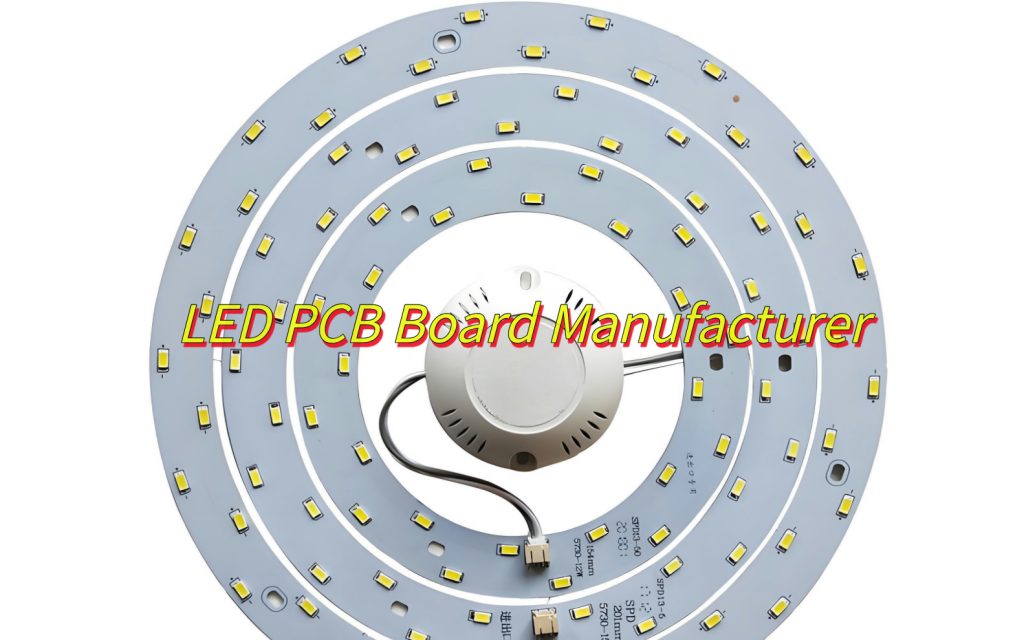

Looking for a reliable LED PCB board manufacturer? Learn about LED PCB board design, manufacturing process, and how to reduce costs effectively in this blog.

Best technology, a LED PCB board manufacturer, we focus on LED PCB Board design and manufacturing for 18 years. We provide one-stop PCB solutions and PCBA service for LED PCB board to achieve fast delivery. we can provide DFM analysis for led board design, which can predict production issues in advance and reduce production costs a lot. Then we have obtained ISO 9001, RoHS and UL We have obtained ISO 9001, RoHS and UL certification, so we can provide you high quality PCB products If you’re interested in our service, welcome to contact us sales@bestpcbs.com.

What Is LED PCB Board?

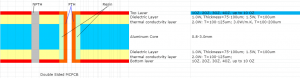

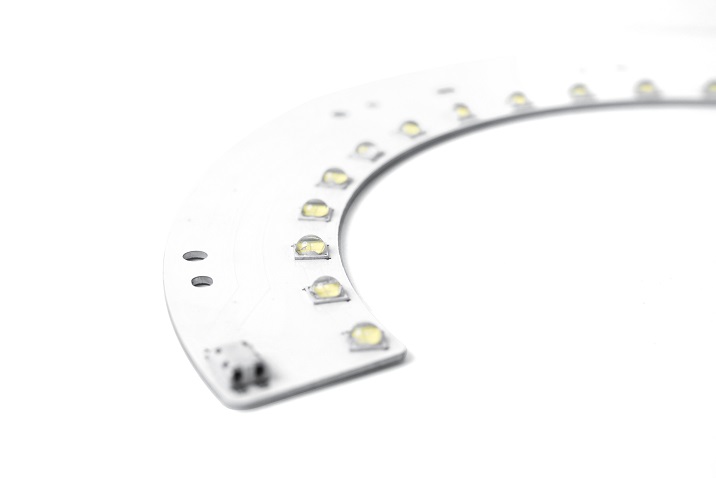

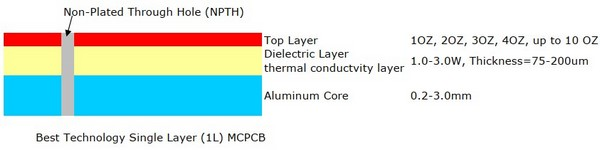

LED PCB board is a type of printed circuit board specifically designed to support and power light-emitting diodes (LEDs). These boards use materials with high thermal conductivity, such as aluminum, to efficiently dissipate heat generated by LEDs. LED PCBs are widely used in applications like automotive lighting, display screens, medical devices, and general illumination systems.

