Bulk conductivity of copper is a fundamental property that defines how well the material can conduct electricity. This feature makes copper a leading material in a variety of electrical applications, including printed circuit boards (PCBs). Whether in power transmission or complex electronics, understanding how bulk conductivity influences performance is essential for selecting the right materials. In this blog, weâll explore the significance of copperâs electrical properties, its comparison to other materials, and how these properties affect the design and performance of PCBs.

What is the Bulk Conductivity?

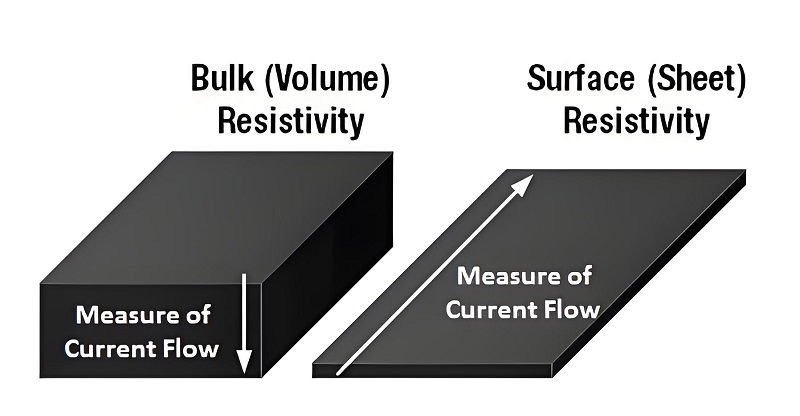

Bulk conductivity refers to the ability of a material to conduct electric current throughout its entire volume. This property is influenced by factors such as the materialâs atomic structure and the presence of impurities. In simple terms, it measures how easily electrical charges can flow through the material when an electric field is applied. Copper, with its excellent bulk conductivity, is a top choice for electrical wiring and PCBs because of its efficiency in transmitting electrical signals.

What is the Conductivity of Copper?

Copper stands out due to its high electrical conductivity. The electrical conductivity of copper is about 5.8 Ă 10â· S/m, which is one of the highest of any metal. This makes it an ideal material for electrical wiring, connectors, and components in PCBs. Its high conductivity ensures that electrical signals travel with minimal resistance, enhancing the efficiency of devices.

This conductivity is essential when it comes to maintaining high-speed data transmission and power distribution. Copperâs low resistance reduces energy loss, ensuring devices run efficiently, which is why it’s so widely used in the electronics industry.

What is the Bulk Resistivity of Copper?

Bulk resistivity is essentially the inverse of conductivity and indicates how much a material resists the flow of electric current. Copperâs resistivity is very lowâaround 1.68 Ă 10â»âž Ω·m, making it an excellent conductor. This low resistivity contributes to copperâs superior performance in applications that demand high-efficiency electricity flow, such as in the production of PCBs, which rely on copperâs excellent electrical properties.

In terms of practical applications, low resistivity allows copper to handle higher currents without excessive heat buildup, a critical factor in maintaining the reliability and longevity of electrical systems.

What is the High Electrical Conductivity of Copper?

The high electrical conductivity of copper is a key reason itâs used in almost all electrical wiring and devices. The structure of copper atoms allows for easy movement of free electrons, enabling efficient electrical current flow. This characteristic makes copper indispensable in applications where high efficiency and low loss are essential, such as in communication systems, automotive electronics, and renewable energy technology.

Furthermore, the high conductivity of copper ensures that devices and systems can operate at optimal efficiency without overheating. This makes it a preferred material for high-performance applications.

What is the Difference Between Conductivity and Resistivity?

While conductivity and resistivity are closely related, they describe two opposite properties. Conductivity measures a materialâs ability to carry an electric current, while resistivity measures how strongly the material resists the flow of that current. The two are mathematically connected: high conductivity means low resistivity, and vice versa.

Understanding this difference is essential when designing electrical systems. For example, when choosing materials for PCBs, low resistivity (high conductivity) is vital for reducing energy loss and heat production, which ensures the system runs more efficiently and lasts longer.

