LED PCB Board Design is essential for creating efficient and durable LED lighting solutions. Whether for consumer electronics, automotive applications, or industrial lighting, a well-designed LED Light PCB Circuit Design ensures optimal performance and longevity. With the right PCB Design Service, you can achieve improved heat dissipation, electrical efficiency, and seamless integration of LEDs onto circuit boards.

This led pcb design guide will walk you through everything you need to know about LED PCB design, from materials and circuit design to mounting methods and cost considerations.

What is an LED PCB Board?

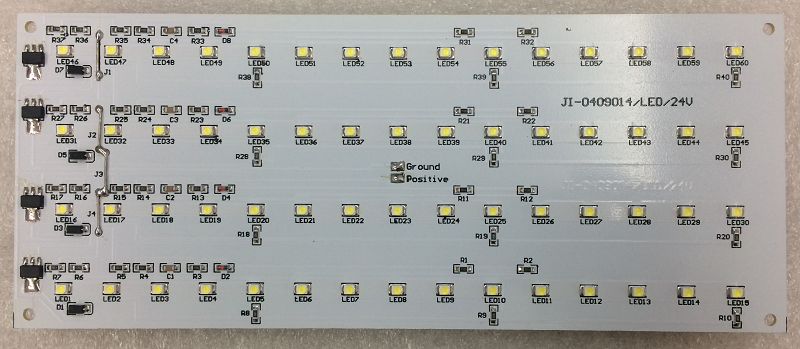

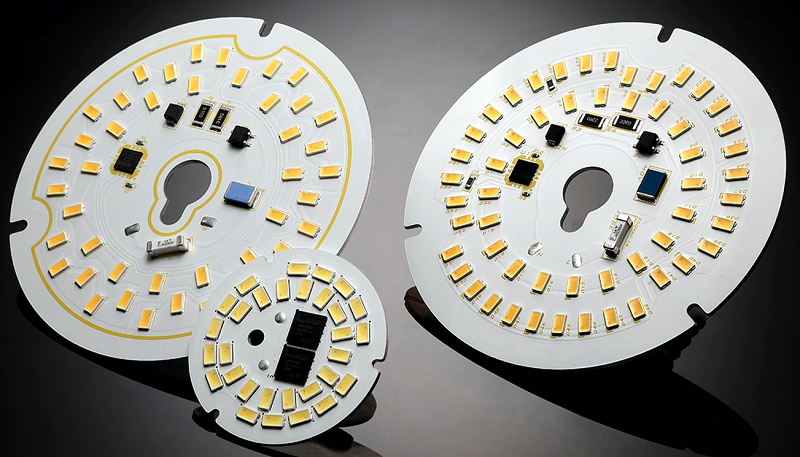

An LED PCB board is a printed circuit board (PCB) specifically designed to support and power light-emitting diodes (LEDs). Unlike standard PCBs, LED PCBs focus on thermal management since LEDs generate heat, which, if not managed properly, can reduce efficiency and lifespan.

Common applications of LED PCB boards include:

- LED lighting strips for residential and commercial use

- Automotive headlights and dashboards

- Medical equipment displays

- Smartphones, TVs, and digital billboards

A well-planned LED PCB design ensures even light distribution, durability, and energy efficiency.

What Materials Are Used in LED PCB?

Choosing the right material is crucial for LED PCB circuit design, as it directly affects heat dissipation, durability, and cost. The most commonly used materials are:

