PCB & PCBA manufacturer services have become essential for electronics design and innovation. Whether you’re building simple devices or smart tech systems, choosing the right manufacturing partner matters. In this blog, we‚Äôll break down the full process‚ÄĒfrom design to assembly‚ÄĒand guide you in selecting a trusted supplier.

Best Technology offers both PCB manufacturing and PCBA services under one roof that saves time, reduces mistakes, and improves communication across the production cycle for customers. We provide single to multilayer PCB manufacturing and assembly and have ISO9001, AS9100D, ISO13485, UL, and IATF16949 certifications. Best Technology is competitive in fast lead time in low-volume PCB & PCBA production while maintaining high-quality control. A warm welcome to get a fast quote or share your files with us via sales@bestpcbs.com. We’re here to help.

What is PCB and PCBA?

Understanding the difference between PCB and PCBA is the first step when entering the electronics world.

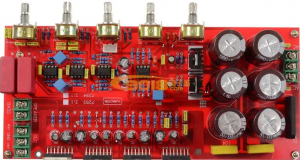

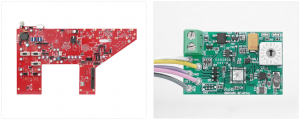

- PCB stands for Printed Circuit Board. It’s the bare board that holds all the components. It can be single-sided, double-sided, or multilayered depending on the design.

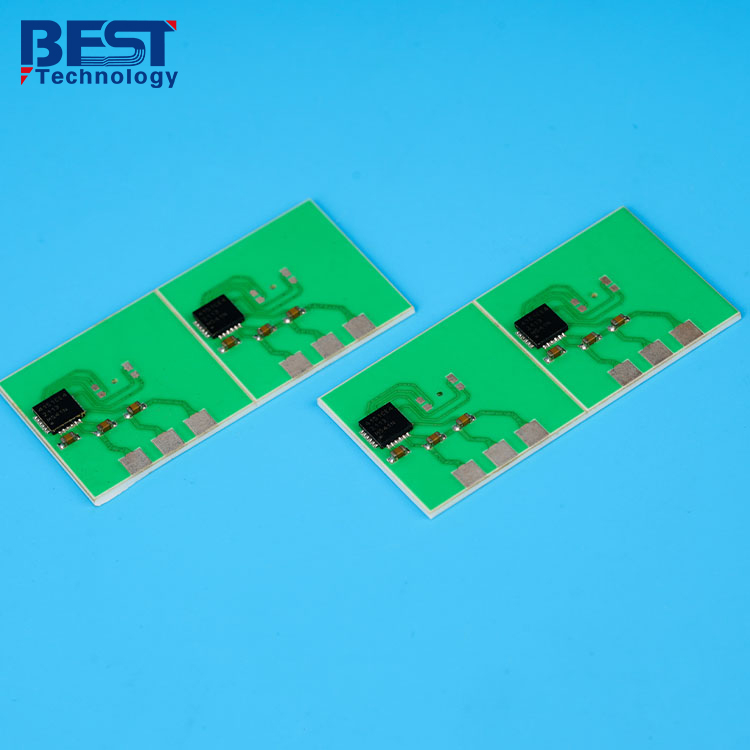

- PCBA means Printed Circuit Board Assembly. This refers to the finished board with all components mounted. It’s the working version of the circuit that can be used in a product.

So, the key difference: PCB is the blank base, while PCBA is the complete board with parts soldered on.

