China ceramic PCB manufacturers are becoming the top choice for companies needing high-performance and heat-resistant circuit boards. Their experience, innovation, and advanced equipment help meet various industry needs. Whether you work in aerospace, automotive, LED, or medical devices, reliable ceramic PCBs are vital. But what makes Chinese suppliers stand out? Letās explore their strengths and the processes behind their work.

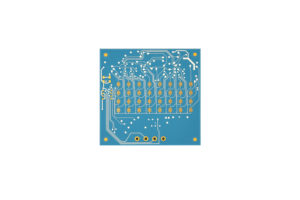

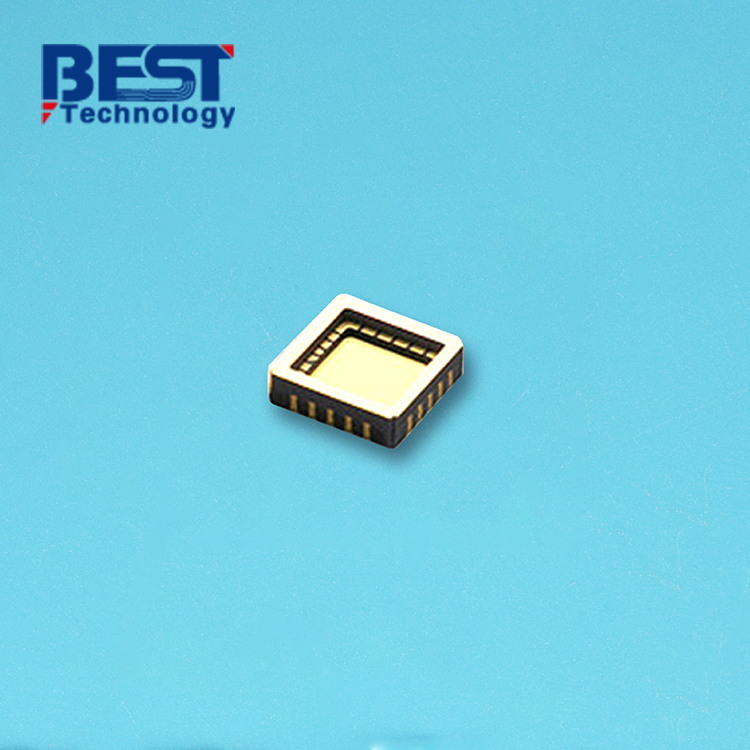

Best Technology is one of the professional China ceramic PCB manufacturers. Our company vision is to be China’s most trusted one-stop ceramic PCB fast solution provider. Our ceramic PCBs include thick film PCB, thin film PCB, DPC PCB, DBC/DCB PCB, AMB PCB, LTCC PCB, and HTCC PCB. Best Technology has continuously optimized the production control process so that we can offer defective-free products to our customers. There is a 97.2% on-time delivery rate in our ceramic PCB manufacturing factory. The monthly capacity in Best Technology is up to 200000 panels. 3067 customers across 40 countries give us good feedback on the quality and the lead time.

If any inquiries about ceramic PCBs, warm welcome to contact us via sales@bestpcbs.com. Once got your approval of ceramic PCB prototypes and the decision of MP (mass production), the fast lead time will be 2-3 weeks.

Ceramic PCB Manufacturing Process

Understanding the ceramic PCB manufacturing process helps you choose the right partner. At Best Technology, the DBC (Direct Bonded Copper) production process includes the following steps:

- IQC Inspection: Incoming ceramic substrates are carefully checked to ensure they meet specifications.

