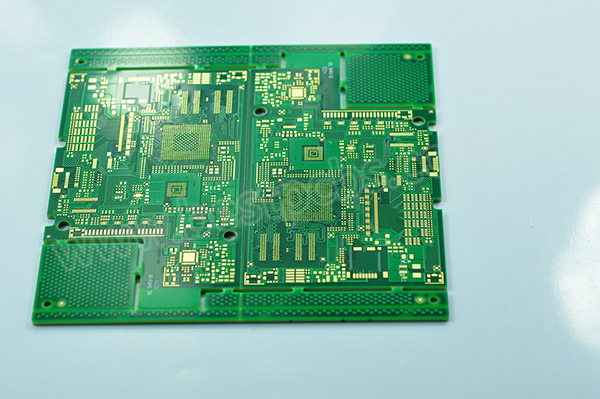

HDI PCB manufacturer is the first thing that comes to mind when high performance meets compact electronic design. With rising demand for compact and reliable products, HDI technology plays a key role in modern electronics. But how does HDI differ from regular PCBs? What makes a good HDI PCB manufacturer? And why are so many companies turning to India, USA, China, or even Europe for fabrication? In this blog, you’ll get answers to those questions and more.

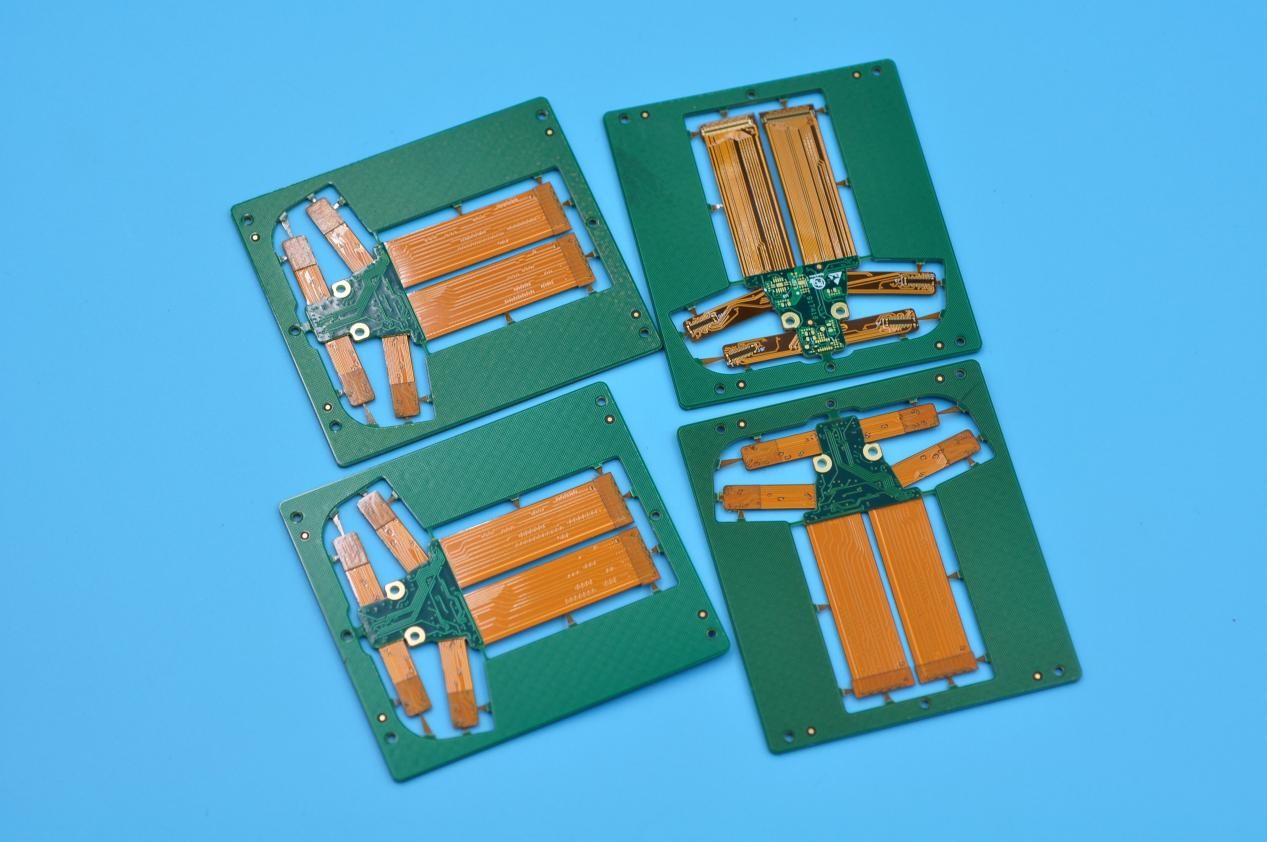

Best Technology offers pioneering HDI PCB manufacturing solutions for Cell phones, UMPC, MP3 Players, PMP, GPS, and other applications. Our solutions integrate advanced signal integrity analysis and impedance control (±5%) to meet 5G/millimeter wave and high-speed computing requirements. HDI PCBs in Best Technology include standard HDI PCB, HDI flex PCB, 2-16 layers HDI multi-layer PCB, any layer HDI PCB, and rigid-flexible PCBs to high-frequency PCBs. ISO 9001, IATF 16949, ISO13485 & AS9100D certified manufacturing processes ensure aerospace-grade reliability. If you have any questions about HDI PCB design, HDI PCB prototyping, or HDI PCB assembly, let us know via sales@bestpcbs.com.

What is HDI for PCB?