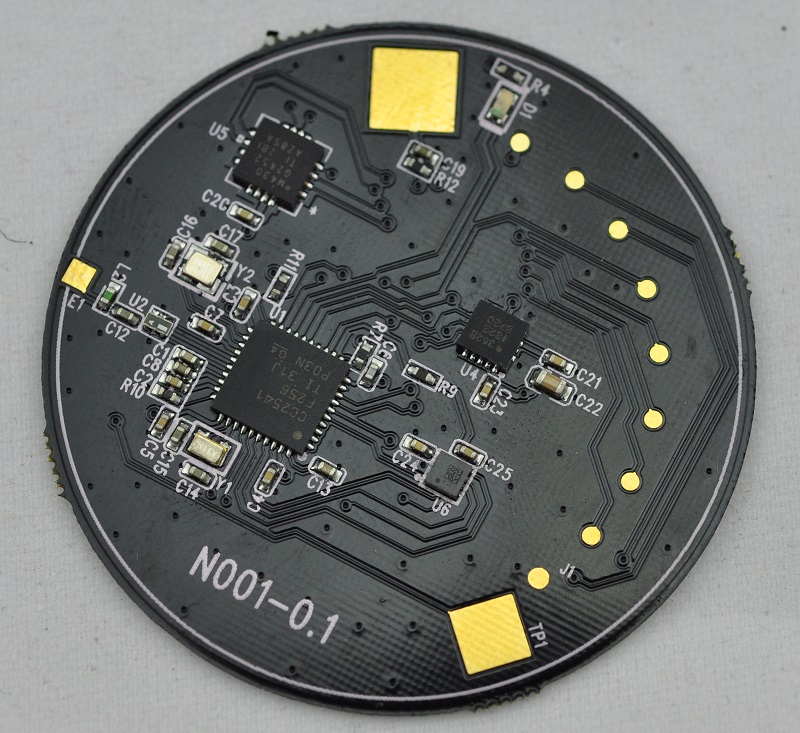

How is a PCB Manufactured?

PCB manufacturing is a detailed process. Let’s simplify it into key steps:

Step 1: Design

- Everything starts with a PCB design using CAD software. Gerber files are generated to guide the production.

Step 2: Printing the Inner Layers

- The copper pattern is printed onto a laminate sheet. This forms the board’s inner circuits.

Step 3: Etching

- Excess copper is removed using a chemical process, leaving only the desired traces.

Step 4: Layer Alignment

- For multilayer boards, layers are stacked and aligned with precision.

Step 5: Drilling

- Holes are drilled to create pathways between layers.

Step 6: Plating and Copper Deposition

- The drilled holes are plated with copper to form conductive connections.

Step 7: Solder Mask Application

- A green solder mask covers the board, except for areas where components will be soldered.

Step 8: Surface Finish

- This step protects the exposed copper and improves solderability.

Step 9: Silkscreen Printing

- Markings are printed to identify parts and polarity.

Step 10: Electrical Testing

- Each PCB is tested to ensure the circuit paths are correct.

The board is now ready for assembly.

How Much Does PCB Assembly Cost?

PCB assembly cost depends on several variables. Here’s what affects the price:

- Component types: SMT parts are usually cheaper to place than through-hole ones.

- Quantity: Higher volumes lower per-unit cost.

- Board size and layers: More layers or larger sizes mean higher assembly fees.

- Turnaround time: Rush orders add to the price.

- Testing requirements: If functional or in-circuit testing is needed, it adds cost.

- Location of manufacturer: Prices vary by country or region.

On average, a basic PCBA could start at $10‚Äď$30 per board for small quantities. Higher-end boards cost more.

How Much Does a Custom PCB Cost?

Custom PCBs are priced based on the following:

- Number of layers ‚Äď A 2-layer board is cheaper than a 6-layer one.

- Board dimensions ‚Äď Larger boards use more material.

- Surface finish ‚Äď ENIG or immersion gold costs more than HASL.

- Material ‚Äď FR4 is standard. Ceramic, aluminum, or polyimide costs more.

- Volume ‚Äď A prototype might cost $100+, but bulk orders can drop it below $2 per piece.

- Fabrication complexity ‚Äď HDI boards or those with fine traces cost more.

Using a PCB maker online can help you estimate costs in minutes and compare options.

Who Manufactures PCBs?

India is home to several reliable PCB circuit board manufacturers, especially for industrial, consumer, and automotive electronics. Some of the well-known PCB Circuit Board Manufacturers in India include:

- AT&S India ‚Äď Specializes in HDI and automotive PCBs.

- Shogini Technoarts ‚Äď Offers multilayer, metal core, and flexible boards.

- Genus Electrotech ‚Äď Provides full PCB & PCBA solutions.

- CIPSA-TEC India ‚Äď Focuses on quality rigid boards.

Indian factories have improved a lot in terms of technology, certifications, and lead times. As a result, global buyers are increasingly turning to them.

Who is the Biggest PCB Supplier?

China leads the global PCB market. It’s the largest production base with hundreds of factories.

The biggest PCB manufacturer in China is Best Technology (BEST), known for high quality and complex PCB fabrication. BEST provides full PCB & PCBA service to 1700 customers across 40 countries in the communication, automotive, medical, and aerospace industries. BEST also has strong R&D capabilities and international certifications. Other big names include:

- Shennan Circuits: Founded in 1984, Shennan Circuits is a key player in the Chinese PCB industry. It provides advanced PCBs, packaging substrates, and electronic assembly services.

