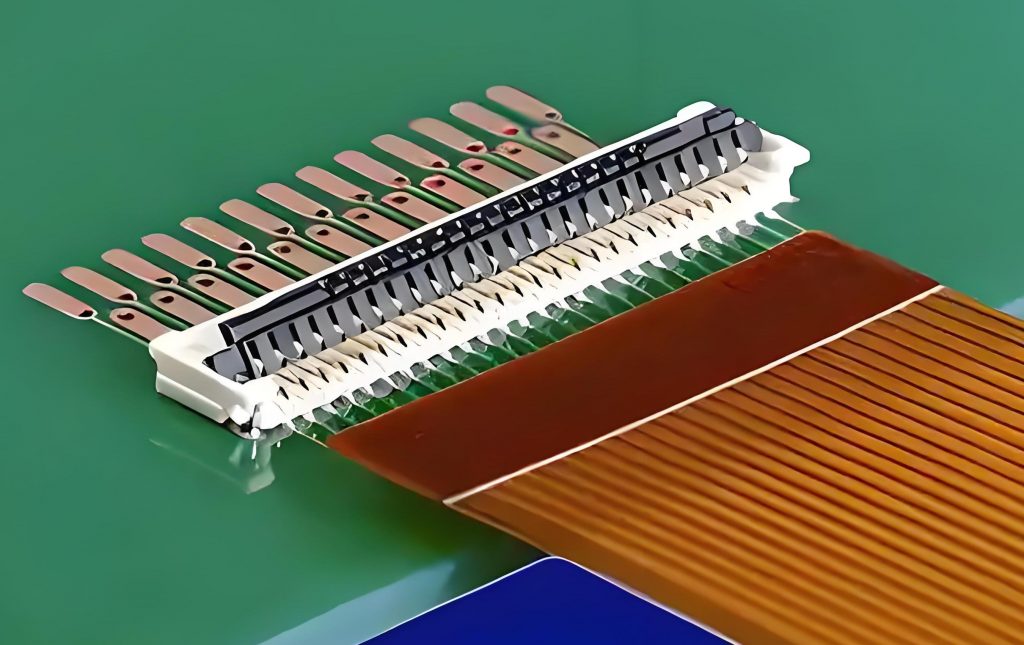

What is the ffsd pcb connector? The FFSD PCB connector is a high-performance, high-reliability printed circuit board connector, usually used to connect flexible flat cables (FFC/FPC) and flexible printed circuits (FPC). The FFC/FPC cable connected by the FFSD connector has good flexibility, can bend and move in a small space, and can adapt to the connection requirements between circuit boards of different shapes and sizes.

What is a PCB connector?

The PCB connector is a connector specifically used to connect and fix printed circuit boards (PCBs). It usually adopts a pin press-in design with super strong FPC cable clamping force. It is mainly used for PCB board and board connection to ensure precise and reliable electrical connection.

In terms of classification, it is divided into plug-in type (convenient plug-in and replacement), crimping type (high reliability, suitable for vibration environment) and welding type (stable electrical performance, not easy to replace) according to the connection method; it is divided into power connector (transmitting power), signal connector (transmitting signals) and hybrid connector (transmitting power and signals at the same time) according to the purpose.

What is the ffsd pcb connector?

