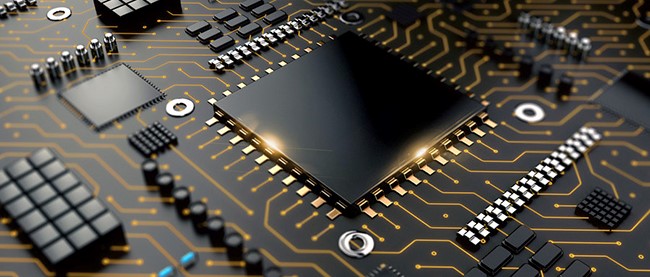

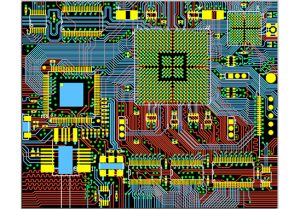

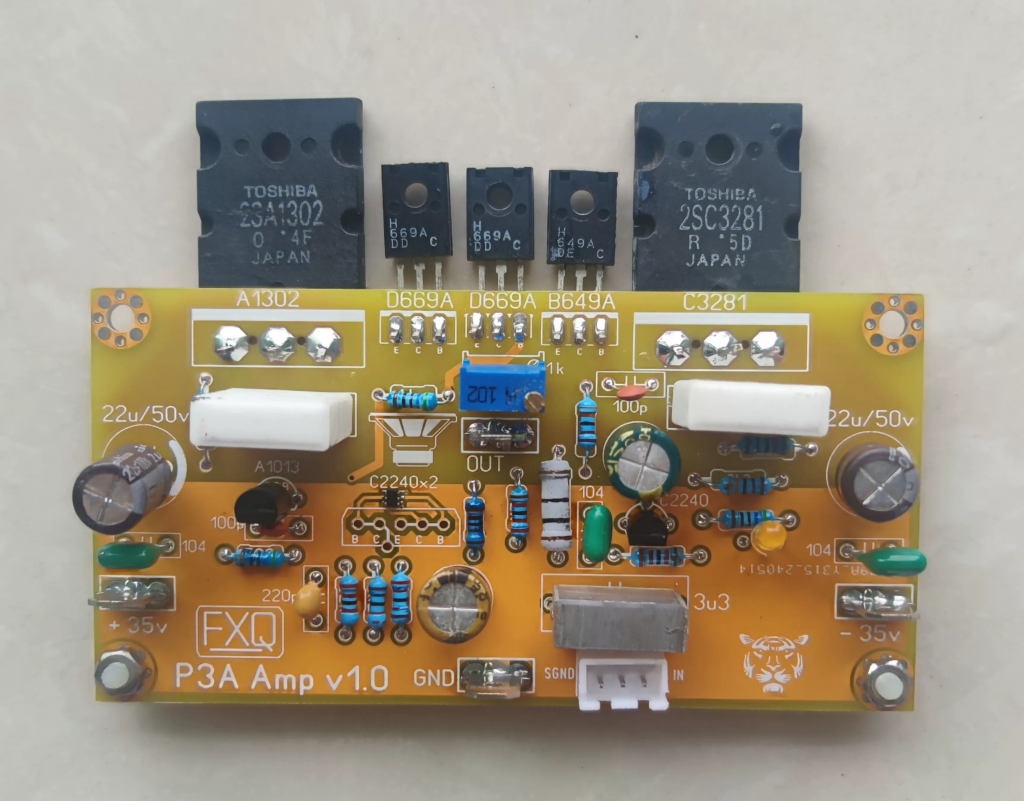

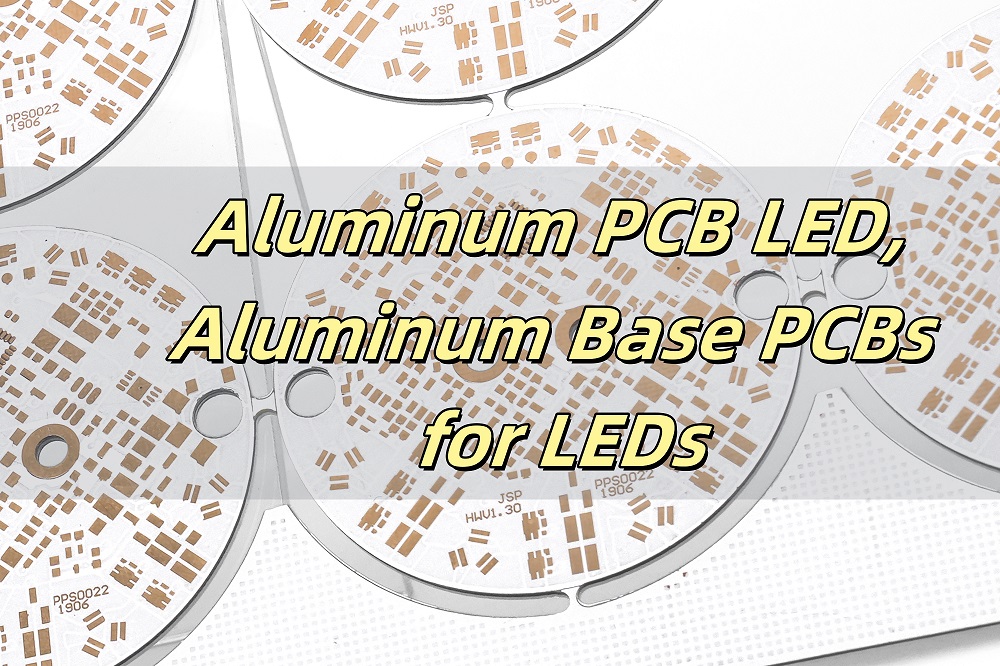

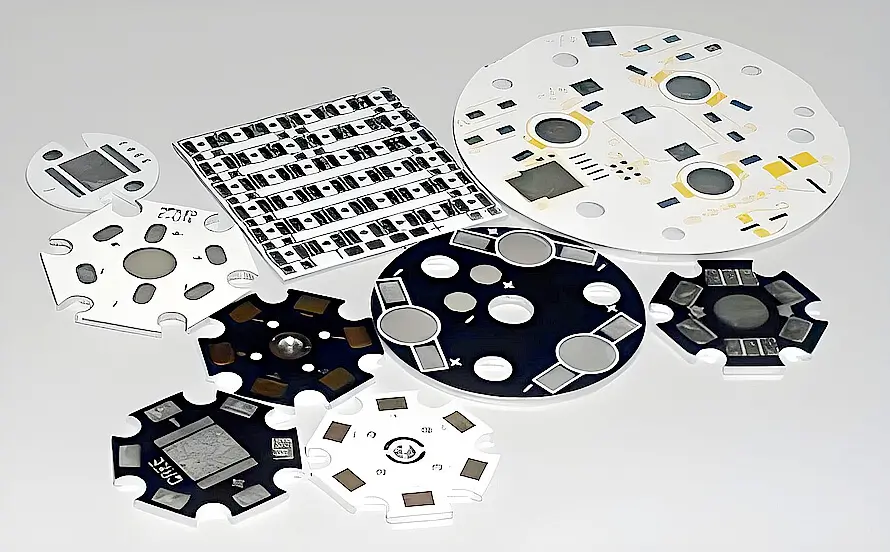

An aluminum PCB LED refers to a specialized printed circuit board (PCB) that uses an aluminum base to support and enhance LED (Light Emitting Diode) applications. These PCBs are specifically designed to manage the heat generated by LEDs during operation. In essence, an aluminum PCB LED combines the benefits of advanced circuit design with excellent thermal conductivity, ensuring optimal performance for LED systems.

Aluminum PCBs have revolutionized LED lighting by addressing heat dissipation challenges. These circuit boards, crafted with an aluminum base, deliver excellent thermal management, durability, and efficiency. This blog explores their material composition, thermal properties, and significance in LED applications. Whether you’re designing LED systems or curious about the advantages of aluminum PCBs, this comprehensive guide offers valuable insights.

What Is the LED of Aluminum?

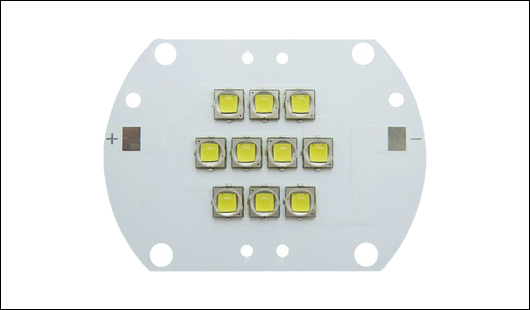

LEDs mounted on aluminum PCBs are essential for applications demanding high efficiency and longevity. The aluminum base acts as a thermal conductor, transferring heat away from the LED components. This process enhances the lifespan and performance of LEDs, particularly in high-power applications like floodlights and automotive lighting. These PCBs are also lightweight, making them suitable for compact designs.