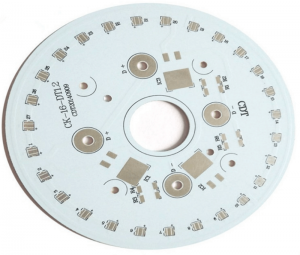

1. Aluminum Core PCB

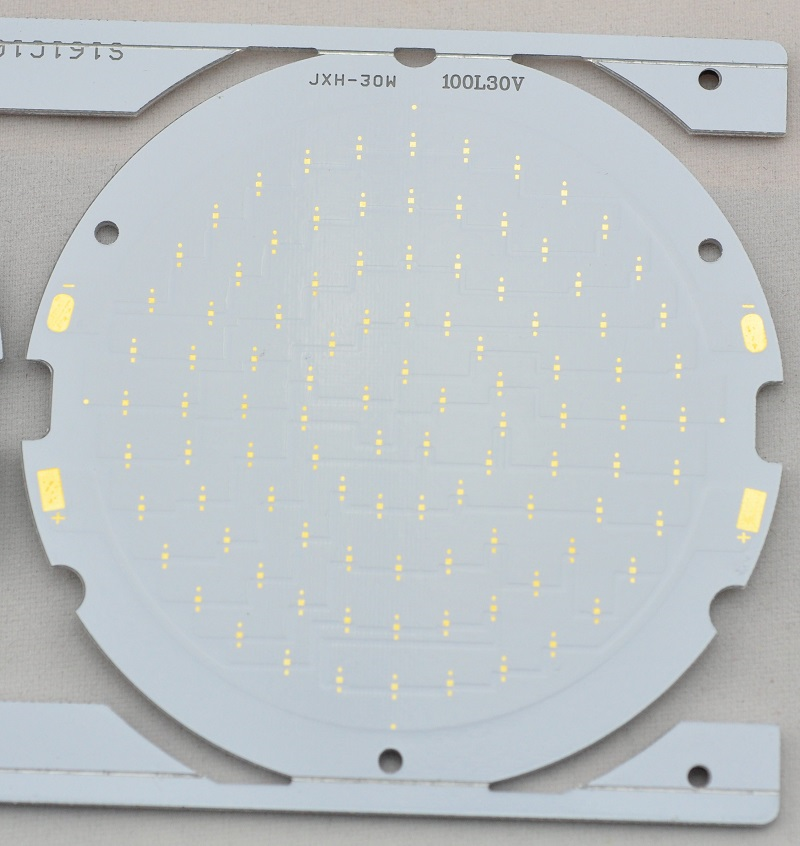

- The best choice for high-power LED PCB design

- Features a metal core that dissipates heat efficiently

- Commonly used in LED strip PCB design and automotive lighting

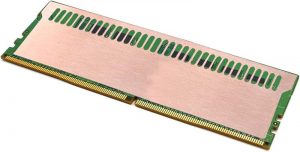

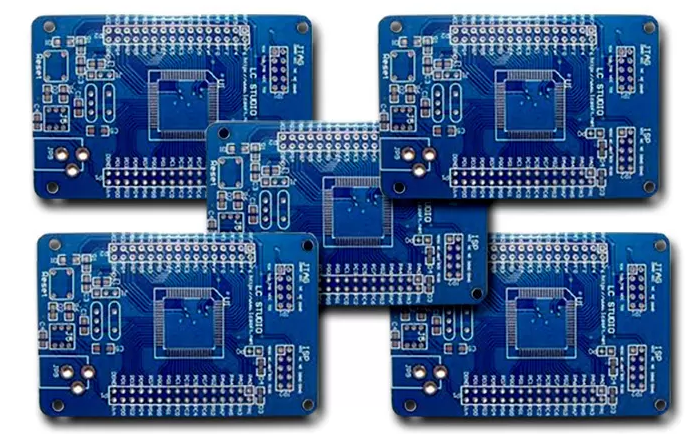

2. FR-4 (Fiberglass) PCB

- A cost-effective choice but requires additional heat dissipation measures

- Used in low-power LED applications

3. Ceramic PCB

- Offers superior thermal conductivity

- Used in high-end LED lighting applications requiring maximum heat resistance

Selecting the right material ensures that LED boards operate efficiently without overheating.

How to Make LED PCB Design?

When working on PCB design for LED light applications, especially for high power LED PCB design, it’s crucial to focus on efficient thermal management and optimized circuit layout to ensure longevity and performance. Proper LED PCB circuit design involves strategic LED placement, adequate heat dissipation, and careful component selection.

Specifically, creating a simple LED PCB design involves several key steps:

1. Schematic Design

Use LED PCB design software like Altium Designer, Eagle PCB, or KiCad to create the electrical layout, including:

- LED placement

- Resistor and capacitor positioning

- Power supply routing

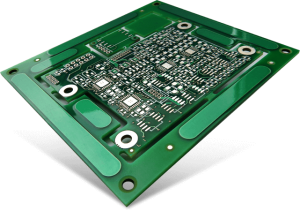

2. PCB Layout

- Optimize trace width and routing for efficient current flow

- Use wide copper traces to prevent overheating

- Implement thermal vias for heat dissipation

3. Simulation & Prototyping

Before manufacturing, test the PCB LED design using simulation software to detect issues early.

