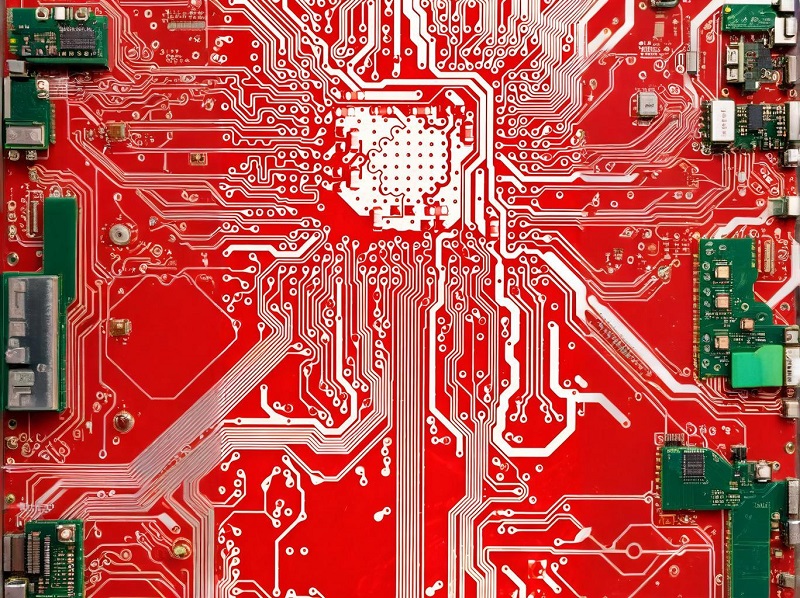

Circuit board red is more than just a color choice. Itâs a powerful tool in electronics design that can impact both functionality and aesthetics. Whether you’re working on consumer electronics, industrial equipment, or high-tech gadgets, red printed circuit boards (PCBs) are becoming an increasingly popular choice. But why? In this blog, weâll explore what circuit board red means, why itâs gaining popularity, and how it can benefit your electronic projects.

What Does Circuit Board Red Mean?

When we talk about “circuit board red,” we are referring to the color of the PCBâs surface. This color is achieved by using specific solder masks during the PCB manufacturing process. Red PCBs are typically used in applications where both performance and a unique visual identity are important. The red color is a bold choice, setting these boards apart from the standard green or black PCBs commonly used in the industry.

Red printed circuit boards can also signal a specialized or high-end product. The color may not just be an aesthetic decision; it could indicate that the board is designed to handle more demanding functions, such as higher temperatures or higher power applications.

What is the Color Code for Red PCB?

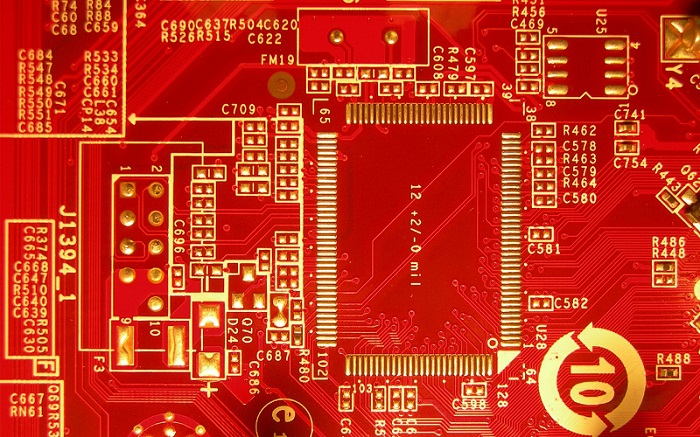

The color of a PCB is determined by the solder mask, and the exact shade of red used can vary. For red PCBs, manufacturers typically use a color code of RAL 3000 (Flame Red) or RAL 3020 (Traffic Red) for a bright, vivid appearance. These colors offer excellent contrast, making the circuit board stand out.

The choice of color code is important because it ensures consistency across various applications, especially when the appearance of the PCB is a key factor in product branding or design. This standardization helps manufacturers deliver products that meet specific visual and functional expectations.

Why Are Circuit Boards Different Colors: Blue, Green, Red?

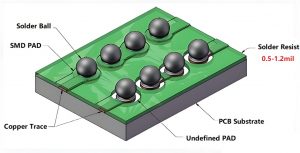

Circuit boards come in various colors, including blue, green, and red, primarily due to differences in the solder mask material used during the manufacturing process. The solder mask is a protective layer applied to the circuit board to prevent solder from bridging between conductors and to provide insulation.

The choice of color for the solder mask is often based on several factors, including:

âVisibility and Contrastâ: Different colors offer varying levels of visibility and contrast during the manufacturing and assembly process. For example, green has traditionally been a popular choice for PCBs because it provides good contrast against the copper traces and components, making it easier to inspect and assemble the board.

âAesthetic Preferencesâ: The color of the circuit board can also be influenced by aesthetic considerations. Manufacturers may choose a particular color to match the overall design or branding of their product.

