PCB Boards Manufacturing is the core of almost every electronic device. From smartphones to smart cars, PCBs hold the components and make sure everything runs properly. But have you ever wondered how these boards are made? Whether you’re curious about the manufacturing process, costs, or suppliers, this blog will help you understand it all clearly. Let’s take a closer look at the world behind the green board.

Best Technology has focused on PCB board manufacturing services since 2006. Located in Shenzhen, China, our headquarters serves as the core of our global operations. In addition, we have established SMT factories in both China and Vietnam to better support our customers worldwide. Moreover, our PCB board manufacturing facility holds certifications including ISO9001, ISO13485, IATF16949, and AS9100D, ensuring high standards across all industries we serve. To guarantee aerospace-grade reliability, each production batch undergoes a rigorous 72-hour thermal cycling test. Furthermore, Best Technology implements the MES Material Traceability System, which allows complete tracking of every componentāfrom incoming material inspection to final production. All components we use are UL, REACH, and RoHS compliant, aligning with global safety and environmental standards.

If you have any questions regarding the PCB board manufacturing process, or if you’re starting a new project that requires expert support, please donāt hesitate to contact Best Technology at sales@bestpcbs.com.

How Are PCB Boards Made?

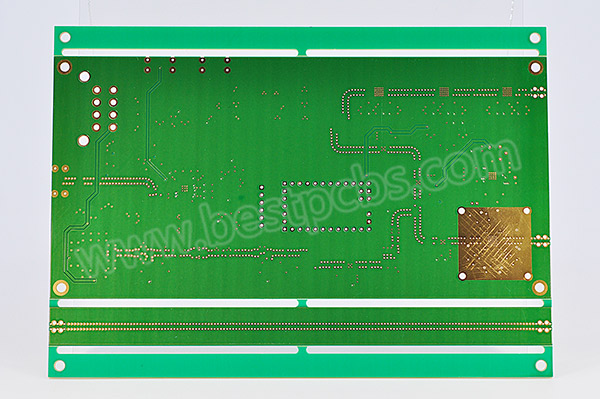

The PCB board manufacturing process starts with a design. Engineers use software to draw the layout. Then, the manufacturer prints the layout onto copper-coated boards. The next steps include etching away the extra copper and drilling holes for components. After that, they add protective layers, silkscreen labels, and surface finishes.

Here’s a simple breakdown:

- Design and layout

- Photolithography (imaging the layout)

- Etching copper

- Drilling holes

- Plating (hole metallization)

- Solder mask application

- Silkscreen printing

- Surface finishing

- Testing and quality checks

Each step must be done with high precision. Even a small mistake can lead to failure in the final device. Reliable circuit boards manufacturing always includes strict testing before delivery.

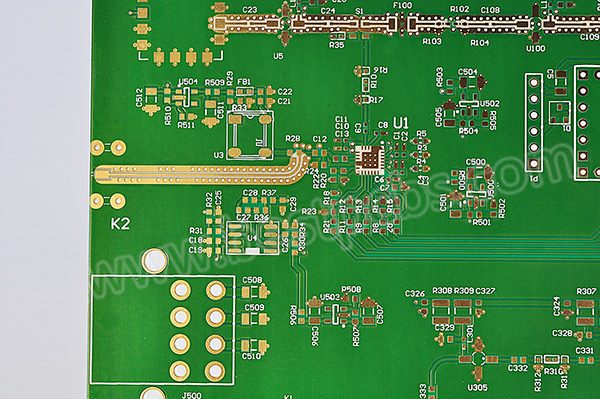

How Do PCB Boards Work?

PCB boards are like the nervous system of a machine. They connect different components using copper tracks. Signals and power travel along these paths to make everything function. For example, in a phone, the PCB connects the battery, screen, and processor.

Without a PCB, the electronic parts would be hard to organize. The board keeps everything in place and allows current to move smoothly. Many layers are used in complex devices, with signals traveling through different paths. Thatās why the design must be perfect.

How Do You Clean a PCB Board in Manufacturing?

Clean boards lead to better performance. In PCB board manufacturing, cleaning is essential. During the process, dust, oil, and metal particles can collect. So, before assembly, cleaning is done using machines and solutions.

Most manufacturers use deionized water or alcohol-based cleaners. These help remove any leftover chemicals or particles. Ultrasonic cleaning is also common, using high-frequency waves to shake off dirt. This keeps the board reliable and free from short circuits.

What is Tenting on PCB Boards Manufacturing?

Tenting means covering vias (small holes) with solder mask. This is done for protection. It prevents dirt and moisture from entering the holes. In high-quality PCB manufacturing, tenting also improves looks by hiding the copper pads.

