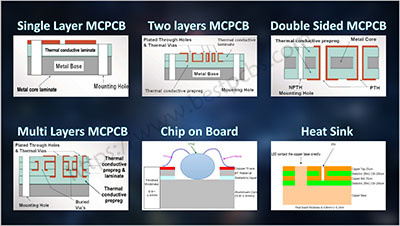

Metal Core PCB are differentiated on the basis of their construction, which can be divided into following types: single layer, double/two layers, double sided, and multi layer. The double sided and double/two layers MCPCB are commonly used in advanced electronic circuits, some people may be confused about them due to their similar names. So in this blog Iââ¬â¢d like to share with you the differences between the two types.

Actually the main difference is the double sided and double/two layers MCPCB have different layout due to the positioning of the metal core.

Double/two layers MCPCB

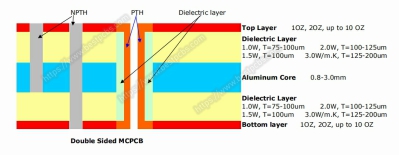

As you can see the following stack up, the metal core is at the bottom, with two copper layers on top side, the dielectric layer is between the copper layer and the bottom metal base. In short, the conductor layers is in same side of the metal core. The components can only be assembled on the top layer.

Double sidedMCPCB

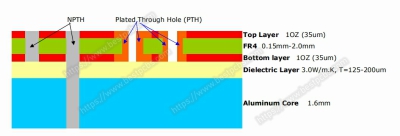

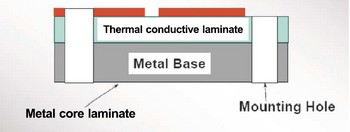

As you can see the following MCPCB stack up, the metal core is in the middle of two conductor layers. There is also a dielectric layer between the metal core and a copper layer. The metal core and conductors are connected to each other through PTH (Plated Through Hole). The components can be assembled on both the bottom and top.

Both double sided and double/two layers aluminum/copper core have the good heat dissipation, reliable performance at high temperatures and excellent thermal expansibility, according to our experience, for the same design, the heat dissipation on Double Sided MCPCB is a little better than Double Layers MCPCB.

The choice of the either type will depend on customerââ¬â¢s application requirements. If you are still confused about the two types and their benefits for your application, please feel free to contact Tammy (Email:sales9@bestpcbs.com), the Metal Core PCB International Sales in Best Technology.

Welcome to visit our website to learn more about us, we can provide different types of MCPCB in diverse specifications.