What Does NRE Stand For?

NRE, or Non-Recurring Engineering, refers to the upfront cost associated with developing and preparing the tools, processes, and engineering resources required for manufacturing a specific product. When it comes to PCB projects, NRE fees are vital because they cover the initial setup expenses that are incurred only once during the product development phase. These charges include design, tooling, programming, and testing requirements tailored to a particular PCB design, ensuring that the production is efficient and meets the required specifications.

Why Is It Necessary to Charge NRE Cost?

Charging an NRE cost is necessary because every PCB project is unique. The manufacturer must allocate resources to tailor the production to your specific design. The NRE fee ensures that all the necessary engineering work is done upfront to avoid delays or errors during mass production. If this fee werenât charged, manufacturers would have to spread these costs across the entire production, making each unit more expensive, especially for small runs. This way, you can keep per-unit costs lower once production begins.

What Is the NRE Charge For?

The NRE charge is a crucial investment in ensuring that your PCB project gets off to the right start. It covers the engineering resources, setup, and processes that are required to customize the production environment specifically for your PCB design. Here are the main aspects that NRE fees typically cover:

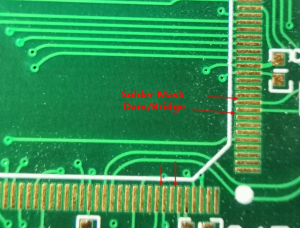

- Design Validation

Before manufacturing begins, the manufacturer must confirm that your PCB design is feasible and ready for production. This involves scrutinizing the layout for errors, verifying that it meets performance specifications, and ensuring compatibility with the chosen materials. This step can prevent expensive issues later in the process, such as defective boards or production delays.

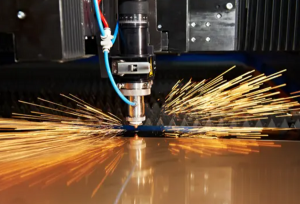

- Custom Tooling Setup

Every PCB design requires specific tools and fixtures to manufacture efficiently. NRE fees cover the creation or modification of tools that will allow your design to be assembled accurately. This might involve creating custom molds, dies, or specialized equipment that aligns with your PCB’s dimensions and complexity.

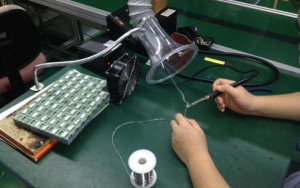

- Programming and Firmware

For PCBs that require microcontrollers or other programmable components, the NRE charge often includes developing the necessary firmware or software to test and initialize these components. Manufacturers need to upload specific programs to ensure each unit functions correctly in real-world applications.

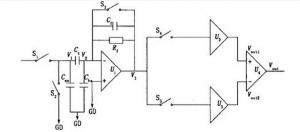

- Prototype Creation

In some cases, the NRE fee also covers the cost of creating prototypes for testing. These prototypes are essential for verifying that the design works as intended before moving into full-scale production. The prototype phase allows for any last-minute adjustments and ensures that the final product will perform optimally.

How to Pay NRE Cost?

Paying the NRE cost is straightforward, but itâs important to clarify this with your manufacturer. Typically, the NRE fee is charged as a separate, one-time payment when you place your order. Depending on your arrangement with the manufacturer, it might be paid upfront or included in the first invoice along with the cost of your first production run. Payment terms can vary, but many manufacturers will expect it before starting the engineering and tooling processes. By paying this fee early, you ensure that your project can begin on time.

How to Reduce NRE Fee?

Reducing NRE costs may not always be possible, but there are ways to minimize them:

1. Reusing designs: If youâve produced a similar PCB before, you can avoid some NRE costs by reusing or adapting the same designs.

2. Standardization: Using standard components and layouts rather than custom or unusual specifications can cut down on the design and tooling time.

3. Ordering in bulk: A larger production run can sometimes allow manufacturers to absorb some NRE costs, spreading the expense over a larger quantity of units.

4. Simplify design: A less complex design reduces the need for custom tools or special processes, leading to a lower NRE fee.

5. Choose experienced manufacturers: Partnering with a manufacturer like Best Technology who has experience in your industry can reduce the amount of custom setup needed, as they may already have processes and equipment suited to your project.

Considerations During the NRE Process

Itâs important to approach the NRE process with a clear understanding of your projectâs needs and goals. Communicate clearly with your manufacturer to avoid misunderstandings about what the NRE fee covers. For example, make sure you know if the fee includes changes or revisions to the design after the initial setup. You should also ask about the lead time for the engineering work. Knowing how long it will take to complete the NRE tasks helps you plan your project schedule more effectively.

Another consideration is the long-term benefits. While NRE fees may seem costly upfront, they are an investment that pays off as your project moves into full production. By ensuring that the initial design and setup are correct, you minimize the risk of costly production errors later.

When to Use Non-Recurring Engineering?

Non-Recurring Engineering is most beneficial when your PCB project involves custom designs or complex requirements. This is especially true when you need prototypes, new product development, or designs that require unique tools or processes. If you are producing a PCB that will have ongoing updates or revisions, it might also be necessary to pay an NRE fee each time the design changes. In general, the NRE fee is used whenever a manufacturer has to set up specialized processes or equipment that wonât be reused for other products.

How to Calculate NRE Cost?

NRE costs are calculated based on several factors. Manufacturers will consider the complexity of the design, the number of custom tools needed, and the extent of testing and programming required. The more custom features your PCB has, the higher the NRE cost is likely to be. Additionally, the cost of manpower to design and set up the project is included. Some manufacturers also calculate NRE based on the projected production runâlarger runs may benefit from lower NRE fees as costs are spread over more units.

While it may seem daunting, NRE costs are ultimately a necessary investment for ensuring the success of your project. They allow manufacturers to deliver the best quality and avoid production errors, which can lead to greater savings in the long run.