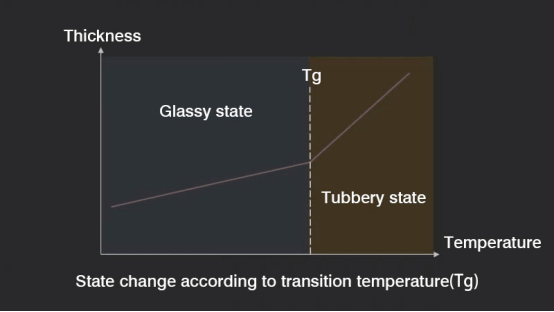

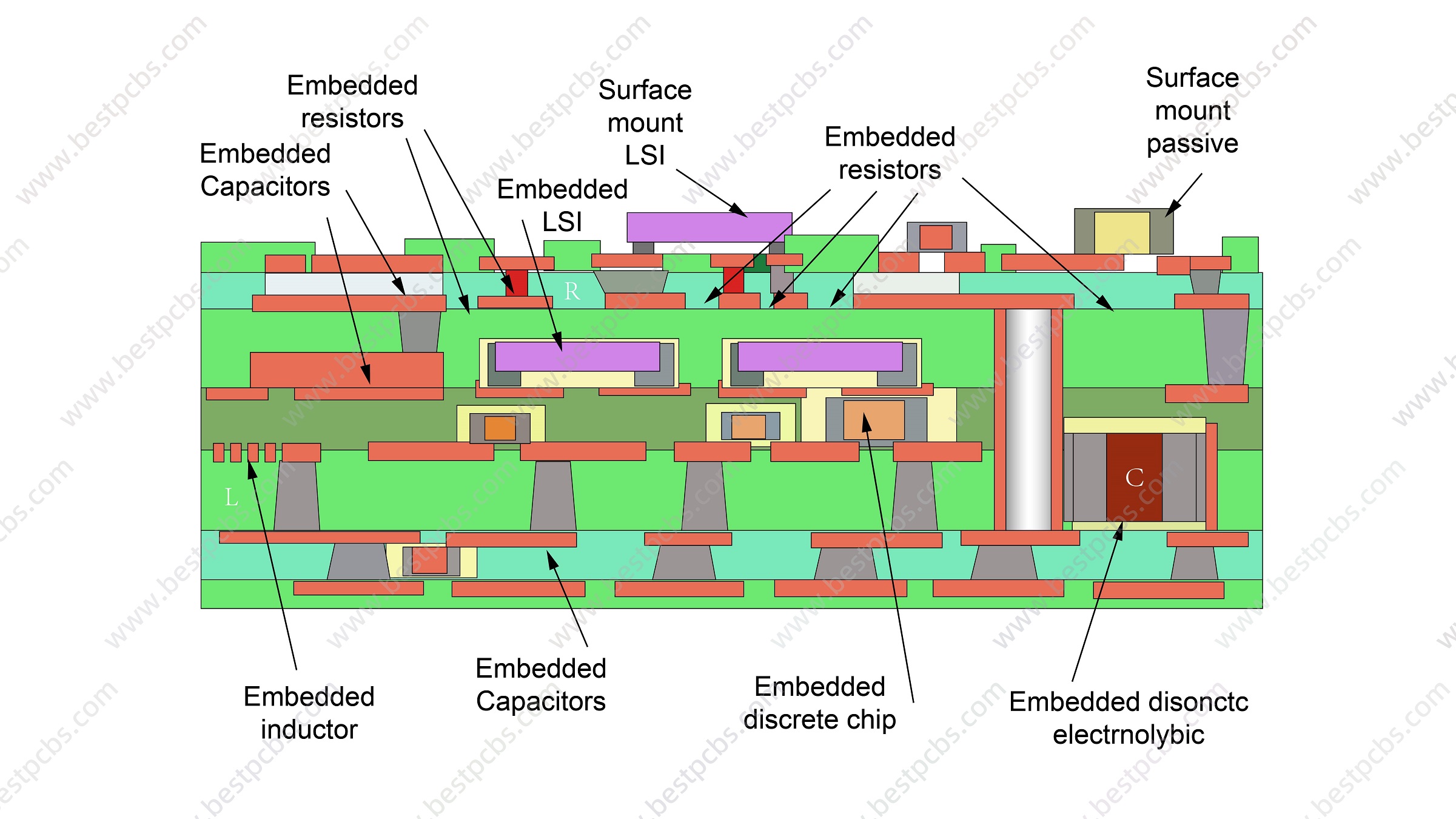

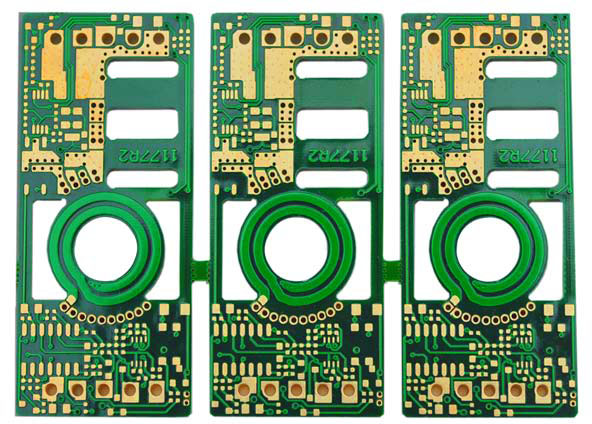

HDI stands for High Density Interconnect. It’s a type of printed circuit board that has a higher wiring density per unit area than standard boards. In simple terms, HDI PCBs are more compact, but they carry more connections. This is made possible with microvias, blind vias, and fine traces.

Compared to regular boards, HDI PCBs support tighter designs, faster signal transmission, and lower power usage. These qualities are essential in smartphones, medical equipment, automotive electronics, and wearable tech. If space is limited, HDI is the answer.

The HDI PCB definition includes features like:

- Laser-drilled microvias

- Multiple layers

- Fine line width and spacing

- Higher pin count in smaller space

Because of these features, HDI is becoming standard in advanced electronics.

What is the difference between HDI PCB and standard PCB?

- Via Types: HDI boards use microvias, blind vias, and buried vias. Standard boards use only through-hole vias.

- Layer Count: HDI can have more layers in a thinner stack-up.

- Design Complexity: HDI supports finer pitch components and smaller trace widths.

- Performance: Better signal integrity, lower crosstalk, and reduced EMI.

- Applications: HDI is used in compact devices. Standard PCBs suit less demanding products.

