Soldering is a crucial process in many industries, especially in electronics and metalworking. It involves bonding materials, primarily metals, using a filler material called solder. This process is essential for creating connections that are both electrically conductive and mechanically strong. But what exactly is soldering? At what temperature does solder melt? And what types of solder are most commonly used? This blog will answer these questions and explain why soldering is important.

What is Soldering?

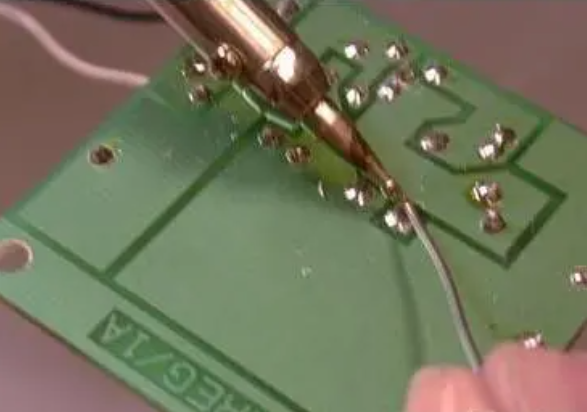

Soldering is a PCB assembly process where two or more metal surfaces are joined by melting and flowing a filler metal (solder) into the joint. Unlike welding, soldering doesnÔÇÖt melt the base metals. Instead, the filler metal, which has a lower melting point, is used to create a bond between the two surfaces. The process is common in electronics, plumbing, and metalwork, where a strong, conductive connection is needed.

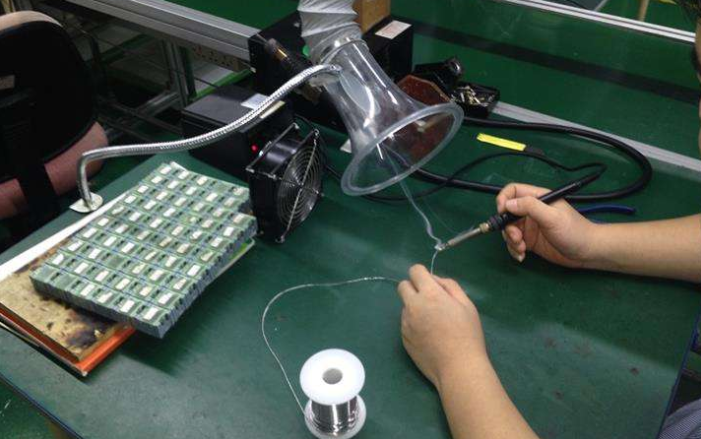

Generally speaking, the commonly used solder materials are tin lead alloy solder, antimony solder, cadmium solder, silver solder, and copper solder. The linear solder used in standard welding operations is called rosin cored solder wire or solder wire. A flux was added to the solder. This flux is composed of rosin and a small amount of active agent. It is very important to set the temperature during welding operation. The most suitable temperature for welding operations is plus 50 degrees at the melting point of the welding used. The set temperature of the soldering iron head, due to the size of the welding part, the power and performance of the soldering iron, and the different types and lines of the solder, it is appropriate to increase 100 degrees on the basis of the above temperature.

The main products of solder are divided into three categories: solder wire, solder bar and solder paste. Applied to all kinds of electronic welding, suitable for manual welding, wave welding, reflow welding and other processes.

What is Soldering Primarily Used For?

Soldering is mainly used in the electronics industry to connect various components on PCBs. Without soldering, it would be nearly impossible to create the intricate electrical connections that power most electronic devices. From mobile phones to computers, soldered joints are everywhere.

Soldering is also widely used in plumbing for joining copper pipes. It creates leak-proof seals that withstand pressure, making it reliable for water supply systems. Additionally, jewelry makers and metalworkers use soldering to join fine pieces of metal. It allows them to create strong, invisible joints without damaging delicate components.

What Temperature Does Solder Melt?

The melting point of solder depends on the type of solder being used. Solder typically comes in two main varieties: leaded and lead-free.

