DOB Full Form in LED

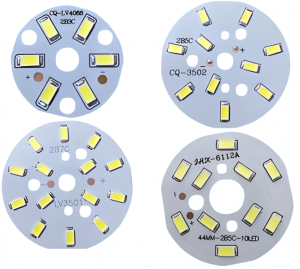

DOB full form in LED is “Driver on Board.” In LED lighting, this means the driver circuit is built directly onto the LED board. There’s no need for a separate external driver. This configuration is based on the consideration that LED drivers have been dominantly designed as switching mode power supplies.

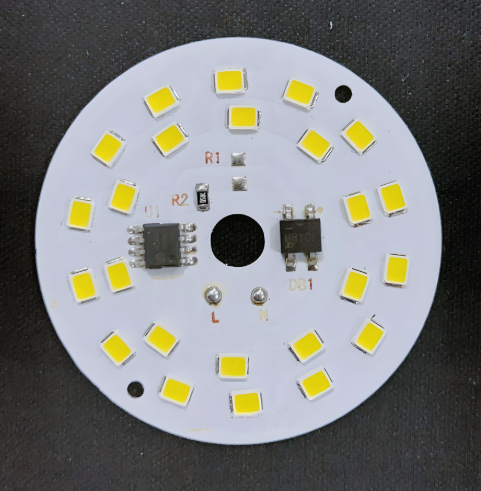

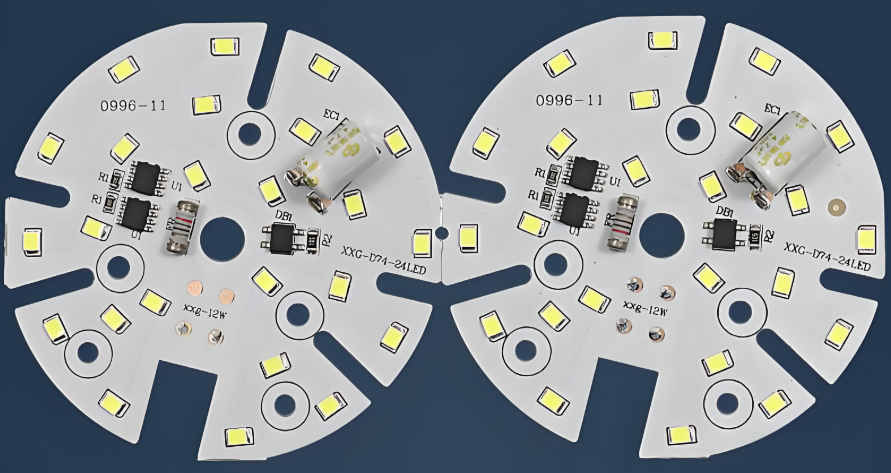

A DOB LED PCB is a neat package. It has the LEDs, power regulation circuit, and other supporting components all mounted on a single board. This includes rectifiers, surge protectors, constant current regulators, and sometimes capacitors to stabilize the current.

Because the dob led driver circuit is built-in, these boards are usually smaller and more lightweight. Most use aluminum base PCBs, which help draw heat away from the components to improve lifespan.

What Is LED Driver?

Simply put, a LED driver is a part that mainly used to control the power going to your LEDs. LEDs work best when they get a consistent current. A driver makes sure the current stays steady, even when the input voltage changes.

Traditional LED lighting uses an external driver. It converts AC (from your wall) to DC (what the LEDs need). But in the LED DOB approach, this conversion happens right on the board. That’s why DOB lights don’t need external drivers.

However, some large-scale lighting systems still prefer external drivers for better thermal control and longer lifespan. For smaller applications, dob led lights are a good choice due to the convenience.

