In the design of electronic devices and systems, power distribution and heat dissipation management are key factors. Bus bar PCB, as an efficient solution, is particularly outstanding in these aspects. In this article, we would like to introduce the advantages of Bus bar PCB and its applications in different industries.

What Is A Bus Bar PCB?

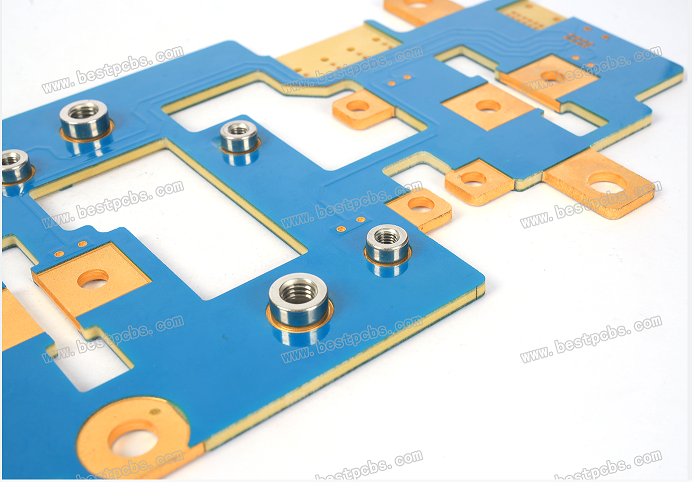

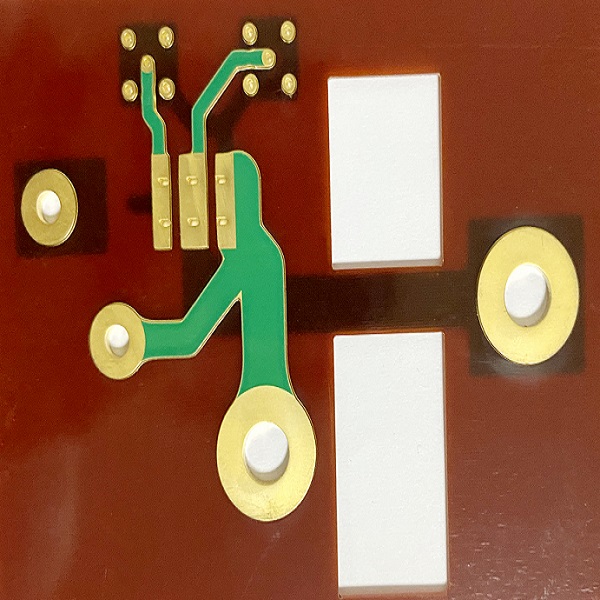

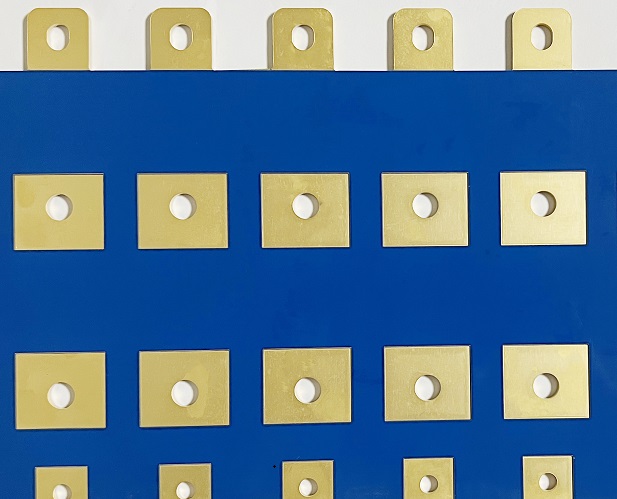

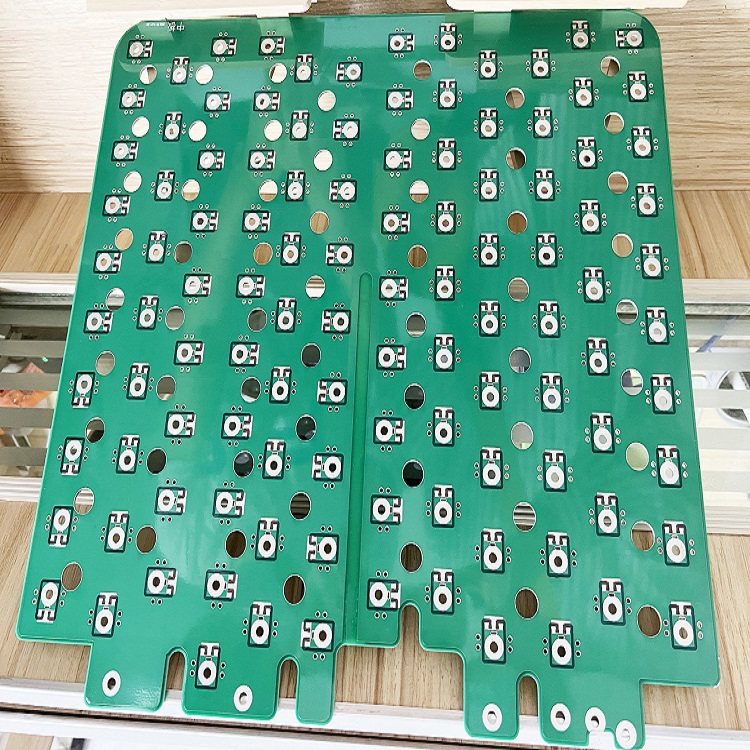

At the beginning, we should know what a bus bar PCB is. The Bus bar PCB is a special and newest design that integrates the FR4 material and metal alloy into a whole product, which allows the current transfer path into the circuit board. Due to the current carry capacity and special shape, it also called busbar PCB, embedded bus bar PCB, extruded copper PCB, copper inlay PCB, copper extrusion PCB.

Bus bar circuit board provide a more compact and efficient means of current distribution than traditional wires and cables. This design improves the overall performance of the electronic system by reducing inductance, increasing current carrying capacity, and optimizing heat dissipation.

What Are the Advantages of Bus Bar PCB?

Bus bar PCB offers numerous benefits when be using the power supply applications, its main functions are:

1. Reduce the inductance

Bus bar PCBs reduce inductance by allowing current to flow between tightly spaced conductors. This layout reduces the loop area and thus the inductance value. This is particularly important for high-frequency and highspeed applications, as it reduces voltage spikes and noise, improving system stability and performance.

2. Enhanced current carrying capacity

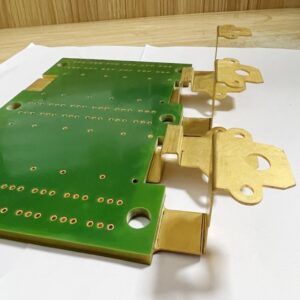

Due to its large cross-sectional area and high-quality conductive materials, Bus bar PCB can efficiently carry large currents. This is particularly useful in applications that require a large amount of power distribution, such as power supplies, electric vehicles, and renewable energy systems. Bus bar PCBs support higher current density compared to conventional PCB wiring, which improves thermal management and reliability.

