What is a PCB Layout? PCB layout is the process of arranging and positioning electronic components on a printed circuit board in order to optimize circuit performance, improve reliability, and meet specific design requirements. A good layout can reduce signal interference, lower electromagnetic radiation, and keep size and cost under control.

What is a PCB Layout?

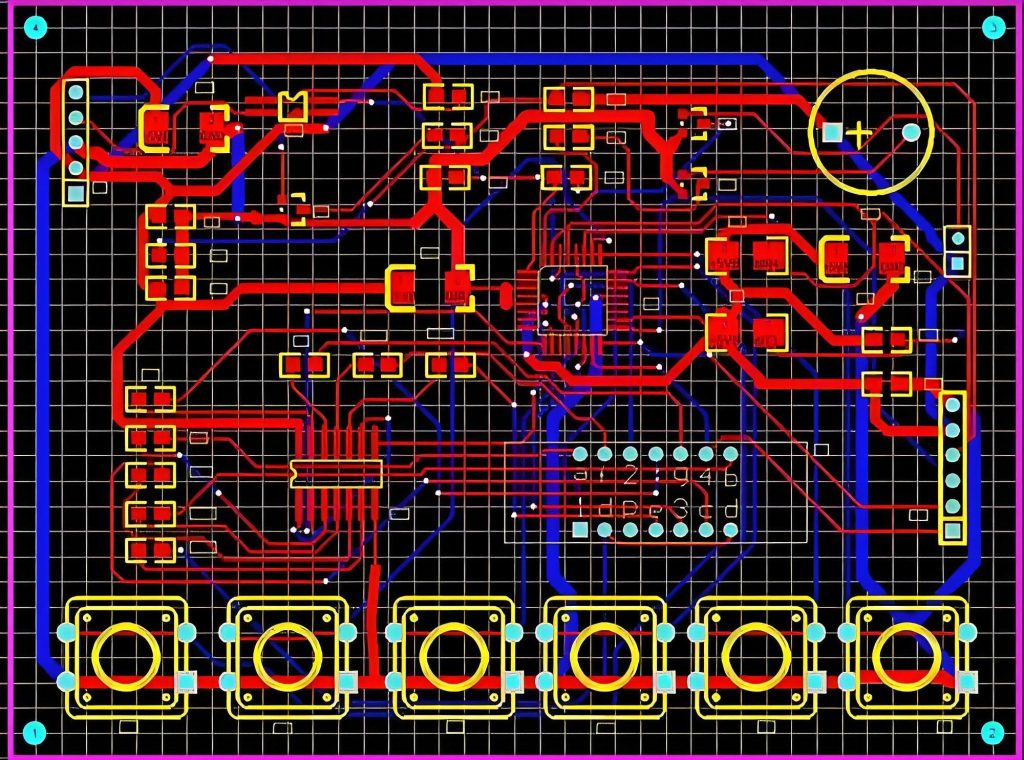

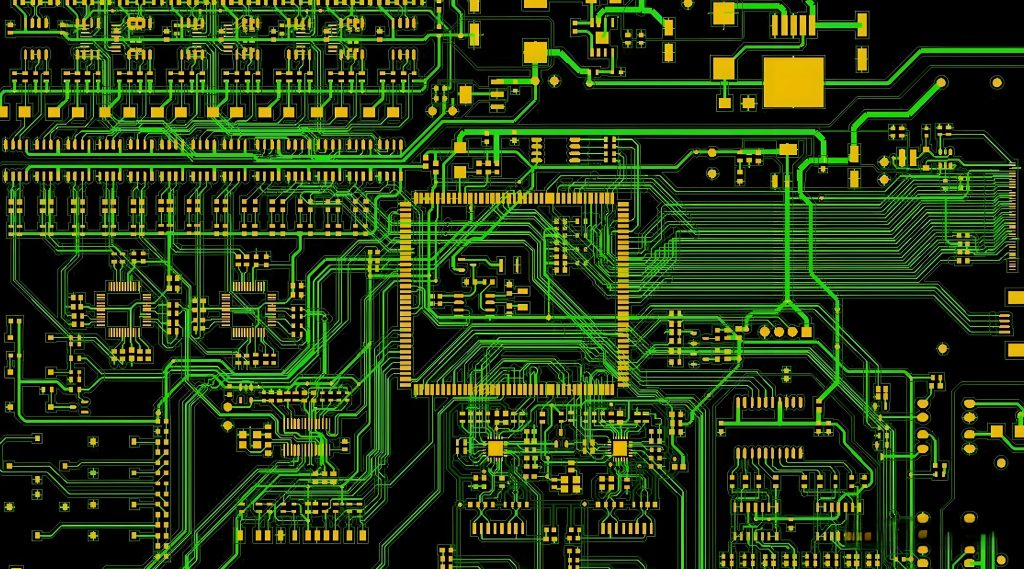

A PCB layout is the arrangement of components and the electrical connections between them on a printed circuit board. Itâs essentially a map that dictates where each component goes and how electrical signals travel from one component to another.

The layout specifies the placement of parts like resistors, capacitors, integrated circuits, and connectors, as well as the routing of copper traces that carry the electrical current.

In simple terms, the PCB layout is the blueprint for building the physical circuit board. The success of the entire electronic system depends on how effectively this layout is created.. It ensures that components are connected correctly, that electrical signals travel efficiently, and that the final product meets its functional and performance goals.

How to Create a PCB Layout?

Creating a PCB layout is a process that requires attention to detail, a bit of creativity, and the right tools.

- Start with a Schematic Design:

Before you can lay out a PCB, you need a schematic diagram. The schematic represents all the components of the circuit and how they are connected electrically. This design serves as the foundation for your PCB layout, guiding the placement of components and the routing of traces.

- Place the Components:

This step requires careful consideration of how components should be positioned. Components should be placed logicallyâimportant parts like connectors or power supplies should be positioned in ways that make routing and assembling the board easier. High-frequency components should be positioned close to each other to reduce signal interference.

- Route the Traces:

Traces are the electrical paths that connect components. Routing the traces involves creating paths for signals to travel between components. Itâs crucial to route traces with the shortest possible path to minimize resistance and signal delay. For high-power components or sensitive signals, special care must be taken to route traces properly to avoid interference.