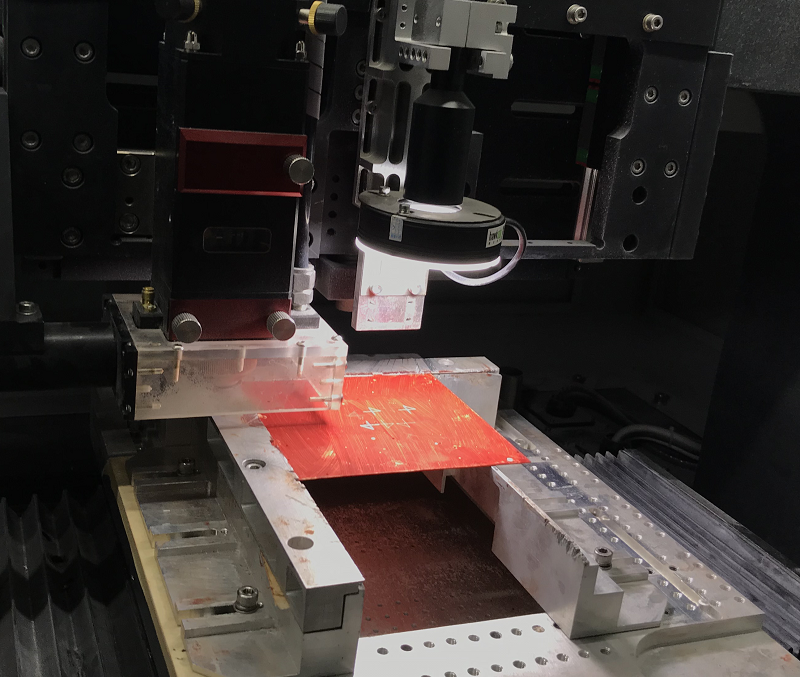

- Laser Drilling: Precise laser machines drill necessary vias and holes.

- Vacuum Sputtering (PVD): A thin metal layer is applied to the ceramic surface using Physical Vapor Deposition.

- Flash Plating: A light coating is applied for better conductivity.

- Pattern Transfer: The design pattern is transferred onto the board using photoresist.

- Pattern Plating: Conductive layers are built up in the patterned areas.

- Brushing and Polishing: Surface is brushed and polished for smoothness.

- Photoresist Removal: Residual photoresist is stripped from the surface.

- Etching and Titanium Removal: Unwanted copper is etched off, and any titanium barrier layers are removed.

- Electrical Testing: Boards are tested for shorts, opens, and continuity.

- Solder Mask: A protective layer is added over areas not meant for soldering.

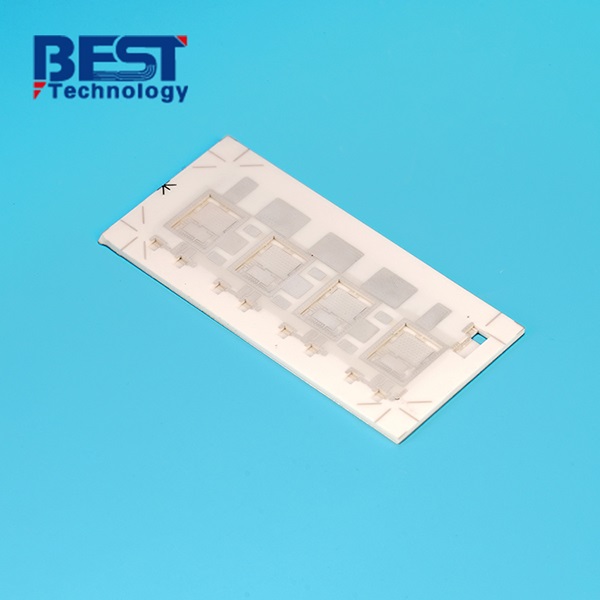

- Pre-Cutting: For silver surface finishes, pre-cutting comes before plating; for gold, it usually happens after.

- Surface Treatment: Final surface finish is applied (silver or gold).

- Incoming Inspection: Boards are inspected again before moving to final stages.

- FQC and FQA: Final Quality Control and Final Quality Assurance ensure boards meet customer standards.

- Packing: Boards are cleaned, labeled, and packed for safe delivery.

This well-controlled flow helps reduce defects and maintain high reliability, making Chinese ceramic PCBs a trusted option worldwide.

Key Materials Used by China Ceramic PCB Manufacturers in Production

Materials decide how well a ceramic PCB performs. Here are the most used ones:

- Aluminum Oxide (Al2O3): Common, cost-effective, and offers good insulation.

- Aluminum Nitride (AlN): Preferred for its excellent thermal conductivity.