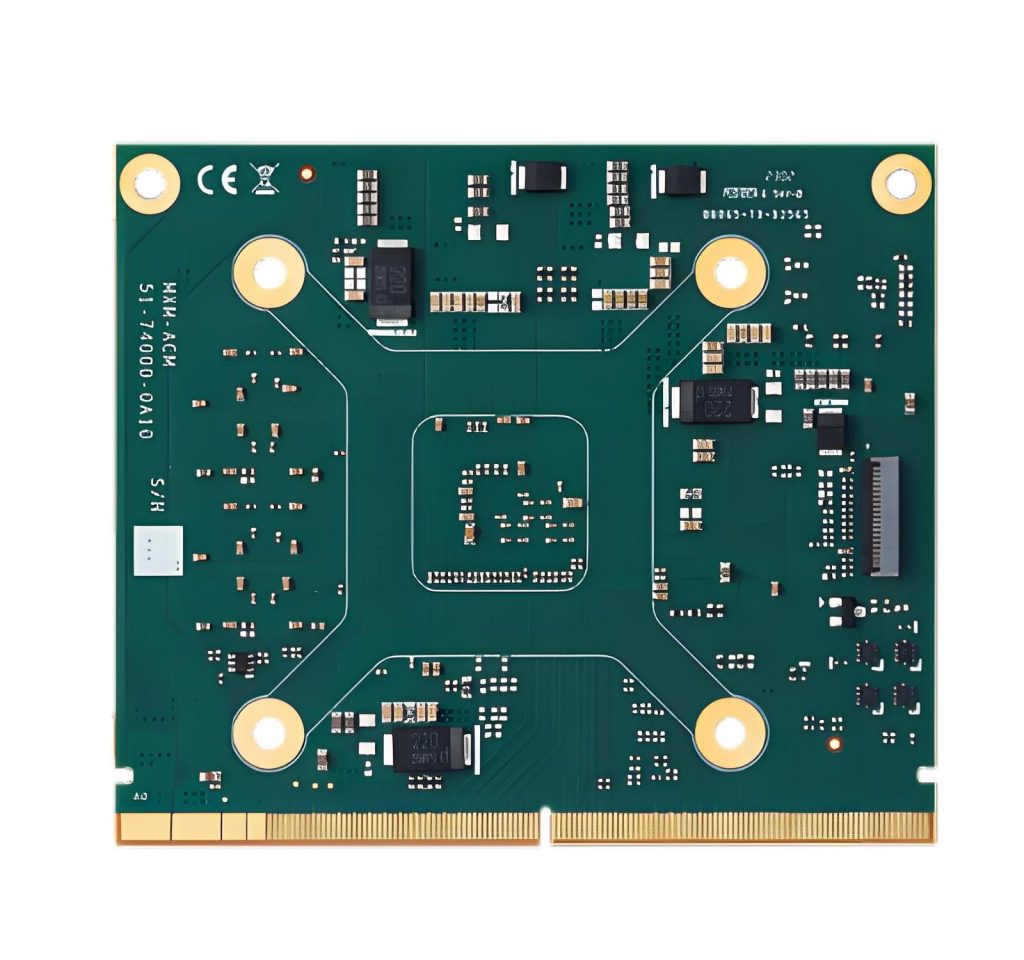

FFSD connector is a type of PCB connector with specific design, specifications and performance characteristics. FFSD connectors generally adopt specific contact systems and shell designs, with compact shells and unique locking devices, etc., to ensure the stability and reliability of the connection and adapt to its specific application scenarios and signal transmission requirements.

FFSD connectors are designed and developed for flexible connection with shielded flat cables. Its excellent characteristics enable it to perform well in environments with strict requirements for high anti-interference and compact layout, and can effectively connect flexible flat cables (FFC/FPC) and flexible printed circuits (FPC).

FFSD cables are mostly made of special flexible and anti-bending materials. The shielding layer on the surface can significantly reduce electromagnetic interference (EMI) in high-frequency environments, effectively ensure the stability and accuracy of signal transmission, and provide solid guarantees for the efficient and stable operation of various precision electronic equipment.

What is the structure of the ffsd pcb connector?

