Chip On Board (COB) technology is transforming the way we approach lighting and electronics by offering higher efficiency, compactness, and enhanced performance. In todayâs rapidly evolving world of LEDs and high-performance displays, COB has become a game-changer. Whether youâre looking for brighter, more energy-efficient lighting solutions or advanced electronic designs, COB delivers superior results. This article will explore what COB is, how it works, its advantages, and why itâs becoming the go-to solution for many industries. Letâs dive deeper into how Chip On Board technology is revolutionizing the world of LEDs and beyond.

What Does Chip On Board Mean?

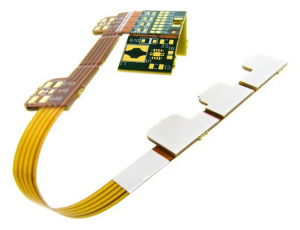

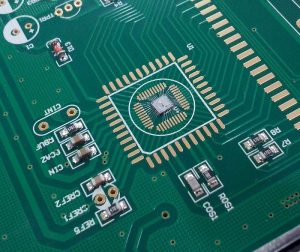

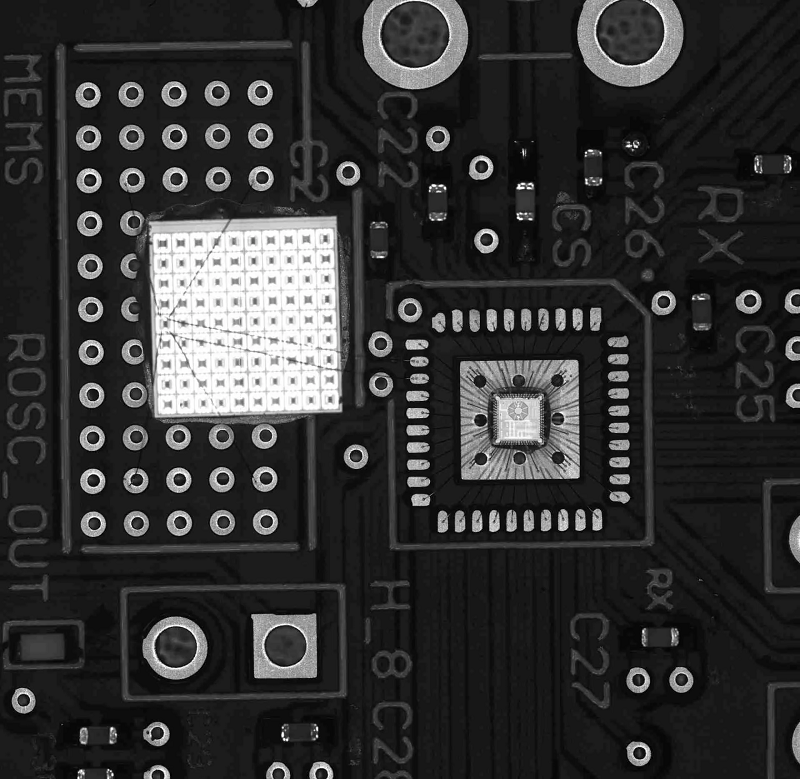

Chip On Board (COB) is a technology that involves mounting bare semiconductor chips directly onto a circuit board. The chips are typically used for LED applications, where theyâre attached to the board without the use of traditional packaging methods. In simpler terms, instead of using individual LED packages, COB technology allows for the integration of multiple LEDs into a single unit, which increases performance and reduces space.

This innovative approach makes the board more efficient in transferring heat and enhances the overall durability of the light source. Over time, COB has become a popular choice in high-performance lighting and electronic systems due to its compact nature and increased energy efficiency.

What is a Chip-on-Board Also Called?

Chip-on-Board (COB) technology is sometimes referred to as âbare-chipâ packaging. In this method, the chip is directly mounted onto the board, and electrical connections are made via wire bonding or soldering. The term “COB” is commonly used in LED lighting, but the technology can be applied to other types of semiconductors as well. Other variations or related terms include:

COB LED (Chip-on-Board Light Emitting Diode)

COB packaging

COB assembly

These terms generally describe the same principle, which is the direct attachment of chips to a board for enhanced efficiency.