- Silicon Nitride: Less common but offers high mechanical strength and resistance to thermal shock.

Chinese manufacturers often maintain a stable supply of high-purity materials. This allows consistent performance in each batch. Some even offer custom material blends depending on your needs. As a leading China PCB manufacturer, Best Technology enables full customization across all our ceramic PCB offerings.ā In reference to Best Technology’s ceramic substrate specifications, the standard thicknesses of Alumina (AlāOā) substratesā include 0.15/0.25/0.38/0.5/0.635/0.8/1.0/1.2/1.5/2.0 mm. Aluminum Nitride (AlN) substratesā are available in 0.15/0.25/0.38/0.5/0.635/0.8/1.0/1.5 mm thicknesses. Non-standard ceramic substrate types require customization. For tailored thickness specifications, kindly consult our account management team or sales engineering specialists to discuss project-specific parameters.

Best China Ceramic PCB Manufacturers

When looking for the best China ceramic PCB manufacturers, consider the following names that regularly top industry reviews:

- Best Technology: Known for its focus on high-quality ceramic PCBs with fast delivery. BEST offers one-stop EMS ceramic PCB solution without minimum order requirements.

- Weller PCB: Offers a wide product range and supports complex, high-mix projects.

- Shenzhen Kinwong: One of the largest PCB makers in China with global recognition.

What sets them apart? Itās their constant investment in better machines, tighter process control, and good customer support.

How Do China Ceramic PCB Manufacturers Ensure High Thermal Conductivity?

High thermal conductivity is key for ceramic PCBs. Chinese manufacturers make this happen through several strategies:

- Use of AlN substrates: These offer better heat transfer than traditional materials.

- Thicker metal layers: Copper or silver layers are optimized for heat spreading.

- Advanced firing techniques: This reduces internal voids and boosts thermal flow.

These steps help their ceramic PCBs survive in high-power LED lighting and RF power devices.

What Certifications Do Top China Ceramic PCB Manufacturers Hold?

Certifications add credibility. Most leading China ceramic PCB manufacturers meet strict global standards. Look for these:

- ISO 9001: Quality management system

- ISO 14001: Environmental responsibility

- IATF 16949: Needed for the automotive sector

- RoHS & REACH: Compliance for hazardous substances

These certifications show that the manufacturer values safety, sustainability, and precision. Best Technology is certified by the above ISO 9001, and IATF 16949 certifications. All materials are traceable via MES and ERP systems in Best Technology. Moreover, the materials we adopt are compliant with UL, RoHS, and REACH. Besides, we are compliant with ISO13485, and AS9100D, which gives us a competitive edge in providing tailored solutions in the medical industry and the aerospace, space, and defense (ASD) industry.

What Sets the Best China Ceramic PCB Manufacturers Apart?

Not all manufacturers are the same. The best ones offer:

- Experience: Over 10 years in ceramic PCB manufacturing.

- Customization: Ability to make prototypes and high-mix, low-volume orders.

- Responsive teams: Fast feedback, technical help, and post-sales support.

- Global shipping: Quick delivery to the USA, Europe, and other markets.

Their flexibility helps customers save time and avoid costly delays.

How to Find Reliable China Ceramic PCB Manufacturers for Your Project?

Finding the right partner doesn’t have to be hard. Here’s how to do it smartly:

- Research: Start with Google and LinkedIn. Check if they have case studies or client reviews.

- Request Samples: Good suppliers will offer test samples.

- Factory Audit: If possible, visit or request a video tour.

- Communication: A reliable partner will respond quickly and clearly.

Also, choose a supplier who understands your industry. This helps avoid back-and-forth and speeds up your project.

In conclusion, China ceramic PCB manufacturers have evolved into trusted global partners. Their strength lies in combining advanced materials, strong R&D, and top-notch service. They can deliver cost-effective solutions without compromising performance.

If you’re looking for a supplier who values time, quality, and support, it’s smart to consider an experienced name like Best Technology. With over 18 years in the PCB industry, we specialize in ceramic PCBs that meet the toughest standards. Reach out to us at sales@bestpcbs.com to get a favorable quote or specification sheet.