LED Bulb DOB Circuit Diagram

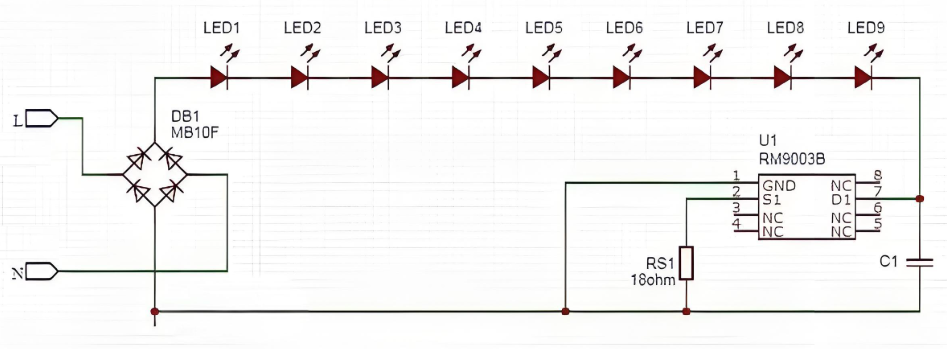

A basic led bulb dob circuit diagram includes:

Input terminals (AC supply)

Bridge rectifier

Filtering capacitor

Constant current IC or regulator

LED array

Here is a typical diagram of DOB LED circuit:

How Does DOB LED Driver Circuit Work?

The DOB LED driver circuit operates through several key functional blocks, including input overvoltage protection, rectification and filtering, current limiting, and PWM dimming.

1. Input Overvoltage Protection

The DOB LED circuit includes an overvoltage protection mechanism to handle power surges caused by lightning or sudden spikes from the mains. When a DC voltage is applied across the “+48V” and “GND” terminals, current first flows through resistor R1 to limit the surge. If the voltage rises beyond a safe level, the current through R1 increases, causing a voltage drop. Once this drop exceeds 1W, the protection system activates—R1’s resistance instantly increases to an extremely high value, effectively blocking the current and shielding the +48V input line from damage.

2. Rectification and Filtering Circuit

When the input is AC power, a bridge rectifier converts the alternating current into direct current. This DC output passes through the rectifier for polarity protection, preventing damage from reversed connections. Components like capacitors C1 and C2, along with inductor L1, smooth out the ripples and produce a stable DC voltage.

3. Current Limiting Circuit

LEDs require stable current to operate efficiently and avoid damage. That’s why DOB circuits use a current-limiting mechanism, typically based on either resistors or constant current sources. A constant current driver is commonly preferred because it maintains consistent brightness across varying input voltages and temperatures, helping extend LED life and performance.

4. PWM Dimming Control

To control brightness, DOB LED circuits often use PWM technology. By adjusting the duty cycle of the PWM signal, the average current through the LED changes, which alters the brightness. This is usually done by modifying the voltage at the top end of the feedback resistor, which in turn regulates the current through the LED.

DOB LED PCB Advantages and Disadvantages

Advantages:

- Fewer components: With no external driver, the whole assembly becomes simpler.

- Cost-effective: Fewer parts and simpler design reduce production costs.

- Space-saving: The integrated design is ideal for compact lighting like LED bulbs or tubes.

- Lightweight: No bulky driver means less weight.

- Easy to install and replace: Just plug and go. No extra wiring or enclosures.

Disadvantages:

- Limited in high-wattage systems: Integrated drivers can heat up quickly and struggle with larger currents.

- Heat management is critical: Without good cooling, performance drops over time.

- Lifespan is tied to board quality: A poorly designed dob led driver circuit may shorten LED life.

- Not suitable for dimming: Most DOB circuits don’t support dimming out-of-the-box.

Despite the challenges, dob led lights work well in most indoor environments. They offer an easy plug-in lighting solution without the need for complex wiring.

What Is DOB LED Used For?