âFunctionality and Applicationâ: In some cases, the color of the circuit board may be chosen for functional reasons. For example, certain colors may be better suited for specific applications or environments. However, it’s important to note that the color itself does not typically determine the functionality or performance of the circuit board; rather, it’s the materials and design that dictate its capabilities.

âCost and Availabilityâ: The availability and cost of different colored solder mask materials can also play a role in the choice of color. Manufacturers may opt for a color that is more cost-effective or easier to source.

In summary, the different colors of circuit boards are primarily the result of differences in the solder mask material used, as well as factors such as visibility, aesthetic preferences, functionality, and cost considerations.

Does the Color of a Circuit Board Matter?

While the color of a circuit board may not directly impact the performance of the electronics, it does play an important role in some cases. The color can affect the heat management of the PCB, especially in high-power applications where thermal management is crucial. Red PCBs, with their reflective properties, can help in dispersing heat more effectively.

Additionally, color is often used as a branding tool. Companies that use red PCBs might do so to make their products stand out in a crowded marketplace. The color can also serve as a visual cue, helping technicians easily identify boards during assembly or repair.

In short, while the color of the PCB may not affect its core functionality, it can have secondary benefits related to heat dissipation, brand identity, and ease of identification during manufacturing.

Red Circuit Boards vs. Green Circuit Boards: Which One Should You Choose?

When choosing between red and green circuit boards, itâs essential to consider both functionality and aesthetic preferences. Green PCBs have been the industry standard for decades. They are cost-effective, provide good visibility during assembly, and perform well in most applications. Green boards are ideal for mass-market electronics where cost and simplicity are primary considerations.

On the other hand, red circuit boards are often used for custom, high-end, or specialized applications. The vibrant color is attention-grabbing, and red PCBs are often chosen for their ability to improve heat dissipation in more demanding environments. Theyâre commonly found in high-performance electronics, automotive, and medical devices.

Ultimately, the choice between red and green PCBs depends on your specific needs. If youâre working on a high-tech or premium product, red PCBs can provide both functional and aesthetic benefits. However, for everyday devices, green PCBs are still the go-to option.

What Are the Advantages of Using Red Printed Circuit Boards in Your Electronics?

Red printed circuit boards offer several advantages that make them stand out in electronic design:

Aesthetic Appeal: Red PCBs are visually striking, making them an excellent choice for premium or custom products.

Better Heat Management: The reflective nature of red can help disperse heat, improving the thermal performance of the PCB.

Enhanced Durability: Red PCBs are often built with superior materials, making them more durable and suitable for harsh environments.

Improved Visibility: The bright red color makes it easier to inspect the board for defects or during assembly, reducing the chances of errors.

These advantages make red PCBs ideal for industries where both form and function matter, such as consumer electronics, automotive, and medical technology.

Which Top Industries Benefit from Using Red Circuit Boards?

Red circuit boards are not just a trendâtheyâre an essential choice for industries that require high-performance and visually distinct designs. Some of the top industries benefiting from red PCBs include:

Consumer Electronics: For premium gadgets and custom designs, red PCBs provide an elegant, standout look while maintaining high performance.

Automotive Industry: In automotive electronics, red PCBs help manage heat in devices like electric vehicle charging stations and high-performance sensors.

Medical Devices: The durability and heat management properties of red PCBs make them ideal for medical technology that operates under demanding conditions.

Aerospace: Red PCBs are used in aerospace applications where both functionality and reliability are critical, particularly in electronic systems that need to withstand extreme environments.

As demand for high-performance products continues to rise, red circuit boards are becoming increasingly important in these advanced industries.

What You Need to Know About Customizing Red PCBs for Your Specific Needs?

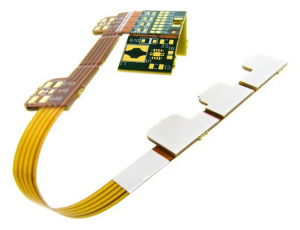

Customizing red PCBs allows you to tailor the board to your unique specifications. Whether itâs adjusting the thickness, changing the material for better heat dissipation, or adding additional layers for increased functionality, customization ensures that your PCB meets the demands of your project.

When designing red PCBs, youâll also have the option to choose different finishes and coatings, further improving the boardâs performance and aesthetics. Working with an experienced manufacturer who specializes in custom PCBs is essential to achieving the best results. At Best Technology, we specialize in high-quality, tailor-made red PCBs, offering rapid delivery and unmatched customer support.

Customized red PCBs not only meet specific design requirements but also help you create products that stand out in the marketplace, offering both functionality and visual appeal.

To sum up, circuit board red is more than just a color choiceâitâs a design decision that impacts both performance and branding. Whether you’re designing a high-end consumer product or a specialized electronic device, red PCBs offer distinct advantages in heat management, durability, and visual appeal. As industries continue to demand higher performance and more innovative designs, red circuit boards are paving the way for the future of electronics. Best Technology excels in delivering full turnkey customized, premium red PCB solutions with fast turnaround times, supported by exceptional customer service. For details or inquiries, feel free to contact us at sales@bestpcbs.com.