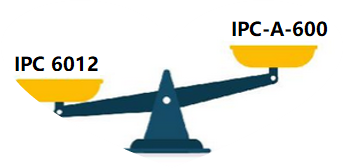

IPC-6012 is primarily concerned with the performance and reliability of rigid PCBs, detailing the requirements they must meet to be deemed acceptable. On the other hand, IPC-A-600 provides visual criteria for evaluating the quality of PCBs.

What does IPC stand for?

IPC stands for the Institute for Printed Circuits. This organization sets the standards for the design, manufacturing, and testing of electronic equipment. These standards ensure that the products meet the required quality and reliability levels. For professionals in the electronics industry, IPC standards are vital because they provide clear guidelines and expectations for the production of printed circuit boards (PCBs). They serve as a common language among manufacturers, suppliers, and end-users, promoting consistency and quality in the global electronics market.

What are IPC-6012 Standards?

IPC-6012 is one of the most critical standards set by IPC. It focuses specifically on the performance and qualification requirements for rigid PCBs. These standards are essential in ensuring that the boards can withstand the environmental and mechanical stresses they may encounter during their lifecycle. IPC-6012 is used by manufacturers to qualify their PCBs and ensure they meet customer requirements. The standard covers various aspects, including the materials used, the methods of testing, and the acceptance criteria. It is widely recognized and utilized across the electronics industry, making it a cornerstone for those involved in PCB production.

What is IPC-6012E en?

The “IPC-6012E en” refers to the specific edition of the IPC-6012 standard. This version includes all the latest revisions and updates. It ensures that manufacturers are using the most current guidelines when producing rigid PCBs. The “E” in IPC-6012E represents the edition, indicating that it is an updated version of the previous standards. The “en” signifies that it is in English, providing clear and concise instructions for English-speaking professionals in the industry. This version of the standard reflects the latest advancements in technology and industry practices, ensuring that the products meet the highest levels of quality and reliability.

What Content Does IPC-6012 Include?

IPC-6012 is a widely recognized standard that includes comprehensive requirements for the qualification and performance of rigid printed circuit boards. It covers a wide range of topics related to rigid PCB manufacturing. It includes detailed guidelines on materials, testing methods, and acceptance criteria. The standard outlines the requirements for the base materials used in the PCB, such as copper-clad laminates and prepregs. It also provides guidelines on the fabrication processes, including drilling, plating, and etching. The standard covers other various areas such as:

- Performance Specifications

- Material Requirements

- Fabrication Process Guidelines

- Dimensional Tolerances

- Testing Methods

- Inspection Criteria

- Cleanliness Requirements

- Defect Classification

- Repair and Rework Procedures

- Documentation Guidelines

- Marking and Labeling Standards

- Class-Specific Requirements

IPC-6012E is the latest revision, incorporating many new requirements, including:

- Back-drilled structures

- Surface finishes

- Copper wrap plating

- Solderability testing

- Plating overhang

- Marking inks

- Microsection evaluation

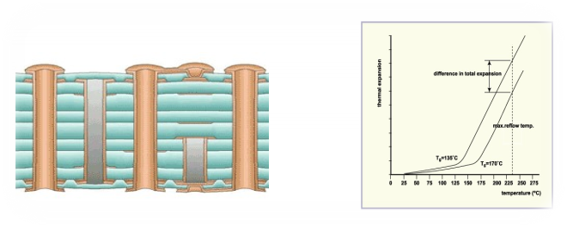

- Thermal shock

- Performance-based testing for micro-via structures

The IPC-6012EA (2021) addendum contains specifications for rigid circuit boards used in the automotive industry. These boards must endure stringent vibration and thermal stress tests. The addendum includes updated requirements for:

- Lifted lands

- Pattern feature accuracy

- Solder mask thickness

- Dielectric removal and wicking

- Cleanliness criteria

- Suitability and reliability testing parameters

What is IPC-A-600 Standard?

IPC-A-600, also known as the “Acceptability of Printed Boards,” is another essential standard in the PCB industry. Unlike IPC-6012, which focuses on performance and qualification requirements, IPC-A-600 provides visual acceptance criteria for finished PCBs. This standard is widely used for inspecting the quality of PCBs before they are shipped to customers. IPC-A-600 includes detailed photographs and illustrations to help inspectors identify defects and determine whether a PCB meets the required quality standards.

- Classification of Printed Boards

Defines different classes of PCBs based on their intended application and reliability requirements, including Class 1 (general electronic products), Class 2 (dedicated service electronic products), and Class 3 (high-reliability electronic products).

- Material Quality Requirements

Sets standards for the materials used in PCB construction, ensuring they meet specific quality and durability requirements.