In short, HDI vs PCB boils down to density, complexity, and function.

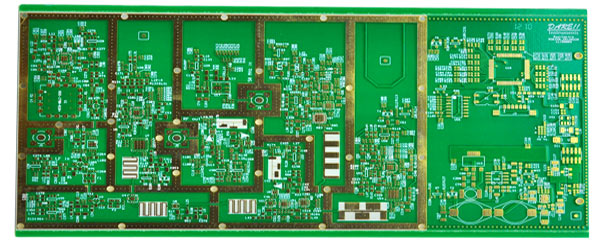

What is the HDI PCB manufacturing process?

The HDI PCB manufacturing process involves advanced steps. It requires more precision than regular PCB production. Here’s how it works:

- Material Preparation: Choose high-quality laminate suitable for fine lines.

- Laser Drilling: Use lasers to drill microvias with precise control.

- Copper Plating: Deposit copper inside vias and on the surface.

- Imaging: Apply photoresist and use UV light to define circuit patterns.

- Etching: Remove unwanted copper, leaving behind trace paths.

- Lamination: Stack multiple layers with insulating layers between.

- Testing: Conduct electrical tests to ensure quality and reliability.

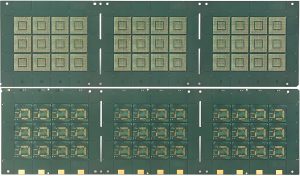

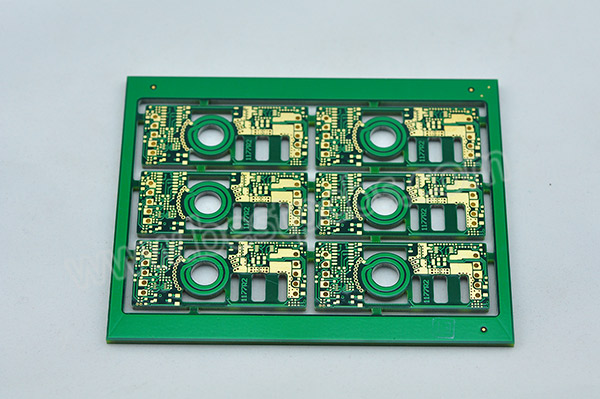

The HDI PCB fabrication process demands cleanrooms, skilled technicians, and controlled environments. This is why choosing the right HDI PCB manufacturer is vital. Best Technology is an original HDI PCB factory, with a monthly capability of up to 260,000 square feet (28,900 square meters), and more than 1,000 different boards will be completed. Warm welcome to contact us at sales@bestpcbs.com to discuss the HDI technology solutions for your projects.

