LED MCPCB, or Metal Core Printed Circuit Board, plays a crucial role in the performance and longevity of modern LED lighting systems. By efficiently dissipating heat, it ensures that LEDs operate at their best, even in high-power applications. As the demand for more energy-efficient and durable LED solutions grows, LED MCPCB has become an essential component in industries ranging from automotive lighting to consumer electronics. In this blog, we’ll explore the different types of LED MCPCBs, the design process, their key advantages.

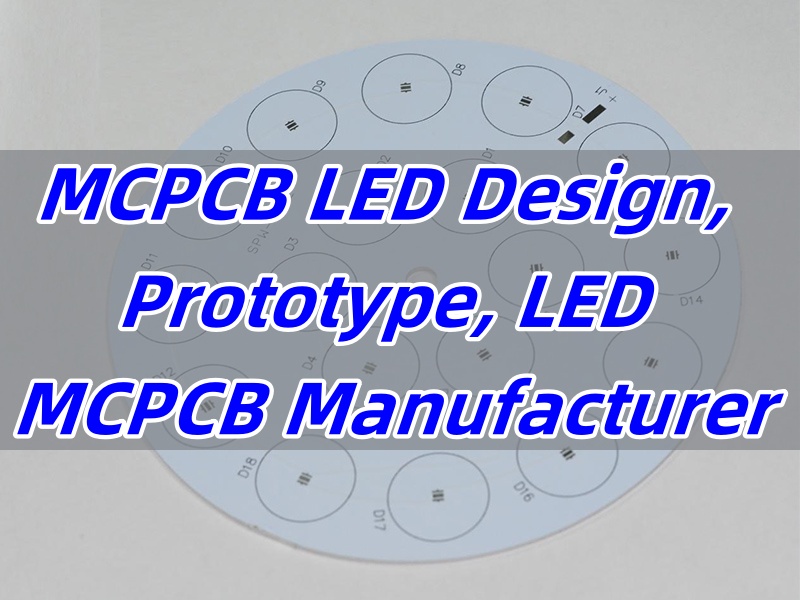

As a professional LED MCPCB manufacturer, Best Technology specializes in MCPCB LED design solutions. We offer high-quality MCPCB LED prototype, MCPCB LED assembly with innovative LED PCB board designs. Whether you need an LED bulb MCPCB or an MCPCB LED strip, feel free to contact us at sales@bestpcbs.com. We’ll provide you with a competitive LED MCPCB price as quickly as possible. Choosing the right LED MCPCB manufacturer, like Best Technology, is vital for ensuring the optimal performance of your LED systems.

What is an MCPCB LED?

LED MCPCB, or Metal Core Printed Circuit Board, is a specialized PCB designed to improve thermal management in LED applications. Unlike standard PCBs, MCPCBs use a metal core, typically aluminum or copper, to efficiently dissipate heat. This design extends LED lifespan, enhances performance, and ensures stable operation even in high-power applications.

LEDs generate a lot of heat, and if it is not managed properly, performance drops, and the lifespan shortens. MCPCBs help solve this issue by transferring heat away from LEDs to prevent overheating. This is why they are used in applications where bright and long-lasting illumination is necessary. From LED bulbs to automotive lighting and streetlights, LED MCPCB boards are essential for efficient performance.

What is the Difference Between FR4 and MCPCB?

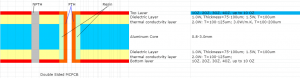

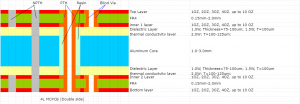

To better understand the advantages of MCPCB, let’s compare it with traditional FR4 PCBs. MCPCB VS Regular PCB: What are Differences? The main difference lies in thermal conductivity. FR4 PCBs use fiberglass material with low heat dissipation, making them less suitable for high-power LEDs. MCPCBs, on the other hand, feature metal cores with thermal conductivity ranging from 1.0W/mK to 4.0W/mK, effectively transferring heat away from LEDs. This reduces overheating risks and improves efficiency.

Material Composition: FR4 is made of epoxy and fiberglass, while MCPCB consists of metal (usually aluminum or copper).

Heat Dissipation: MCPCB is far superior in handling heat compared to FR4.

Durability: MCPCB can withstand extreme conditions better than FR4.

Cost: FR4 is cheaper but lacks thermal efficiency.

When designing LED circuits, using MCPCB ensures stable and long-lasting performance, especially in high-power applications.

What Are the Different Types of LED MCPCBs?

There are several types of LED MCPCBs based on design and application needs:

Single-Layer MCPCB: A single conductive layer on a metal core, used in simple circuits like LED bulbs and small lighting fixtures.

Double-Layer MCPCB: For more complex designs, double-layer MCPCBs are often used. Two conductive layers separated by an insulating layer, suitable for more complex designs such as LED drivers and automotive lighting.

Multi-Layer MCPCB: Multiple conductive layers, ideal for high-performance LED applications like medical equipment and industrial lighting.

Flexible MCPCB: Designed with bendable insulating materials for non-traditional shapes, used in wearable tech and curved LED strips.

Each type serves specific applications, and selecting the right one depends on the complexity and power requirements of the LED system.

What Are the Key Steps in LED PCB Design?

Designing an LED MCPCB requires several steps to ensure efficiency and performance:

Define Requirements: Determine electrical and thermal needs based on LED type and power. Once the requirements are clear, the next step is material selection.

Select Materials: Choose between aluminum and copper based on heat dissipation needs.

Create Circuit Schematic: Map out LED placements and connections.

Optimize Layout: Arrange components for efficient thermal performance.