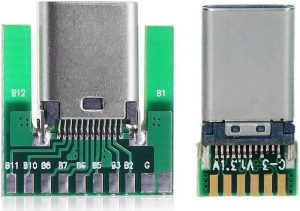

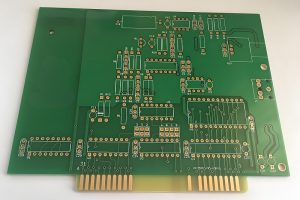

What is the Difference Between PCB and COB?

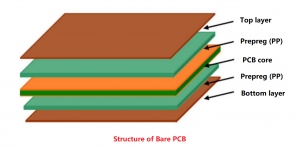

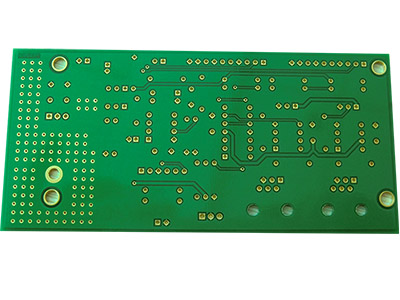

The primary difference between PCB (Printed Circuit Board) and COB (Chip on Board) lies in the way components are mounted. While a PCB is a physical board that provides the electrical connections and support for various components, COB focuses on mounting semiconductor chips directly onto the PCB without additional packaging.

In PCB-based designs, individual components like resistors, capacitors, and LEDs are usually placed on the board. In COB, the semiconductor chip, often an LED, is directly connected to the board without the need for extra packaging or casing. This results in a more compact and efficient design. At Best Technology, we specialize in providing high-quality printed circuit boards (PCBs) that are essential for supporting innovative technologies like Chip On Board (COB). Our expertise in PCB manufacturing ensures that we can meet the demands of advanced COB applications in various industries, delivering reliable and efficient solutions.

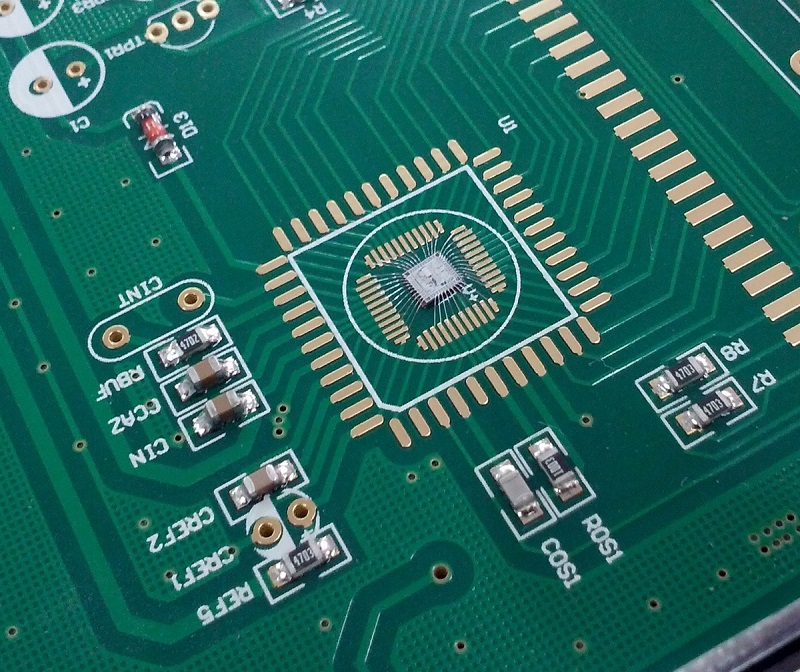

What is a COB Package?

A COB package refers to the method of integrating multiple LEDs into a single compact unit. Unlike traditional LED packaging that involves mounting individual LED chips into separate packages, COB uses a single substrate to host multiple LED chips. This method allows for a higher density of LEDs per unit area, providing more light output in a smaller space.

The COB package is often used in applications that require high brightness and low thermal resistance, such as automotive lighting, street lights, and even high-end television displays. The efficiency of COB packages has made them essential in industries where space and power consumption are critical.

Which is Better, COB or LED?