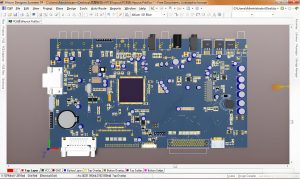

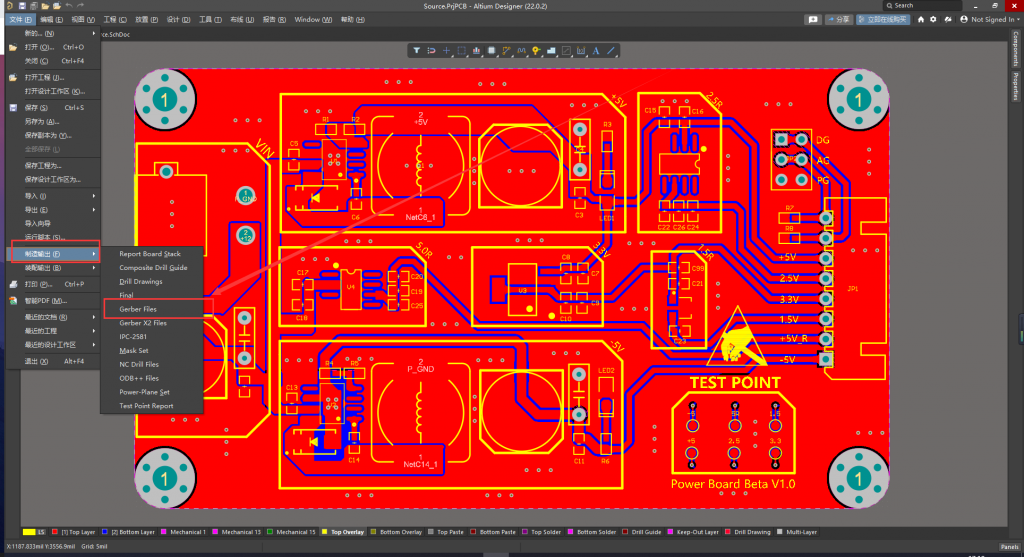

What Is the Material of Aluminum PCB?

