Circuit board black have grown increasingly popular in electronics projects. But why are these black PCBs so widely used? What makes them stand out in different color alternatives? In this blog, weâll dive into the reasons behind the growing preference for black PCBs.

What Is Circuit Board Black?

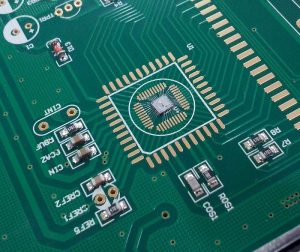

Circuit board black refers to the color of the solder mask applied to the surface of the PCB. The solder mask is a protective layer that prevents unwanted solder bridges from forming during the manufacturing process. This layer can come in various colors, but black is particularly sought after due to its sleek, modern aesthetic.

Unlike traditional green PCBs, which have been the industry standard for years, black PCBs have a unique and professional look that appeals to many industries. They are commonly used in consumer electronics, high-end gadgets, and automotive applications. The black color helps create a contrast, making the components and traces more visible, and enhancing the overall design.

What Is the Black Layer on a PCB?

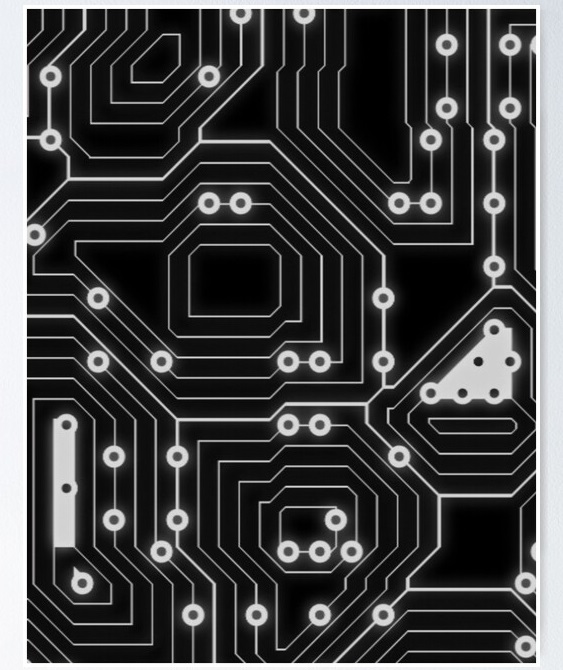

The black layer on a PCB is the solder mask, a thin coating applied over the copper traces to protect them from damage, moisture, and corrosion. This layer also insulates the traces and prevents electrical shorts. While black is the most common color for the solder mask, other colors such as blue, red, and white are also used, depending on the specific requirements of the design.

The black solder mask is created by applying a special polymer resin, which is then exposed to UV light, curing the material. The result is a durable, long-lasting layer that protects the integrity of the circuit board. It also gives the board its distinctive black appearance, which can be a design preference for many.

Why Is Solder Mask Usually Black?

Solder masks are often black because it offers several practical advantages. One of the main reasons is that black solder masks provide a higher contrast for the components, making them easier to identify and inspect. This is particularly beneficial when working with tiny, high-density components where visibility is crucial.

Another reason black is so commonly used is its durability. The dark color tends to resist UV degradation better than lighter colors, ensuring the PCB remains visually appealing for longer periods. Additionally, the black color can absorb heat better than lighter shades, making it ideal for high-performance applications where heat dissipation is important.

Why Are Most Motherboards Black?

If youâve ever wondered why most motherboards are black, the reason is simple: itâs about both aesthetics and practicality. Black gives motherboards a more professional, sleek appearance, especially when paired with other high-end components. It also provides a sharp contrast to the intricate circuits and soldered components, making them stand out more clearly.

In terms of performance, black PCBs are often preferred for high-speed or high-performance applications. The color not only improves the visual appeal but also minimizes the potential for signal interference, making black motherboards ideal for modern gaming rigs, computers, and even networking equipment.

Does PCB Color Affect Performance?

While the color of the PCB itself doesnât directly affect performance in terms of functionality, it can influence certain aspects such as heat dissipation and visibility. The black color, for example, can help absorb heat more effectively, which can be an advantage in applications that generate a lot of heat, such as power electronics or processors.

However, itâs important to note that the performance of a PCB is primarily determined by factors like the quality of the materials used, the design of the circuit, and the manufacturing process. While black PCBs might look more stylish or professional, the overall performance of the circuit board relies on more technical specifications rather than the color itself.

Black PCB vs Green: Which Is Better for Your Project?

When it comes to choosing between black and green PCBs, both options offer their unique benefits. Green PCBs are the most common and cost-effective choice. Theyâre readily available, have been used for decades, and are reliable for most standard applications.

On the other hand, black PCBs are often favored for premium, high-end projects. They are commonly used in consumer electronics, automotive systems, and gadgets where appearance is just as important as performance. The main difference lies in the visual appeal and heat management. Black PCBs tend to offer a more professional and modern aesthetic, which is why they are often used in luxury products or high-performance systems.

When selecting the right color for your project, consider factors such as cost, aesthetics, and heat dissipation needs. Black PCBs may cost slightly more, but the design and performance advantages might be worth it for certain projects.

Is Black PCB More Expensive?

Yes, black PCBs are generally more expensive than their green counterparts. The primary reason for the higher cost is the more complex manufacturing process required to produce black solder masks. The materials used in the black mask tend to be pricier, and the process of applying and curing the mask can add to the overall cost.

However, for certain applications, the increased cost may be worth it. The sleek and professional look of black PCBs can enhance the value of a product, especially in industries like consumer electronics, luxury products, or high-end automotive systems. Ultimately, the decision should be based on your projectâs budget and aesthetic needs.

How to Choose Between Black and Other PCB Colors?

Choosing the right PCB color depends on various factors, including the intended use, aesthetics, and budget. If youâre working on a high-performance, high-end product where visual appeal is important, black PCBs might be the best choice. They not only enhance the product’s appearance but also offer better heat dissipation and contrast for easier component identification.

For more cost-effective projects, or those where performance is the priority over appearance, traditional green PCBs might be the better option. Green PCBs are also ideal for general-purpose electronics and standard applications. Other colors, like blue or red, can be chosen for specific design needs but may come with their own set of costs and manufacturing complexities.

In the end, your decision should align with the aesthetic goals and performance requirements of your project. Black PCBs can elevate the look of your product, while green ones are reliable and economical for everyday applications. Are you looking for fast delivery and customized circuit board black products? Best Technology delivers top-notch circuit board black solutions with efficiency and precision.

Circuit board black has undoubtedly become a popular choice in the world of electronics. Whether itâs for enhancing the look of consumer devices, improving heat dissipation, black PCBs offer a combination of style and functionality. While they may come at a slightly higher cost than traditional green boards, the benefits they bring to high-end and high-performance products often justify the investment. Best Technology stands out by providing customized, high-quality black PCB products with quick turnaround times, all backed by our top-tier customer service. For more information or any inquiry, warm welcome to reach us at sales@bestpcbs.com.