What is the application of HDI PCB?

HDI boards are popular in sectors that need compact, high-speed, and multi-functional electronics. The most common HDI PCB application includes:

- Consumer Electronics: Smartphones, tablets, cameras.

- Medical Devices: Pacemakers, imaging systems.

- Automotive Electronics: ADAS systems, ECUs.

- Aerospace: Navigation, communication modules.

- Industrial Controls: Smart meters, automation systems.

Also, flex PCB application often overlaps with HDI for folding or wearable designs. With more features packed into less space, HDI PCBs support innovation across industries.

Who is the manufacturer of HDI PCB in China?

China leads the global PCB market, with many strong HDI PCB manufacturer options. Some top names include:

- Shennan Circuits – Large-scale production with global clients.

- Suntak Technology – Strong in multi-layer and HDI designs.

- Victory Giant – Offers high-quality PCB fabrication at scale.

Most of these companies also serve as PCB manufacturer in China for global OEMs. They provide competitive pricing, fast lead times, and complete design-to-delivery support. With 24/7 rapid prototyping (24-hour turnaround) and an on-time delivery rate of 97% delivery time rate in mass production, Best Technology empowers global customers to achieve smaller form factors, higher reliability, and 2-3 weeks faster time-to-market across consumer electronics, automotive ADAS, and IoT ecosystems. Best Technology empowers global customers to achieve smaller form factors, higher reliability, and 2-3 weeks faster lead time across consumer electronics, automotive ADAS, and IoT ecosystems.

HDI PCB Manufacturer in USA

If you prefer local support and fast logistics, many HDI PCB manufacturer in USA offer reliable options. Leading suppliers include:

- TTM Technologies – One of the biggest US-based HDI producers.

- Advanced Circuits – Known for prototype to volume HDI boards.

- Sanmina – Serves aerospace, defense, and medical sectors.

The PCB fabrication USA market focuses on quality, IP protection, and technical collaboration. If your design is sensitive or requires close engineering support, the USA is a strong choice.

HDI PCB Manufacturer in India

India is rapidly growing in the electronics space. Several HDI PCB manufacturer in India offer both quality and affordability. Top names include:

- AT&S India – Specializes in high-end HDI and advanced multilayer PCBs.

- Shogini Technoarts – Offers flexible, rigid-flex, and HDI solutions.

- Genus Electrotech – Supports mass production of HDI for local and export markets.

India’s rising strength in HDI electronics is driven by local demand, government support, and skilled labor.

HDI PCB Manufacturer in Europe

European companies often prioritize environmental standards and high precision. Reliable HDI PCB manufacturer Europe list includes:

- AT&S (Austria) – Strong in HDI and IC substrate solutions.

- NCAB Group (Sweden) – Provides engineering-focused HDI support.

- Würth Elektronik (Germany) – Offers HDI, RF, and advanced PCB types.

Europe may not match Asia in volume, but it leads in innovation and tight specs.

How to Choose an HDI PCB Manufacturer?

Finding the right HDI PCB manufacturer takes more than price comparison. Here are some key tips:

- Experience: Check how long they’ve worked with HDI designs.

- Certifications: Look for ISO, UL, RoHS, and IPC standards.

- Capabilities: Ensure they can handle microvias, stacked vias, fine traces.

- Prototyping: Choose someone who can support you from prototype to mass production.

- Support: Good communication matters. Ask for an HDI PCB manufacturer address to know their actual site.

- Documentation: A good partner can offer design tips or an HDI PCB design guide pdf.

Also, consider whether they offer other tech, like RF PCB manufacturing or flex PCB manufacturing services. It helps if they can grow with your needs.

In conclusion, choosing the right HDI PCB manufacturer affects the performance, cost, and speed of your project. With HDI technology, the margin for error is slim. Whether you’re working with a HDI PCB manufacturer in China, India, the USA, or Europe, the key is to find a trusted, experienced partner.

At Best Technology, we specialize in HDI boards, flexible circuits, RF PCBs, and complex stack-ups with tailored solutions. We support customers worldwide with professional engineering, fast prototyping, and reliable delivery. Reach out to Best Technology at sales@bestpcbs.com to get a free quote for your next HDI PCB need. We’re always here to help.