What is the Role of Bulk Conductivity in Electrical Circuits?

The bulk conductivity of copper plays a crucial role in electrical circuits. In any circuit, especially complex ones like those found in PCBs, the conductivity of the materials used determines how easily electrical signals can travel from one point to another. Copperâs high bulk conductivity ensures that signals are transmitted quickly and with minimal interference.

Moreover, the efficiency of electrical systems is directly linked to conductivity. Poor conductivity materials result in energy loss and potential system overheating, which can reduce the lifespan of electronic devices. Copperâs role in maintaining high conductivity ensures that electronic devices perform at their best for longer periods.

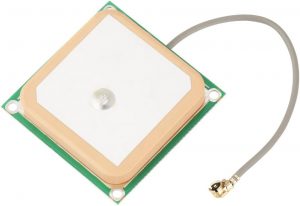

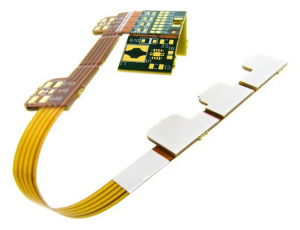

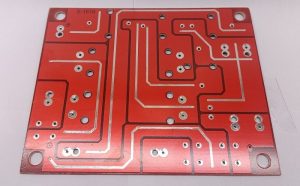

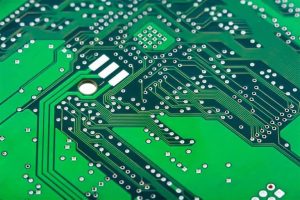

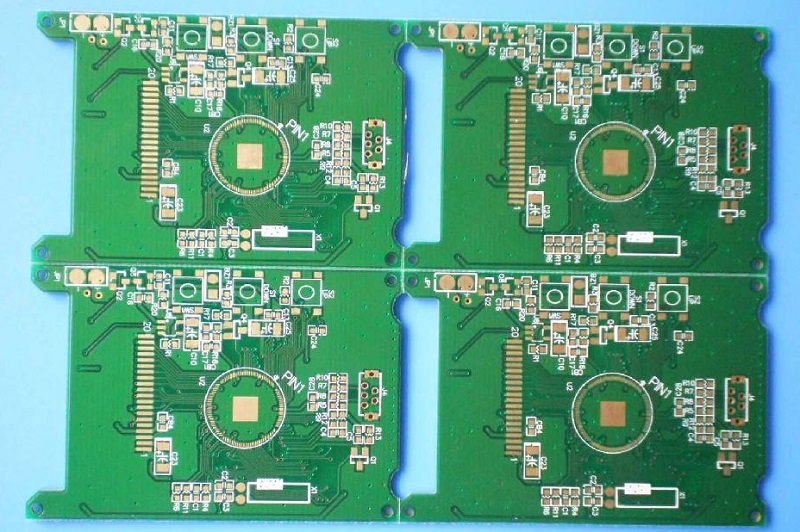

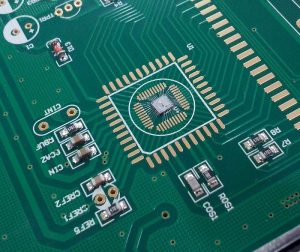

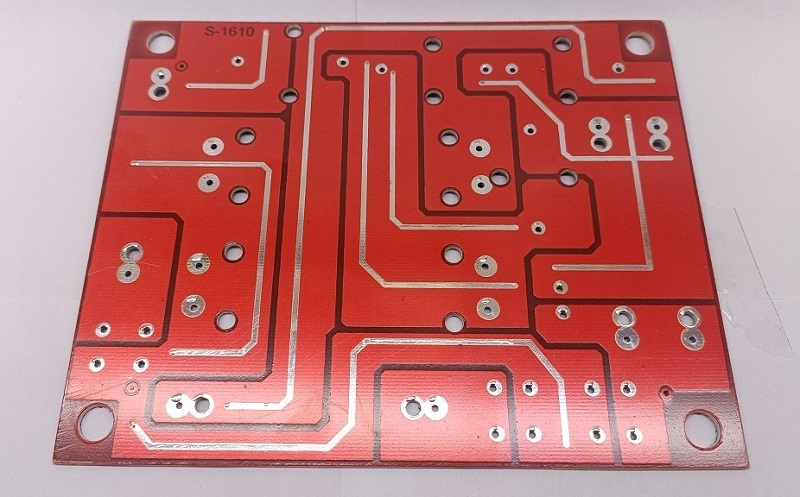

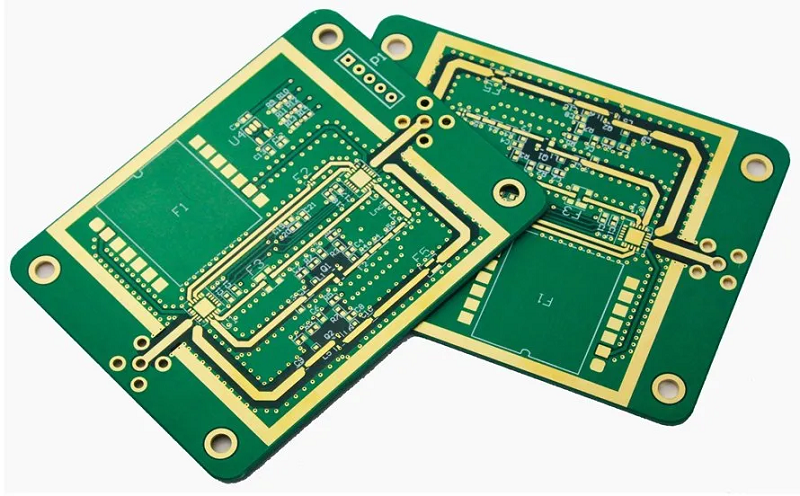

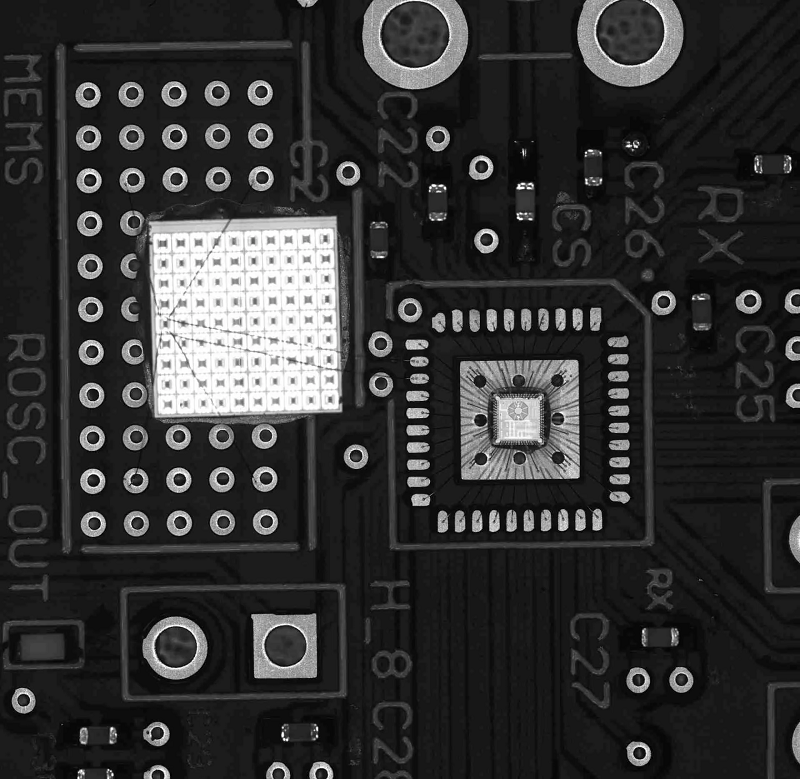

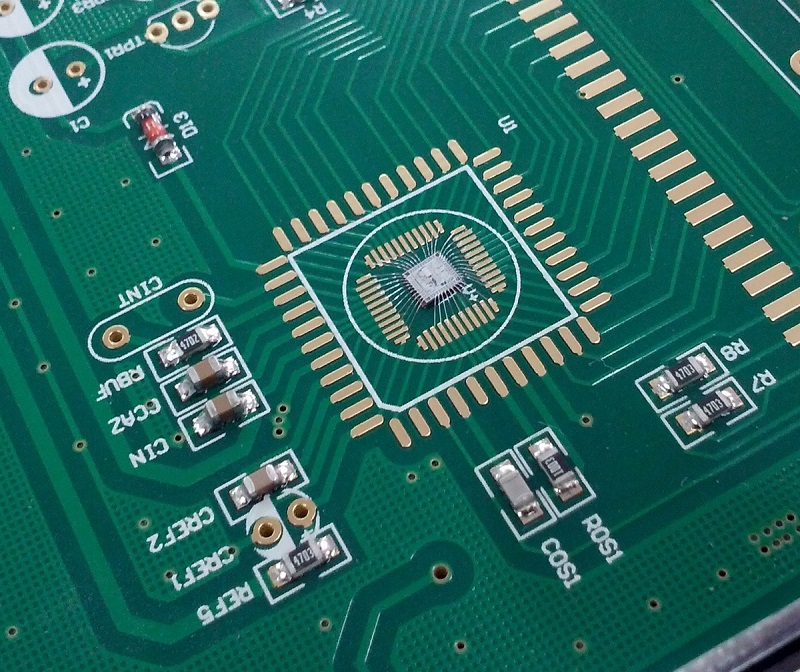

How Does Copperâs Bulk Conductivity Affect Its Use in PCBs?

