Today, we continue to talk about AOI technology applied in the PCB manufacturing. The component mounting inspection is followed by the reflow inspection, if you would like to know more details, please click The Application of AOI in Component Mounting Inspection to know.

AOI can be divided into two types: preventing problem phase and finding problem phase. The inspections after solder paste printing and SMT belongs to preventing problem phase and the inspections followed by reflow soldering are finding problem phase.

In the back end inspection of reflow soldering, AOI technology is able to detect some problems as below:

├ó╦ć┼í├é┬áwhether the components are missed, deviated or skewed.

├ó╦ć┼í├é┬áThe defects of polarity.

├ó╦ć┼í├é┬áWhether solder joints are correct.

├ó╦ć┼í├é┬áWhether the solder paste is enough.

├ó╦ć┼í├é┬áWhether there is short circuit in soldering etc..

The back end inspection of reflow soldering is the most prevailing choice for AOI now. Because all of the assembly errors can be found at this process, so that the quality of printed circuit boards are able to step forward to a higher level.

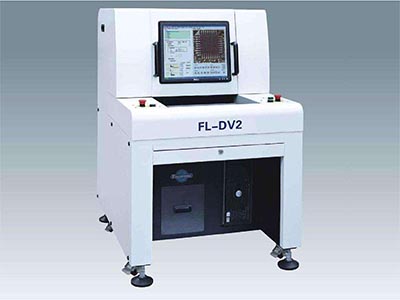

Best Technology is the premier expert in manufacture of PCB and PCBA. Our unique AOI testing technology and high quality products give you a competitive supply of printed circuit board and rigid-flex circuit board. To learn more, contact us at 0755-29091601 or check our website: https://www.bestpcbs.com/