- Define Power and Ground Planesï¼

Power and ground planes are large areas of copper that provide a stable voltage reference for the components. These planes help reduce noise and improve the stability of the circuit. Proper grounding is especially important in high-speed or high-power circuits to avoid voltage fluctuations and interference.

- Consider Thermal Managementï¼

Power-hungry components generate heat, which can cause problems if not managed properly. Thermal vias, larger copper areas, and heat sinks are sometimes necessary to ensure that heat is efficiently dissipated. Placing heat-sensitive components away from high-power components can also help prevent overheating.

- Run Design Rule Checks (DRC)ï¼

After placing the components and routing the traces, you need to check your design for errors. Design Rule Checks (DRC) are automated checks that help identify potential issues like trace width violations, inadequate spacing, or improper component placement. These checks ensure that the layout adheres to industry standards and that the board can be manufactured correctly.

- Finalize the Layout and Export Filesï¼

Once youâve completed the layout and fixed any issues, the design is ready for production. The last step is to export the design file, usually in Gerber format, which is the format used to create the physical PCB.

What is the Standard PCB Format?

The most widely used format is Gerber files, which describe the layers, traces, drill holes, and components on the PCB. These files are essential for translating the layout into a physical board.

In addition to Gerber files, other essential formats used in PCB design include:

- Bill of Materials (BOM): This document lists all the components needed for the PCB, including part numbers, quantities, and other relevant information.

- Pick-and-Place Files: These files specify the exact locations where components need to be placed on the PCB during the assembly process.

- Drill Files: Drill files detail the locations and sizes of holes that need to be drilled into the PCB for components or vias.

Each format plays a specific role in ensuring that the design can be accurately manufactured and assembled.

How Long Does PCB Layout Take?

The amount of time required to create a PCB layout depends on several factors, including the complexity of the design, the number of layers, and the experience of the designer.