How to Build a Basic LED Circuit?

A basic LED circuit consists of:

- LEDs (Light-emitting diodes)

- A power source (battery or DC supply)

- Resistors (to limit current and prevent damage)

- Wires or PCB traces (to connect components)

Simple LED PCB Design Example

Step 1: Connect the LED anode (+) to the power supply via a resistor.

Step 2: Connect the LED cathode (-) to the ground.

Step 3: Ensure the resistor value matches the LED voltage and current ratings.

This simple circuit is the foundation of LED matrix PCB design, LED driver PCB design, and more.

What is the Width of LED PCB?

The width (thickness) of an LED PCB board depends on its application:

Standard LED PCBs: 1.6mm (most common for general applications)

High-power LED PCBs: 2.0mm – 3.2mm (for better heat dissipation)

Flexible LED PCBs: 0.2mm – 1.0mm (used in LED strips)

The correct PCB width prevents overheating and ensures mechanical stability.

How Do You Mount LEDs on a PCB?

LEDs can be mounted on PCBs using different methods, depending on the design and application:

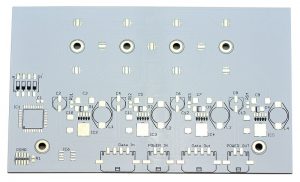

1. Surface Mount Technology (SMT) – Best for SMD LED PCB Design

- Uses solder paste and reflow soldering

- Ideal for compact LED light PCB design

2. Through-Hole Technology (THT) – Used for High-Power LEDs

- LEDs are inserted into holes and soldered on the other side

- Ensures stronger mechanical bonds

3. Chip-on-Board (COB) – Used in LED Matrix PCB Design

- LED chips are placed directly on the PCB for high efficiency and compact design

Choosing the right mounting method improves LED performance and durability.

Where Are LED Boards Used?

LED PCBs are found in a wide range of industries due to their energy efficiency and durability. Common applications include:

1. Consumer Electronics

- Smartphones, tablets, and TVs

- Digital clocks and smart home devices

2. Automotive Industry

- Headlights, dashboard displays, brake lights

3. Industrial and Commercial Lighting

- LED streetlights, floodlights, warehouse lighting

4. Medical Equipment

- LED-based X-ray displays

- Surgical lighting and phototherapy devices

These applications highlight why LED PCB circuit design must be robust and customized for each use case.

How Much Does a Custom PCB Board Cost?

The cost of a custom PCB board can vary significantly depending on several factors. The primary considerations include:

- Size and Number of Layers: Larger PCBs or those with more layers tend to cost more. For instance, a simple two-layer PCB may cost around $5−$15 per board, while multilayer PCBs are generally more expensive. The specific price needs to be determined based on factors such as the actual design, materials, and process requirements.

- Material Type: The choice of material also plays a crucial role. FR-4, a common and cost-effective material, typically costs less than aluminum or ceramic PCBs.

- Manufacturing Volume: The quantity produced affects the unit cost. Prototypes and small batches tend to be more expensive due to setup and engineering costs. As the production volume increases, the unit cost decreases, with prices potentially dropping for mass production.

- Special Processes and Quality Standards: Additional factors such as surface treatment (e.g., OSP, lead-free soldering, gold plating), copper foil thickness, design complexity, quality inspection standards, mold fees, and testing jigs can further influence the overall cost. Higher-end processes and stricter quality standards will increase the price.

Therefore, for an accurate quotation, it is advisable to consult with a PCB manufacturing service that can provide customized pricing based on your specific project requirements.

In a nutshell, designing an LED PCB board requires careful planning, right material selection, and thermal management strategies. Whether you’re working on a simple LED PCB design, an SMD LED PCB board design, or a high-power LED PCB design, the key to success lies in proper circuit design, component placement, and manufacturing methods.

If you’re looking for expert support, consider a PCB Design Service to streamline your LED light PCB circuit design and ensure the highest quality for your LED projects. With the right LED PCB design software and PCB manufacturing partner, you can create efficient, cost-effective, and long-lasting LED lighting solutions for various applications.

Best Technology offers a full range of Led PCB Board Design, customized to match the unique requirements of each customer. With competitive ODM & OEM pricing, we deliver reliable custom led pcb solutions to support your projects from initial design to final production. For more information or inquiries, feel free to contact Best Technology at sales@bestpcbs.com.