolution of 20 microns. This allows them to be adapted to more complex and refined circuit designs, suitable for microelectronics and high-precision applications.

Best Technology provides professional one-stop ceramic PCB design and manufacturing service all around the world. We welcome all the friends and partners from domestic and abroad to visit our ceramic circuit board workshop.