Nowadays, LED lighting has become increasingly popular in our daily life. With its rapidly rise in popularity, the term LED PCB has become commonplace. LED PCB also referred to as LED circuit board, LED aluminum PCB, or simply LED PCB board. Today, our team will share some informational knowledges about LED PCB circuit board, let’s keep reading if you are interested!

What is a LED PCB Circuit Board?

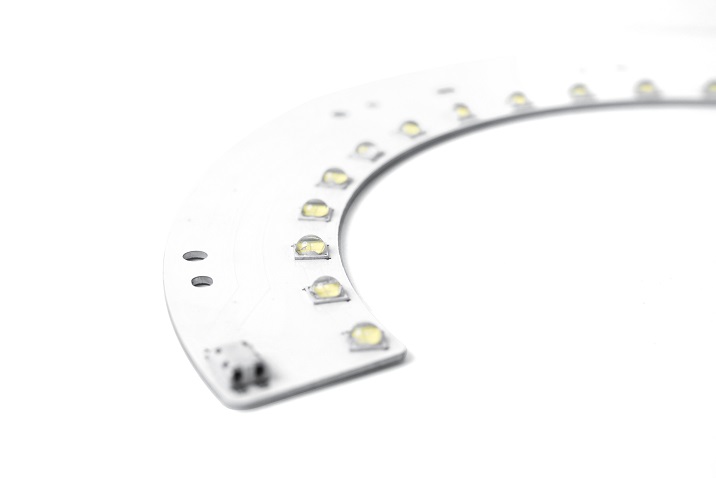

A LED PCB circuit board is a unique type of board crafted to hold and connect light-emitting diodes (LEDs). They are specially designed for lighting applications, like LED car headlights, pool lighting, UV LED, hotel lighting, grow light, high bay lights, stair lights, supermarket lighting, street light, etc. They are used almost everywhere. These boards provide the support and connections needed for LEDs to function efficiently and last longer. They are crucial in areas like lighting, automotive, and electronics, thanks to their ability to manage heat effectively and enhance the lifespan of LEDs.

What are the Different Types of LED PCB?

LED PCB boards are preferred over traditional lighting methods like fluorescent and incandescent bulbs. There are in total five types of LED PCBs, each designed for specific applications:

- Aluminum based LED PCB

An LED PCB board, often made of aluminum alloy, serve as the base for mounting LEDs. This is the most common type of LED PCB, since it has good thermal management and cost-effective compared to other materials. The thermal conductivity of aluminum can be 1.0-3.0W/m.k, it can meet the almost heat requirements of low-middle power applications, like streetlights and floodlights. Additionally, Best Technology developed a new product called semi-flexible aluminum PCB for specific device. It can be bent and folded when necessary.

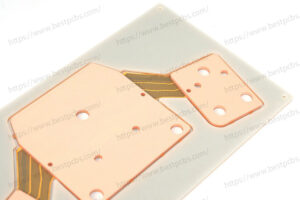

- Copper core LED PCB

Copper core LED circuit board can be divided into two types: normal copper core LED PCB and thermoelectric separation copper-based LED PCB. The copper material has higher thermal conductivity than that of aluminum, and it can up to 400W/m.k when made by thermoelectric separation technology. Copper based LED PCB board commonly used in high power devices like new energy vehicles.

- Ceramic LED PCB

Ceramic LED PCB boards are made from ceramic substrates like aluminum oxide (Al2O3) or aluminum nitride (AlN). They have superior thermal management, and it can withstand extreme environment when used in high-temp and low temperatures. Ceramic substrates can handle high power and thermal cycling better than other materials, making them ideal for automotive, aerospace, and high-power LED applications.

