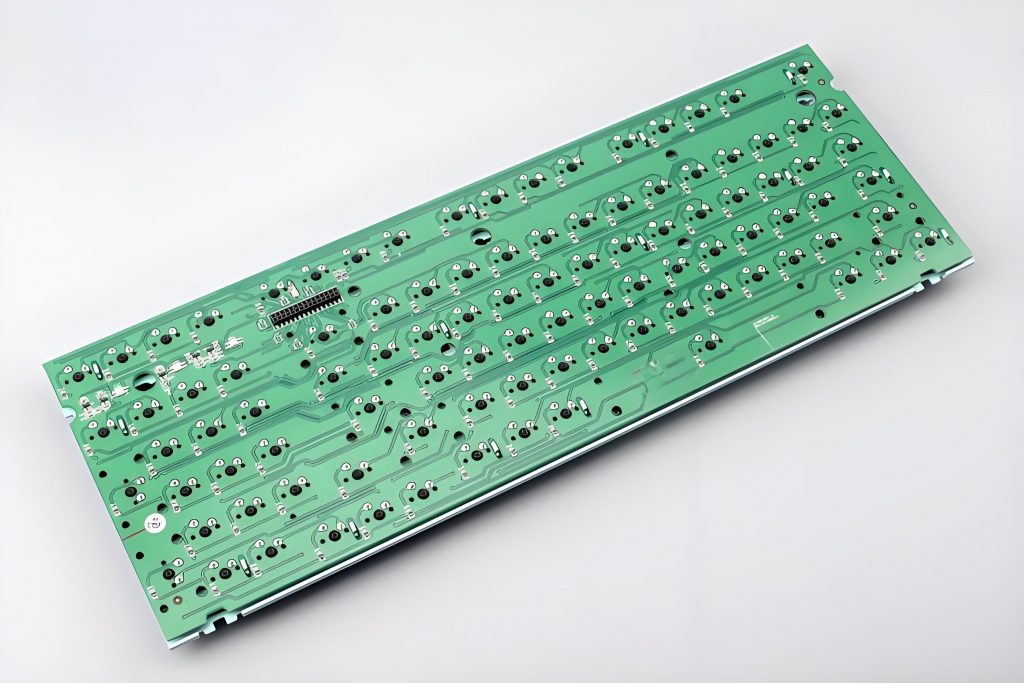

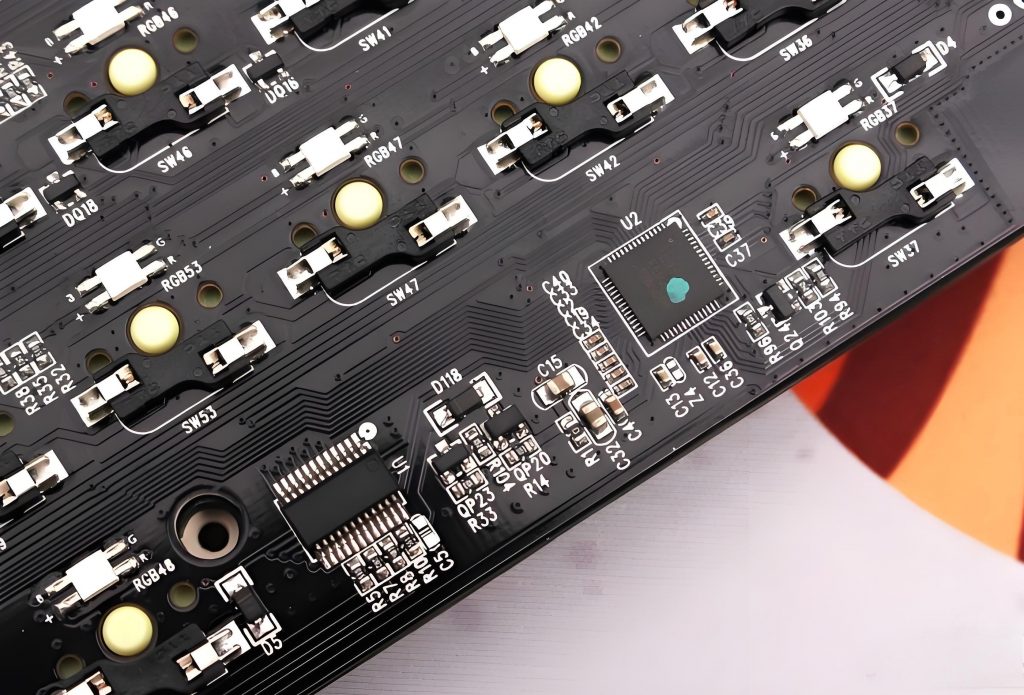

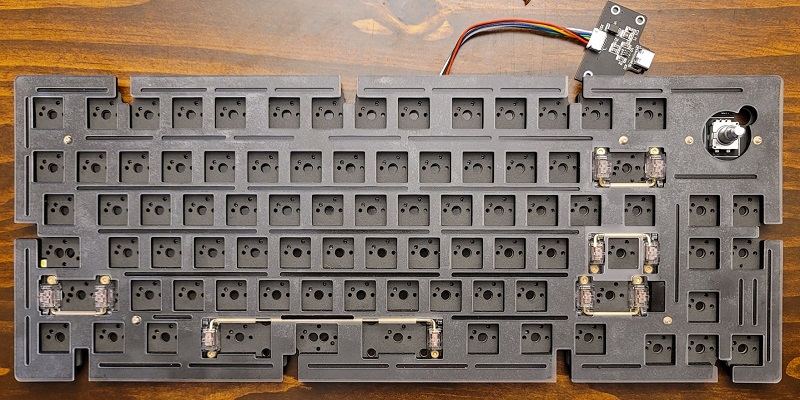

The Mammoth 75 PCB thickness is a key factor that influences the overall feel, sound, and durability of your custom keyboard. Whether you’re building a new keyboard or upgrading your existing one, understanding the impact of PCB thickness is essential. In this blog, we‚Äôll break down the ideal thickness for the Mammoth 75 PCB, explore the differences between various options, and help you make the right choice for your build.

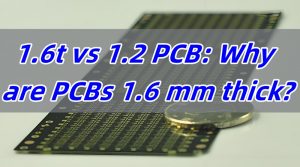

What is the Standard PCB Thickness?

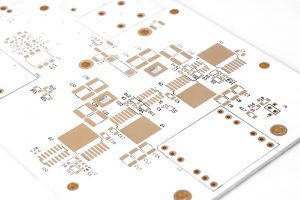

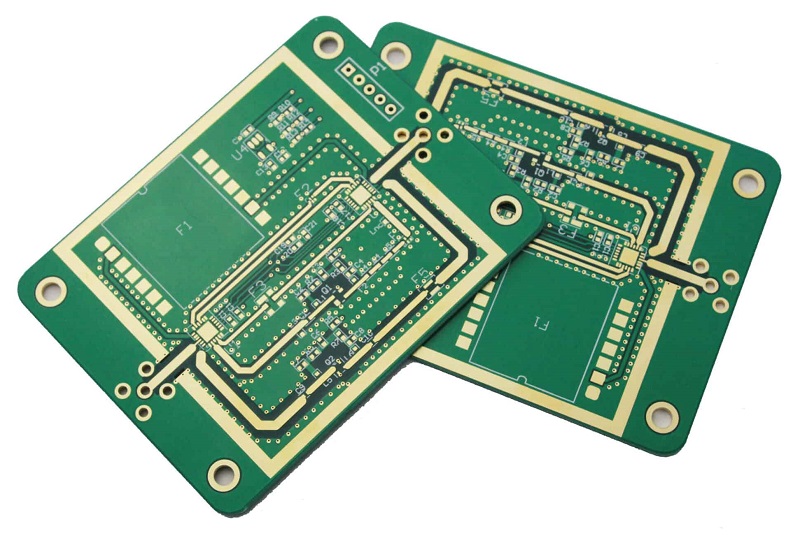

PCB thickness refers to the measurement of the circuit board’s overall depth. The 1.6 mm thickness is the most widely adopted standard across the electronics industry. This thickness provides an optimal balance of rigidity and durability, ensuring structural stability for most applications while remaining compatible with standard components and manufacturing processes.

For mechanical keyboards, such as the Mammoth 75 PCB, 1.6 mm is frequently used as it offers sufficient rigidity to maintain switch alignment and resist flex during typing. However, some keyboards may use thinner PCBs (e.g., 1.2 mm) to introduce controlled flexibility, which can influence the typing feel or sound profile (e.g., in gasket-mounted designs). Conversely, thicker PCBs (e.g., 2.0 mm) are occasionally used to add weight or alter acoustics. Adjustments in thickness are typically made to optimize performance characteristics like sound, weight, or mechanical behavior, rather than aesthetics alone.

What is the Difference Between 1.2 mm and 1.6 mm Keyboard PCB?

When you compare a 1.2 mm PCB to a 1.6 mm PCB, the primary difference lies in rigidity and durability. A 1.6 mm PCB offers better structural support, making it more robust and resistant to bending or flexing during use. It also tends to provide a more solid feel, which many users prefer in their mechanical keyboards. On the other hand, 1.2 mm PCBs are lighter. They’re often chosen for keyboards that emphasize portability.