There are two types of tenting:

- Full tenting: The via is completely covered.

- Partial tenting: Some part of the via remains open.

Tenting is common in compact designs where protection and space-saving are important. Itās a small detail, but it helps a lot in product quality.

Do PCB Manufacturers Install Files on Your Board?

Yes, but with limits. Most PCB board assembly manufacturers only place the components. They follow files like Gerber, BOM (Bill of Materials), and pick-and-place. These tell them what to mount and where.

If you need software installation or firmware upload, it must be discussed early. Some manufacturers offer this service, but not all. Always ask before placing an order. It helps avoid confusion later.

How Long It Takes to Get PCB Board from Manufacturing?

The lead time depends on the order. Standard production usually takes 5 to 7 days. If itās a complex board or a large batch, it may take up to 2 weeks. Some companies offer express services. These can deliver boards in 24 to 72 hours.

Hereās a lead time in Best Technology for FR4 prototypes for your reference, with a standard specification, of less than 1 sq meter.

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| >=10 | TBD | TBD |

Delays happen if the files are incorrect. So, always check your design and requirements before sending them.

How Much Does It Cost to Manufacture a PCB Board?

Cost varies. Factors include size, layers, material, quantity, and lead time. A simple board may cost under $5 for a small batch. But high-frequency or multilayer boards can cost $50 or more each.

Here are key cost factors:

- Board type (single, double, multilayer)

- Material (FR4, aluminum, ceramic)

- Quantity (small vs. bulk)

- Lead time (standard vs. express)

Using a PCB manufacturing process flow chart helps reduce waste and control costs. It ensures every step is optimized. Requesting a PCB manufacturing process PDF from your supplier helps you understand the full breakdown.

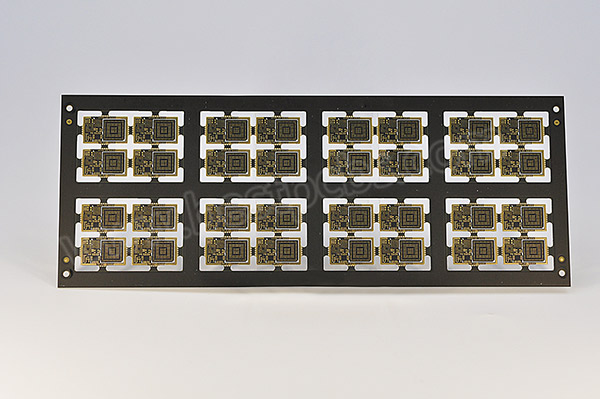

Who Makes PCB Boards Manufacturing?

Many companies offer PCB boards manufacturing, but choosing the right one is important.

Here are trusted names:

- Best Technology ā Based in China, BEST have 18+ years of experience. We offer a full range of services including bare board production and assembly. BEST is known for high precision, fast delivery, and great customer support.

- PCB Board Manufacturer in Pune ā Several companies in Pune are reliable, such as Circuit Systems India and Fine-Line Circuits. They offer competitive pricing and good turnaround time.

- PCB Board Manufacturers in Bangalore ā Examples include AT&S India and Genus Electrotech. These firms serve automotive, medical, and industrial clients.

- PCB Board Manufacturer in USA ā Advanced Circuits, Sierra Circuits, and Sunstone Circuits are top names. They offer high-quality products with fast shipping.

Always compare services, lead time, and support before choosing.

How to Find PCB Board Manufacturers?

Finding the right manufacturer is not hard if you know what to look for. First, check their capabilities. Do they support the PCB manufacturing process steps PPT or offer detailed quotes? Can they show previous work?

Next, review customer feedback. Look at their certifications (like ISO, UL, or RoHS). A good website, clear contact details, and sample requests are signs of a professional company.

Hereās a short checklist:

- Experience and reputation

- File support (Gerber, BOM, etc.)

- Production capacity

- Certifications and quality control

- After-sales service

Try to visit the factory or request a video tour if possible. It shows how serious they are about their work.

In conclusion, PCB Boards Manufacturing is the foundation of modern electronics. From design to delivery, every step must be handled carefully. Choosing the right partner makes a big difference. At Best Technology, we provide not only high-quality PCB boards but also full support through each stage. With over 18 years of experience, weāve helped 1700 clients turn their PCB boards design into PCB boards manufacturing.

If you’re searching for a trustworthy PCB board manufacturer, start with us. We make the process smooth, clear, and cost-effective. A warm welcome to contact us at sales@bestpcbs.com to begin your project with tailor solutions.