3. Improve thermal management

The Bus bar PCB effectively dissipates heat generated by key components. In high power applications, the buildup of heat can affect performance and life. The Bus bar PCB helps maintain optimal operating temperatures through efficient heat distribution, reducing the need for additional cooling mechanisms.

4. Save space and weight

The compact design of the Bus bar PCB reduces the overall size and weight of the electronic components. Its simple construction and elimination of multiple wire connectors contribute to space savings. This is particularly beneficial for applications where size and weight are critical, such as the aerospace and automotive industries.

5. Improved reliability and durability

Bus bar PCBS have superior mechanical strength and durability compared to traditional wiring systems. Its robust construction and secure connections reduce the risk of loose connections, failure due to vibration, and mechanical wear. This improves system reliability and service life for harsh environments and demanding applications.

6. Simplify assembly and maintenance

Using a Bus bar PCB simplifies the assembly process because it reduces the number of individual wires and connectors. This not only speeds up installation, but also reduces assembly errors. In addition, the Bus bar PCB provides a more orderly and accessible layout for easy troubleshooting and repair.

7. Cost effective

Although there may be a high initial cost, Bus bar PCBs can provide cost savings in the long term. Its advantages in reduced inductance, improved thermal management and enhanced reliability reduce operating and maintenance costs. In addition, Bus bar PCB reduces the need for addons, such as heat sinks or complex wiring bundles, thereby increasing overall cost effectiveness.

What Applications of Bus Bar PCB?

Due the high current carry capacity of the bus bar PCB, makes it very suitable for power supply or power management devices. Bus bar PCB can perform well in such fields. Here are some common application examples that bus bar PCB can be used for. If you are seeking for a PCB to integrate into your power supply project, then bus bar PCB is the go-to-choice.