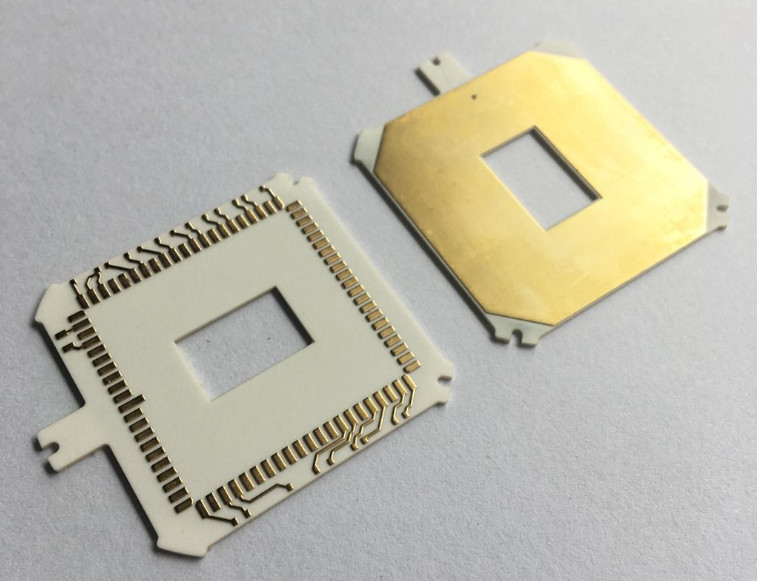

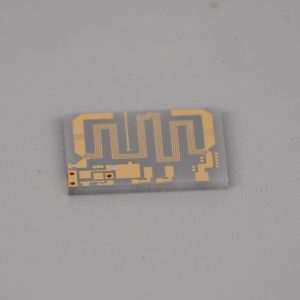

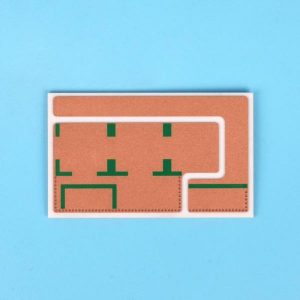

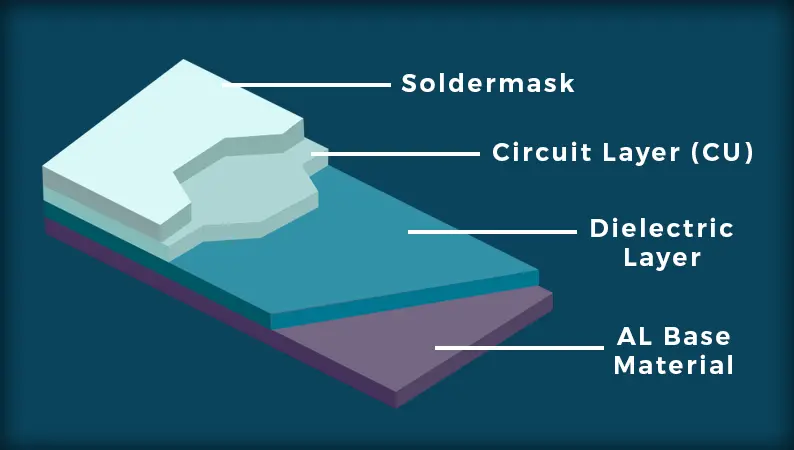

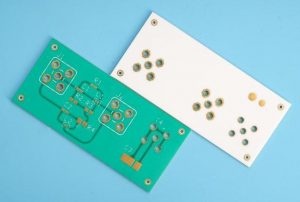

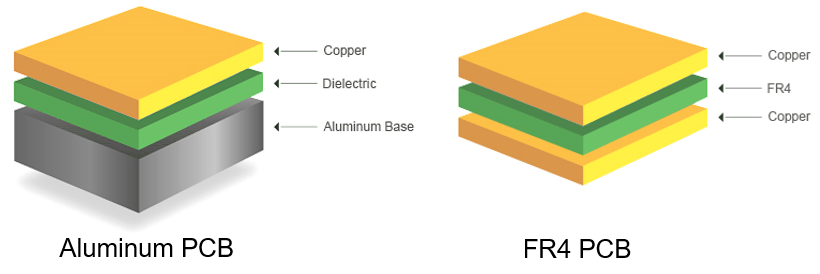

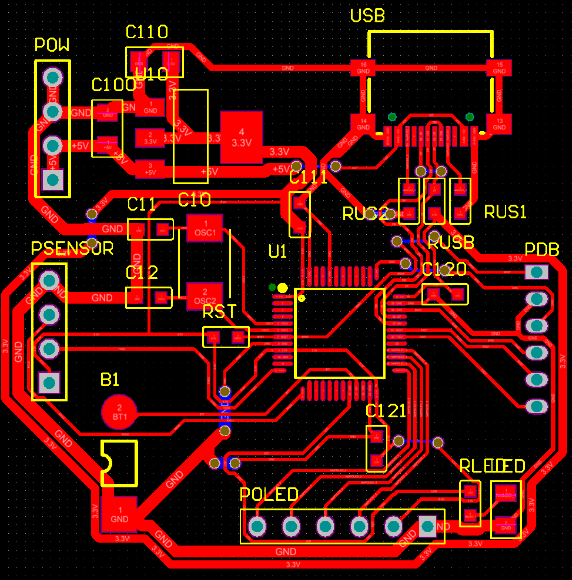

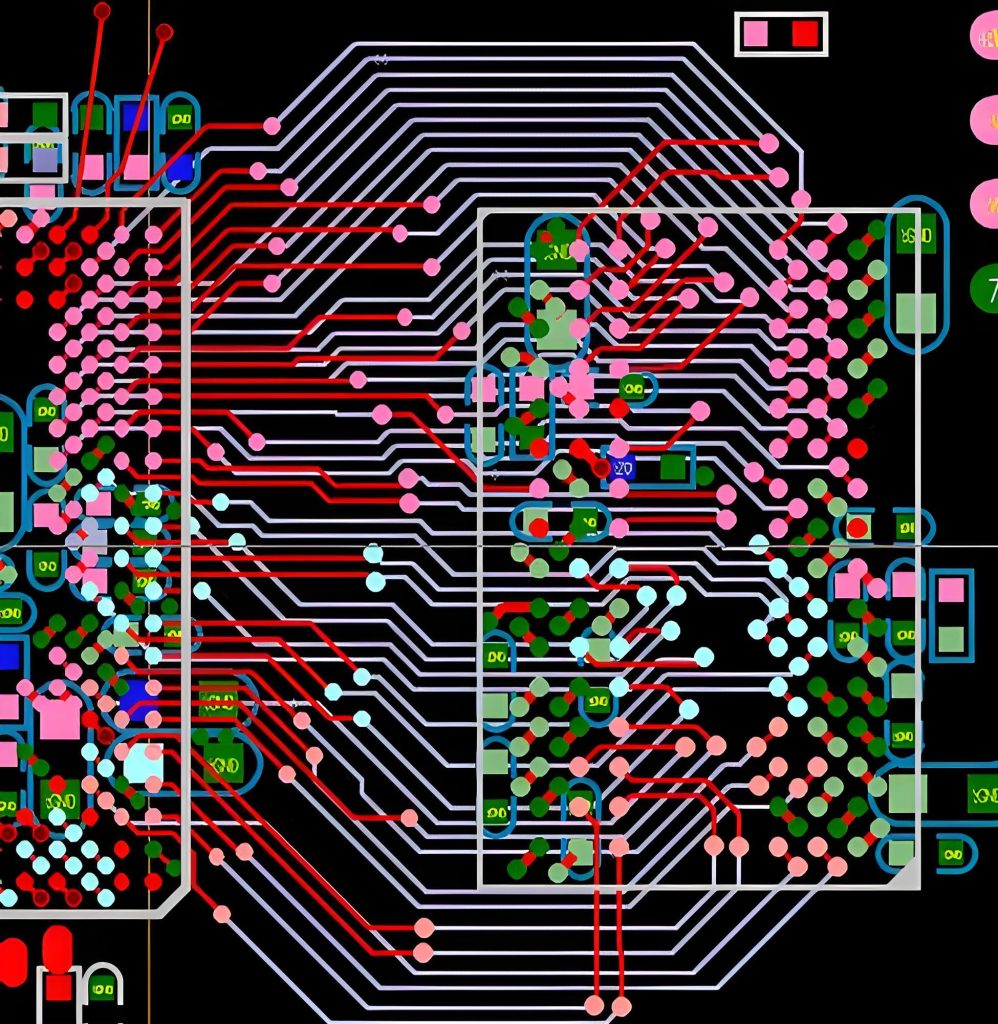

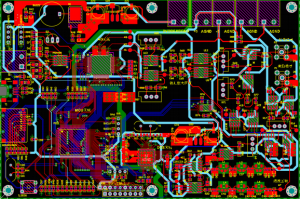

Aluminum PCBs typically consist of three layers:

1. Base Layer: Made of aluminum, this layer provides structural support and excellent heat dissipation.

2. Dielectric Layer: Positioned between the base and the circuit layer, it ensures electrical insulation while conducting heat.