- Leaded Solder

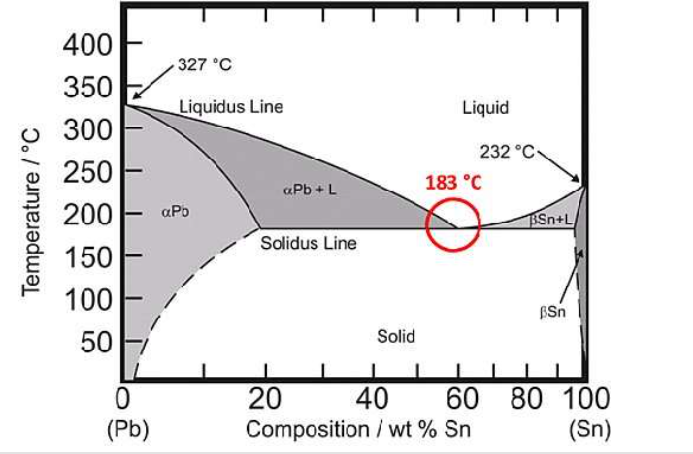

The most common composition of leaded solder is a mixture of tin (Sn) and lead (Pb), typically in a 60/40 ratio. This type of solder melts at around 183┬░C (361┬░F). Leaded solder has been used for decades due to its reliable melting point and easy flow properties, making it ideal for electronics.

- Lead-Free Solder

Lead-free solder is now more widely used due to health and environmental regulations. Lead-free solder typically contains a mix of tin, copper, and sometimes silver. Its melting point is slightly higher, around 217┬░C (423┬░F). Although it requires more heat, lead-free solder is considered safer and more environmentally friendly.

It’s important to note that different solders may have varying melting points depending on their specific composition. Always check the specifications of the solder you’re using to ensure you apply the correct temperature.

Does Solder Have Lead?

Not all solder contains lead. Leaded solder was once the standard for many years, especially in the electronics industry. However, due to the harmful effects of lead exposure, leaded solder is being phased out, particularly in consumer electronics.

Lead-free solder is now the preferred option, especially for products sold in regions that regulate the use of hazardous materials. The shift to lead-free solder has become more prevalent with the Restriction of Hazardous Substances (RoHS) directive, which bans the use of lead in many electrical and electronic products. Today, many manufacturers and companies use lead-free solder for health and environmental reasons.

While lead-free solder is generally considered safer, leaded solder is still used in some industries due to its lower melting point and reliability in certain applications.

What is the Melting Point of Solder?

The melting point of solder depends on its composition, but the most commonly used solders have predictable melting temperatures:

- Leaded Solder: 183┬░C (361┬░F)

- Lead-Free Solder: 217┬░C (423┬░F)

These are standard temperatures, but other specialized solders may melt at higher or lower temperatures. For instance, silver-bearing solders may melt at higher temperatures, while low-temperature solders for specific applications can melt as low as 138┬░C (280┬░F).

Knowing the exact melting point of your solder is important because using the wrong temperature can lead to poor joints or even damage to components. In electronics, overheating can affect sensitive components, while underheating can result in weak or unreliable connections.

What is Lead-Free Solder Made of?

Lead-free solder typically contains a mixture of metals designed to mimic the properties of traditional leaded solder. The most common lead-free solder composition is a mix of tin (Sn), copper (Cu), and sometimes silver (Ag). This combination ensures a solid joint while keeping the melting point manageable.

- Tin (Sn): The main ingredient in most solders, providing strength and flexibility.

- Copper (Cu): Helps to enhance the mechanical strength of the solder joint.

- Silver (Ag): Sometimes added to improve conductivity and joint strength, though this increases cost.

Lead-free solder is used to create safer work environments, particularly in industries where workers are regularly exposed to soldering fumes. It is also more environmentally friendly as it reduces the risks associated with lead contamination.

Is Tenshan Lead-Free?

Yes, most manufacturers, including Tenshan, now offer lead-free solder options in compliance with environmental standards. Lead-free solders, like those provided by Tenshan, are designed for use in various industries, ensuring safe and effective soldering without the risks associated with lead exposure.

Lead-free products from companies like Tenshan are developed to meet both performance and safety standards. These solders deliver excellent bonding capabilities without compromising the health of the workers or the environment. With the growing emphasis on eco-friendly practices, lead-free options are becoming the preferred choice for many applications.