So, where do you use a dob led? Pretty much everywhere light is needed in a simple, cost-effective form. You’ll find dob led pcbs in:

- LED light bulbs

- Tube lights

- Panel lights

- Garden lights

- Wall lamps

- Street lamps (low wattage)

Because the entire system is compact, manufacturers often choose DOB for plug-and-play lighting. A dob led light is cheaper to make and easier to sell in volume. The efficiency and simplicity make DOB ideal for home lighting, budget projects, and commercial interiors.

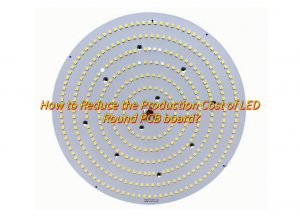

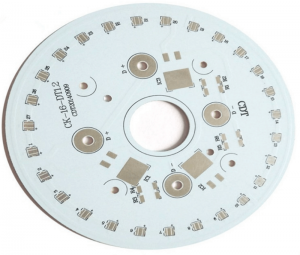

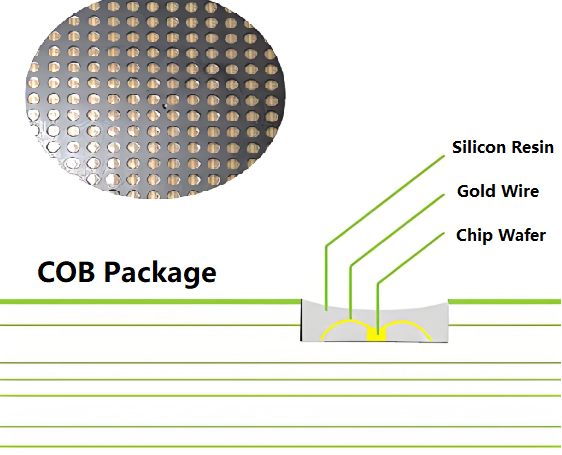

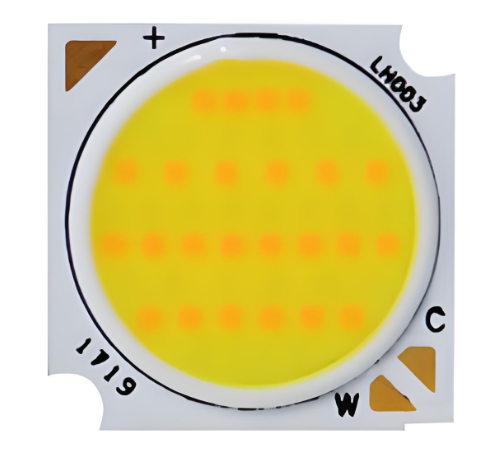

What Is COB LED PCB?

COB, which stands for “Chip on Board.” In this case, multiple LED chips are mounted directly onto the PCB with very little space between them. This setup creates a dense, bright light source. The PCB itself is usually aluminum-based. The close grouping of chips gives the COB LED PCB its signature even, shadow-free glow. COBs are used in spotlights, floodlights, and other high-intensity applications.

Unlike dob led, a COB PCB doesn’t have a driver built-in. It needs an external LED driver to control current and voltage.

Features of COB LED PCB

- High density of LEDs on one board

- Excellent brightness and high lumen output

- Smooth and even light beam

- Strong thermal management (especially with aluminum core PCBs)

- Compact design for high-power fixtures

COB designs work well in lighting products where powerful and uniform light is needed.

COB LED PCB Advantages and Disadvantages

Advantages:

- Brighter output: More chips in one place = more light.

- Compact but powerful: Ideal for high-performance lighting in small sizes.

- Low glare: Even distribution of light reduces harsh spots.

- Thermal efficiency: Designed for good heat dissipation.

Disadvantages:

- Needs an external driver: That adds cost and space requirements.

- Not flexible: Fixed shape and size limit design options.

- Slightly higher cost: More complex manufacturing process.

Still, for strong lighting needs—like industrial or architectural setups—COB wins over dob led in brightness and beam quality.