When comparing COB with traditional LED technologies, COB offers several advantages that can make it a better choice depending on the application. One of the primary benefits of COB over conventional LED is its ability to integrate multiple LEDs into a single unit. This leads to:

Higher Brightness: COB can provide more light output in less space, making it ideal for applications like outdoor lighting or large display screens.

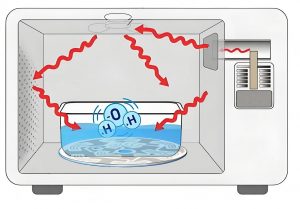

Better Heat Dissipation: The direct contact of the LED chips with the board allows for more efficient heat management, reducing the risk of overheating.

Compact Design: COB eliminates the need for individual LED packages, leading to a smaller, more streamlined design.

However, traditional LED technology might be preferable in applications where cost is the primary factor, as COB systems can be more expensive to manufacture.

What Does a Chip On Board Do?

A Chip On Board (COB) system serves a variety of purposes in modern electronics. In the case of LED applications, COB allows for a more efficient and compact design. By placing multiple LED chips onto a single substrate, COB systems can produce a larger light output while occupying less space. This makes it perfect for applications requiring high brightness in a small form factor.

COB technology also plays a critical role in heat management. The direct mounting of the chip onto the board enables efficient thermal conductivity, helping to maintain optimal operating temperatures. This is especially crucial for long-lasting LED lights used in automotive, industrial, and residential applications.

What is the Purpose of a COB?

The purpose of a Chip On Board (COB) system is to improve the overall performance, size, and efficiency of electronic systems, particularly in the realm of LED technology. Some of the primary goals of COB include:

Energy Efficiency: COB LEDs are known for their lower power consumption compared to traditional LEDs, making them a more energy-efficient choice.

Space Efficiency: By integrating multiple LED chips into a single unit, COB minimizes the need for additional space, allowing for more compact designs.

Enhanced Durability: COB systems are generally more durable since they have fewer components that could potentially fail, such as individual LED packages.

This makes COB ideal for applications where performance and space are critical factors, such as in high-end lighting systems, television panels, and automotive lights.

What is the Process of Chip On Board Manufacturing?

The process of manufacturing Chip On Board (COB) involves several key steps to ensure that the semiconductor chips are securely attached to the circuit board and function as intended. Hereâs a simplified breakdown:

Chip Preparation: The semiconductor chips are prepared for mounting by removing any excess material from the wafer.

Placement: The bare chips are placed directly onto the PCB using precise automated equipment.

Bonding: Electrical connections are made between the chip and the PCB via wire bonding or soldering.

Encapsulation: The chips are then encapsulated with a protective layer to safeguard them from environmental factors like moisture and dust.

Testing: After assembly, the COB units undergo rigorous testing to ensure that the LED chips are functioning correctly and that the heat dissipation is efficient.

This manufacturing process results in a highly compact, efficient, and reliable product, particularly suited for applications requiring high-performance LEDs.

What Are the Advantages of Chip On Board?

Chip On Board technology offers several key advantages, which explain its increasing popularity in industries ranging from automotive lighting to consumer electronics. Some of the standout benefits include:

Improved Efficiency: With better heat dissipation and reduced power consumption, COB systems are more energy-efficient.

Compact Size: By integrating multiple chips into one unit, COB systems take up less space, allowing for more versatile designs.

Higher Light Output: COB technology allows for brighter LED lighting, which is essential in applications like street lights and displays.

Cost-Effective for High Volume: While the initial setup cost can be higher, COB becomes more cost-effective in high-volume production due to the reduction in packaging materials.

COB is an essential technology for modern high-performance lighting and electronics, offering unmatched benefits in terms of energy efficiency, space-saving, and overall reliability.

In conclusion, Chip On Board (COB) technology is revolutionizing the way LED lights and other electronic systems are designed and manufactured. With its compact size, improved thermal management, and enhanced brightness, COB is a critical component in industries ranging from automotive lighting to consumer electronics. Whether youâre considering COB for your next project or simply want to understand its benefits, itâs clear that this technology is leading the way in efficient, high-performance systems. Best Technology specializes in customized solutions, offering high-quality PCB products with quick turnaround times. For more information or inquiries, feel free to contact us at sales@bestpcbs.com to discuss how we can help elevate your next project with our top-notch PCB solutions.