3. Circuit Layer: Copper circuits are etched onto this layer to form the electrical connections.

The combination of aluminum and copper enhances conductivity and thermal efficiency. These materials make aluminum PCBs reliable for LED applications.

What Temperature Can Aluminum PCB Withstand?

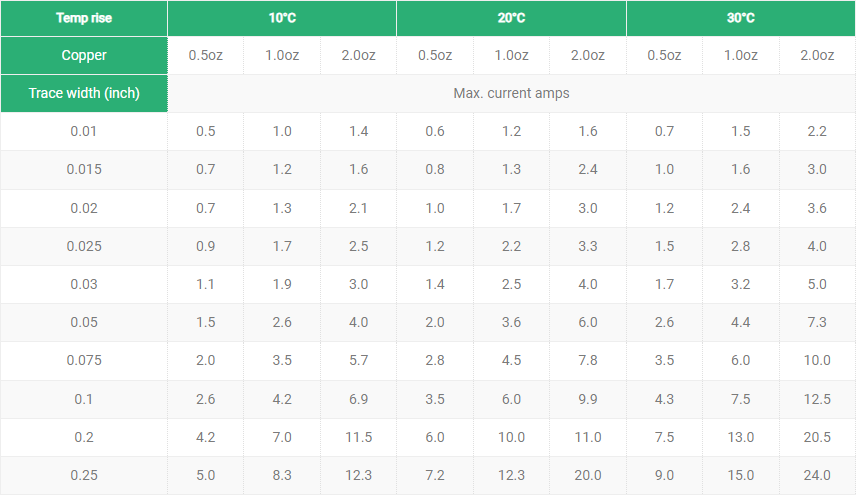

Aluminum PCBs are designed to operate in high-temperature environments. They can typically withstand temperatures between 120°C and 150°C, depending on the design and material quality. High thermal resistance ensures consistent performance, even in demanding applications like outdoor LED lighting and automotive headlights. Selecting the right PCB thickness and dielectric material is critical for optimizing thermal tolerance.

What Is the Thermal Resistance of Aluminum PCB?

The thermal resistance of an aluminum PCB is the measure of its heat transfer capability. It typically ranges between 1.0°C/W and 2.0°C/W, depending on the board’s structure and material quality. Lower thermal resistance indicates better heat dissipation, which is essential for high-power LEDs. Aluminum PCBs achieve this through their unique combination of metal cores and dielectric materials.

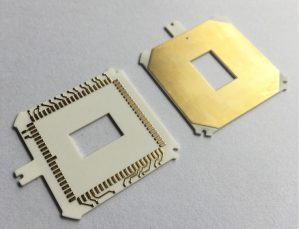

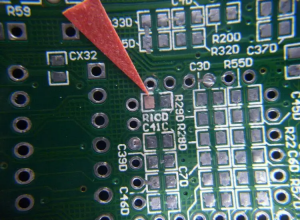

How Thick Is Aluminum PCB?

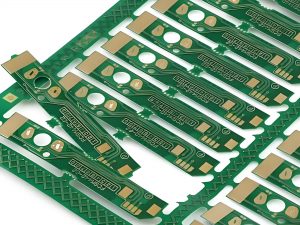

Aluminum PCBs vary in thickness to suit different applications. Common thicknesses include:

Base Layer: Typically 1.0mm to 2.0mm.

Dielectric Layer: Around 0.075mm to 0.15mm.

Circuit Layer: Common circuit layer thickness is about 0.035mmâ.

The choice of thickness depends on the required mechanical strength, heat dissipation, and electrical load. Thicker boards are ideal for heavy-duty applications like industrial LED lighting.

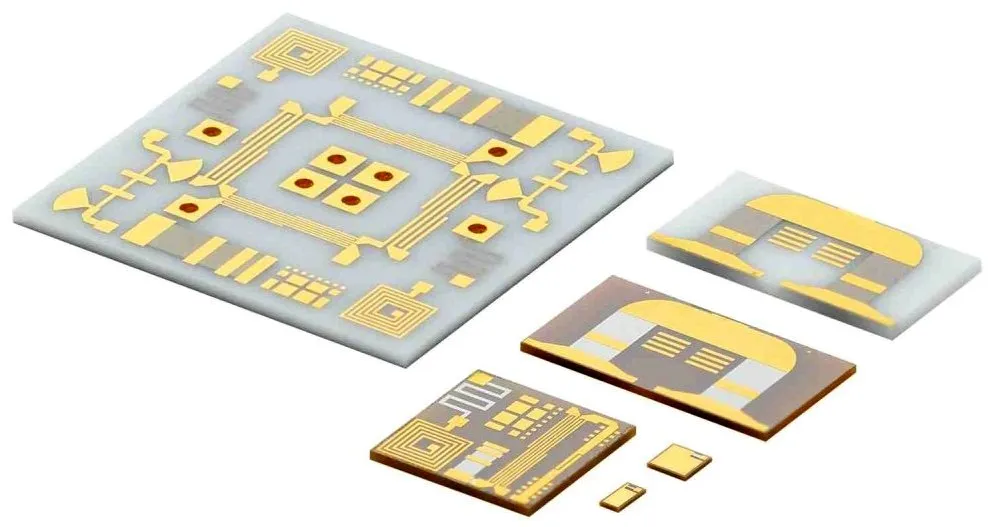

What Is the Difference Between Copper and Aluminum PCB?