What Are the Advantages of LED PCB Board?

- Excellent heat dissipation: The aluminum substrate dissipates heat quickly through thermal conductive media, protecting components from high temperatures.

- High energy efficiency: LED light sources consume 80% less power than traditional incandescent bulbs and have a lifespan of over 20,000 hours.

- Strong reliability: Resistant to high temperatures, humidity, and impact, suitable for harsh environments.

- Flexible design: Customizable in size, shape, and circuit layout, adaptable to different application scenarios.

- Environmental friendliness: Aluminum materials are recyclable, reducing resource waste and environmental pollution.

How to Design LED PCB Board?

Here’re steps for LED PCB board design:

1. Circuit design

- Determine the power supply type: constant voltage (with current limiting resistor) or constant current (dedicated driver chip).

- Calculate the total current: single LED current × quantity, ensure that the power margin is ≥20%.

2. Wiring rules:

- Main current path line width ≥1.5mm (1A current corresponds to 0.5mm width).

- Signal line width ≥0.2mm, spacing ≥0.3mm.

- Add protection circuit: TVS surge protection, reverse connection protection diode.

3. Layout optimization

- LED spacing: evenly distributed according to the light-emitting angle to avoid dark areas.

- High-heat area: reserve heat dissipation copper foil around high-power LEDs (copper plating area ≥2 times the LED size).

- Partition isolation: high-voltage and low-voltage circuits are placed separately, and high-frequency signal lines are short and straight.

4. Heat dissipation design

- A heat sink (thickness ≥3mm) is attached to the back of the aluminum substrate, and thermal grease is applied.

- Add heat dissipation holes: hole diameter 0.5-1mm, spacing ≤5mm.

- High-temperature area: install temperature sensor or thermistor.

5. PCB prototyping verification

- Visual inspection: whether the pad size and aperture match the LED pin;

- Power-on test: step-by-step voltage boost (0V→rated voltage), monitor current and temperature rise.

- Aging test: run at full load for 24 hours to confirm that there is no light decay or solder joint virtual connection.

Then next step you can find move your Gerber file to production.

What Is LED PCB Manufacturing Process?

Here are LED PCB manufacturing processes:

- Cutting substrates : Cut aluminum substrates/FR-4 substrates according to the design size.

- Photoresist coating : Evenly cover the surface of the substrate with a photosensitive resist layer.

- Exposure and development : Irradiate the circuit pattern with ultraviolet light to wash away the uncured parts.

- Etching copper layer : Use chemical liquid to remove excess copper foil to form a conductive circuit.

- Drilling: Mechanically drill LED pin holes, heat dissipation holes and fixing holes.

- Surface treatment : OSP (anti-oxidation) or tin spraying (anti-oxidation, easy to solder).

- SMT patch : Machine mounting of LED lamp beads, resistors, driver chips and other components.

- Reflow soldering : High-temperature furnace melts solder and fixes components.

- Electrical test & Functional test: Check short circuit, open circuit, and current consistency; Light up the LED to verify brightness, color temperature, and heat dissipation performance.

- Finished product assembly : Add a heat sink, lens or shell, and package for shipment.

LED PCB Board Manufacturer

As a LED PCB Board Manufacturer, Best Technology can provide the following service:

- Rich Production Experience: 18 years’ experience in multi-layer LED PCB board design and production and can handle production issues flexibly.

- Qualification Certification& DFM Analysis: Obtained ISO 9001, UL certification or RoHS compliance.

- One-Stop PCB solution and PCBA service: Comprehensive services from design to final assembly.

- Quick Turnaround Time& Affordable Price: Offer rapid delivery options ranging from 24 hours to 3 days at affordable price, accommodating urgent project needs.

- Excellent Customer Service& Free Technical Support: Provide customers with exclusive pre-sales and after-sales services and free technical support.

- High-Quality Standards: Adheres to stringent quality standards, significantly reducing the need for reworks and ensuring reliable products.

If you want to know more about us, welcome to leave a message below this blog.