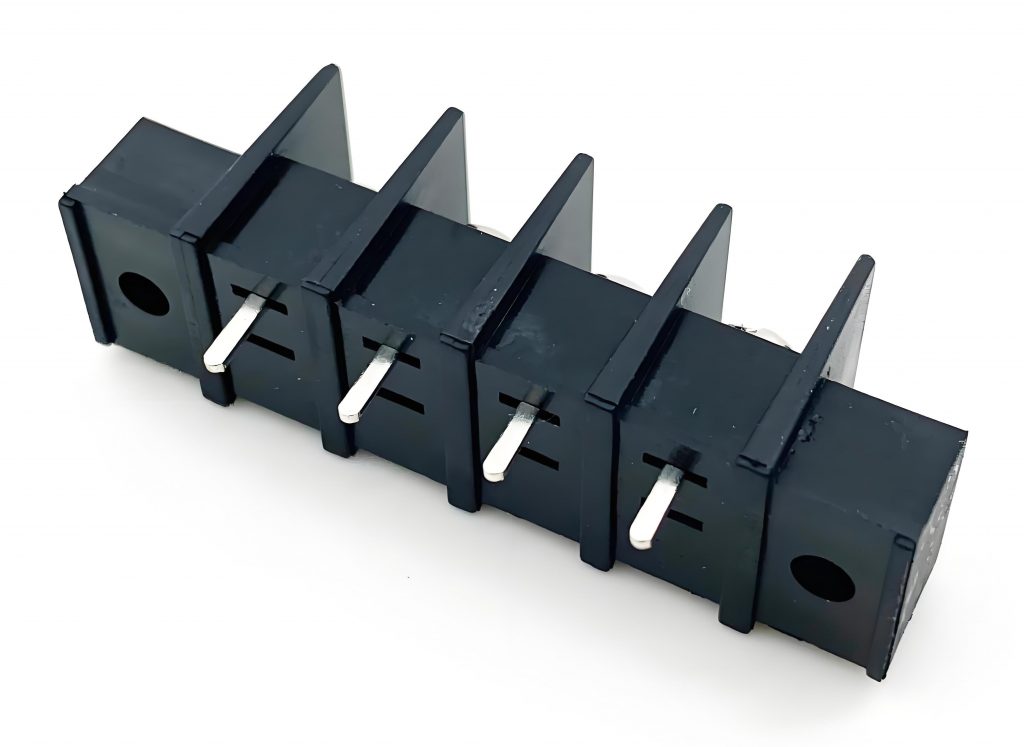

FFSD connectors are mostly designed with double-row pins, and the pin pitch is usually 0.050 inches (1.27mm), which can meet different signal transmission requirements. In addition, the number of pins generally ranges from 3 to 25, which can adapt to various circuit connection requirements.

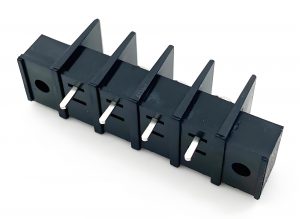

The shell is generally made of insulating materials such as plastic, such as PBT, to provide mechanical support and protection for the connector, ensure the normal operation of the internal contact system, and enable the connector to be properly aligned and installed with other components. At the same time, the shell may also have some special designs, such as locking devices, which are used to fix the connector and the mating parts to prevent loosening or falling off during use.

The common installation method is cable installation, which connects the connector and the cable together through welding or crimping, and then connects the cable to the PCB board to achieve signal transmission. Some FFSD connectors may also support surface mount technology (SMT), directly soldering the connector on the surface of the PCB board to adapt to different circuit layouts and design requirements.

What are the most common PCB connectors?

Common PCB connectors include:

- Pin-and-female connectors: They consist of a pin-and-female connector with metal pins and a female connector with a flexible metal sheet socket, used to connect between circuit boards or other components.

- USB connector: There are many types such as Type-A and Type-B. The internal metal contact piece transmits power and data. It is widely used for data transmission and charging of computers, mobile phones and other devices.

- HDMI connector: It contains multiple pins to transmit high-definition video and audio signals, has shielding measures, and is used to connect video sources and display devices.

- SATA connector: It uses serial data transmission, has data and power interfaces, and is a key component for connecting hard disks, optical drives and motherboards in computers.

- D-Sub connector (VGA connector): It is shaped like a “D”, and multiple pins transmit analog video signals. It is still used to connect computers and monitors in some old devices or low-resolution occasions.

- RJ45 connector: It has 8 internal metal contacts, which are used for Ethernet connection. It is an important component for computer network card interfaces, router LAN interfaces, etc. to achieve wired network communication.

How to choose PCB connectors?

There are several key factors to consider when choosing PCB connectors:

- Technical parameters: First, understand the technical requirements of the application, including pin spacing, welding method, rated voltage, rated current, number of plug-in and pull-out times, temperature range, board spacing, connector geometry, and solder hole diameter of the soldering lug.

- Electrical performance: The electrical performance of the connector includes limiting current, contact resistance, insulation resistance, and dielectric strength.

- Installation space: Pay attention to the outer dimensions and installation space of the connector to ensure that it does not interfere with other parts. Pay attention to the number of pins and spacing to avoid high temperature deformation during the soldering process of the SMT machine.

- Packaging form: For automated assembly, the packaging form is also important. Common packaging forms include tape and reel packaging and strip boxes, the former is more suitable for mass production.

Suggestions for choosing different types of PCB connectors:

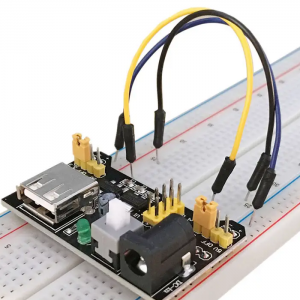

- Pin and female headers: cheap and common, suitable for low-end, large-size devices. The advantages are cheap and convenient, and the disadvantages are large size and difficult to bend.

- High-end board-to-board connectors: many pins, small size, suitable for compact products. The advantage is stable connection, the disadvantage is high price and cannot be plugged and unplugged frequently.