The Mammoth 75 PCB thickness usually falls within the 1.6 mm category, ensuring a solid and sturdy feel, perfect for those who prioritize stability and a premium typing experience.

How Thick Should a Keyboard PCB Be?

The ideal Mammoth 75 PCB thickness depends on what you’re looking for in terms of typing experience and design goals. For most users, 1.6 mm is considered the sweet spot, as it balances durability with flexibility. A thicker PCB could result in a more rigid typing experience, but it may also add unnecessary weight. For those looking for a more flexible typing experience, a thinner PCB around 1.2 mm may be a better choice.

When considering thickness, it’s important to also think about other components of the keyboard, such as the case material and plate. The PCB should complement these elements to create the ideal feel and sound profile.

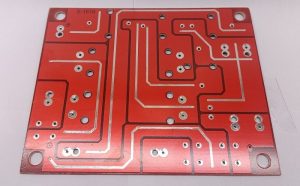

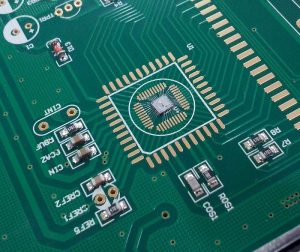

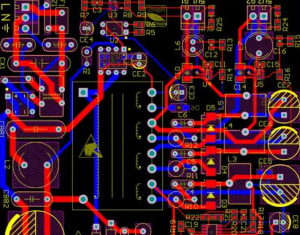

How Thick Should PCB Traces Be?

PCB traces are the pathways that carry electrical signals across the board. The thickness of the traces plays a crucial role in the performance of the PCB. Typically, traces for mechanical keyboards are designed to handle current requirements without unnecessary width. For most Mammoth 75 PCB designs, trace thickness will typically be between 6 mils and 10 mils, depending on the current and signal requirements.

In general, thinner traces can be used for low-power applications like key switches, while thicker traces are used where higher currents are involved. Ensuring that your PCB traces are appropriately sized is critical to ensuring reliable keyboard performance.

What is the Mil Thickness of a PCB?

The mil thickness of a PCB refers to its measurement in mils, where one mil equals one-thousandth of an inch. In custom mechanical keyboard builds, such as the Mammoth 75, the PCB thickness is often specified in mils to ensure it fits properly with the case and other components. For example, a typical Mammoth 75 PCB might be 1.6 mm (about 63 mil), but if you’re aiming for a more robust design, you may opt for a 2.4 mm (or 95 mil) thickness for additional durability and stability. Thicker PCBs offer greater durability and rigidity, contributing to a sturdier build that can better handle the stresses of long-term use.

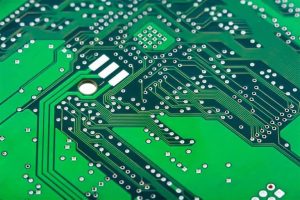

Does PCB Thickness Matter?

Yes, PCB thickness absolutely matters when it comes to building a custom mechanical keyboard like the Mammoth 75. The thickness of the PCB can influence several factors, including:

Weight and feel: Thicker PCBs provide a more solid, premium feel.

Sound profile: Thicker PCBs can dampen vibrations slightly, contributing to a deeper or more muted sound. Thinner PCBs may allow more resonance, potentially brightening the acoustics. However, sound is more heavily influenced by plate material, mounting style, and case design.

Durability: A thicker PCB will usually be more durable and resistant to warping over time.

In summary, choosing the right Mammoth 75 PCB thickness can significantly enhance the typing experience, depending on personal preference and design goals.

Are All Keyboard PCBs the Same?

No, all keyboard PCBs are not the same. They come in various shapes, sizes, materials, and thicknesses. The Mammoth 75 PCB is specifically designed for a 75% layout, which influences its size and port placement. Additionally, the choice of material, like FR4, affects the PCB’s durability and weight.

When choosing a PCB for your custom build, it’s essential to ensure that it matches your keyboard case and plate. Not all layouts and sizes will fit, so it’s crucial to pick a PCB that works well with the other components.

In conclusion, understanding Mammoth 75 PCB thickness is essential for anyone looking to build or modify a custom mechanical keyboard. The thickness of the PCB affects everything from durability and sound to the overall typing experience. While 1.6 mm is the most common thickness for high-quality keyboards, some users may prefer a thinner or thicker option based on their specific needs.

By knowing the differences in thickness, trace size, and material, you can choose the right PCB thickness for your keyboard. Whether you’re designing your dream Mammoth 75 keyboard or just curious about PCBs, the thickness plays a pivotal role in shaping your keyboard‚Äôs performance and feel. Best Technology excels in delivering customized, premium PCB solutions with fast turnaround times, supported by exceptional customer service. For details or inquiries, feel free to contact us at sales@bestpcbs.com.