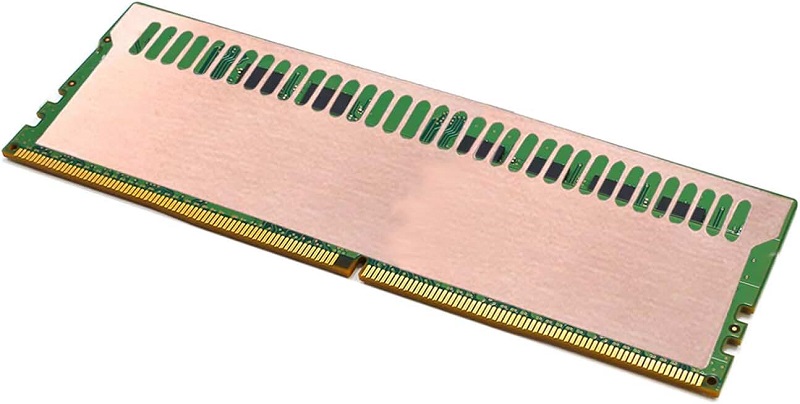

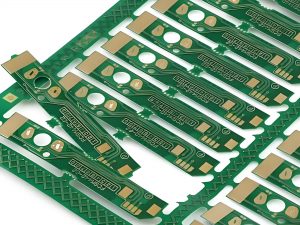

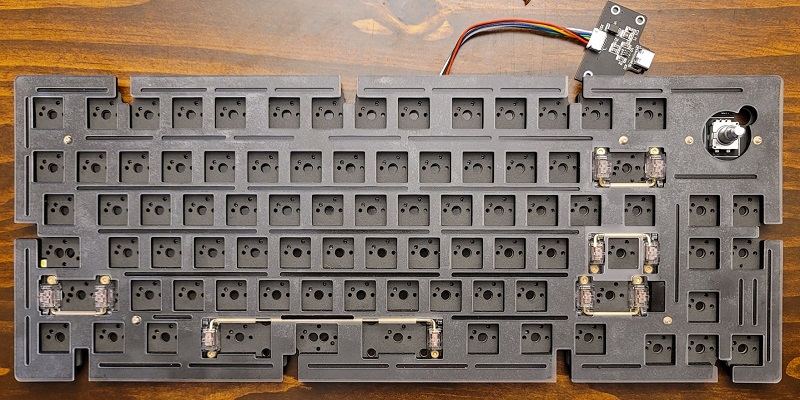

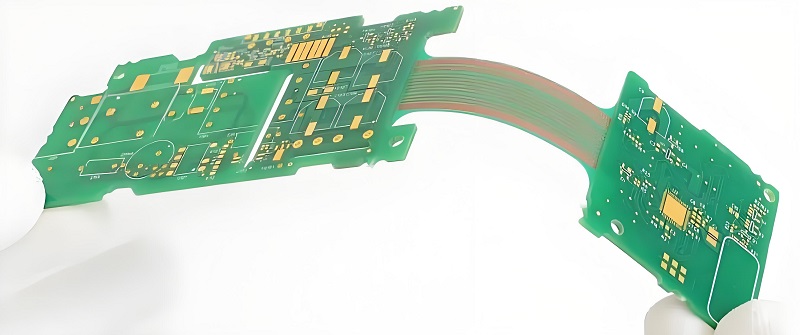

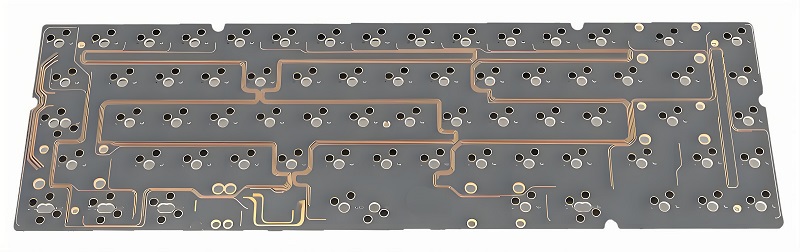

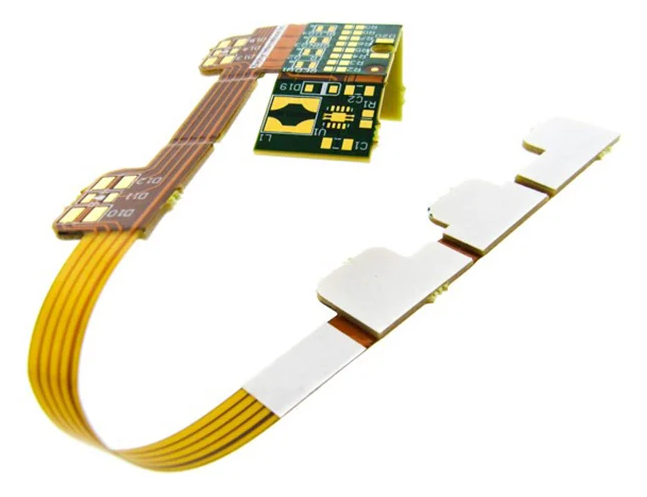

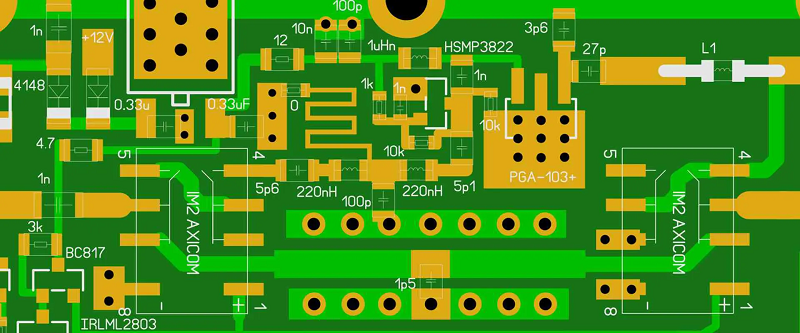

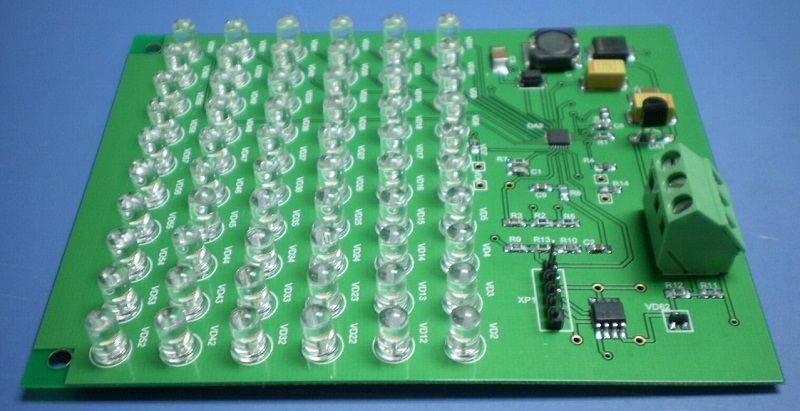

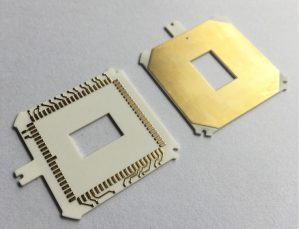

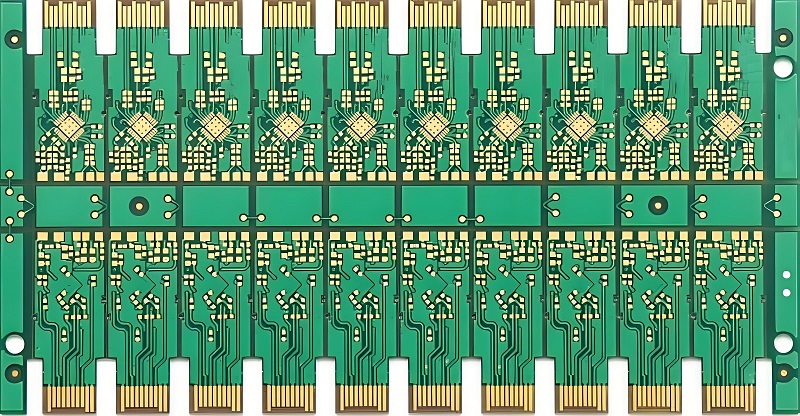

Copperâs bulk conductivity is particularly important in PCBs, as it ensures fast and efficient signal transmission. In PCBs, copper is used to create the traces that connect various components. These traces must have low resistance to avoid energy loss and signal degradation. The high conductivity of copper allows for thinner traces, which in turn makes PCBs more compact and cost-effective.

Additionally, copperâs excellent conductivity helps reduce the heat generated in PCBs, which is critical for preventing damage to sensitive components. This is especially crucial in high-performance electronics like processors and communication devices.

What Are the Key Factors Influencing the Bulk Conductivity of Copper?