For a simple single-layer PCB, the layout process may take only a few hours or a day. However, for more complex designs, such as multi-layer boards or designs with high-speed components, the layout can take several weeks or even months.

The complexity of the project, the need for iterative testing, and the level of optimization also influence the timeline. The more components involved and the more layers in the design, the more time it will take to finalize the layout.

Why is PCB Layout Important?

The PCB layout is crucial for several reasons:

- Ensures Functionality: A well-designed PCB layout ensures that the electrical components interact as intended. Poor placement or incorrect routing can result in malfunctioning circuits, which could cause a device to fail entirely.

- Minimizes Power Loss: By optimizing trace lengths and selecting appropriate trace widths, you can minimize power losses and improve the overall efficiency of the circuit.

- Reduces Signal Interference: Properly routing traces helps reduce electromagnetic interference (EMI) and ensures signal integrity. This is particularly important in high-speed or RF (radio frequency) applications.

- Prevents Overheating: Effective thermal management is a key part of PCB layout. Properly placed heat sinks, thermal vias, and wide copper traces can help prevent components from overheating, which could lead to failures.

- Improves Manufacturability: A well-designed PCB layout adheres to industry standards, which makes it easier and more cost-effective to manufacture the board. Proper layout rules ensure that the board can be produced with minimal errors and at a lower cost.

- Supports Future Upgrades: A clear, well-documented layout makes it easier to update and improve the design in the future. Whether you need to add new features or troubleshoot existing issues, a good layout helps streamline the process.

How Do I Optimize My PCB Layout?

Optimization is key to creating an efficient, reliable PCB. Here are a few tips to help optimize your PCB layout:

- Minimize Trace Lengths: Shorter traces reduce resistance, noise, and delay. Try to keep traces as direct as possible, especially for high-frequency or high-power components.

- Use Wider Traces for High-Current Components: For components that draw significant power, use wider traces or dedicated bus bars to prevent overheating and power loss.

- Avoid Trace Crossovers: Crossing traces can increase complexity and lead to errors. Try to avoid unnecessary crossovers by carefully planning the component placement.

- Group Related Components: Group components that work together close to each other to minimize the need for long interconnections. This makes routing easier and improves signal quality.

- Use Ground and Power Planes: A solid ground and power plane ensures stable voltage levels and reduces noise. This is particularly important in high-speed designs.

- Check for Design Rule Violations: Always use automated design rule checks to ensure that your layout meets industry standards and manufacturing requirements. These checks help avoid errors that could complicate production.

- Consider Thermal Management: Pay attention to heat-sensitive components and their proximity to power-hungry components. Include thermal vias or large copper areas to dissipate heat effectively.

What Are the Rules for PCB Design?

When designing a PCB layout, following certain rules is essential for creating a functional and manufacturable board. Some important PCB layout rules include:

- Trace Width and Spacing: Ensure that traces are wide enough to carry the current they will handle and that there is enough space between traces to prevent short circuits.

- Component Placement: Components should be placed in an organized manner, with clear signal paths and minimal trace lengths. High-speed components should be placed near each other to reduce signal degradation.

- Signal Integrity: Keep high-speed signal traces as short as possible and avoid running them parallel to power traces, as this can lead to noise or interference.

- Thermal Management: Ensure that heat-sensitive components are placed away from power components and that thermal vias or heatsinks are included as needed.

- Ground Planes: Always include a solid ground plane to reduce noise and provide a stable reference for the circuit.

What is the Difference Between PCB Layout and Design?

Although the terms “PCB layout” and “PCB design” are often used interchangeably, they actually refer to two different stages of the PCB creation process.

PCB Design refers to the overall planning stage, where the schematic is created, components are selected, and the overall functionality of the circuit is planned.

PCB Layout focuses on the physical arrangement of components and routing of traces. Itâs about creating the blueprint.

In conclusion, a well-designed PCB layout is essential for the successful operation of any electronic circuit. It ensures efficient signal flow, minimizes power loss, and supports the overall reliability of the device. If you have any PCB design layout needs, please contact us via sales@bestpcbs.com to get the best solution.