- FR4 LED PCB

FR4 LED PCB boards are made from woven fiberglass cloth with an epoxy resin binder, which provides good mechanical strength and insulation properties. FR4 is a widely used material for general-purpose PCBs due to its cost-effectiveness and versatility. While it has lower thermal conductivity (around 0.3W/m.k) compared to aluminum or copper, FR4 LED PCBs are suitable for low to medium power applications where thermal management is less critical. These PCBs are commonly used in consumer electronics, LED displays, and indoor lighting.

- Flexible LED PCB

Flexible LED PCB boards are constructed using flexible plastic substrates like polyimide or polyester. This flexibility allows the PCBs to be bent, folded, and shaped to fit various applications. Flexible LED PCBs are ideal for products that require dynamic or complex designs, such as wearable electronics, flexible displays, and medical devices. Despite their lower thermal conductivity compared to rigid PCBs, flexible LED PCBs offer unique design advantages and are increasingly used in innovative LED applications.

What are the Benefits of Using Aluminum LED PCB Boards?

Aluminum LED PCB boards offer numerous advantages that other materials cannot achieved.

1. Better Heat Management: LED PCBs, particularly aluminum ones, help in cooling LEDs, preventing overheating and extending their lifespan.

2. Compact and Light: These boards are small and lightweight, making them perfect for applications with space and weight constraints.

3. Dimensional stability: Aluminum LED PCB board has good dimensional stability compared with flexible LED PCBs. And it has low CTE during the manufacturing.

4. Cost-Effective: Producing aluminum LED PCBs is relatively affordable, making them a budget friendly option for various applications.

5. Versatile: Available in different shapes and sizes, Aluminum LED PCBs can be customized to meet specific needs, enhancing their usefulness in various scenarios.

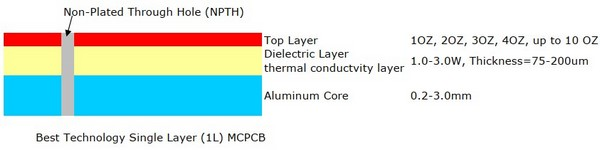

The Structures of a LED PCB Board in Manufacturing?

A LED PCB is similar to traditional rigid board, the only one difference is the LED mounting on the pads. Herein, we listing the basic composition of a LED pcb board, letÔÇÖs see it together.

1. Substrate – The base of the PCB, which can be flexible (like polyimide), metal alloy (aluminum, copper), or ceramic, depending on the required thermal performance.

2. Copper foil – A thin layer of copper is used for forming the circuit paths on the PCB.

3. Solder mask – This is a protective layer covers the copper paths to prevent oxidation and short circuits. It also aids in SMT (surface mounted technology) soldering.

4. Silkscreen – Used to print labels, logos, vendors, symbols, and pick and place on the PCB for easy identification during assembly.

5. Adhesives ÔÇô Aiming to bond different PCB layers, different material used different adhesive, always are prepreg (PP).

6. LEDs: The main components mounted on the PCB, available in various sizes, colors, power ratings, voltages and so on.

Your Reliable LED PCB Board Manufacturer ÔÇô Best Technology

Best Technology stands out as a leading manufacturer of high-quality LED PCB boards. We offer a wide range of products and services to cater to various needs. With extensive experience and expertise in the industry, we are committed to providing reliable and cost-effective solutions.

- Advanced Facilities

We are equipped with advanced machinery and technology, ensuring precision and efficiency in production.

- Experienced Team

Our skilled professionals are dedicated to delivering topnotch LED printed circuit boards. Most of our core members has more than 10 years-experience in the PCB manufacturing.

- Quality Assurance

We have passed ISO9001, ISO13485, IATF16949 certifications, and integrated them into our daily manufacturing process. These strict quality control measures can make sure every product meets the highest standards of industry.

- Customization

We offer tailored customized LED PCB board solutions to meet customer specific requirements.

- Competitive Pricing

Best Technology has our own factory in China and Vietnam, we can provide most affordable solutions without compromising on quality.

Choosing Best Technology means opting for excellence, reliability, and superior service. Partner with us for your LED PCB needs and experience the difference we bring.