- Thickened board-to-board connector: suitable for development boards and test boards, the advantage is cheap and easy to connect and measure, the disadvantage is large size and not suitable for mass production scenarios.

- FPC connector: suitable for the connection between the main board and the sub-board, the advantage is small size and flexibility, the disadvantage is high price.

How does the ffsd pcb connector work?

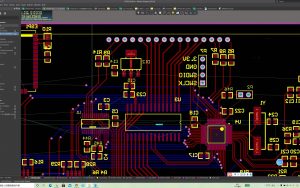

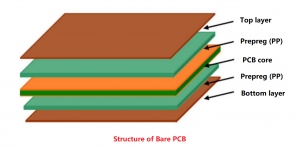

The working principle of the ffsd pcb connector is mainly based on the design and manufacture of printed circuit boards (PCBs). PCB connectors are made of printed circuits and printed components or a combination of the two by pre-designing on insulating materials to achieve electrical connections between electronic components.

Specific working mechanism of PCB connectors

- Electrical connection: The wires and metal lines on the PCB are used to connect electronic components. The electrical performance requirements of the circuit are met by laying out and designing the parameters such as the path, width and spacing of the wires.

- Mechanical support: PCB provides mechanical support and fixation for electronic components, fixes components by welding, plug-in or surface mounting, and ensures the relative position and stability between components.

- Signal transmission: The wires and circuit paths on the PCB are used to transmit signals in electronic devices, considering factors such as signal integrity, noise suppression and interconnection length to ensure stable signal transmission and reduce interference2.

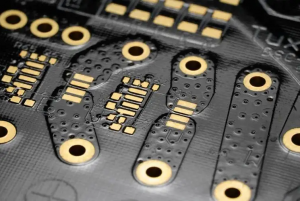

PCB connectors include not only traditional pin connectors and terminal blocks, but also various forms such as SMT (surface mount technology) and BGA (ball grid array).

The design and manufacture of these connectors have improved the miniaturization, integration and reliability of electronic products. In practical applications, PCB connectors are widely used in various electronic devices as an important carrier for connecting, supporting and managing electronic components.

What are the advantages of ffsd pcb connector?

The advantages of FFSD PCB connectors mainly include the following points:

- High flexibility and adaptability: The FFC/FPC cable connected by the FFSD connector has good flexibility, can bend and move in a small space, and can adapt to the connection requirements between circuit boards of different shapes and sizes.

- Excellent anti-interference ability: The shielding layer on the surface of the FFSD cable can effectively reduce electromagnetic interference in high-frequency environments, ensure the stability and reliability of signal transmission, and enable the equipment to work normally in complex electromagnetic environments.

- High reliability: The locking mechanism of the connector can firmly fix the cable to prevent it from loosening or falling off due to vibration, impact and other factors during use, ensuring the stability of the connection, thereby improving the reliability and service life of the entire electronic system.

- Good electrical performance: It can meet the requirements of high-speed signal transmission, has low contact resistance and transmission loss, and ensures the integrity and accuracy of the signal.

- High degree of customization: FFSD connectors can be customized according to specific application requirements, such as cable length, width, bending angle, number of connector pins, spacing, etc. can be designed on demand, which can better meet personalized connection needs.

What are the applications of ffsd pcb connectors?

FFSD PCB connectors usually refer to FFC/FPC PCB connectors, which are widely used, mainly in the following fields:

- Consumer electronics: Connecting various components in smartphones and tablets to meet their small space, multi-function, and thin requirements, and ensure signal and power transmission.

- Medical electronics: In monitoring, imaging, circuits and displays, it helps data acquisition and processing to meet the needs of small and portable equipment.

- Industrial control: Connect key components in automated production lines and instrumentation to achieve signal interaction and coordination, and improve production and equipment performance.

- Communication equipment: Connect related modules in base stations, optical communications, routers, etc. to ensure stable signal transmission and adapt to high-speed communication and anti-interference requirements.

- Aerospace: Applied to avionics and satellite communication equipment to ensure stable signals and reliable operation of equipment in harsh environments, which is related to flight and communication safety.

As a high-performance and high-reliability electronic connection component, FFSD PCB connector plays an indispensable role in modern electronic devices. Its high flexibility, anti-interference ability, miniaturization, convenient assembly, high reliability, good electrical performance, high degree of customization and cost-effectiveness have made it widely used in consumer electronics, automotive electronics, medical electronics, industrial control, communication equipment, aerospace and other fields.