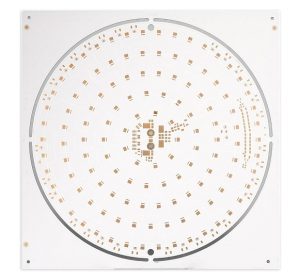

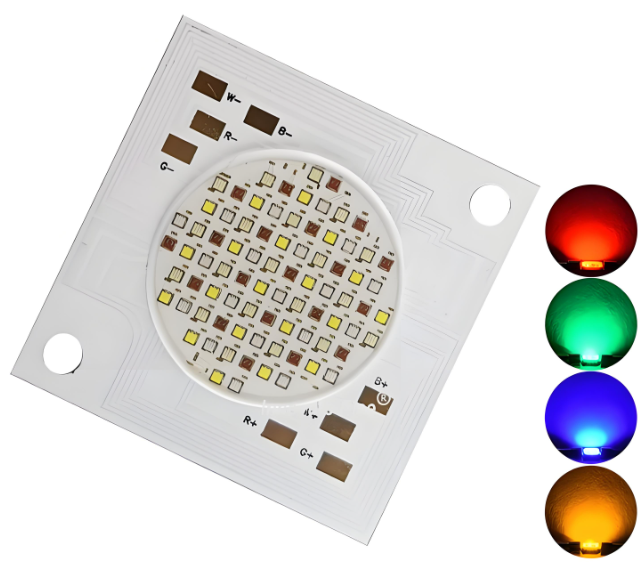

What Is SMD LED PCB?

SMD stands for Surface Mounted Device. These are individual LED chips mounted directly onto the surface of the board. Unlike COB, where chips blend into one source, SMDs remain separated.

Common package sizes of SMD LED include 3528, 2835, and 5050 SMD chips. Each number relates to the dimensions in millimeters. These chips are popular for flexible LED strips, signage, and backlit displays.

A smd led pcb often supports RGB functions. That means each LED can emit different colors, which is useful for digital billboards, decorative lights, and custom control systems.

Features of SMD LED PCB

- High flexibility in design layout

- Small and lightweight LEDs

- Available in different color options (RGB & RGBW)

- Can be used on both rigid and flexible boards

- Suitable for decorative and general-purpose lighting

SMD LED PCB Advantages and Disadvantages

Advantages:

- Design freedom: Great for custom layouts and creative shapes.

- RGB ready: Many SMDs support multi-color output.

- Lower cost: Ideal for mass production.

- Good performance: Bright, efficient, and adaptable.

Disadvantages:

- Less heat-resistant: Not as efficient as COB in thermal handling.

- May require more circuitry: For full color and control, extra components are needed.

- Light is more scattered: Doesn’t provide a focused beam like COB.

COB, SMD, DOB LED PCB Manufacturing and Assembly – Best Technology

When it comes to high-quality COB, SMD, and DOB LED PCB manufacturing, Best Technology stands out as a reliable and experienced partner. We deliver solutions that meet the exact requirements of every customer—from indoor DOB LED panels to high-power COB lighting and custom SMD strip assemblies.

Our facilities are equipped with 4+ advanced SMT lines and a full set of testing equipment to ensure precision, stability, and long-term performance. Whether you need rapid prototyping, low-volume production, or high-volume assembly, we tailor our services to your schedule and technical needs.

We offer:

- Custom LED PCB design based on your lighting application

- Metal core PCB (Aluminum, Copper), FR4, and ceramic PCB options for optimal thermal performance

- One-stop assembly service, from component sourcing to final testing

- Strict quality control with AOI, ICT, and functional testing

- On-time delivery and responsive support to help you meet market demands

If you’re seeking durable, energy-efficient, and cost-effective LED lighting solutions, choose Best Technology for your next project. Whether it’s a simple dob led driver circuit, a multi-chip COB LED module, or a flexible smd led pcb, we have the capabilities and experience to deliver!

Related Post