Perform Thermal Analysis: Simulate heat dissipation to identify potential issues.

Develop Prototypes: Test the design under real conditions.

Conduct Testing: Ensure electrical and thermal stability before mass production.

A well-designed LED MCPCB improves efficiency, reduces failures, and ensures the best performance in real-world applications.

How to Remove LED Die on MCPCB?

Removing an LED die from an MCPCB must be done carefully to avoid damage:

Turn Off Power: Disconnect the board from power sources.

Apply Heat: Use a soldering iron or heat gun to soften the adhesive or solder. Once the adhesive or solder is softened, the LED die can be safely removed.

Remove LED Die: Use tweezers to lift the LED gently once loosened.

Clean the Surface: Remove residual solder or adhesive for a clean reinstallation.

This process is necessary when replacing faulty LEDs or upgrading components in an LED MCPCB.

What Are the Advantages of LED MCPCB?

LED MCPCB provides multiple advantages over traditional PCB designs:

Superior Heat Dissipation: Prevents overheating and extends LED life.

Increased Reliability: Withstands high temperatures without performance loss.

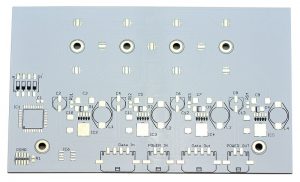

Compact and Efficient Design: Supports high-density LED placement.

Stronger Mechanical Support: Metal core enhances durability and stability.

Better Power Efficiency: Reduces energy waste by maintaining optimal LED temperature.

These benefits make MCPCB LED boards suitable for a wide range of applications, particularly those requiring high performance and longevity.

What Are the Applications of LED MCPCB?

LED MCPCBs are widely used in various industries due to their efficiency and reliability:

Automotive Lighting: Used in headlights and signal lights for better durability.

Consumer Electronics: Found in LED TVs, mobile screens, and backlighting.

Aerospace: Essential in aircraft lighting systems requiring high stability.

Medical Equipment: Applied in surgical and diagnostic lighting systems.

Industrial and Street Lighting: High-power LEDs require MCPCBs to function efficiently under extreme conditions.

LED Grow Lights: Used in indoor farming where heat management is essential.

As LED technology continues to advance, the demand for high-quality MCPCBs will only grow.

Why Should You Choose Best Technology as Your LED MCPCB Manufacturer?

Best Technology stands out as a trusted LED MCPCB manufacturer, delivering high-quality solutions with advanced technology and exceptional service. Here’s why we are the right choice for your LED MCPCB needs:

1. Over 18 Years of Industry Expertise

With nearly two decades of experience, Best Technology has been providing top-quality MCPCBs for various industries. Our team includes skilled R&D professionals and engineers with over 10 years of expertise, ensuring technical excellence. Backed by a strong management team, we respond to customer inquiries within 12 hours, no matter where you are, and always ensure on-time delivery.

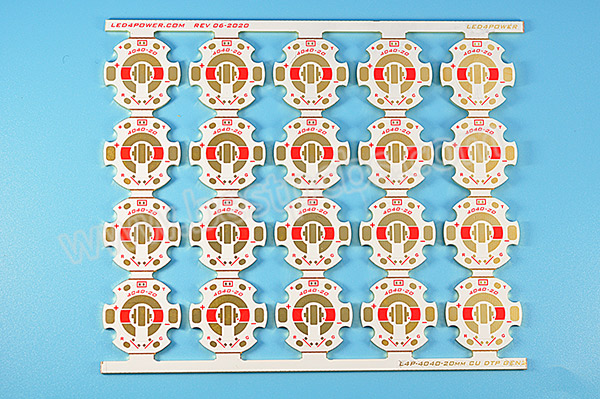

2. Comprehensive Customization Options

Equipped with in-house core technology, including a thermal conductivity value tester and laminator, we can manufacture MCPCBs with high thermal efficiency and specialized parameters. Our ability to produce custom designs quickly allows us to meet the unique requirements of different applications.

3. Strict Quality Control Standards

Quality is at the heart of everything we do. Our engineers, each with over a decade of experience, ensure that every product meets the highest industry standards. We comply with UL, REACH, RoHS, ISO9001, ISO13485, IATF16949, and AS9100D certifications. Our goal is to deliver defect-free products that fully align with customer specifications, guaranteeing exceptional quality in every part we manufacture.

4. State-of-the-Art Manufacturing Facilities

Our facility is equipped with advanced computer-controlled auto-routing and V-cutting machines, enabling precise and efficient production. We specialize in high thermal conductivity MCPCBs (up to 3W/mK), heavy copper boards (up to 10 ounces), ultra-thin MCPCBs (0.3mm), and COB PCBs. Additionally, we are one of only three manufacturers in mainland China producing metal core PCB thermal dielectric raw materials, setting us apart in the industry.

By choosing Best Technology, you gain a reliable partner dedicated to delivering high-performance LED MCPCB solutions that meet and exceed industry standards.

In conclusion, LED MCPCB plays a crucial role in modern LED applications, enhancing performance through superior heat dissipation. Understanding the different types, design steps, and applications helps in making the right choices for various industries. Choosing a trusted manufacturer like Best Technology guarantees high-quality LED MCPCB solutions tailored to specific needs.

Best Technology implement strict quality control at every stage, from LED MCPCB raw materials to the LED MCPCB making machine and LED MCPCB testing machine. If you need the MCPCB LED 9W price or have any other inquiries, feel free to contact us at sales@bestpcbs.com. We are committed to fast responses, efficient manufacturing, and consistently delivering high-quality products. Best Technology will be your reliable partner in China.