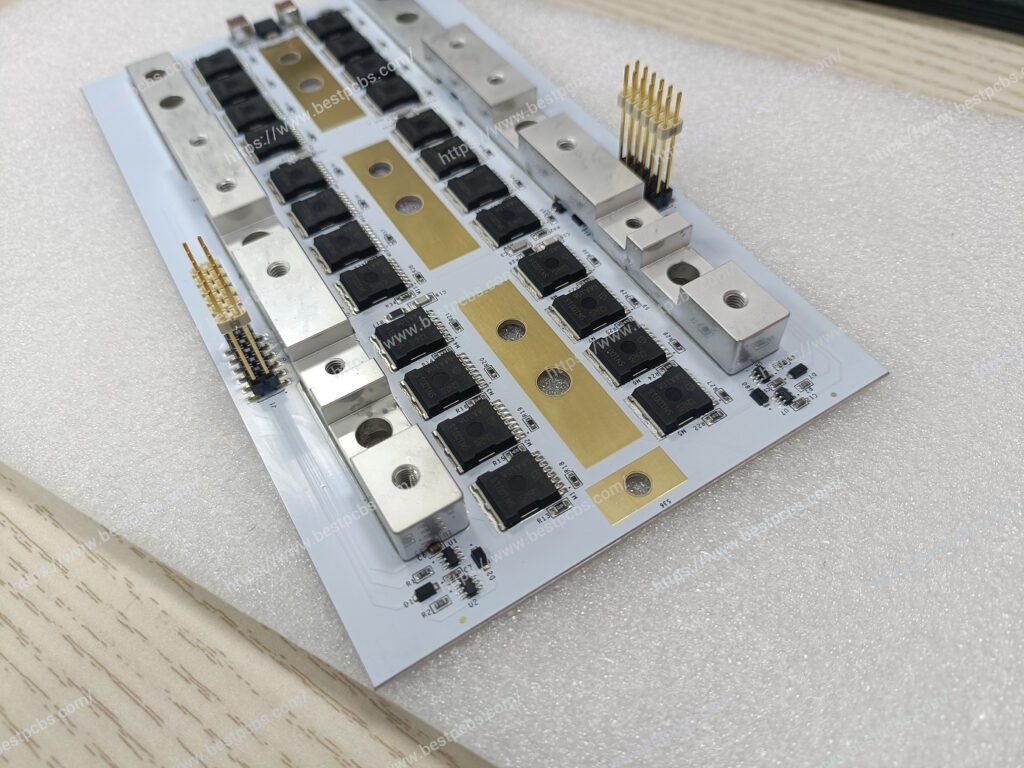

1. Power Electronics

In power converters, inverters and high-current power supplies, Bus bar PCBS are widely used because of their ability to efficiently handle high currents and excellent thermal performance.

2. The Automobile industry

Another popular field that bus bar PCB used in is automotives, especially in electric vehicles (EVs) and hybrid electric vehicles (HEVs). In the electric cars, it can be used for battery connectivity and power distribution, contributing to weight reduction and performance improvements.

3. Renewable energy

Bus bar PCB is an environment friendly material, it is often used in solar systems, wind turbines and energy storage solutions to manage high currents and enhance reliability.

4. Industrial equipment

In industrial machinery and equipment, Busbar PCB provides powerful and efficient power distribution for motors, drives and control systems.

5. Aerospace

Bus bar PCBS are used in aerospace applications, such as avionics and power distribution systems, where size, weight and reliability are key factors.

Final Words

All in all, bus bar PCB offers significant advantages in handling high currents, improving thermal management, and providing reliable power distribution across various applications. By integrating bus bar PCBs, industries can achieve better power management, reduced system size and weight, and improved overall reliability.

Best Technology is a one-stop PCB solution provider in Asia, we offer various kinds of PCBs not only include bus bar PCB, but also Extra thin PCB, RF PCB, HDI PCB, Heavy copper PCB, Ceramic PCB, Metal Core PCB, Flex PCB and rigid flex PCB, PCBA and so more. We have more than 17 years-experience in PCB design and manufacturing, and served more than 1200 customers. Choosing Best Technology as your supplier ensures you get high quality PCBs, helping to improve the performance and competitiveness of your products. Contact us right now to customize your own PCB!