- Kinwong Electronics: Established in 1993, operates multiple production bases in China. It focuses on both rigid and flexible PCBs, offering solutions for automotive, industrial control, and consumer electronics. Kinwong is one of the top 10 PCB suppliers in the world by revenue and is listed on the Shenzhen Stock Exchange.

- SCC (Shenzhen): SCC is a major PCB maker specializing in high-layer-count and high-precision PCBs. It supports complex manufacturing needs across industries like networking, medical, and aerospace. SCC has also invested heavily in smart manufacturing and green production practices to improve efficiency and sustainability.

These suppliers offer both low-cost and high-performance options, serving industries from telecom to aerospace.

PCB & PCBA Manufacturer in USA

When it comes to high-quality, local production, many companies turn to a PCB & PCBA manufacturer in USA. Some of the trusted names are:

- TTM Technologies ‚Äď A leader in defense and industrial PCBs.

- Sanmina Corporation ‚Äď Offers full PCBA services and testing.

- Advanced Circuits ‚Äď Known for quick-turn PCBs and online quoting.

- Bay Area Circuits ‚Äď Popular among startups and engineers.

U.S. manufacturers are often chosen for their precision, certifications (like ITAR), and short lead times‚ÄĒdespite higher costs.

How to Choose a PCB & PCBA Manufacturer?

Choosing the right pcb & pcba manufacturer is important. Here’s a simple checklist:

1. Capabilities

- Can they build the type of board you need? Check if they offer multilayer, rigid-flex, or metal-core PCBs.

2. Certifications

- Look for ISO, UL, IPC, and RoHS compliance. These prove the company meets quality and safety standards.

3. Design & Support

- Do they help with DFM (Design for Manufacturability)? Can they handle Gerber corrections?

4. Turnaround Time

- Can they deliver in days, not weeks? Ask about lead times and shipping.

5. Pricing

Request a detailed quote. Compare costs for fabrication, assembly, and testing.

6. PCBA Services

- Do they offer sourcing, SMT, testing, and packaging all in one place?

7. Reviews & Reputation

- Search for customer reviews and case studies. A strong track record speaks volumes.

By working with a full-service PCB PCBA factory, you reduce risks, save time, and improve quality control.

Why Choose Best Technology as Your PCB & PCBA Supplier?

At Best Technology, we are more than just a PCB & PCBA Supplier. As an original PCB & PCBA manufacturer, we support global businesses from PCB design to market With 18+ years of experience. Here’s what sets us apart:

- One-stop service ‚Äď Best Technology provides one-stop service, including component purchasing, PCB design, PCB manufacturing, PCB assembly, testing, and all-around technical support before and after-sales.

- Skilled team ‚Äď Our engineers catch design issues early. Our China-based engineering team & Vietnam team provide real-time support during EST business hours. Most of the engineers have concentrated on the PCB specialty and expertise over 10 years.

- Fast response ‚Äď Quotes within 24 hours and quick production.

- Global shipping ‚Äď From prototypes to volume orders, the lead time in Best Technology is about 2 weeks wherever you are on Earth and ship out goods always on time! The urgent boards can be shipped out within 24 hours.

- Flexible options ‚Äď Best Technology builds FR4, aluminum, ceramic, and PCBA. Whether you need standard PCB & PCBA service or customization PCB service for the above types, we give full support.

Whether you’re a startup or a large brand, we‚Äôre here to make your ideas real. Choosing us means getting a reliable partner who listens and delivers.

In conclusion, finding the right PCB & PCBA manufacturer isn‚Äôt just about cost. It‚Äôs about getting dependable quality, consistent delivery, and real technical support. Whether you’re building a PCB prototype or scaling for mass production, a reliable partner helps you move faster and stay ahead.

Best Technology, with over 18 years of experience in the field, stands out by delivering one-stop PCB & PCBA solutions tailored to customer needs. From PCB design reviews and DFM suggestions to precision PCB assembly and on-time delivery, we support your product every step of the way.

If you’re looking for a trustworthy PCB & PCBA manufacturer with the ability to scale and adapt, just feel free to contact Best Technology via sales@bestpcbs.com, we’re here to help.