Copper and aluminum PCBs serve similar purposes but have distinct characteristics:

Thermal Conductivity: Copper PCBs offer higher conductivity, while aluminum PCBs balance thermal performance and cost.

Weight: Aluminum PCBs are lighter, making them ideal for compact designs.

Cost: Aluminum PCBs are generally more affordable than copper-based alternatives.

Aluminum PCBs are preferred for LED applications due to their efficient heat dissipation and lower production costs.

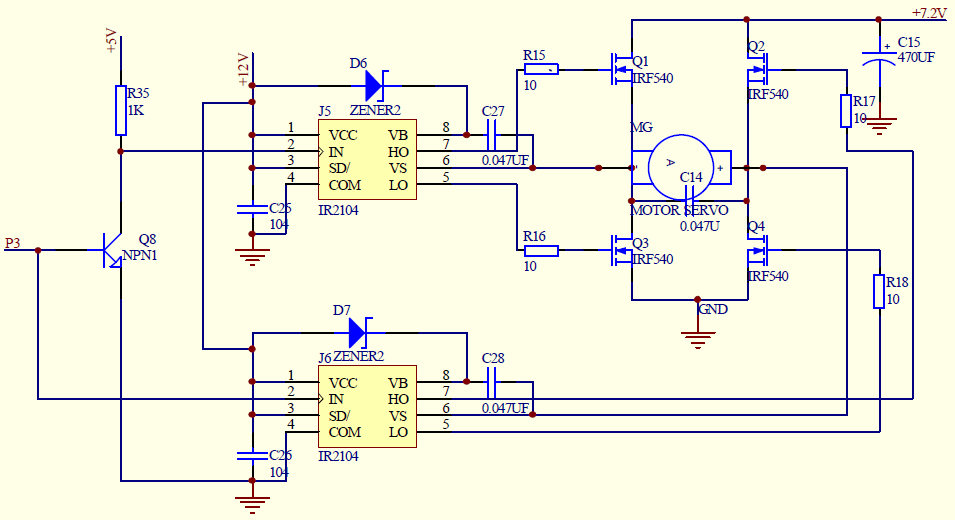

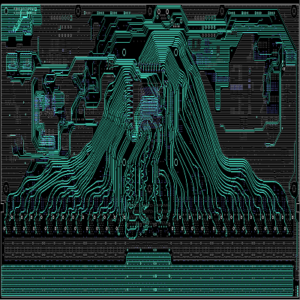

How Do You Connect LED to PCB?

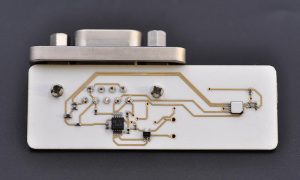

Connecting LEDs to aluminum PCBs involves precise soldering. Here’s a simplified process:

1. Prepare the PCB: Clean the board and check the circuit layout.

2. Place the LED: Align the LED pins with the PCB pads.

3. Solder the Connections: Use a soldering iron to secure the LED.

4. Test the Circuit: Verify functionality with a power supply.

Aluminum PCBs are designed to handle heat generated during soldering, ensuring durability and reliable connections.

Why Use Aluminum PCB?

Aluminum PCBs are preferred for LED applications due to several reasons:

1. Heat Management: They efficiently dissipate heat, ensuring LEDs operate at optimal temperatures.

2. Durability: Aluminum provides structural strength and resistance to wear.

3. Lightweight: The boards are easy to integrate into compact devices.

4. Energy Efficiency: They reduce thermal losses, improving overall efficiency.

These features make aluminum PCBs a cornerstone in modern LED lighting solutions, from consumer electronics to industrial systems. Best Technologyâs competitive edge lies in its ability to deliver multiple types of products, customized to your needs, with fast delivery and unmatched quality.