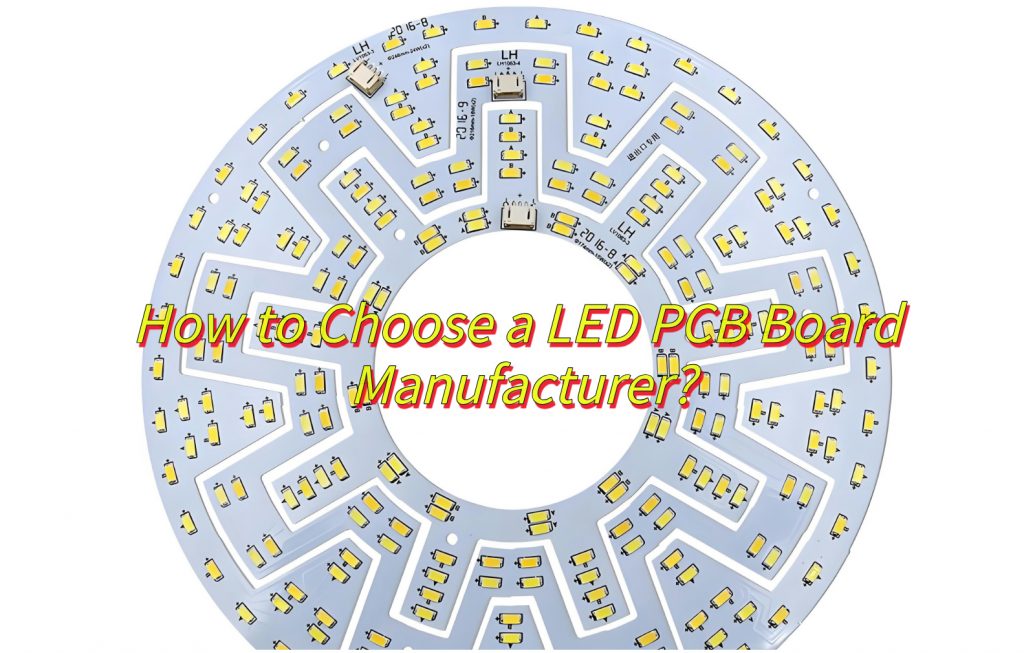

How to Choose a LED PCB Board Manufacturer?

Here are tips about how to choose a LED PCB board manufacturer:

- Experience in LED PCB manufacturing for quality assurance.

- Certifications (ISO, UL, RoHS) for safety and reliability.

- One-stop PCB solution and PCBA service

- Fast delivery and competitive price

- Strong customer support for technical assistance.

How Much does LED PCB Cost?

1. Material Cost

- FR4 (Standard PCB): Around $0.50–$5 per board.

- Aluminum (Better heat dissipation): Around $1–$10 per board.

- Copper (High-performance applications): Around $5–$50 per board.

- Ceramic (Extreme heat resistance): Around $10–$100 per board.

2. Layers & Thickness

- Single-layer: Around $0.50–$10.

- Double-layer: Around $1–$20.

- Multilayer: Around $5–$100+.

- Thicker copper (better heat dissipation) increases cost.

3. Order Quantity

- Small orders (1–10 pcs): Around $5–$50 per piece.

- Bulk orders (1000+ pcs): Around $0.50–$10 per piece.

4. Assembly Costs

- Manual assembly: Around $0.05–$0.50 per LED.

- Automated SMT assembly: Around $0.01–$0.20 per LED.

5. Final Estimate

- Basic LED PCB: Around$1–$5 per board.

- Aluminum LED PCB: Around $3–$20 per board.

- High-end Ceramic LED PCB: Around $10–$100+ per board.

Do you want to get an accurate quote? If you want to get an accurate quote for your case, please feel free to contact Best Technology.

How Can I Make LED PCB Cheaper?

Here are some methods about how can you make LED PCB board cheaper:

Material optimization

- Board selection: Use FR-4 substrate for conventional scenarios, and avoid unnecessary aluminum substrate/ceramic substrate.

- Copper thickness and ink: Copper thickness ≤1oz for non-high-power scenarios, use ordinary green ink, and avoid special colors (blue oil/white oil).

Design optimization

- Number of layers and wiring: Single/double-sided boards are preferred to reduce the number of layers; line width and line spacing ≥5/5mil to avoid fine line price increase.

- Through holes and processes: Standard aperture ≥0.3mm to reduce the cost of micro holes; avoid special processes such as blind buried holes and half holes.

Simplification of production process

- Surface treatment: Use tin spraying (lead-free) or OSP for conventional scenarios to avoid immersion gold/gold plating.

- Processing standard: Use conventional testing (non-military standard/IPC3) to reduce the cost of pass rate loss.

Choose Reliable supplier collaboration

- DFM analysis: choose manufacturers that support design optimization to reduce rework risks.

- Board matching: flexibly adjust the design according to the manufacturer’s inventory boards (such as TG130/150) to reduce the cost of stock preparation

In conclusion, selecting the right LED PCB board manufacturer is very important for achieving high-quality lighting solutions. Understanding the design, manufacturing process, and cost factors can help in making informed decisions. Whether you need a small batch or large-scale production, working with an experienced LED PCB supplier ensures reliability, performance, and cost-effectiveness.