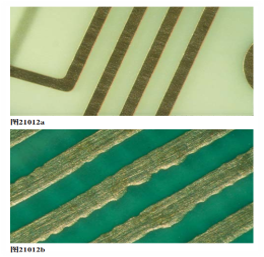

- Surface and Subsurface Conditions

Provides criteria for acceptable and non-acceptable surface and subsurface conditions, such as laminate voids, cracks, and other defects that could affect board performance.

- Conductor Criteria

Outlines requirements for conductor width, spacing, and thickness, as well as the acceptability of defects like nicks, cuts, and scratches on conductors.

- Solder Mask and Coating Criteria

Specifies the quality standards for solder masks and other protective coatings, including their application, coverage, and defects like pinholes or bubbles.

- Plating and Coating Integrity

Describes the acceptable levels of plating thickness and the presence of defects like blisters, peeling, or voids in the plated layers.

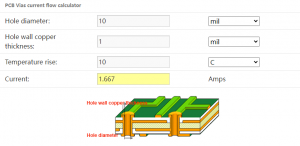

- Hole/Interconnection Quality

Provides guidelines for the quality of holes and interconnections, including criteria for plating thickness, hole wall quality, and annular ring size.

- Annular Ring and Land Criteria

Specifies the acceptable size and quality of annular rings and lands, as well as the alignment of pads and vias.

- Warp and Twist Tolerances

Defines the acceptable levels of board warpage and twist, which can affect the assembly process and the final product’s performance.

- Bow and Twist Evaluation

Methods for evaluating and measuring the bow and twist of PCBs to ensure they remain within specified tolerances.

- Contamination and Cleanliness

Establishes cleanliness standards for PCBs, including acceptable levels of ionic and non-ionic contamination.

- Repair and Rework Guidelines

Offers procedures for repairing and reworking boards while maintaining compliance with the standard.

- Marking and Documentation Requirements

Sets forth the standards for marking and documentation to ensure traceability and compliance with the IPC-A-600 standard.

- Visual Inspection Criteria

Includes detailed visual inspection criteria, with numerous illustrations and photographs, to help inspectors and manufacturers determine the acceptability of PCBs.

- Dimensional Tolerances

Specifies tolerances for various PCB dimensions, ensuring consistency in the final product.

- Advanced Board Types

Criteria for newer and more complex board types, including high-density interconnect (HDI) boards, rigid-flex, and metal-core PCBs.

What is the Difference Between IPC-6012 and IPC-A-600?

While both IPC-6012 and IPC-A-600 are essential standards in the PCB industry, they serve different purposes. IPC-6012 focuses on the performance and qualification requirements for rigid PCBs, ensuring that they meet the required quality and reliability levels. On the other hand, IPC-A-600 provides visual acceptance criteria for finished PCBs, helping inspectors identify defects and determine whether a PCB meets the required quality standards. In essence, IPC-6012 is used during the manufacturing process to ensure that the PCBs are produced to the required specifications, while IPC-A-600 is used during the inspection process to ensure that the finished products are free from defects and meet the required quality standards.

Is IPC-6012 Cleanliness?

Cleanliness is an essential aspect of PCB manufacturing, and IPC-6012 does address this issue. The standard includes guidelines for ensuring that the PCBs are free from contaminants that could affect their performance and reliability. Cleanliness is crucial in PCB manufacturing because contaminants can cause various problems, such as short circuits, reduced performance, and even failure of the PCB. IPC-6012 provides specific guidelines on how to ensure cleanliness during the manufacturing process, including cleaning procedures, inspection methods, and acceptance criteria. Ensuring cleanliness during the manufacturing process is essential for producing high-quality PCBs that meet the required performance and reliability standards.

FAQs

Q: What is the difference between IPC-6012 Class 2 and Class 3?

A: IPC-6012 Class 2 is designed for electronic products where extended reliability is required but not critical, while Class 3 is for high-performance electronic products, where continued performance or performance-on-demand is critical. Class 3 has stricter requirements than Class 2.

Q: What does the latest revision of IPC-6012 include?

A: The latest revision of IPC-6012 includes updates to materials, testing methods, and acceptance criteria, reflecting the latest advancements in PCB manufacturing technology.

Q: What is IPC 6012F?

A: IPC 6012F is a specific revision of the IPC-6012 standard, which includes updates and improvements to the previous versions. It reflects the latest industry practices and ensures that the products meet the required performance and reliability levels.

Q: How does IPC 6012ES differ from other revisions?

A: IPC 6012ES is a specialized version of the IPC-6012 standard that includes specific guidelines for certain applications, such as military or aerospace, where the requirements for performance and reliability are more stringent.

Q: What is the role of IPC standards in PCB manufacturing?

A: IPC standards provide clear guidelines and expectations for PCB manufacturing, ensuring that the products meet the required quality and reliability levels. They serve as a common language among manufacturers, suppliers, and end-users, promoting consistency and quality in the global electronics market.