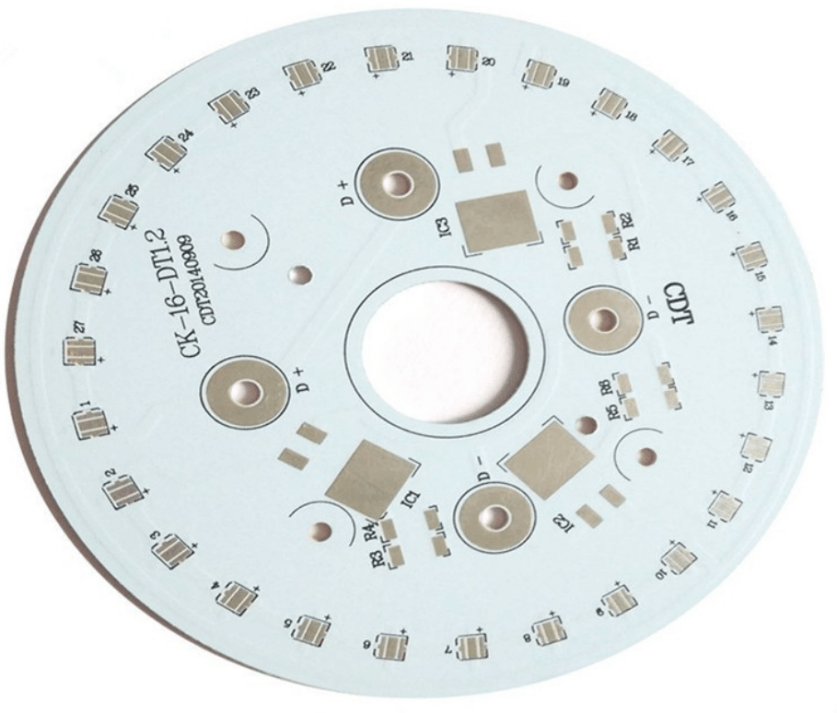

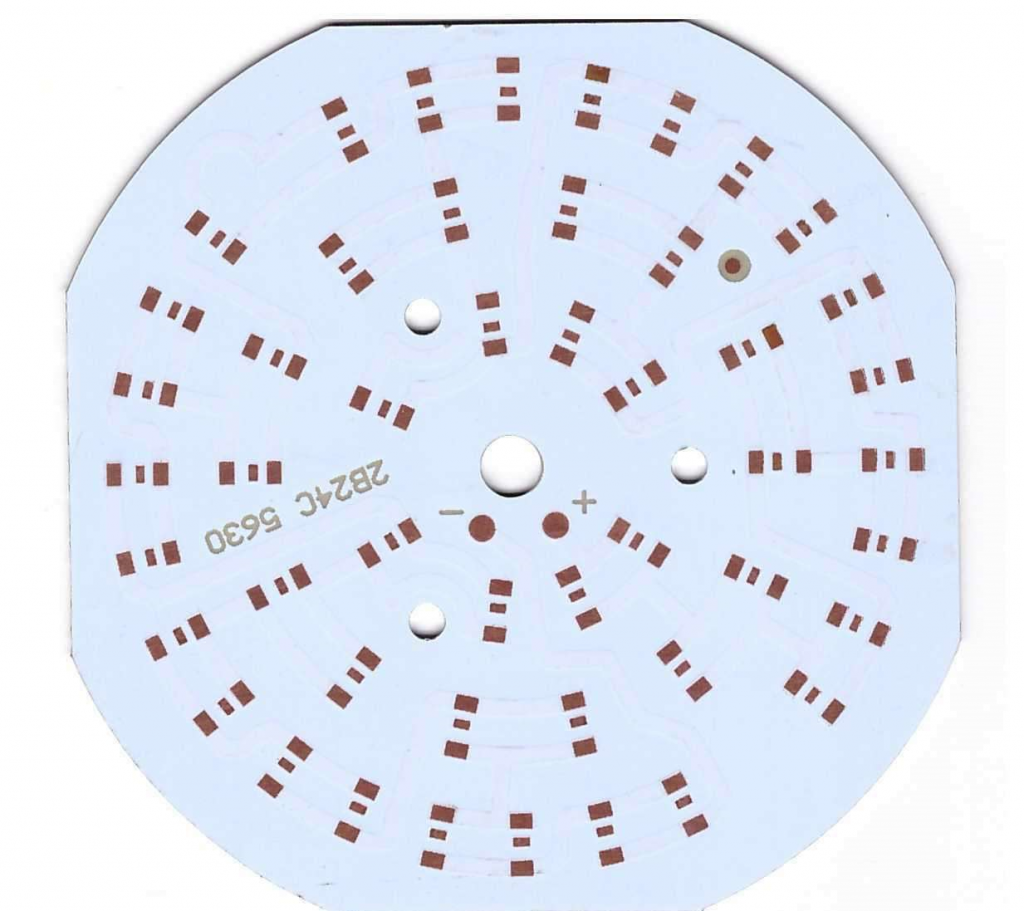

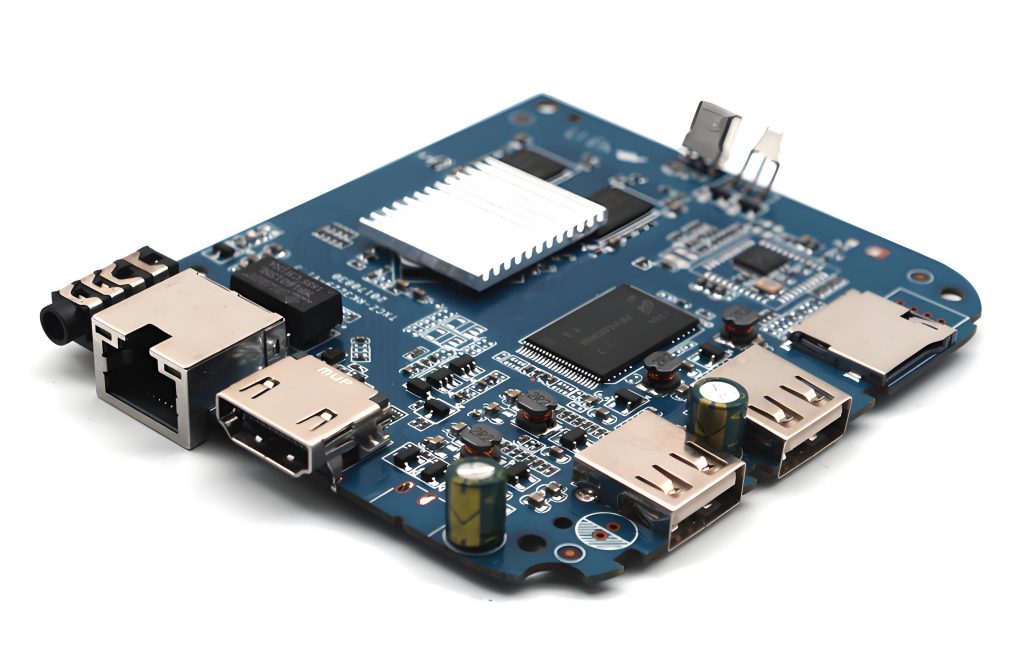

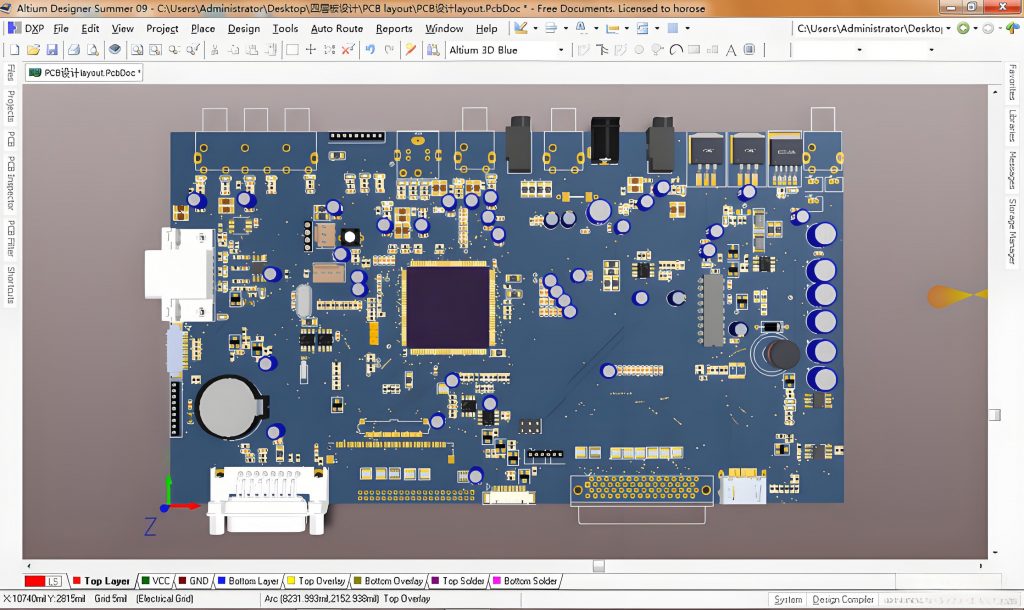

What are Applications of Aluminum PCBs in LEDs?

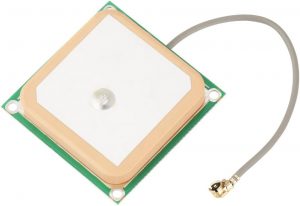

Aluminum PCBs (Printed Circuit Boards) are widely used in LED applications due to their excellent thermal management properties. Here are the main applications of aluminum PCBs in LEDs:

1. High-Power LED Lighting: Aluminum PCBs are ideal for high-power LED lighting systems, such as streetlights, floodlights, and spotlights. The metal core provides effective heat dissipation, preventing LEDs from overheating and improving their efficiency and lifespan.

2. LED Modules for Displays: Aluminum PCBs are used in LED modules for large-scale digital displays, such as billboards and signage. The thermal management capacity of aluminum ensures the stability of the LEDs during continuous operation.

3. Automotive Lighting: In automotive lighting systems, aluminum PCBs are used for headlights, tail lights, and interior lighting. The ability of aluminum to manage heat is critical to maintain LED performance and prevent failure in harsh automotive environments.

4. Backlighting for LCD Displays: Aluminum PCBs are used in the backlight systems of LCD displays, such as those in TVs, monitors, and smartphones. The heat dissipation capabilities enhance the longevity and reliability of the LEDs used for backlighting.

In each of these applications, aluminum PCBs help to reduce the risk of overheating, enhance the performance of LEDs, and extend their operational life, making them a preferred choice for various LED-based lighting and display systems.

In conclusion, aluminum PCBs are indispensable for high-performance LED applications. Their superior thermal management, lightweight construction, and cost-effectiveness provide unparalleled benefits. Choosing the right aluminum PCB for your LED projects ensures durability and efficiency. If you need customized solutions, Best Technology offers premium aluminum PCB led tailored to your requirements. Just feel free to contact us via sales@bestpcbs.com.