Several factors influence the bulk conductivity of copper. Temperature is one of the most significant. As the temperature increases, the atoms in the copper vibrate more, which can hinder the movement of electrons and decrease conductivity. However, the electrical conductivity of copper increases with increase in temperature to a point. Beyond a certain threshold, the increase in resistance becomes more noticeable.

Another factor is the purity of the copper. Impurities in the copper can introduce obstacles to electron flow, reducing conductivity. High-purity copper, with minimal impurities, offers the best conductivity.

What Industries Benefit the Most from Copperâs High Bulk Conductivity?

Industries that rely on high-efficiency electrical systems benefit the most from copperâs high bulk conductivity. This includes the electronics industry, where copper is used in everything from circuit boards to microprocessors. The telecommunications sector also relies on copper for high-speed data transmission lines. Additionally, the automotive industry, particularly in electric vehicles, uses copper in wiring and batteries due to its excellent conductivity.

Moreover, industries involved in renewable energy, such as solar and wind power, use copper extensively. Copperâs high conductivity ensures that electrical systems in renewable energy applications are both efficient and durable.

In summary, the bulk conductivity of copper is a key factor in its widespread use across various industries. Its ability to efficiently conduct electricity makes it indispensable in electronics, telecommunications, automotive, and renewable energy sectors. Understanding the role of copperâs conductivity, and how it compares to other materials, can help businesses and engineers make informed decisions when designing electrical systems and devices. With its low resistivity and high conductivity, copper remains the material of choice for a wide range of applications, from power transmission to high-performance PCBs. At Best Technology, we specialize in high-quality, tailor-made PCBs, offering rapid delivery and unmatched customer support. Reach out to us at sales@bestpcbs.com for more information or questions.